Laser drilling method for miniature loudspeaker brackets

A speaker bracket and laser drilling technology, which is applied in laser welding equipment, welding equipment, metal processing, etc., can solve the problems of high tolerance and precision requirements, to ensure stability and consistency, reduce processing costs, and save labor hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

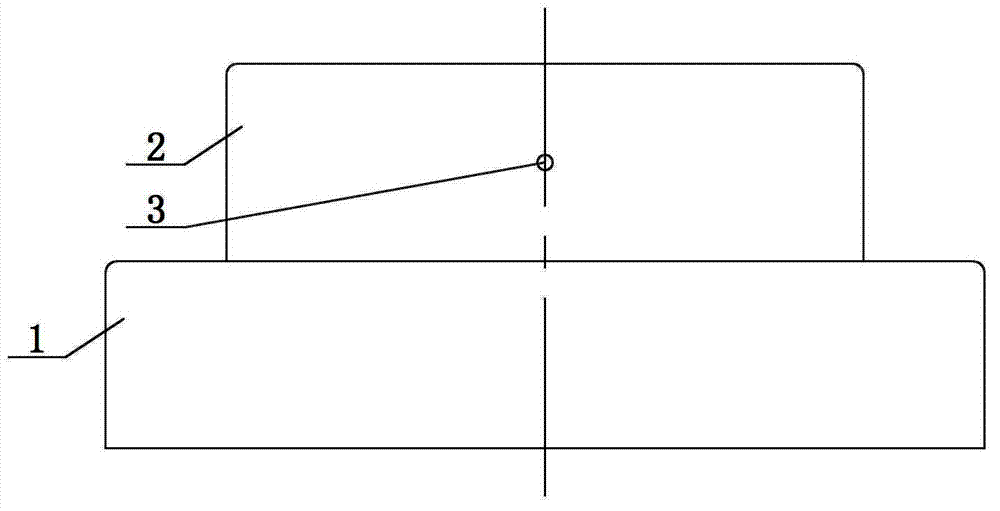

[0035] see Figure 1~3 As shown, a laser drilling method for a miniature horn bracket, the horn bracket is transferred to the laser drilling machine by the vibrating plate through automatic feeding. The laser drilling machine uses a sensor to detect whether the horn bracket is sent to the station. When the sensor detects that the feeder sends the bracket to the laser drilling station, the laser drilling machine is triggered to work, otherwise the laser drilling machine does not work.

[0036] Specifically in this embodiment, the horn bracket has an open first end 1 and a sealed second end 2, and a laser drilling machine punches a round hole 3 on the side wall of the second end 2 of the horn bracket.

