Tailing feeding device for multi-station progressive mould and working method for tailing feeding device

A technology of feeding device and multi-station, applied in the direction of feeding device, positioning device, forming tool, etc., can solve the problem of material waste, and achieve the effect of improving the utilization rate of materials and reducing the utilization rate of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

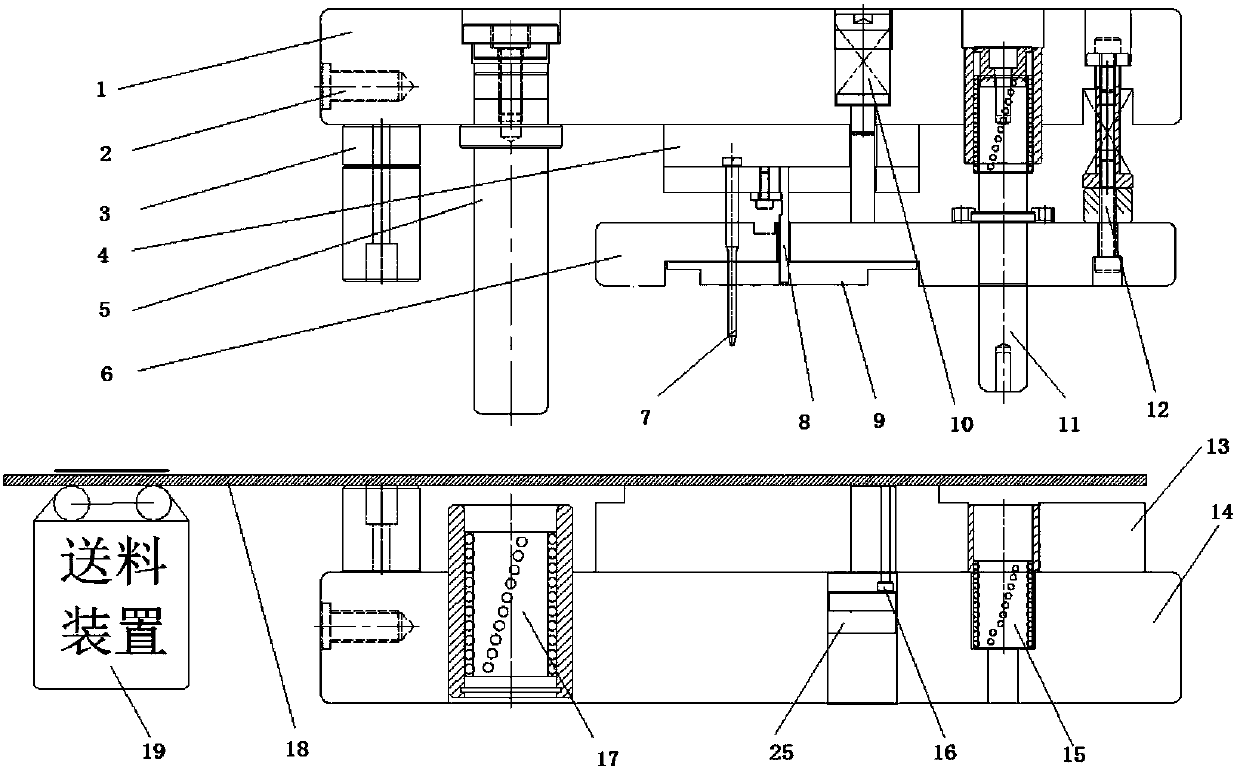

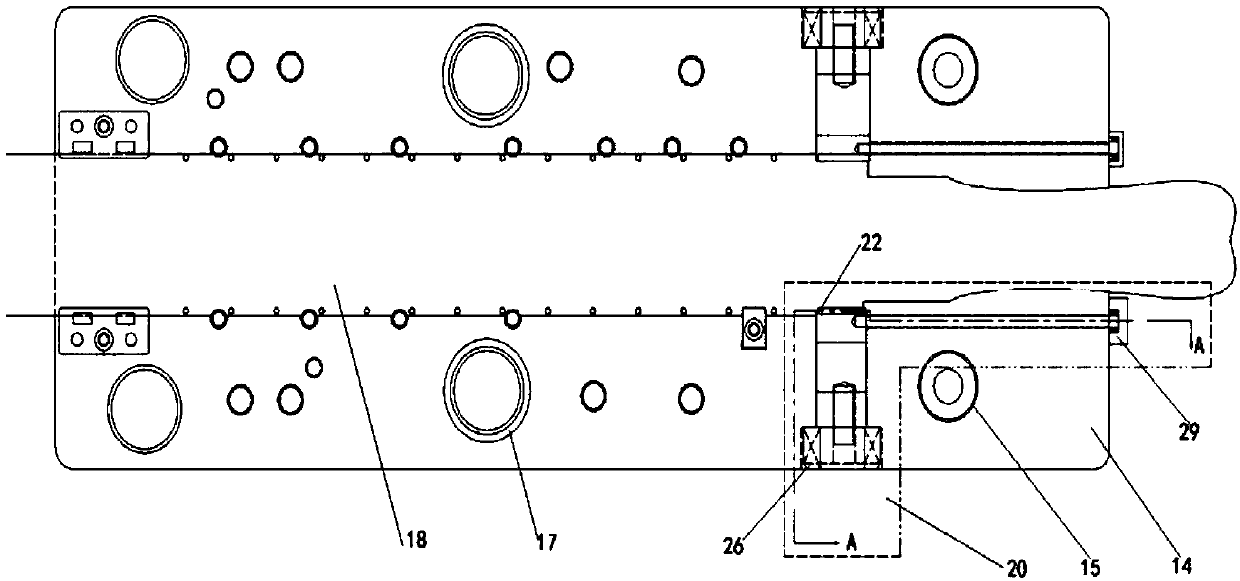

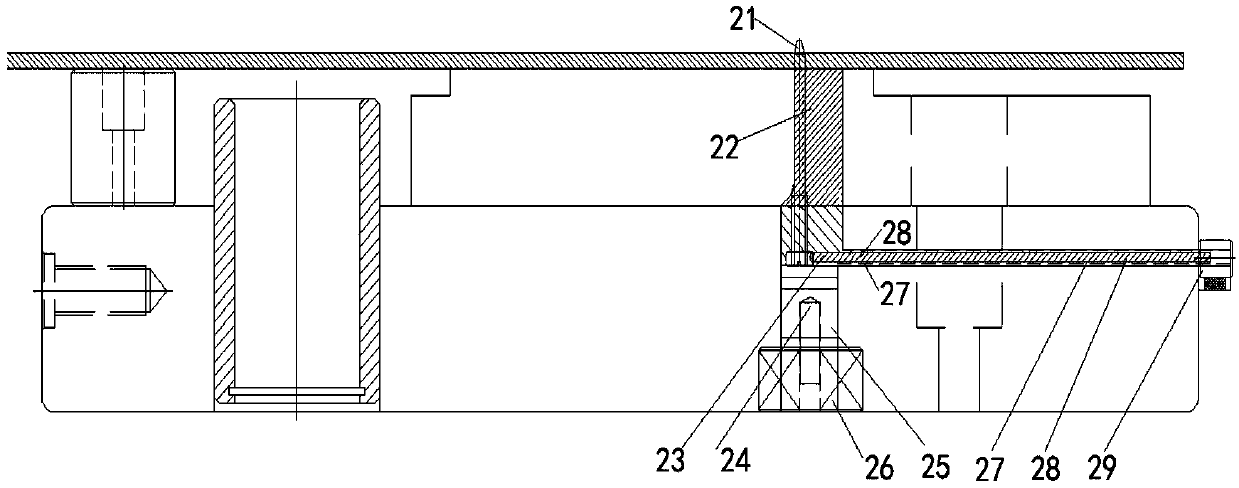

[0027] The following is attached Figure 1-4 The technical solution of the present invention is described in detail.

[0028] Such as figure 1 As shown, this example provides a kind of multi-station progressive die mold, mainly comprises three parts of upper mold part, unloading part and lower mold part;

[0029] The structure of the upper mold mainly includes the upper mold base 1, the screw hole 2, the limit column 3, the upper backing plate 4, the first guide column 5, the punch 8, the inner force transmission component 10 and the outer force transmission component 12;

[0030] The unloading part mainly includes the unloading plate seat 6, the guide nail 7, the small unloading plate 9, and the inner guide post 11;

[0031] The lower mold part mainly includes a concave template 13, a lower mold base 14, an inner guide post cover 15, an inverted guide pin hole 16, and an outer guide post cover 17;

[0032] Among them, the punch 8 and the internal force transmission assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com