Cement automatic grinding test device

A technology of test device and drive device, applied in measurement device, mechanical device, preparation of test samples, etc., can solve the problems of poor control of material fineness, inability to accurately measure the grinding time, and missed stop time, etc. achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

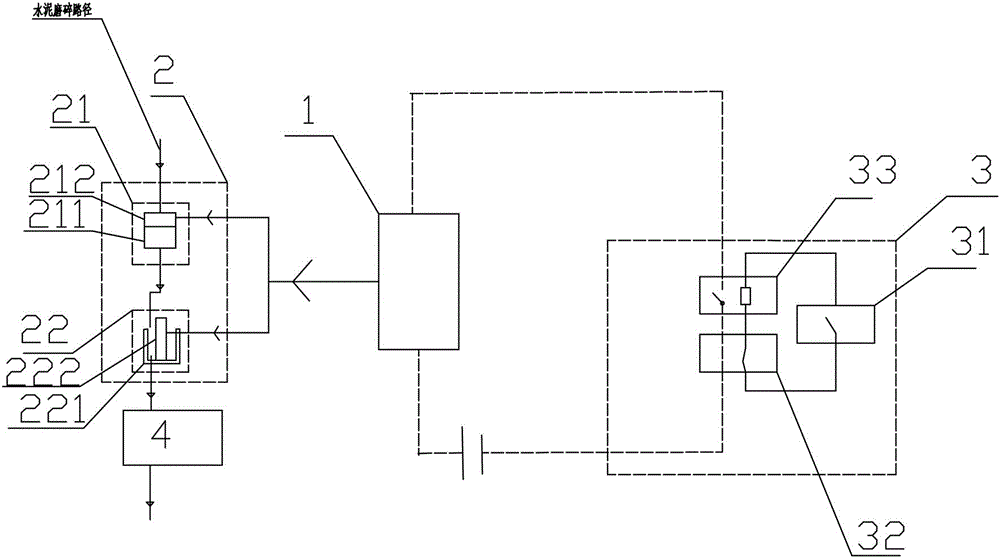

[0014] As shown in the figure, a cement automatic grinding test device includes a drive device 1, a grinder 2, an automatic control device 3, and a timing discharge device 4;

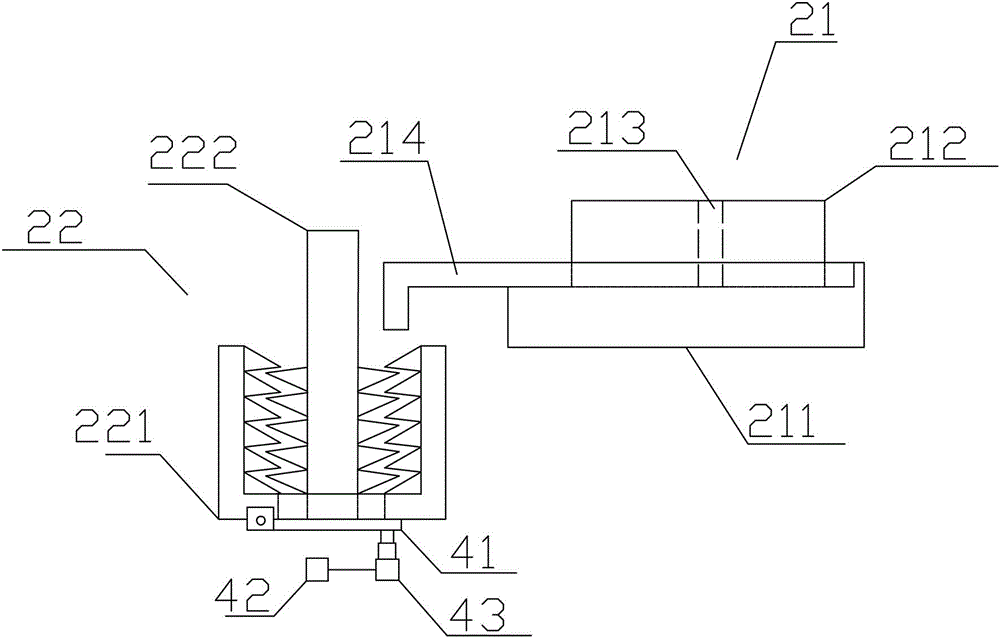

[0015] The grinder 2 includes a rough grinding device 21 and a fine grinding device 22. The coarse grinding device 21 includes a grinding disc 211 and a grinding stone 212. The grinding stone 212 is arranged on the grinding disc 211. A feeding port 213 is provided in the middle of the grinding stone 212. , the grinding disc 211 is provided with a discharge port 214, and the driving device 1 drives the grinding stone 212 to rotate on the grinding disc 211; the fine grinding device 22 includes a U-shaped groove 221 and a grinding shaft 222, and the grinding shaft 222 is located in the U-shaped groove Inside the 221, the inner wall of the U-shaped groove 221 and the outer wall of the grinding shaft 222 are provided with threads, the driving device 1 drives the grinding shaft 222 to rotate in the U-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com