Patents

Literature

43results about How to "Reduce the cost of plate making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

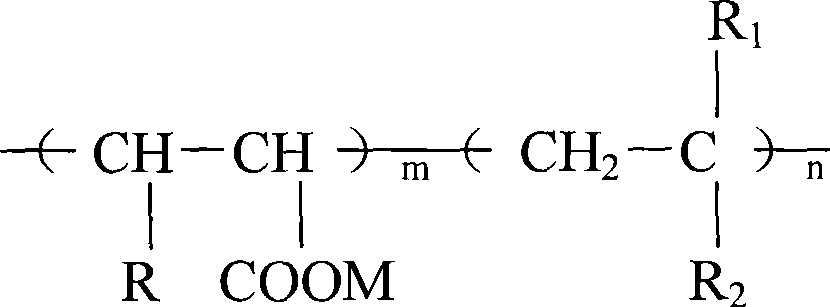

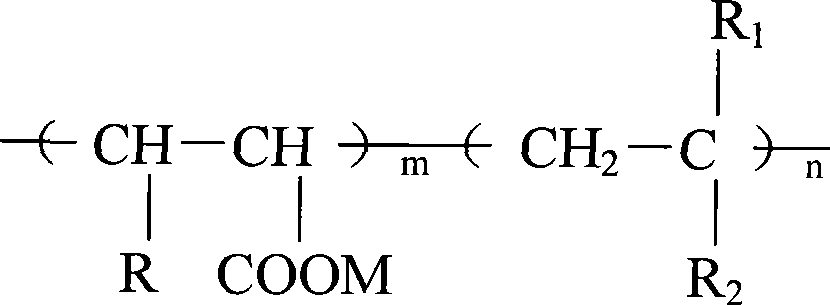

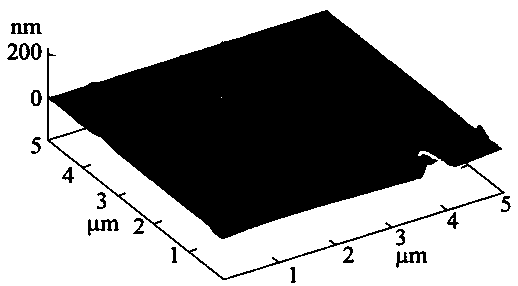

Environment-friendly type on-press-coating ink-jet CTP offset master, pigment ink and preparation method thereof

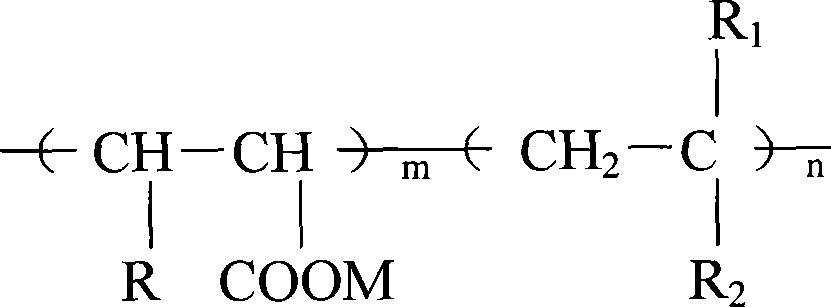

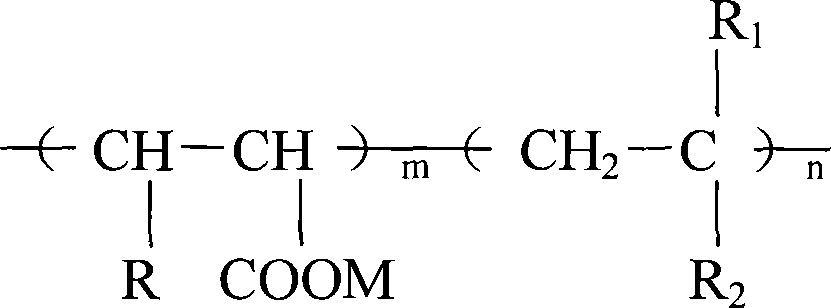

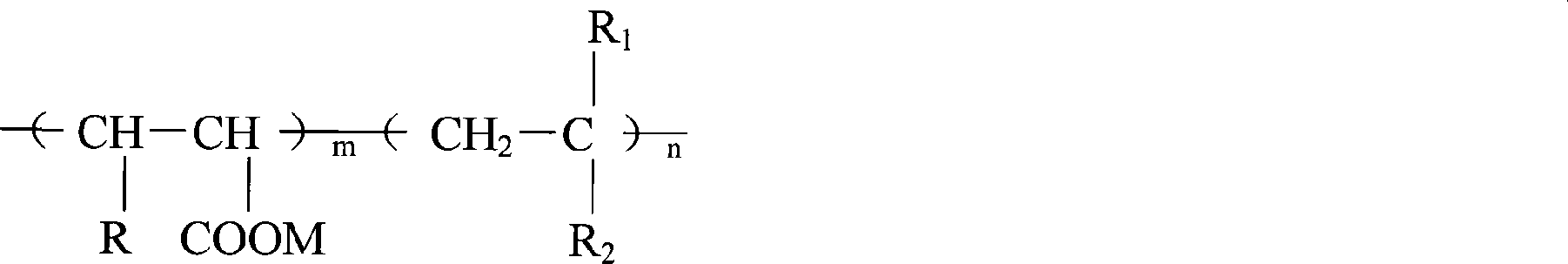

InactiveCN101081952AReduce printing costsPlate making process is simpleInksPrintingCross-linkPulp and paper industry

The present invention relates to printing technology, and is one kind of environment friendly ink jetted CTP offset plate, color ink and its making process. The color ink comprising pigment, dispersed polymer emulsion, water soluble cosolvent, surfactant, cross-linking agent and deionized water is prepared through emulsifying and high speed dispersing. The color ink may be printed fluently without ink jet jamming, and the printed ink may be adhered to the plate fast without flowing. Through printing on aluminum base with one ink jet printer and the color ink and plate settling treatment, one environment friendly ink jetted CTP offset plate may be made without need of further treatment. The plate making process is time saving and environment friendly.

