Electrostatic force driven apparatus for testing resonant two-side flexural-tensile fatigue of microstructure

A technology of bending fatigue and test equipment, which is applied in the field of basic research of micro-nano technology, can solve the problems of difficult and impossible clamping and centering of micron-sized samples, and achieve the goal of avoiding clamping and centering and increasing the stress level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

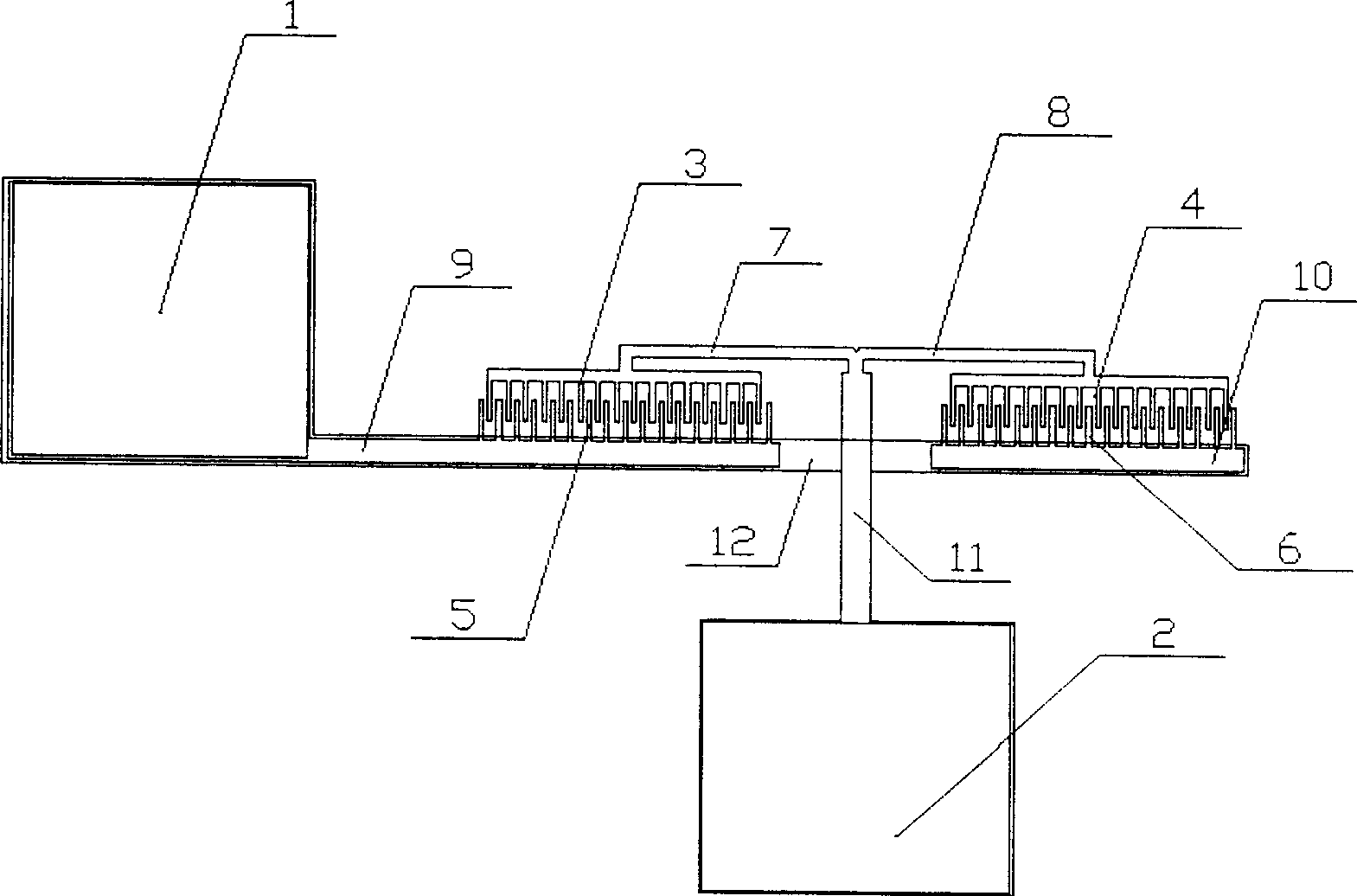

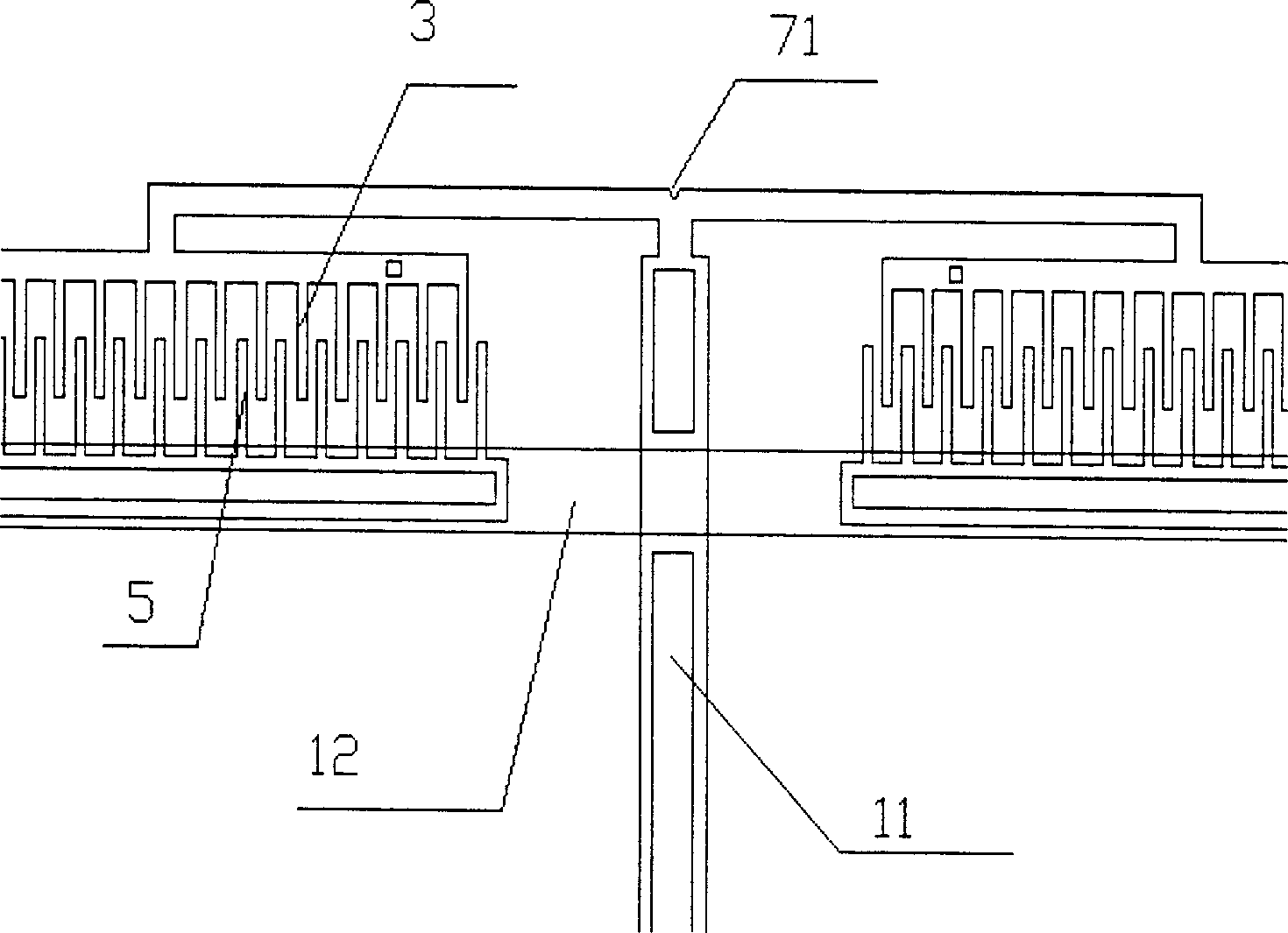

[0021] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

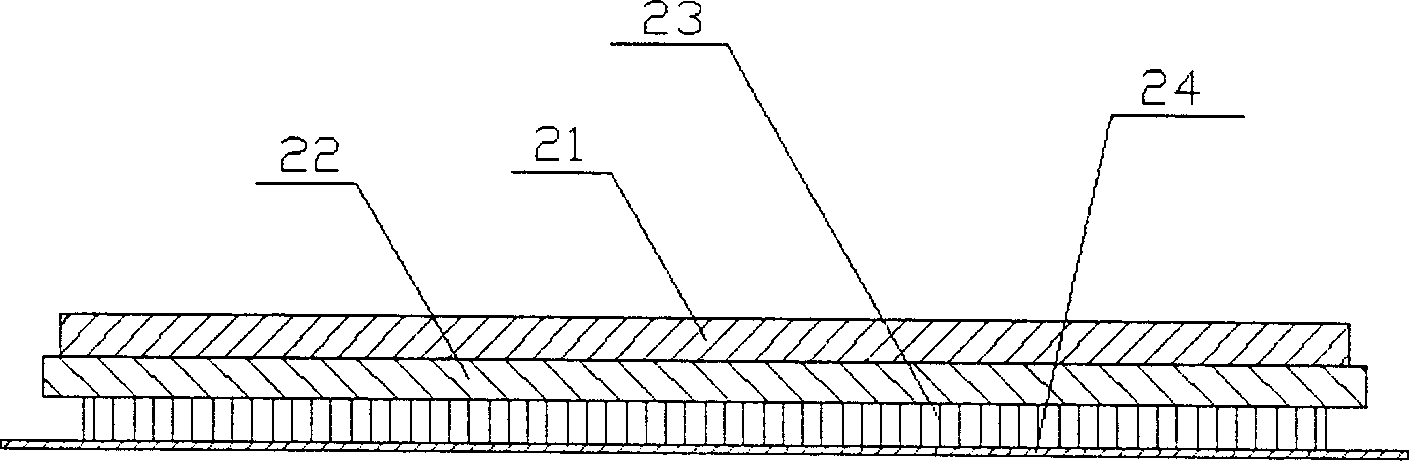

[0022] A microstructure resonance double-sided bending fatigue test device driven by electrostatic force, including: electrodes, side arms connected to the electrodes, and comb teeth arranged on the side arms; one of the electrodes 1 is connected to alternating current, and the bottom of the electrode 1 The electrode layer is connected to two sets of fixed combs integrated with the side arms; the other electrode 2 is grounded; directly connected to the two sets of suspended combs integrated with the side arms through the structural layer; the suspended combs are connected to the The fixed comb teeth are staggered corresponding settings;

[0023] The above two sets of fixed combs are connected by the in-line side arms connected to the AC electrodes, and the sections of the side arms are connected by the bottom electrodes; the above two sets of suspended combs are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com