Microstructure resonance single direction bending pulling multiaxle fatigue experimental device

A fatigue test and microstructure technology, applied in the basic research field of micro-nano technology, which can solve the problems of impossible completion, difficulty in clamping and centering of micron-sized samples, and achieves the improvement of stress level and the avoidance of clamping and centering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

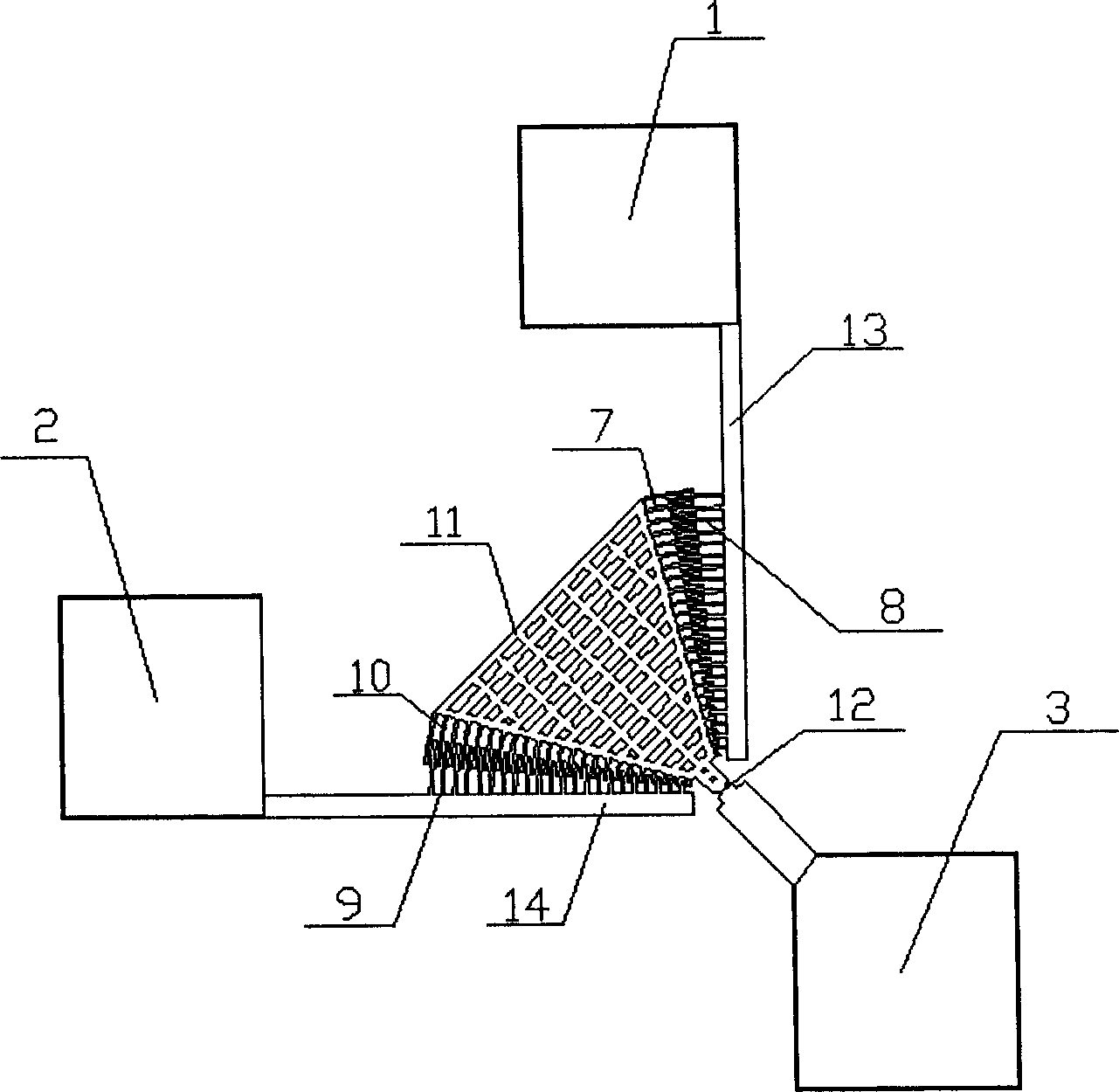

