Method for treating surface of magnesium or alloy thereof

A surface treatment and alloy technology, applied in the field of surface treatment of magnesium or its alloys, can solve the problems of many pretreatment processes and difficult waste liquid treatment, and achieve the effects of simple process flow, shortened production time, and short treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get medicine according to following formula (quantity): oxalic acid 20g, phosphoric acid 20ml, ammonium bifluoride 50g, hexamethylenetetramine 3g, sodium laurylsulfonate 0.005g, after above-mentioned medicine is dissolved with a small amount of deionized water respectively Mix and dilute to one liter.

[0028] The magnesium alloy parts of four grades shown in the table below were degreased and then placed in a stirred chemical solution. From the test process, it can be seen that the reaction was stable and the hydrogen generated on the surface of the workpiece was removed in time. After 5 minutes, the workpiece was taken out and placed on an electronic balance. Weighing, comparison of the weight loss ratio of the workpiece before and after treatment (see Table 1) shows that the use of the treatment solution of the present invention has a moderate degree of corrosion on the magnesium alloy parts, and its loss rate is far lower than that of using the U.S. Dow process. fig...

Embodiment 2

[0032] Take medicine according to following formula weighing (quantity): oxalic acid 10g, phosphoric acid 50ml, ammonium bifluoride 100g, thiourea 5g, polyethylene glycol 0.001g, above-mentioned medicine is dissolved with a small amount of deionized water respectively and mixed and diluted to one liter.

[0033] Preparation of electroless nickel plating solution, the solution is composed of: nickel acetate 20g / L, sodium hypophosphite 20g / L, citric acid 5g / L, lactic acid 5ml / L, ammonium bifluoride 10g / L, ammonia water 30ml / L, saccharin 3g / L , thiourea 0.5mg / L, lead acetate 0.5mg / L, potassium iodide 50mg / L, and the balance is water.

