Cable scraping and grinding test platform

A test platform and cable technology, which is applied in the detection field, can solve the problems of being unable to cope with different temperature and humidity environments, the test environment range is small, and the versatility is not high, so as to achieve the effect of enhancing flexibility and reconfigurability

Pending Publication Date: 2021-11-26

CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Based on this, it is necessary to provide a cable scraping test platform for the problems that the traditional cable scraping test platform cannot cope with different temperature and humidity environments, and the test environment range is small and the versatility is not high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

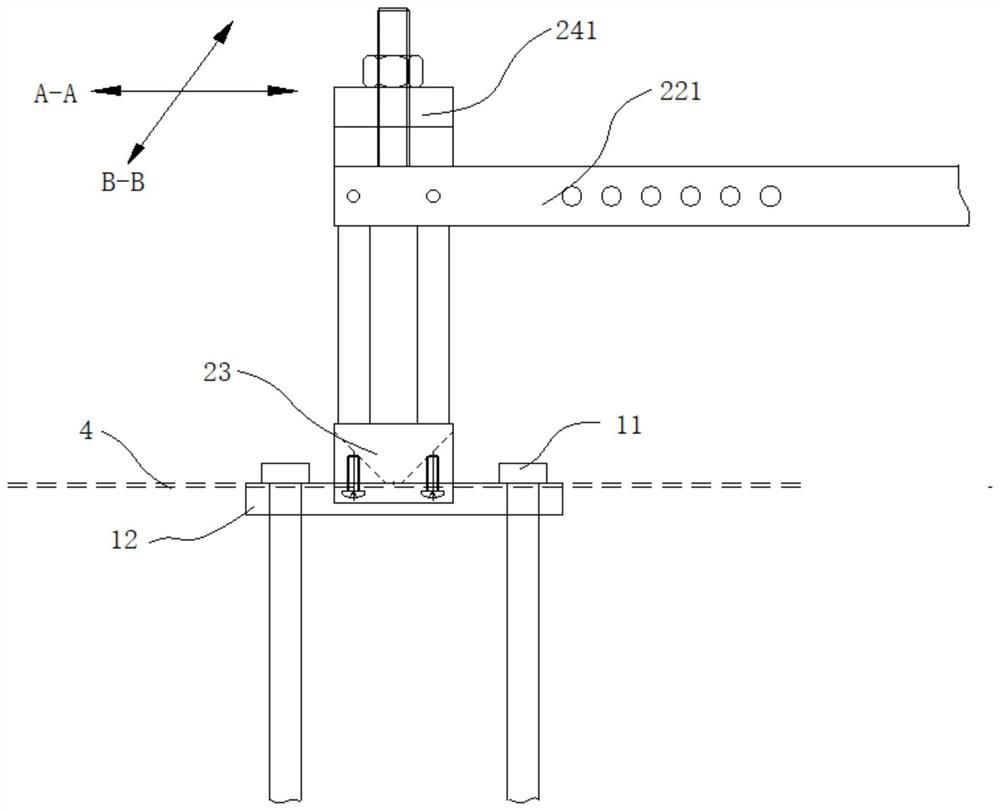

[0065] In one embodiment, the scraper fixing member 23 is a triangular column structure, and the scraper fixing groove 231 is located at one side thereof.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

