Punching equipment for machining solar frames

A technology of solar energy and punching, which is applied in the direction of metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of low processing punching efficiency and poor processing accuracy, so as to ensure punching efficiency and punching accuracy, and avoid artificial Tolerance, the effect of ensuring high-efficiency transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-9 The application is described in further detail.

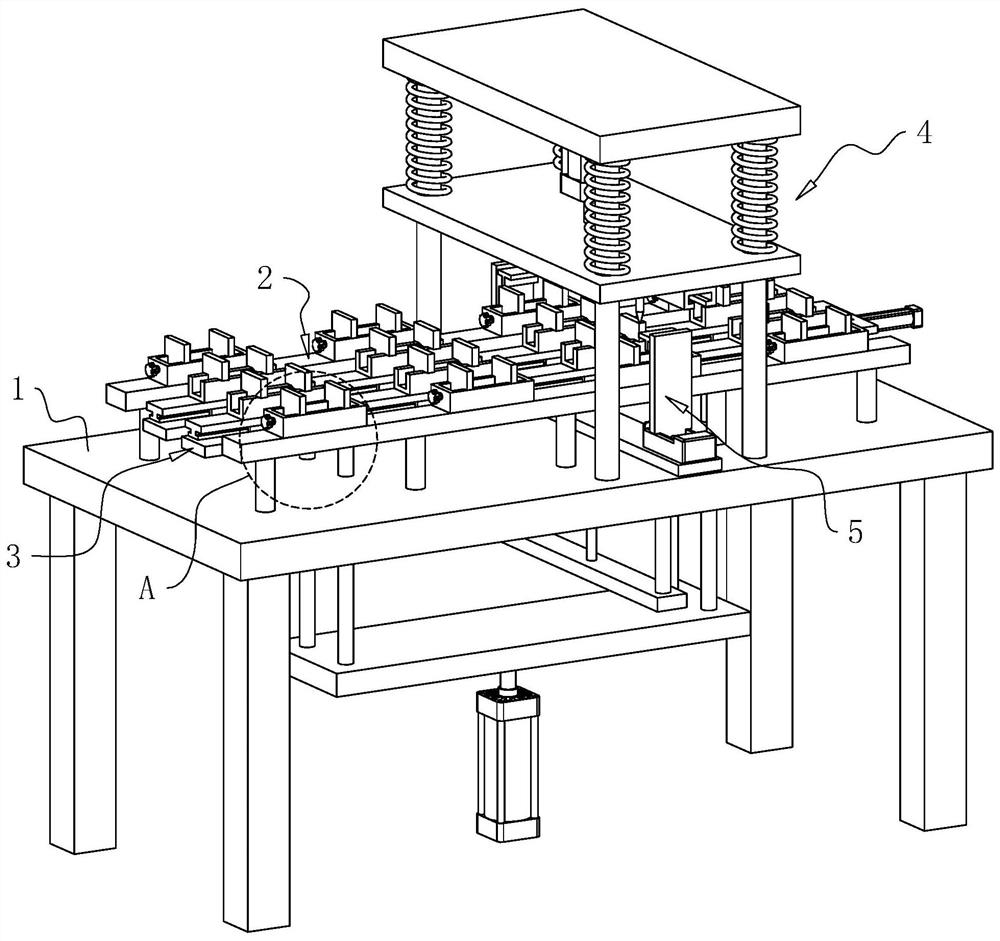

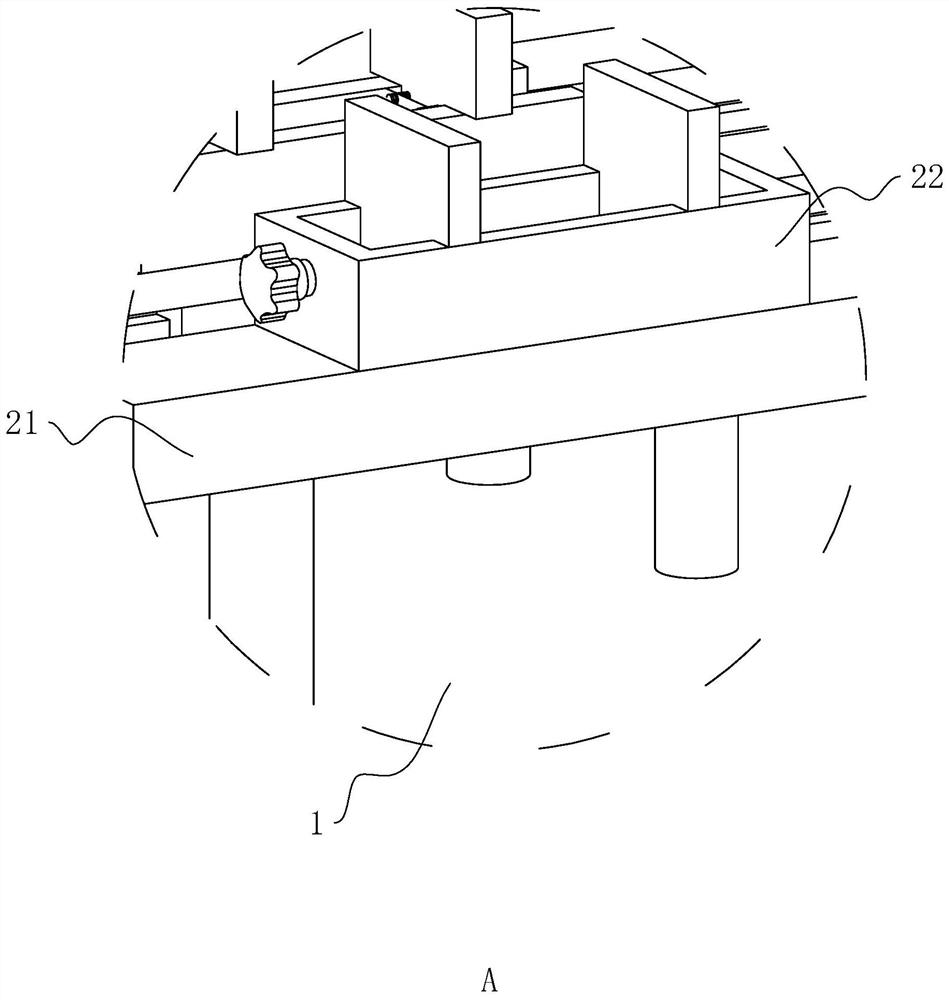

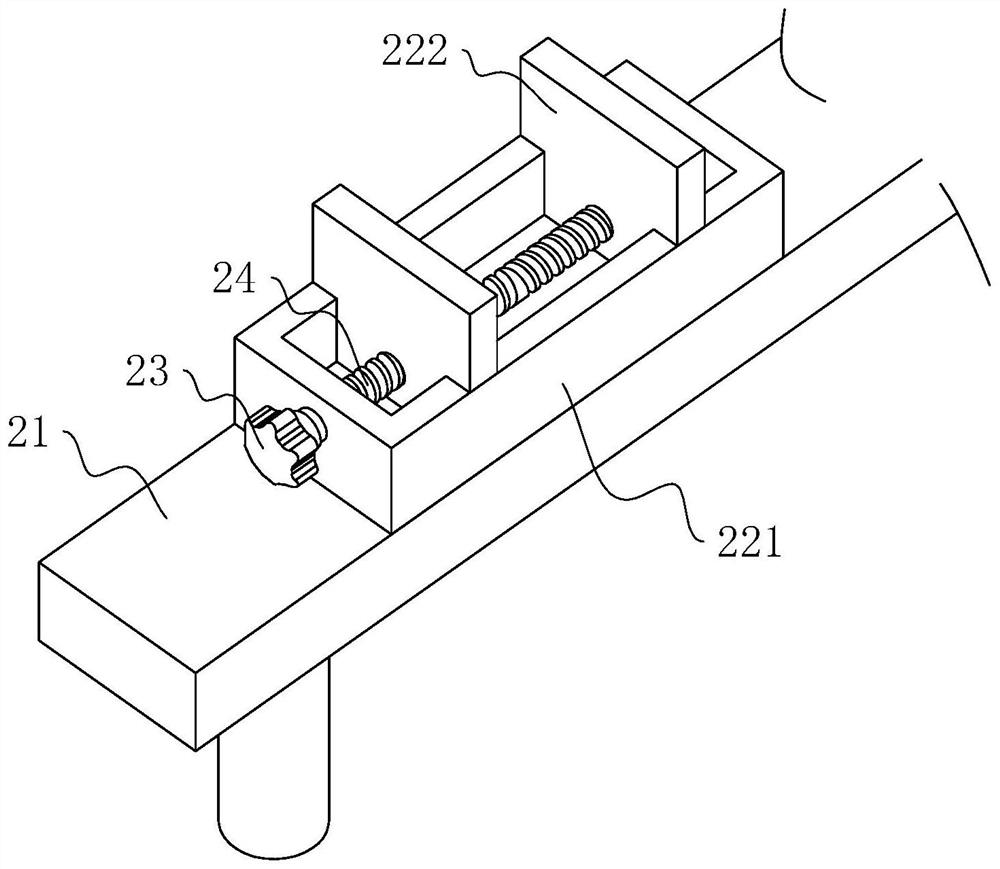

[0041] The embodiment of the present application discloses a punching device for processing a solar frame. refer to figure 1 , the punching equipment includes a frame 1, which is provided with a support device 2 for carrying workpieces, a feeding device 3 for driving workpiece transfer, and a punching device 4 for punching workpieces on the frame 1. A clamping device 5 for clamping the workpiece is also provided, and the clamping device 5 is arranged below the punching device 4 .

[0042] During the operation of the whole equipment, the worker places the workpiece on the supporting device 2, and the feeding device 3 can drive the workpiece to be transferred automatically. When the workpiece to be punched is transferred to the bottom of the punching device 4, the clamping device 5 can The two ends of the workpiece play the role of clamping, so that the punching accuracy is higher a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com