Owner:石深泉

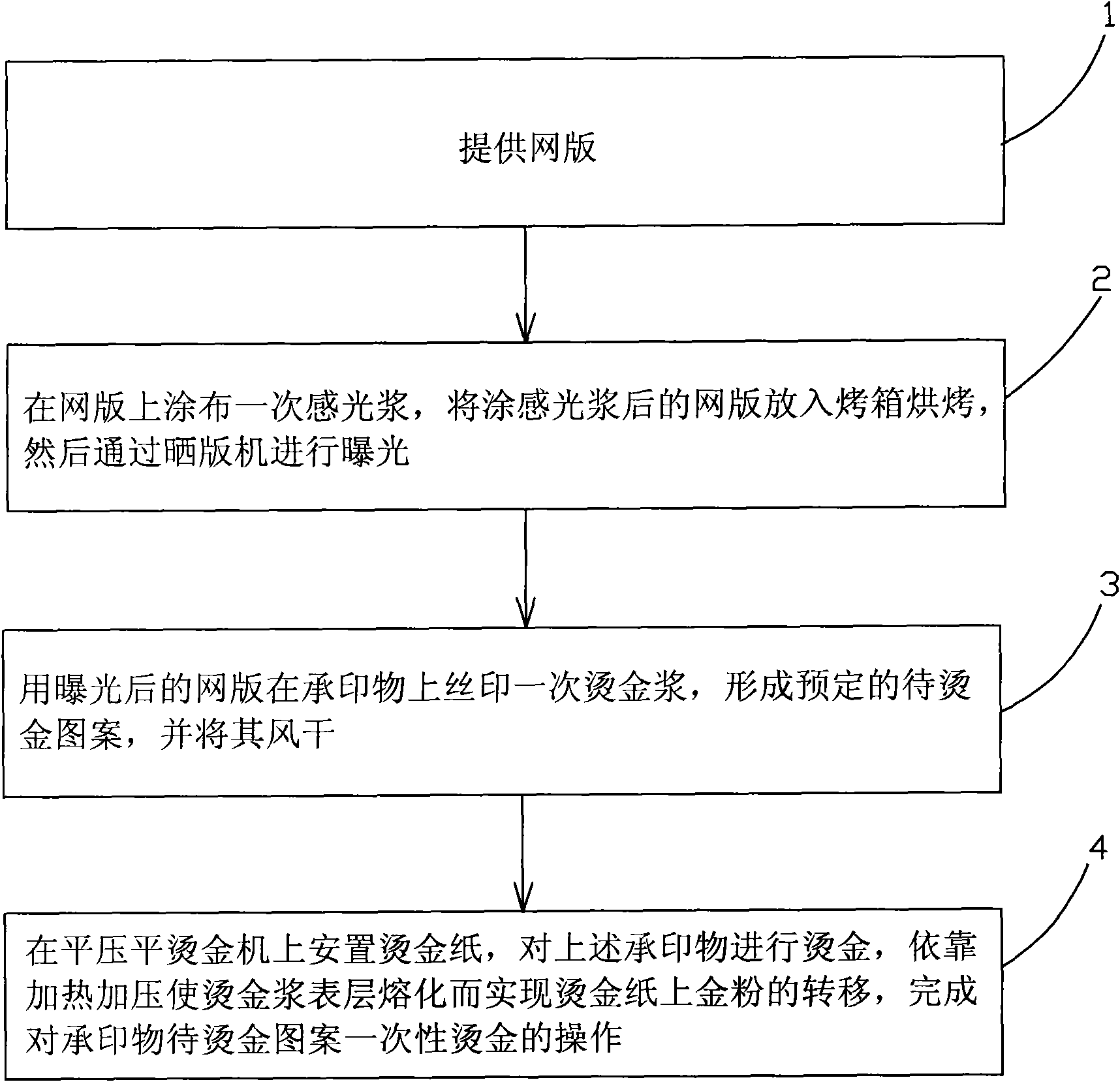

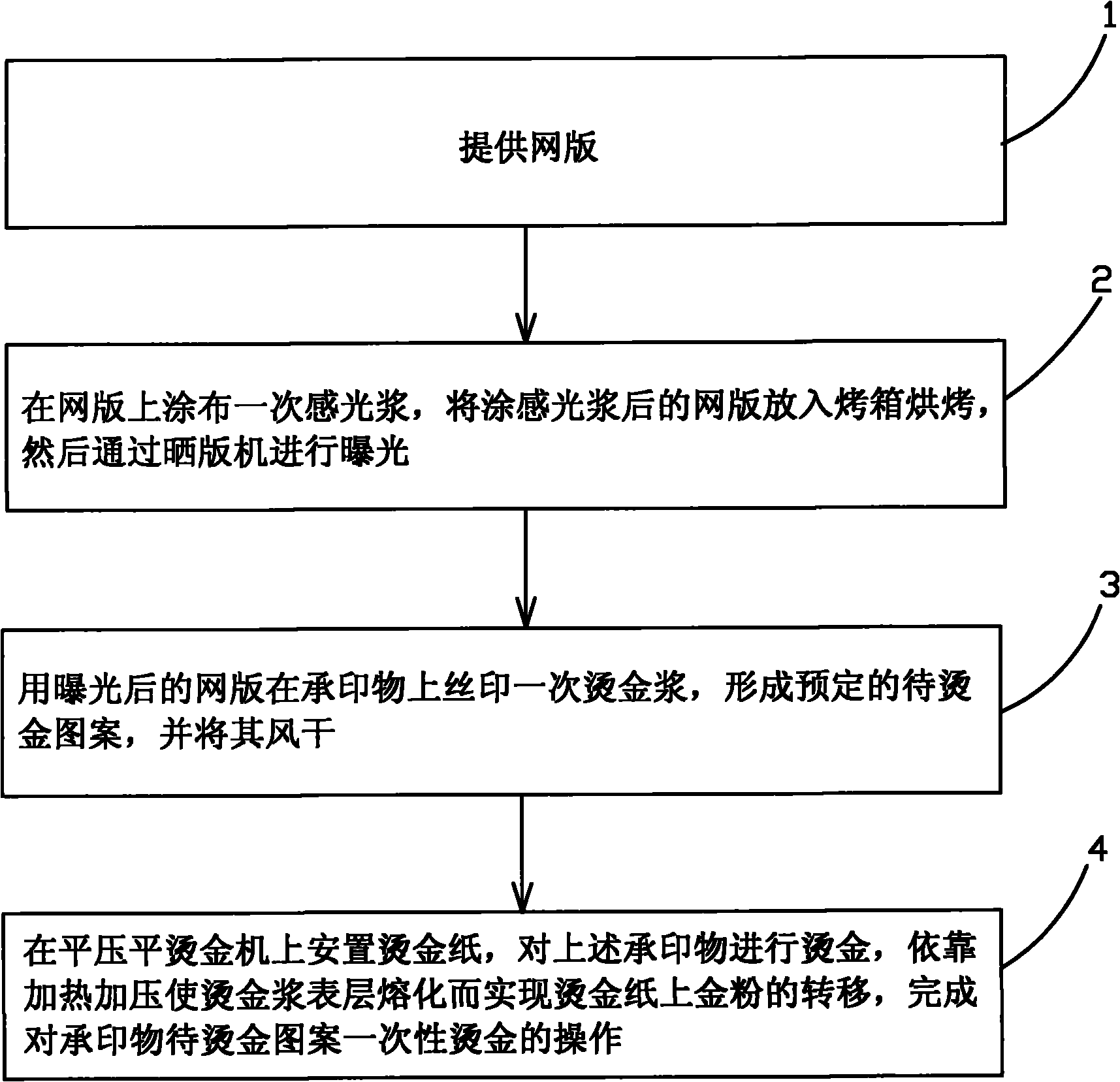

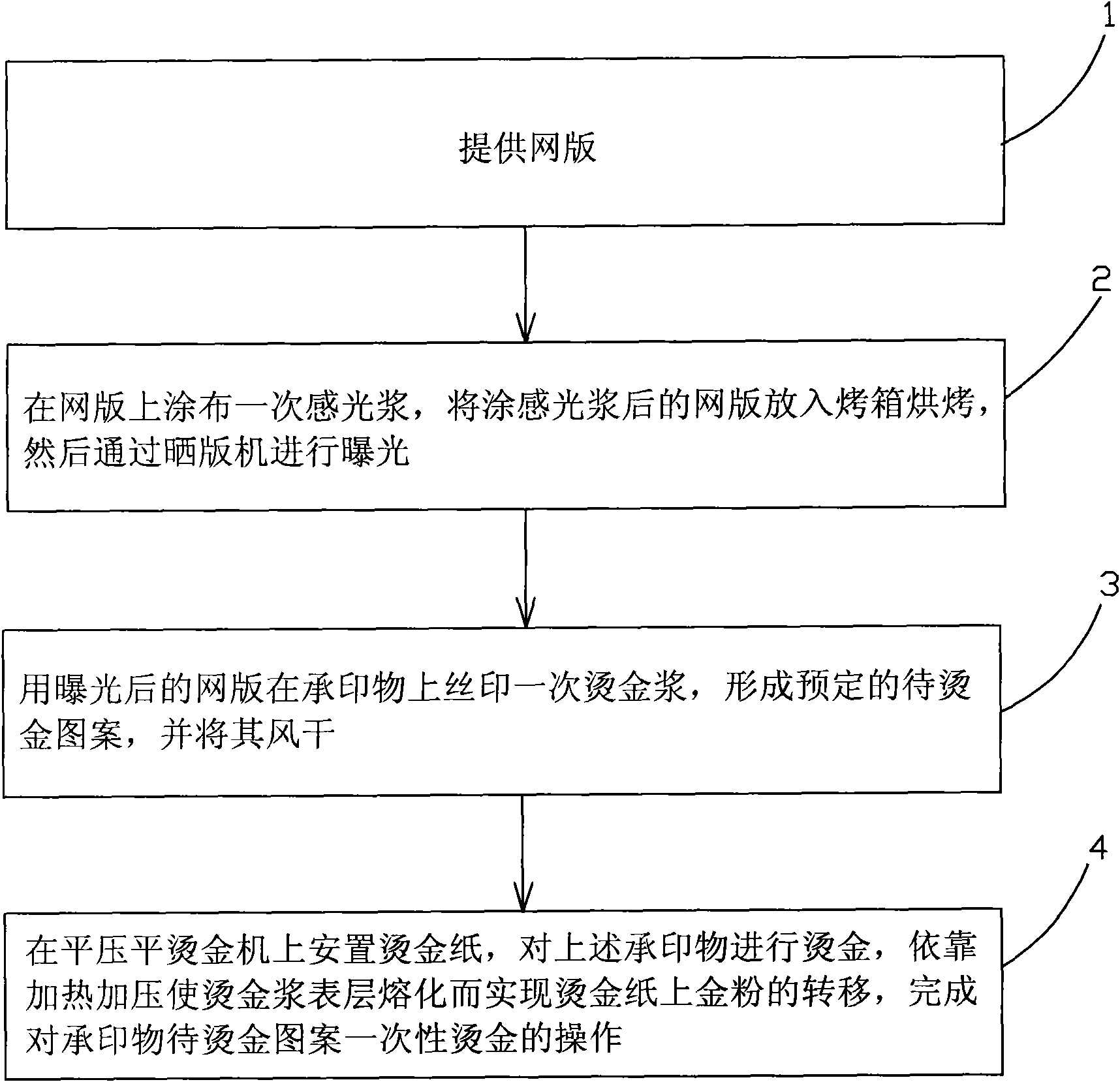

Three-dimensional bronzing method

ActiveCN101670719ATake advantage ofImprove the three-dimensional effectPhotosensitive materialsRotary pressesScreen printingSurface layer