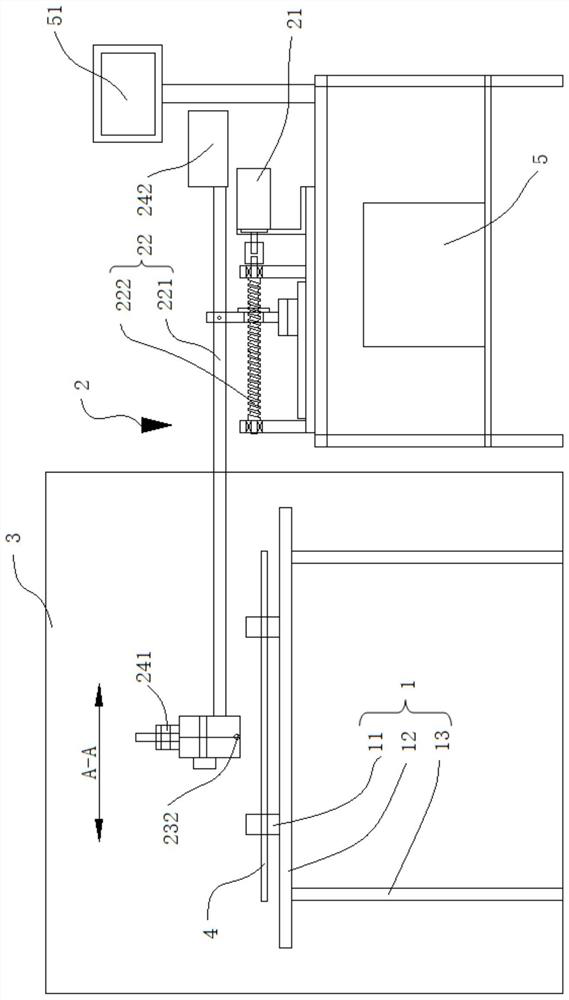

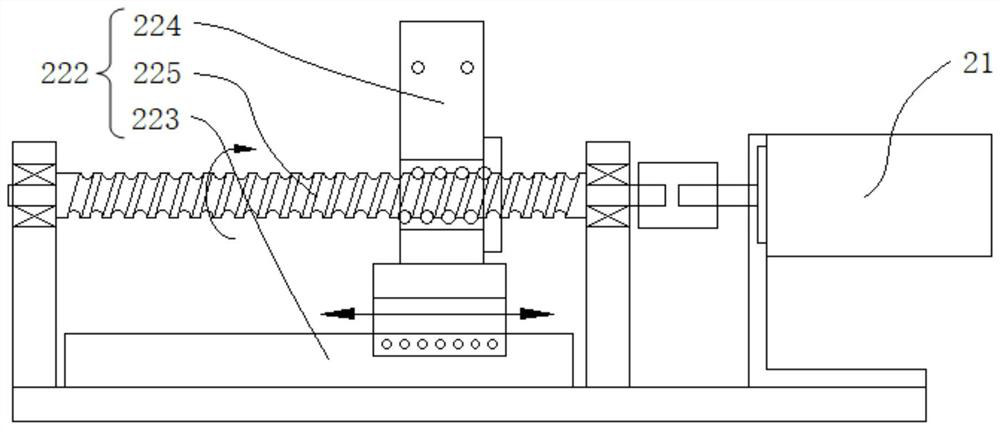

The invention relates to a cable scraping and grinding test platform which comprises a clamping assembly, the clamping assembly comprises a clamp and a clamping platform, the clamp is arranged on the clamping platform, the clamp clamps a cable, the axis of the cable is arranged in the first direction, and the first direction is parallel to the clamping platform; a moving assembly which comprises a driving motor, a transmission assembly and a scraping and grinding device, the transmission assembly is connected with the driving motor and the scraping and grinding device, the driving motor drives the scraping and grinding device to reciprocate in the first direction, and the scraping and grinding device moves to rub the cable; a test box, the clamping platform and the scraping and grinding device are arranged in the test box, and a temperature and humidity control module is arranged in the test box. According to the cable scraping test platform provided by the invention, the whole equipment is divided into two parts through the detachable clamping assembly and the movable assembly, the clamping assembly loaded with the to-be-detected cable can be placed in the test box, and various test environments with different temperatures and humidity are provided through the test box, and the flexibility and reconfigurability of the scraping and grinding test platform are enhanced.

Description

technical field [0001] The invention relates to the technical field of detection, in particular to a cable scraping test platform. Background technique [0002] In various aviation aircraft, aviation wires, as their "meridians", are a key component of the aircraft wiring system, carrying multiple functions such as control, signal transmission, and power transmission, and are important to the safety and reliability of the aircraft electrical system. Impact. Due to the friction between the center line and the wire of the wire harness, as well as the friction between the wire and the metal buckle, and peripheral components in the wiring and operation of the aviation wire, and under the influence of temperature or humidity, the performance of the wire insulation material will change, which will affect the scratch resistance. . Under the action of friction stress, the wire insulation layer is prone to damage, which will expose the conductor core, which will cause problems such ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/56

CPCG01N3/56

Inventor 王小强王斌罗军周帅吴仕煌

Owner CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com