Embodiment 2

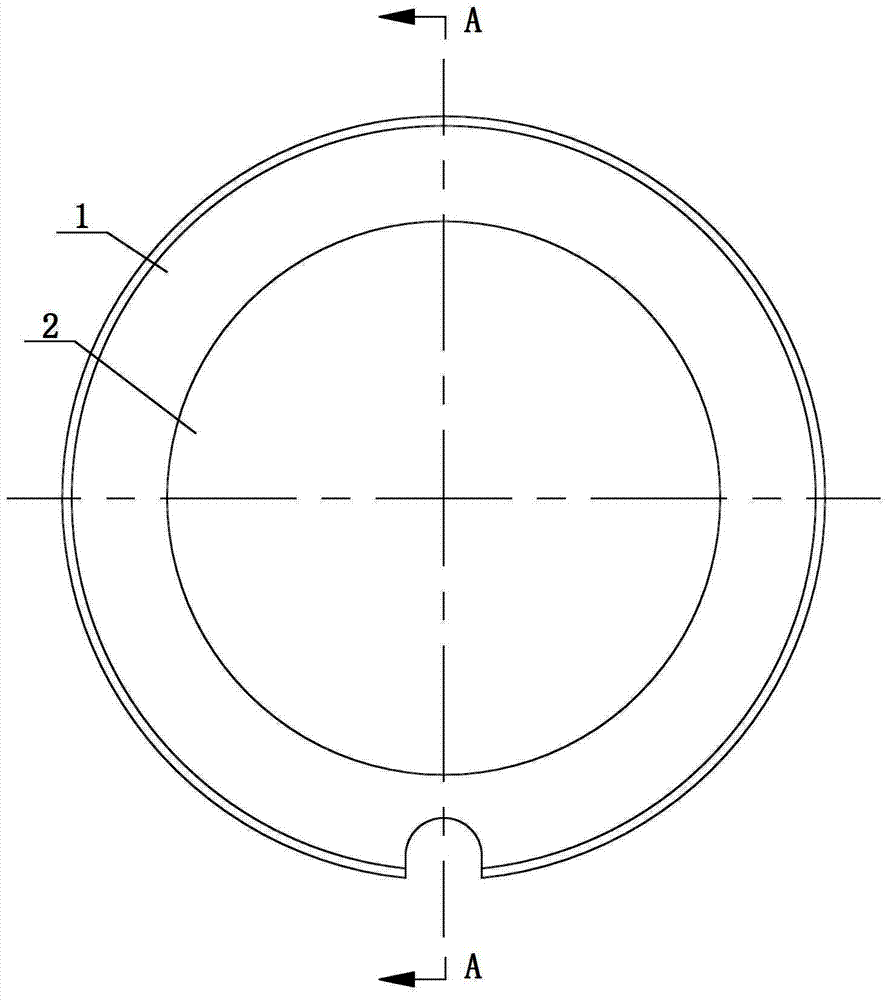

[0038] The difference from Embodiment 1 is only that the laser drilling machine drills holes on the speaker bracket, and the rest are the same. see Figure 4 As shown, the horn bracket has an open first end 1 and a sealed second end 2, and a laser drilling machine punches a circular hole 3 on the sealed end surface of the second end 2 of the horn bracket.

Embodiment 3

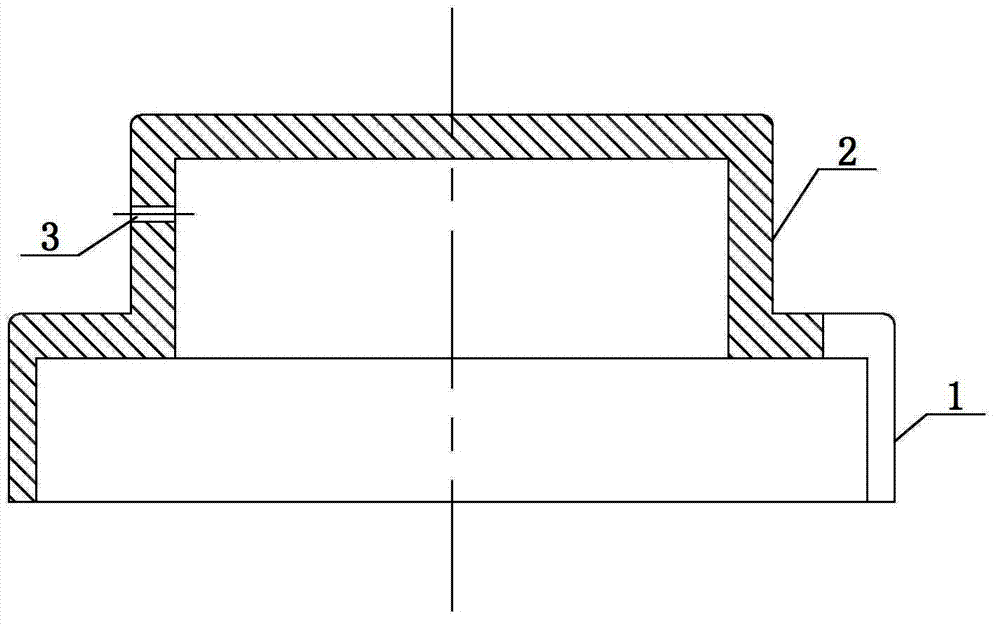

[0040] The difference from the above two embodiments is only that the laser drilling machine punches holes on the speaker bracket, and the rest are the same. see Figure 5 As shown, the horn bracket has an open first end 1 and a sealed second end 2, and a laser drilling machine punches a round hole 3 on the end surface where the first end 1 and the second end 2 of the horn bracket are in contact.

[0041] In the present invention, the vibrating plate transfers the horn bracket to the laser punching machine through an automatic feeding method. When the sensor of the laser punching machine detects that the feeder sends the horn bracket to the laser drilling station, the laser punching machine is triggered to work. Use the laser to drill the specified micro-holes in the designed position of the speaker bracket. Due to the creative use of the laser drilling machine and the automatic feeding machine, it replaces the original adjustment of the speaker by manually coating the glue an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com