Grinding material vibration porous deburring process

A deburring and vibrating grinding technology, which is applied in the direction of manufacturing tools, ultra-finishing machines, metal processing equipment, etc., can solve problems such as high labor intensity and difficulty in meeting processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1 Vibration deburring test of spray rod tiny holes

[0025] (1) Vibrating magnetic abrasive grinding method

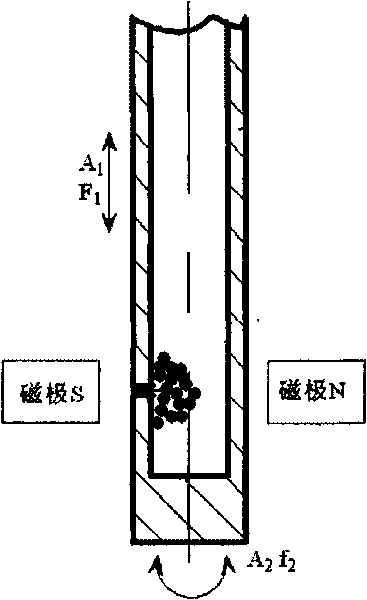

[0026] Process flow: such as figure 1 As shown, the magnet adopts a strong permanent magnet or an electromagnet, and the abrasive particles in the magnetic field act on the burr surface with a certain pressure; when the magnet or the workpiece vibrates with a certain amplitude and frequency, there is a controllable relative motion between the abrasive particles and the workpiece , thus generating cutting force for deburring.

[0027] (2) Vibrating liquid abrasive grinding method

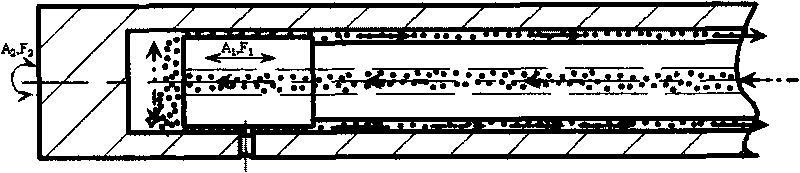

[0028] Process flow: such as figure 2 As shown, the method uses a vibrating device to excite the grinding rod with adjustable amplitude and frequency. The grinding rod drives the liquid abrasive to generate cutting force for removing micropore burrs, and the liquid abrasive is injected circularly by an abrasive pump.

Embodiment 2

[0030] Vibration nozzle deburring test:

[0031] According to the shape of the nozzle bore burr, 3 to 4 processes are used to complete the deburring.

[0032] (1) For large nozzle workpieces

[0033] The process flow is as follows:

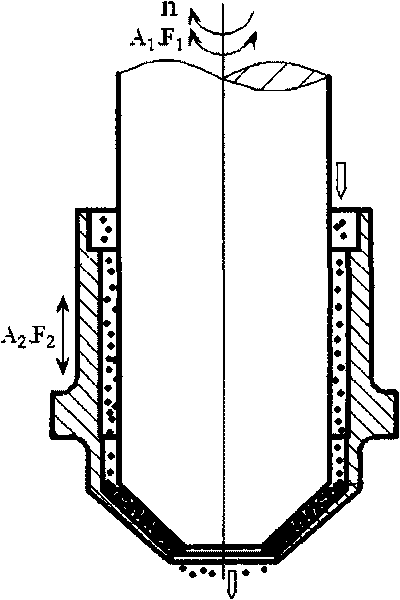

[0034] The first step process: remove the burrs turned outward at the entrance. Such as image 3 As shown, the inner tapered surface of the workpiece is ground with a grinding tool with an outer tapered surface to remove burrs. The abrasive tool rotates at a speed n while making a certain amplitude A 1 , frequency F 1 The torsional vibration accelerates the grinding effect; the amplitude of the workpiece is A 2 , frequency F 2 The axial vibration can make the circulating abrasive fully enter between the abrasive tool and the surface to be ground; the grinding pressure between the abrasive tool and the workpiece is P.

[0035] The second step of the process: remove the burrs turned outward at the exit. Such as Figure 4 As shown, the oute...

Embodiment 3

[0041] Vibration deburring test results of spray rod tiny holes

[0042] (1) Vibrating magnetic abrasive grinding method

[0043] The test parameters are shown in Table 1:

[0044] Table 1 Vibration Magnetic Abrasive Grinding Test Parameters

[0045] Torsional Vibration Parameters

[0046] (2) Vibrating liquid abrasive grinding method

[0047] The actual test device is used as the principle test equipment

[0048] The test parameters are shown in Table 2:

[0049] Table 2 Vibration liquid abrasive grinding method test parameters

[0050] Torsional Vibration Parameters

[0051] Figure 7It is the comparison curve of vibratory grinding and ordinary grinding spray rod: It can be seen from the test results that the two experimental schemes of vibrating magnetic abrasive grinding and vibrating liquid abrasive grinding can completely remove the burrs of the spray rod micropores, while maintaining the uniformity of the pore diameter. Sharp edges, and vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com