The inventio provides a three-dimensional bronzing method, comprising the steps of: 1. providing a screen printing plate; 2. coating disposable photosensory pulp on the screen printing plate, puttingthe screen printing plate coated with the photosensory pulp into an oven to be baked, and exposing by a printing-down machine; 3. printing disposable bronzing pulp on printed material with the exposedscreen printing plate to form a preset pattern to be bronzed, and drying; and 4. setting a bronzing paper on a flat pressing flat bronzing machine, bronzing the printed material, and melting the surface layer of the bronzing pulp by means of heating and pressing to convert the golden powder on the bronzing paper and complete the operation of disposable bronzing to the pattern to be bronzed of theprinted material. The three-dimensional bronzing method disposably produces the multicolour three-dimensional bronzing patterns and characters with good hand feel on the surface of textile or thin paper with the existing common equipment, thereby not only reducing the production cost but also improving the production efficiency to a certain degree.

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

Digital printing method of woodgrained paper

ActiveCN105383199AEasy to controlPromote reductionDuplicating/marking methodsOther printing apparatusPulp and paper industryDigital printing

The invention relates to the technical field of gravure plate making, in particular to a digital printing method of woodgrained paper. The digital printing method comprises the steps of: (1) manuscript scanning; (2) manufacturing and color separation; (3) digital sample printing: files, after the color separation, are directly output and subjected to sample printing through a printer; printed objects adopt 80 g woodgrained paper; the sample products and manuscripts are compared to check if the color separation structure is reasonable and if the sample printing effect can satisfy the demands; if the sample printing effect cannot satisfy the demands, the color separation processing is performed again by returning to the last step; and if the sampling effect satisfies the demands, the next step is performed; (4) plate making through carving; and (5) printing. The digital printing method enables sample paper printed by a digital sampling system to be very approximate to actual printing sample paper through controlling a color management system and adjusting a process, preferably achieves actual gravure effects, improves the plate making quality, and reduces the rework rate.