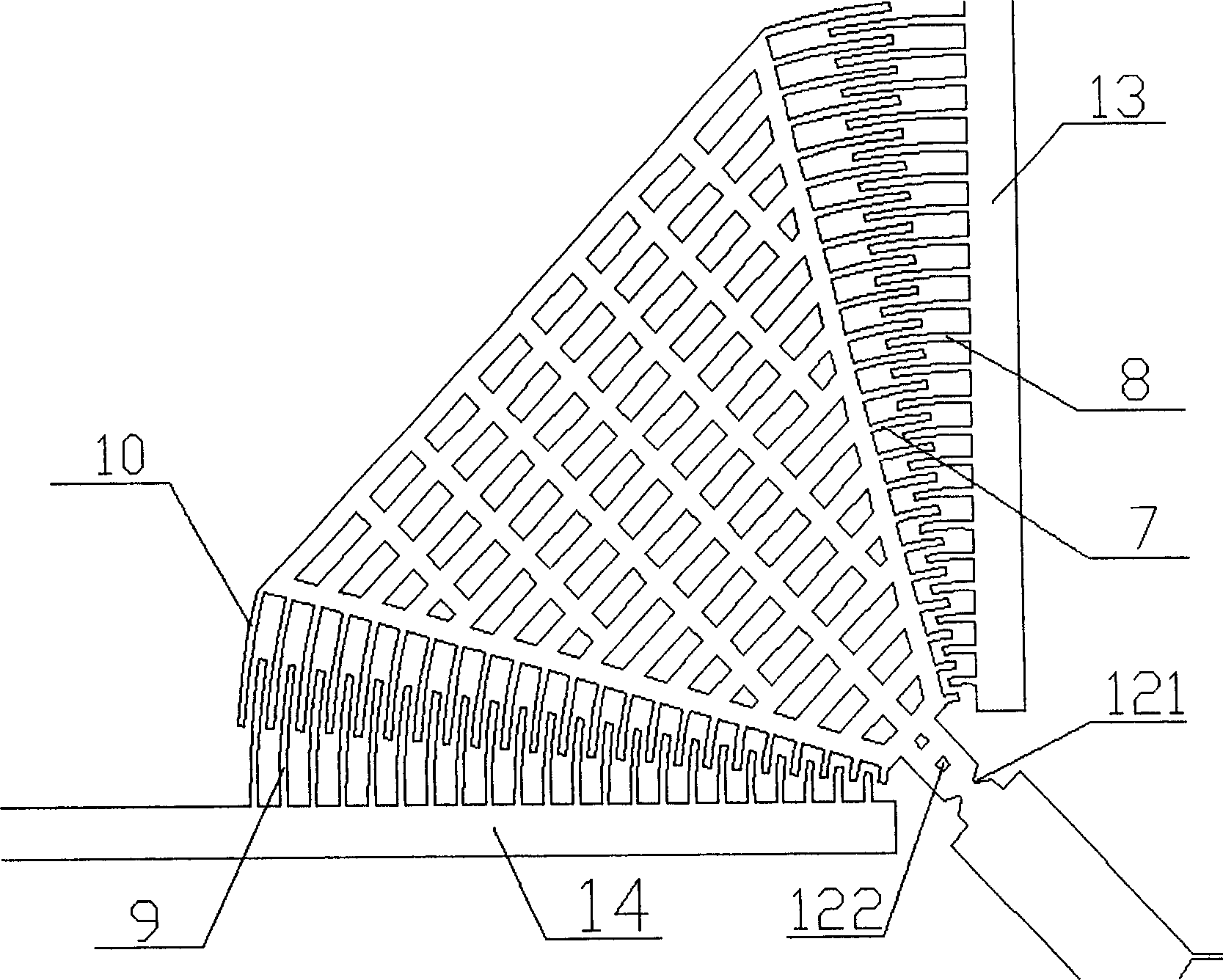

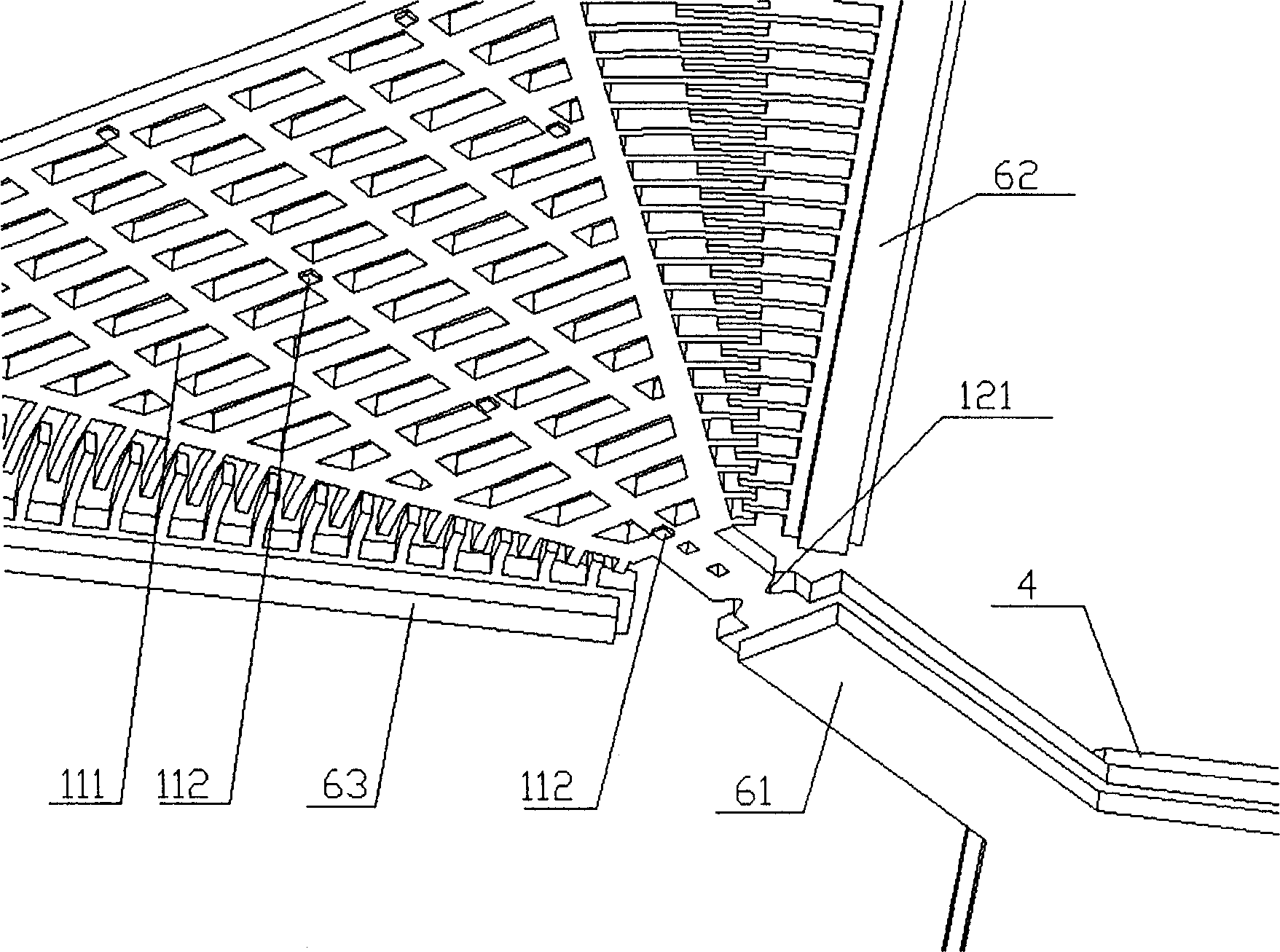

[0029] Schematic diagram of the structure of the microstructure resonance unidirectional bending-tensioning multi-axial fatigue test device of the present invention. see figure 1 As shown, is the front schematic view of the microstructure resonant unidirectional bending-tension multiaxial fatigue test device. It can be seen from the figure that 1, 2, and 3 are three electrodes; electrode 1 is the driving electrode, electrode 2 is the detection electrode, and electrode 3 is the ground electrode; please refer to Figure 4 As shown, it is a cross-sectional view of the electrode structure layer of the microstructure resonant unidirectional bending and pulling multiaxial fatigue test device; the surface of each electrode is a layer of metal called metal layer 4, the purpose is to enhance the conductivity, and the metal layer is under the polysilicon structure Layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com