High-pressure gas blasting-based coal seam roof advance presplitting method

A high-pressure gas, coal seam roof technology, which is applied in earth-moving drilling, mining equipment, mining equipment, etc., can solve the problems of unsatisfactory coal seam hard roof effect, and achieve the effect of eliminating spark danger, good pre-splitting effect and small dynamic disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

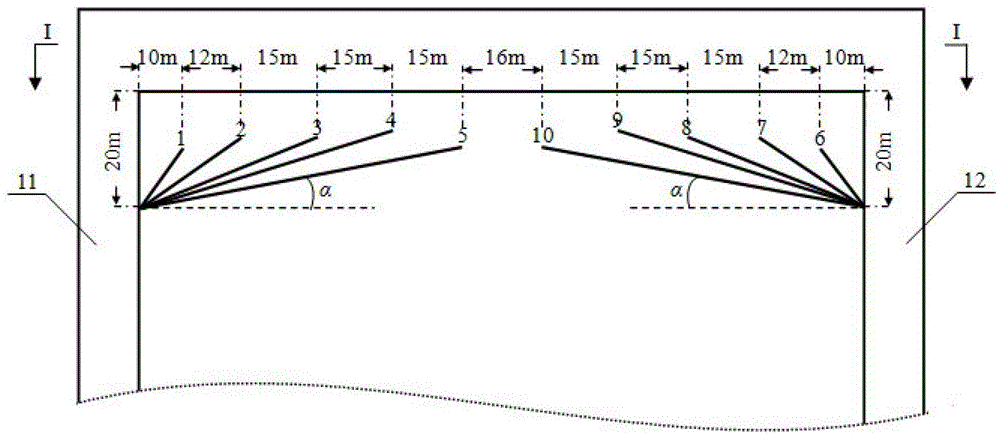

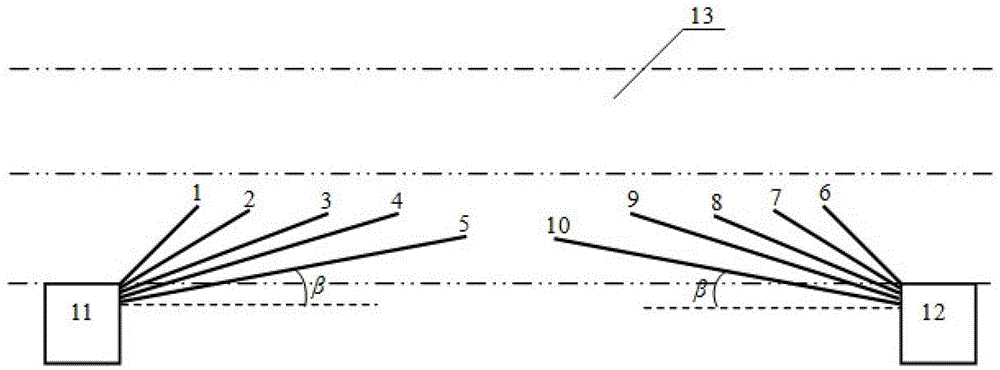

[0021] Below in conjunction with the embodiment (accompanying drawing) of a long 150m working face, the present invention is further described.

[0022] The implementation of the advanced pre-splitting method of the coal seam roof based on high-pressure gas explosion includes the following steps in sequence:

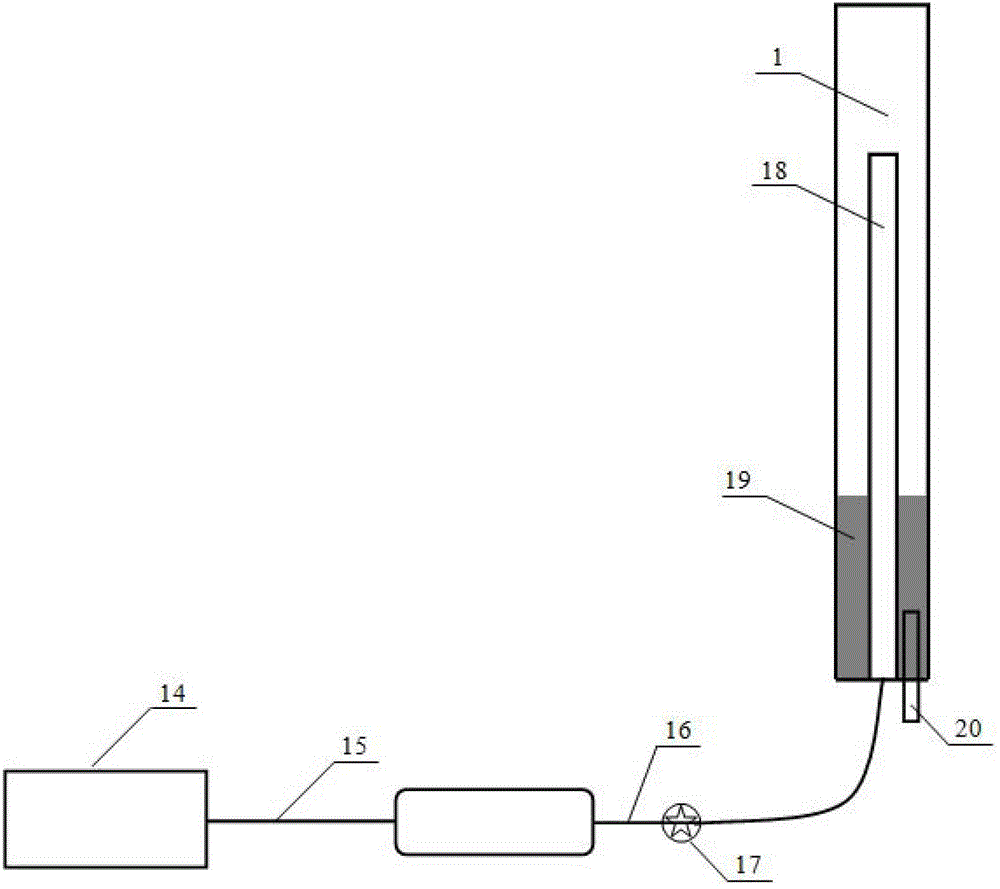

[0023] 1) A group of drill holes with a diameter of 90 mm are made on the coal seam roof 13 at intervals of 20 m on the transport chute 11 and the track chute 12 on the working face. Each group of drill holes is arranged in a fan shape and faces the goaf. Elevation angles of 6, 2 and 7, 3 and 8, 4 and 9, 5 and 10 β Respectively 39.23°, 42.74°, 44.06°, 44.5°, 44.69°, horizontal angle α They are 45°, 24.44°, 15.12°, 10.89°, 8.49° respectively, and the drilling lengths are 17.32m, 26.15m, 39.61m, 53.89m, 68.48m respectively. ~15m, the vertical projection of each group of boreholes and the horizontal projection along the advancing direction of the working face are 10m and ...

Embodiment 2

[0028] The steps of embodiment 2 are basically the same as those of embodiment 1, except that in step 1), the diameter of each drilled hole is 75 mm.

Embodiment 3

[0030] The steps of embodiment 3 are basically the same as those of embodiment 1, except that in step 3), the gas source of the high-pressure gas is air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com