Owner:DONGGUAN YUNCHENG PLATE MAKING

Single paper printing, opening and cutting method

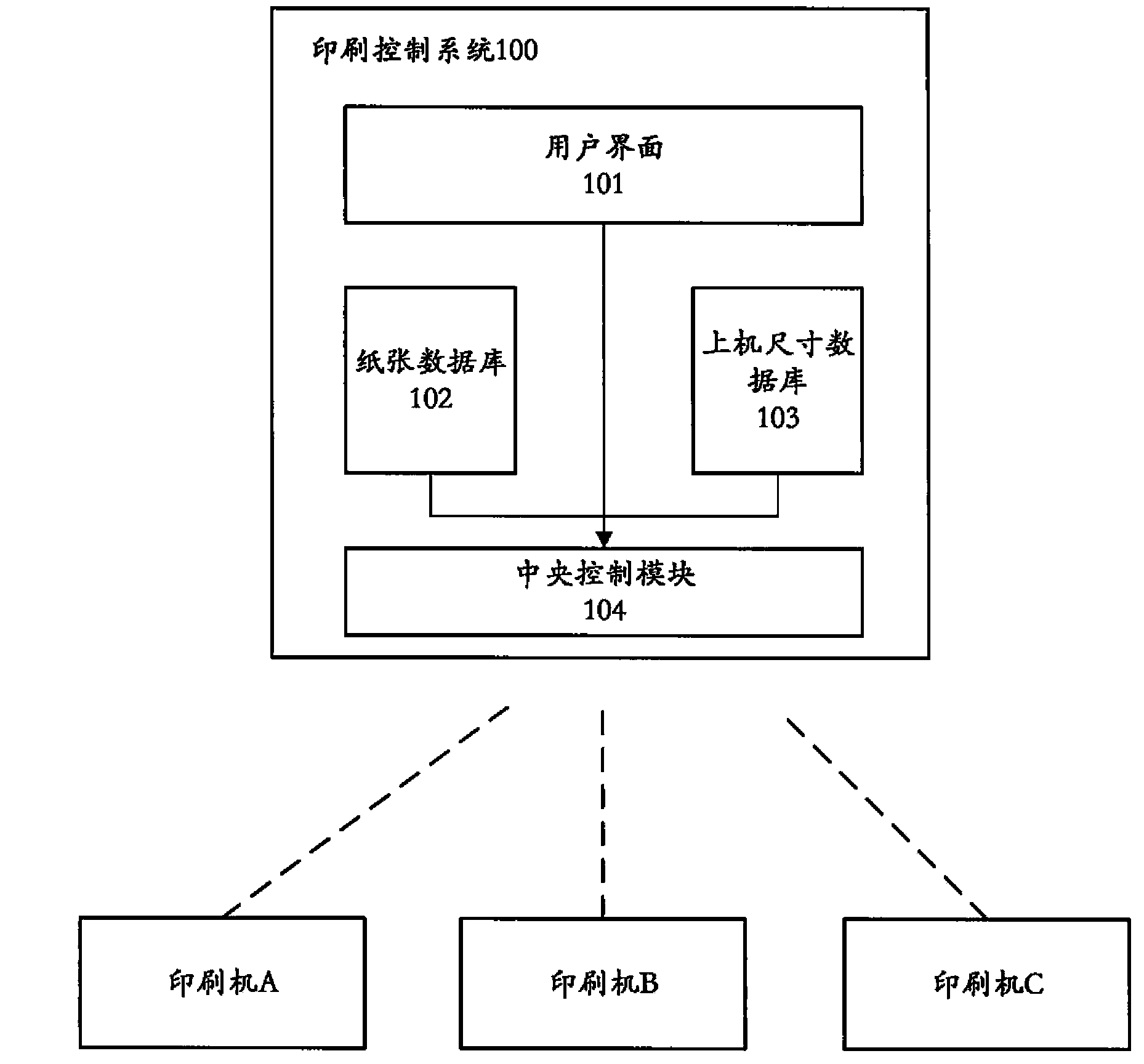

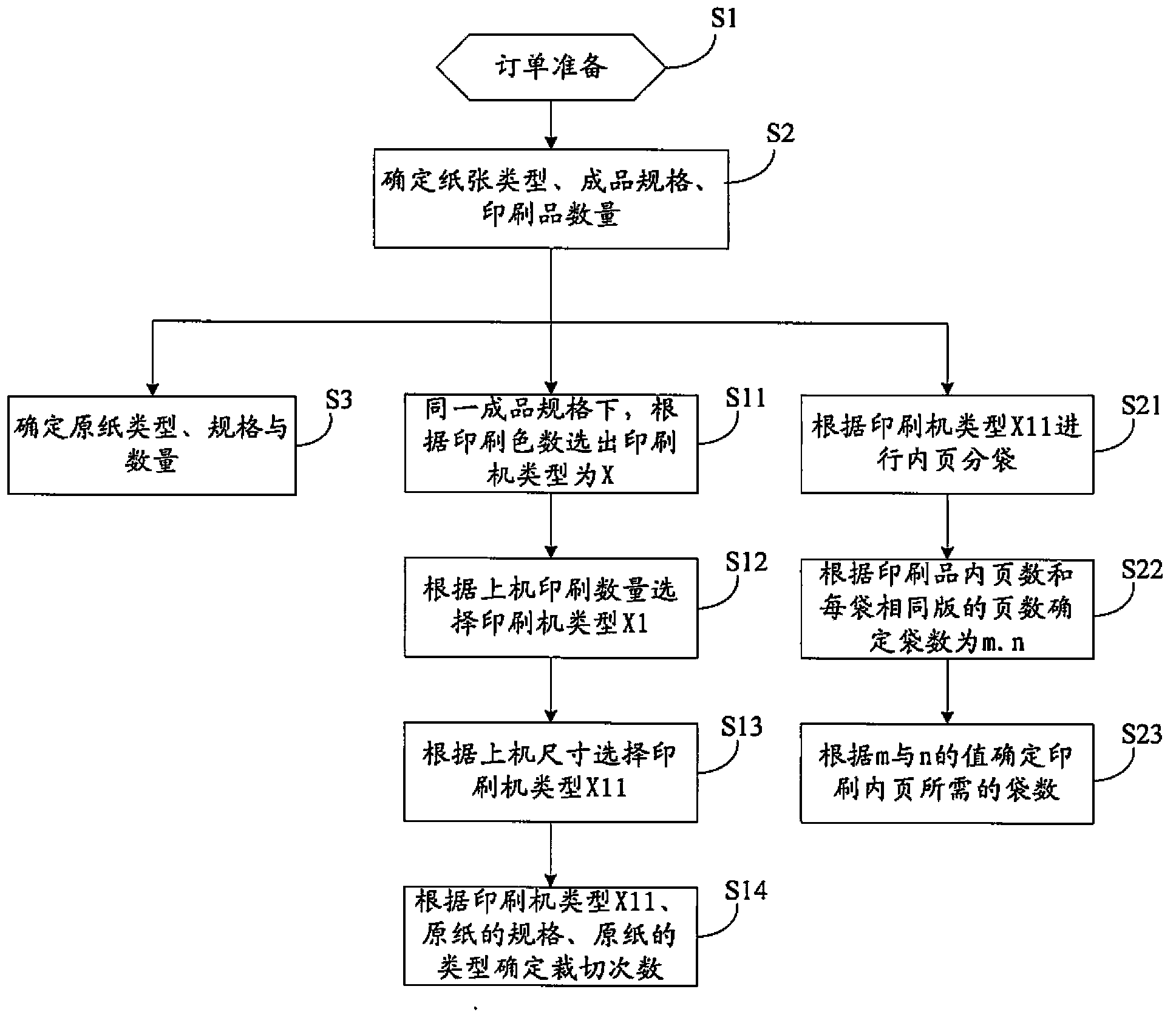

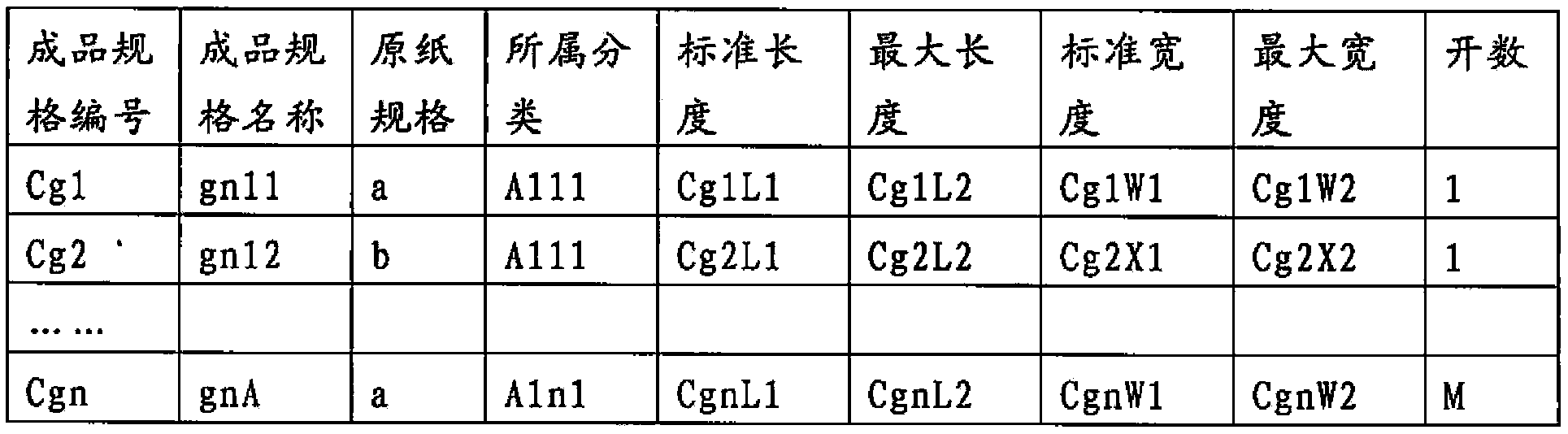

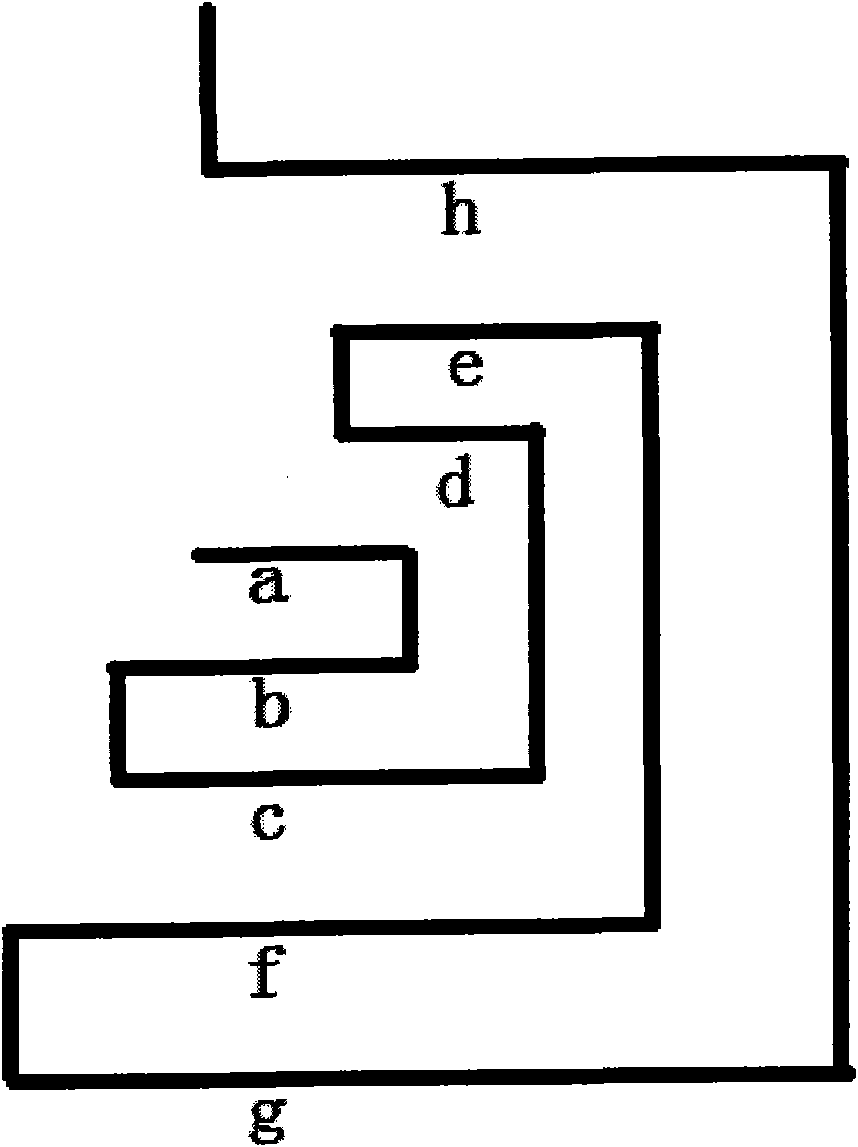

ActiveCN104275928AEasy to useReduce cutting error ratePlaten pressesMetal working apparatusPulp and paper industryWork flow

The invention provides a paper printing method for printing single paper. The method comprises the following steps: a, determining the parameters of a printed matter according to a printing command, and determining the type and quantity of raw paper; b, selecting a corresponding printing device according to the parameters of the printed matter, and generating a cutting command and a printing command; c, controlling a cutting device according to the cutting command in order to cut the raw paper, and controlling the printing device according to the printing command. By adopting the paper printing method, the raw paper cutting error rate is lowered, the paper opening rate is increased, and the production efficiency in a raw paper cutting workflow is increased; moreover, a corresponding platemaking method is generated according to the specifications of finished products, so that the platemaking cost is reduced.

Owner:北京印书网络科技有限公司

Seamless flexible plate making technology

InactiveCN105799306ASolve the seam problemGood printing adaptabilityForme preparationJoint problemLaser engraving

The invention discloses a seamless flexible plate making technology. The seamless flexible plate making technology comprises 1, coating a flitch plate sleeve roller as a base roller with black rubber and carrying out processing through a grinding machine to obtain a rubber layer with thickness of 7-10mm, 2, preparing a carving file according to requirements and inputting the carving file into carving software of a carving machine, 3, inputting actual sizes of the rubber roller into the carving machine, introducing the carving file and carrying out pattern graving on the rubber roller, and 4, preparing a seamless flexible printing plate according to characteristics of diameter error automatic scaling and automatic circumferential joint through the laser carving machine. The seamless flexible plate making technology solves flexible plate joint problems and improves printing adaptability.

