Method for reducing light-cured rapid prototype component surface roughness

A technology of surface roughness and stereolithography, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of reducing the surface roughness of the prototype, increasing the processing cost, and manpower, etc., to achieve Eliminate step effect, save production cost, and easy to operate

Inactive Publication Date: 2010-11-10

XI AN JIAOTONG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the commonly used post-processing methods include grinding, mechanical secondary processing and other mechanical processing methods. The disadvantage is that it is necessary to reserve a machining allowance during molding. Using mechanical processing for secondary processing requires a lot of manpower and material resources, which further increases Processing costs, and not suitable for parts with complex surface shapes

According to the data retrieval conducted by the applicant, there are no related literatures and patents about treating the surface of the prototype by physical and chemical methods to reduce the surface roughness of the prototype

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

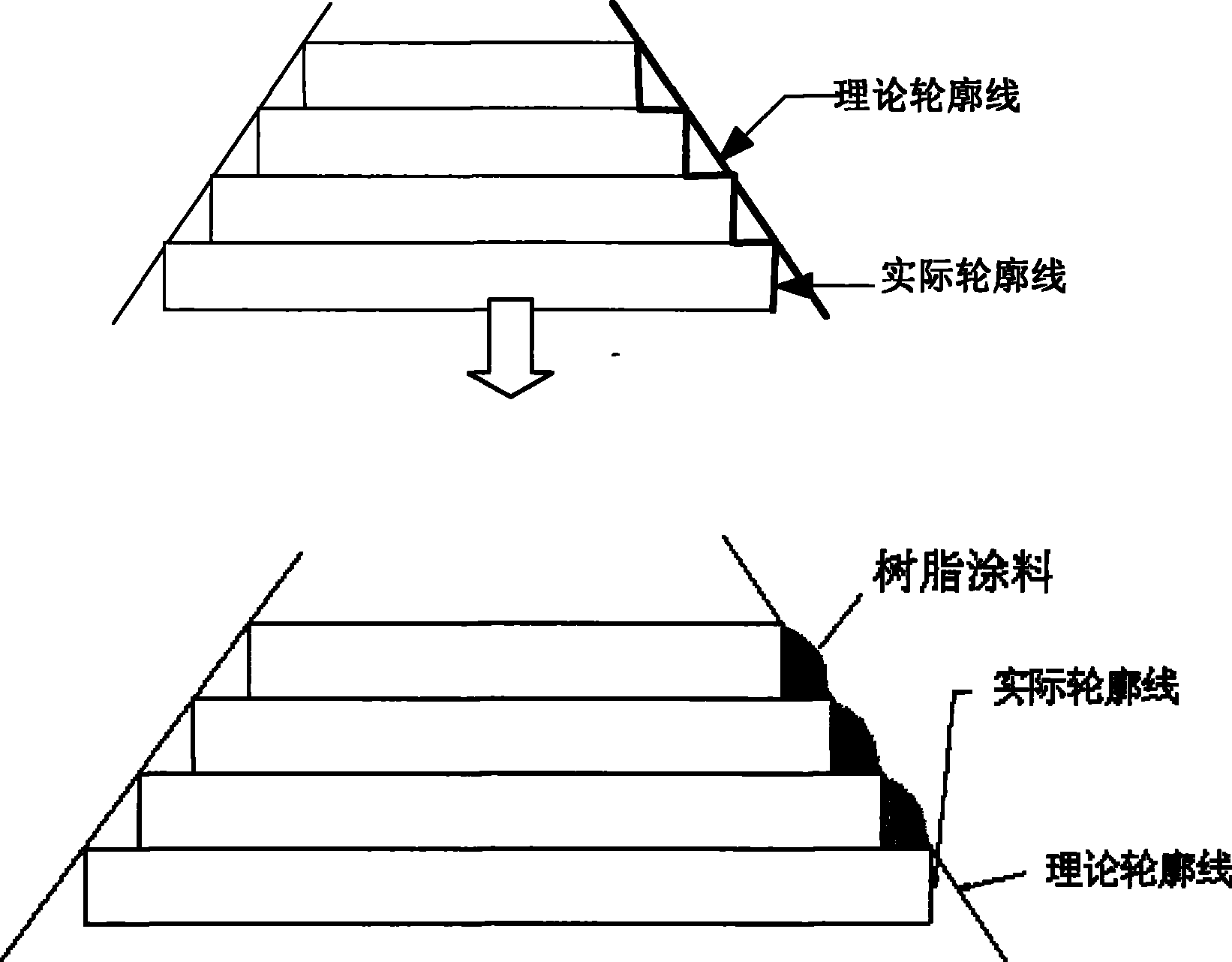

The present invention discloses one kind of physical and chemical method to lower the surface roughness of stereo optically cured body. The method includes the following steps: compounding resin paint through adding surfactant not more than 0.1 %, active diluent in 5-30 % and leveling agent not more than 1 % into resin and regulating the viscosity of the resin paint to 0.25-0.70 Pa.S; and coatingthe resin paint to the surface of the body to form homogeneous coating of thickness within 300 micron, so as to reduce the roughness from 6-15 micron to 3 micron. The method can eliminate the step effect of stereo optically curing, and has excellent application foreground.

Description

A Method for Reducing Surface Roughness of Light-cured Rapid Prototype technical field The invention relates to a post-processing method for photocured three-dimensional molding prototypes, in particular to a method for reducing the surface roughness of photocured rapid prototypes. The method treats the surface of the prototypes by physical and chemical methods to quickly reduce the surface roughness of the prototypes Spend. Background technique Rapid prototyping technology is a processing and forming method based on material accumulation. Rapid prototyping technology can speed up product innovation and shorten product design and production cycles. Stereolithography is currently the most widely used and most precise method among various rapid prototyping methods. It has the advantages of high production efficiency and material utilization rate close to 100%, and it can form particularly complex shapes (such as hollow parts), Extra fine parts. However, there will still be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05D3/00C09D7/00B05D1/38B05D7/24

Inventor 李涤尘同颖稚吴海华

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com