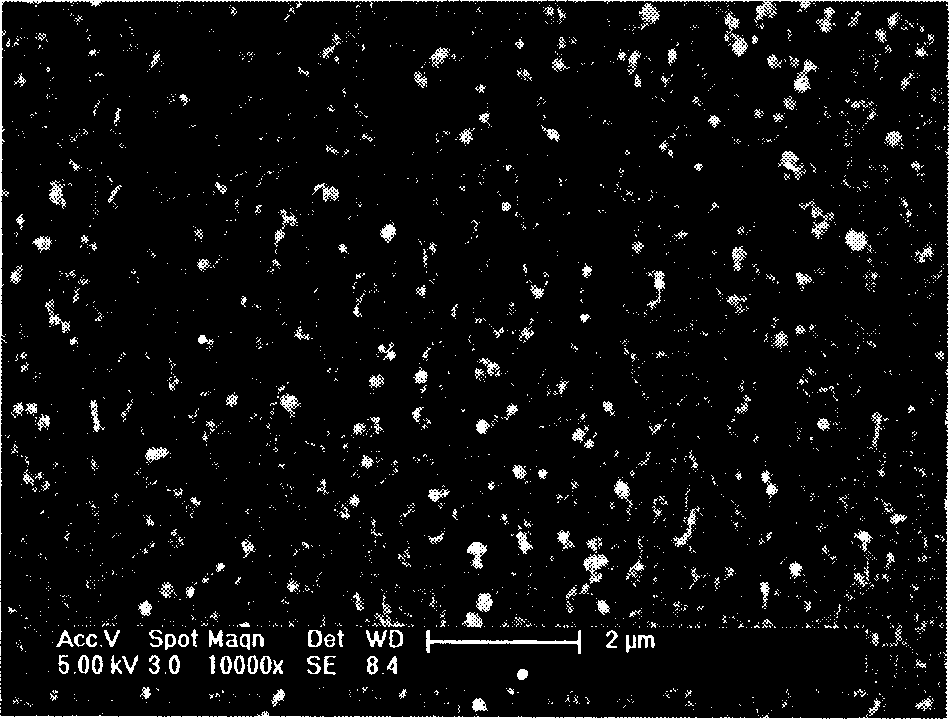

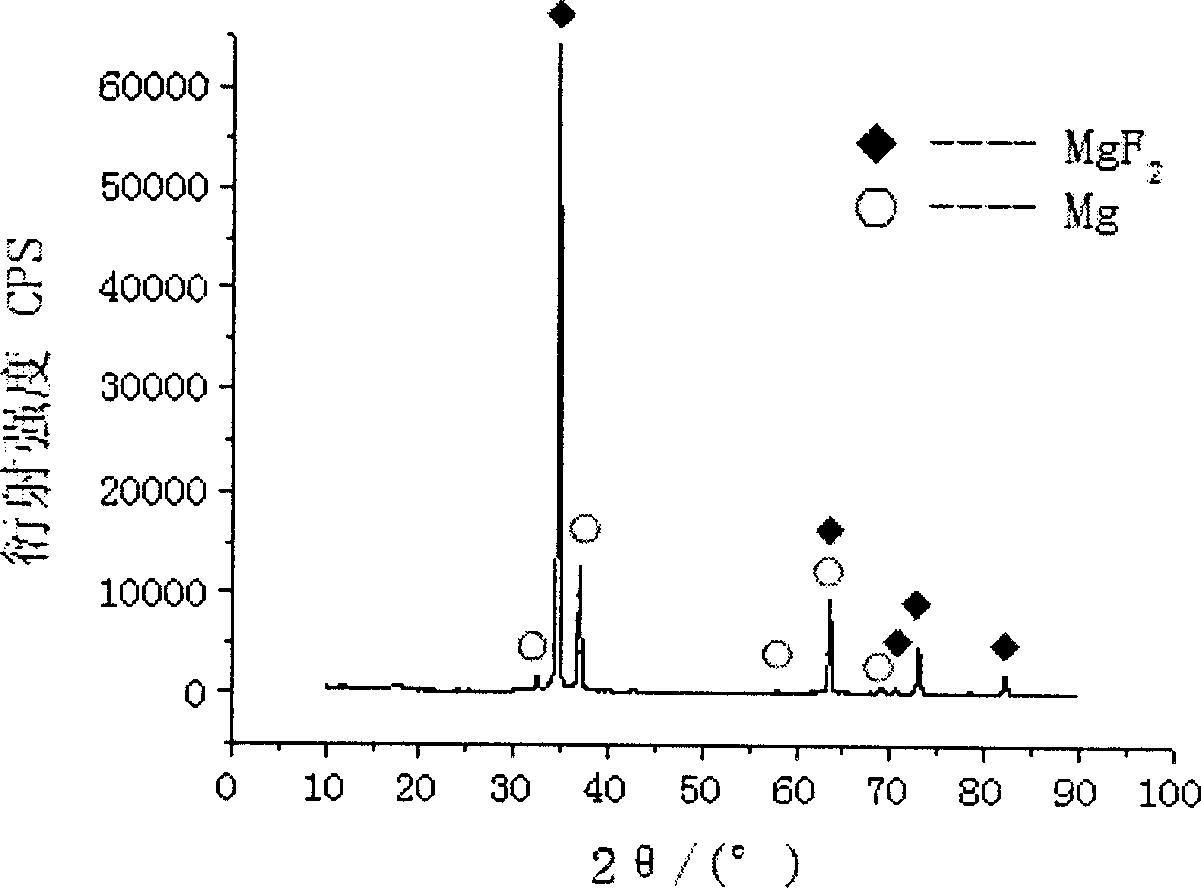

[0034] After degreasing the magnesium alloy parts, place them in a stirred chemical solution. After 2 minutes, take out the workpieces, wash them with deionized water, put them into the 80°C electroless nickel plating solution prepared above, and observe them under a scanning electron microscope after plating for 2 hours. surface topography (see ...

Embodiment 3

[0037] Weigh (amount) the medicine according to the following formula: oxalic acid 50g, phosphoric acid 100ml, ammonium bifluoride 80g, citric acid 3g, sodium dodecylsulfonate 0.001g, dissolve the above-mentioned medicines with a small amount of deionized water respectively, mix and dilute to one Lift.

[0038] Prepare anodic oxidation solution, the solution composition is: potassium hydroxide 120g / L, sodium metaaluminate 30g / L, sodium tetraborate 110g / L, potassium fluoride 30g / L, sodium phosphate 30g / L. Anodizing process parameters are: temperature room temperature, voltage 80V, 10min.

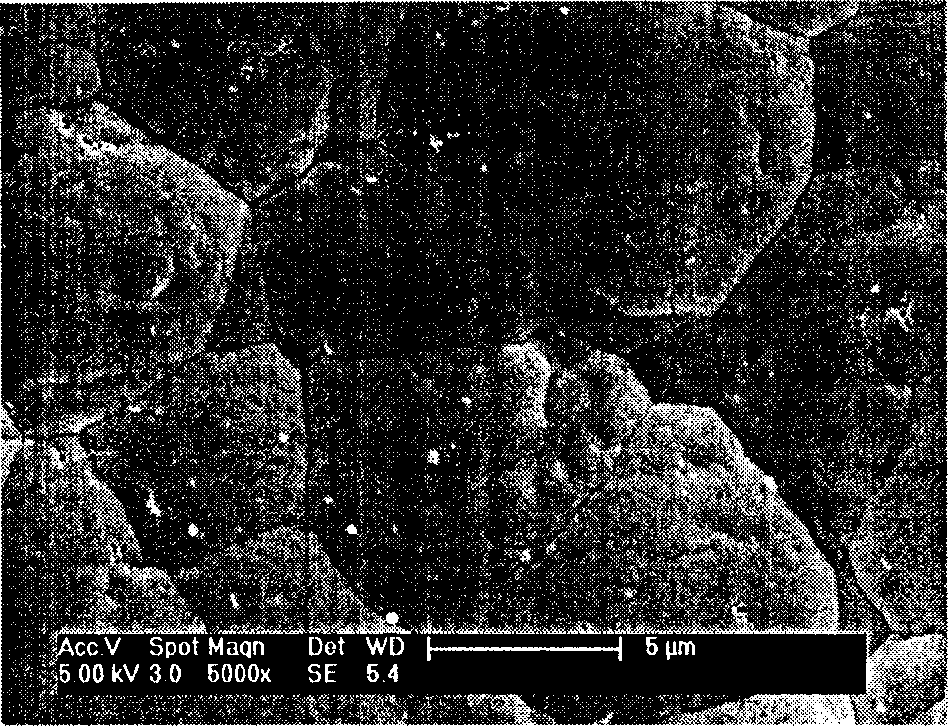

[0039] After the magnesium alloy parts are degreased, they are placed in a stirring chemical solution. After 1 minute, the workpieces are taken out, rinsed with deionized water for 5 minutes, and placed in the above-mentioned anodizing solution to anodize the magnesium alloy parts for 10 minutes. Observe the surface topography (see Figure 5 ); According to the national standard GB / T6461-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com