Numerical control grinding test machine

A testing machine and grinding technology, applied in the direction of grinding frame, grinding machine parts, grinding bed, etc., can solve the problems of low control accuracy, extremely high coordination requirements, and difficulty in meeting high precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

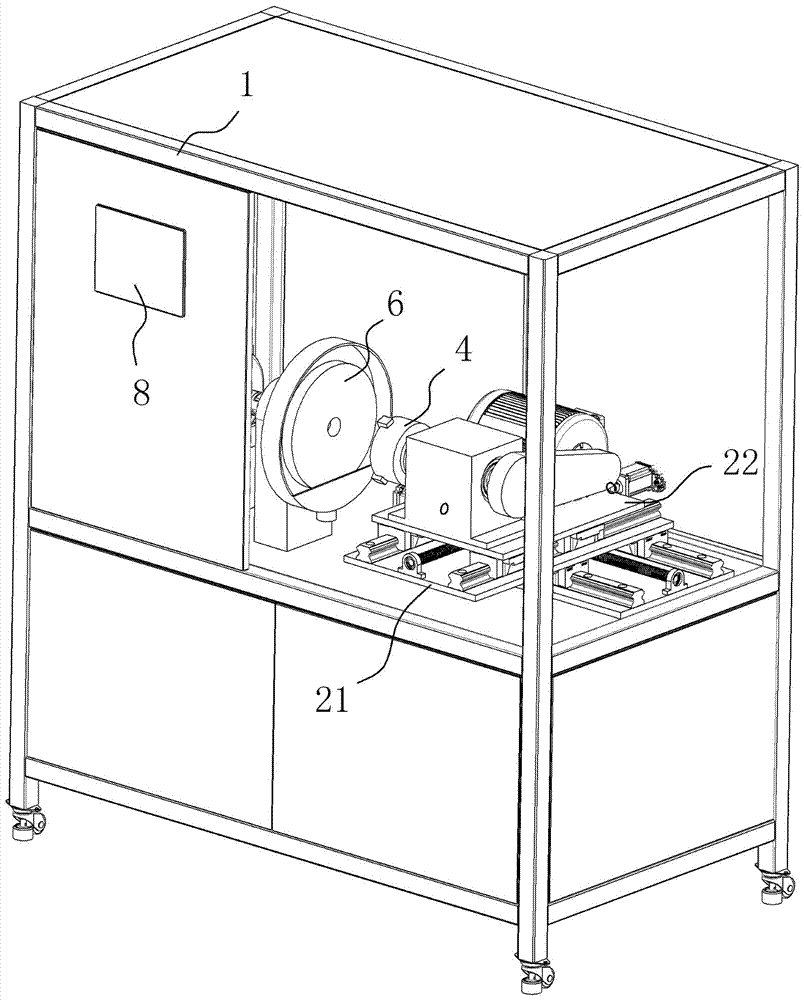

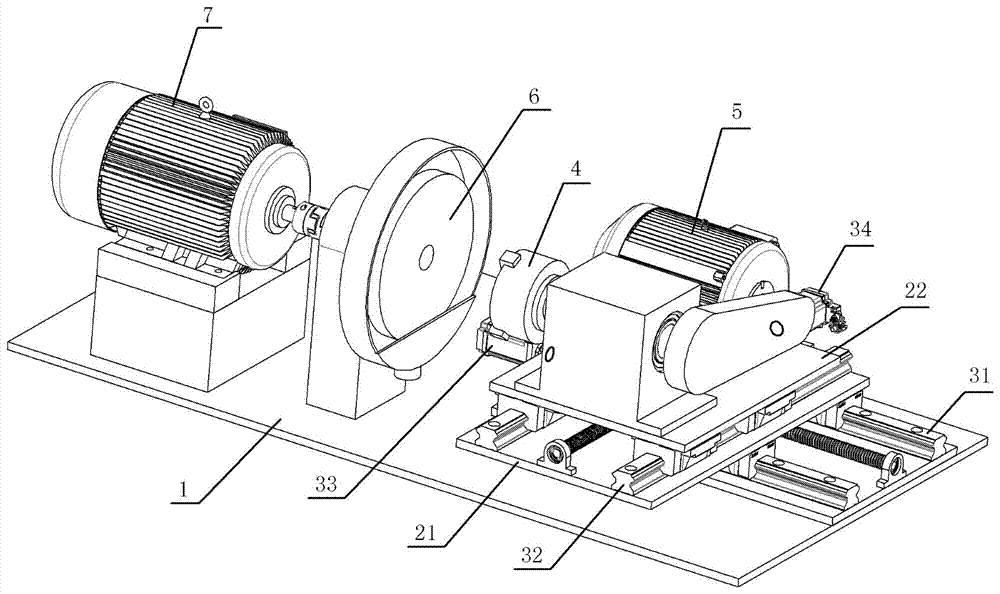

[0010] Such as figure 1 , 2 shown.

[0011] A numerically controlled grinding test machine, comprising an equipment frame 1 and a sand table 6 for grinding workpieces, the frame is equipped with a movable frame that can move horizontally and vertically and a drive mechanism that drives the movement of the movable frame, and the movable frame is equipped with a clamping workpiece The rotary chuck 4 and the chuck motor 5 that drives the rotary chuck to rotate are also equipped with a rotary motor 7 on the frame, and the sand disc is fixedly installed on the end of the rotary shaft of the rotary The axis direction and the longitudinal movement direction of the mobile frame are all parallel; there is also a numerical control terminal, which is connected and controls the work of each component.

[0012] In the CNC grinding testing machine of the present invention, a sand disc is installed on the rotating shaft of the rotating motor on the frame, and the sand disc is driven to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com