Owner:SHANGHAI YUNCHENG PLATE MAKING

Production method for graving gravure on-machine plate

InactiveCN101021681AHigh printing precisionSmall sizeOriginals for photomechanical treatmentSurface layerEngineering

The invention advances an engraved intaglio printing machine plate making method, comprising the steps of: preparing metal plate; making graphics to be printed into photosensitive film, covering the photosensitive film on the metal plate, making plate burning, then corroding parts to be sunken by corrosive solution; and chromeplating the surface layer. And its beneficial effects: the made plate can be directly printed on machine, largely shortening the plate making cycle and saving the plate making cost. Besides, the made plate has advantages of high printing accuracy and strong printing resistance.

Owner:CHINA BANKNOTE PRINTING & MINTING

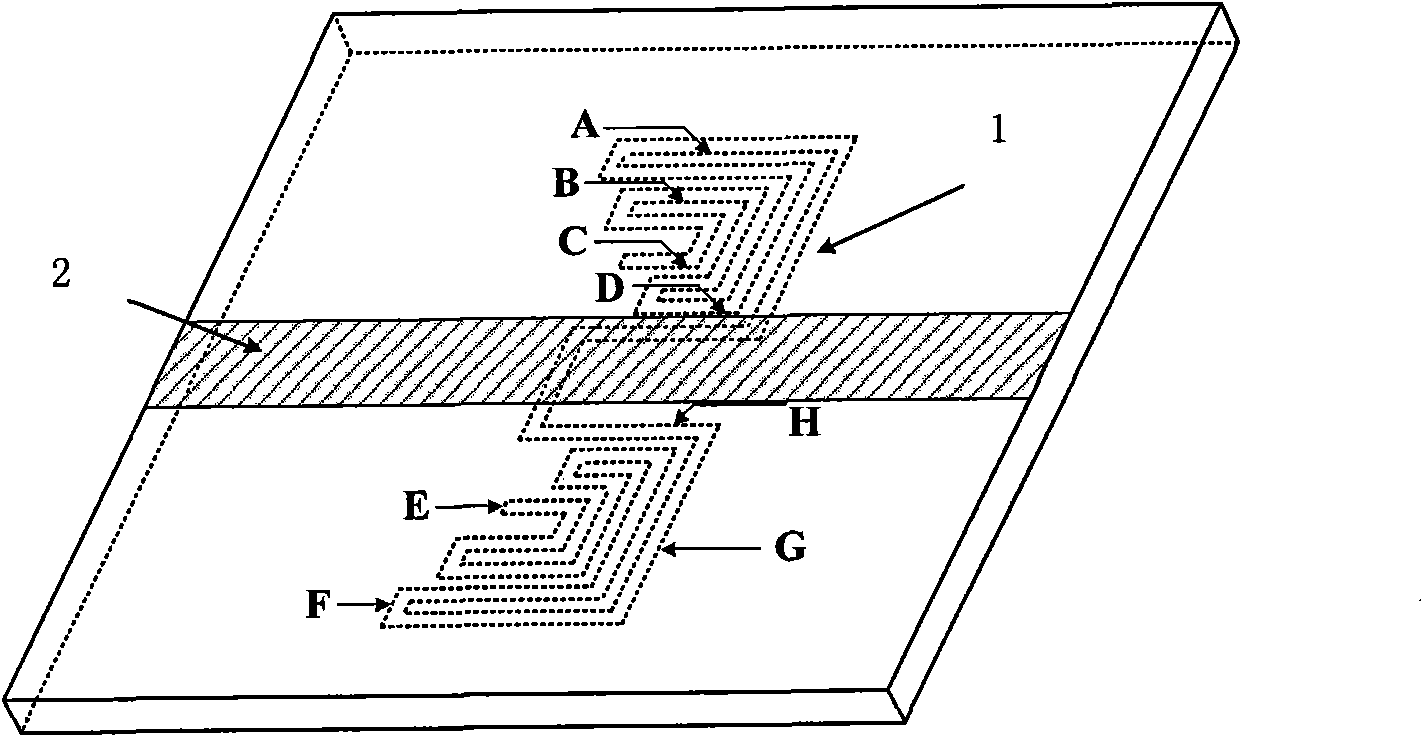

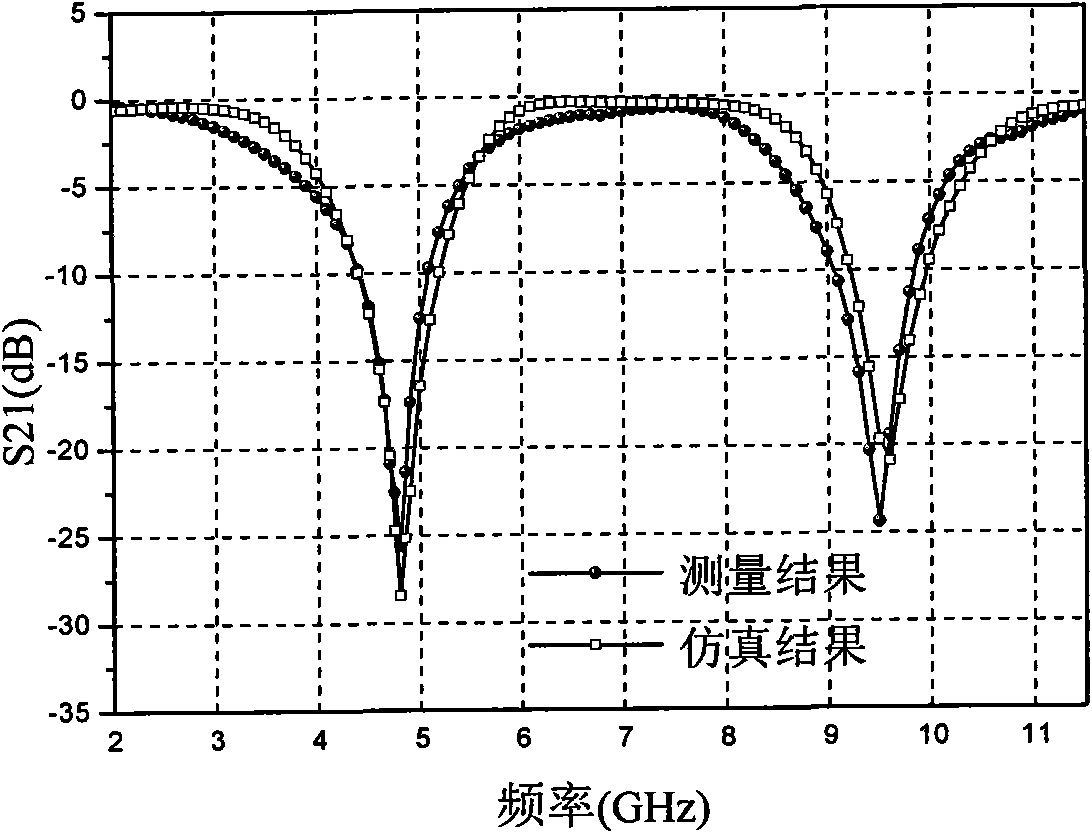

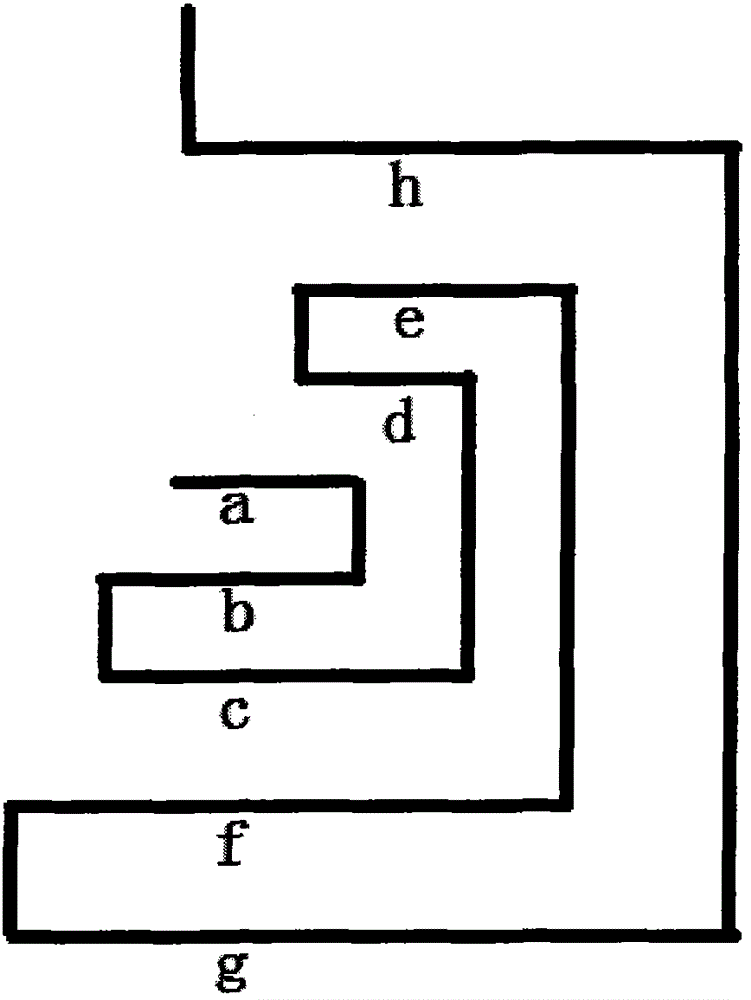

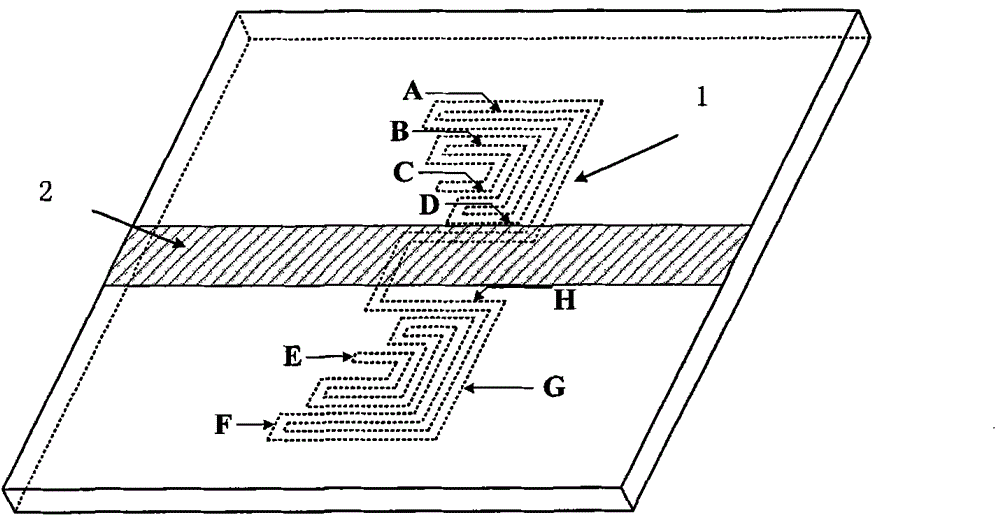

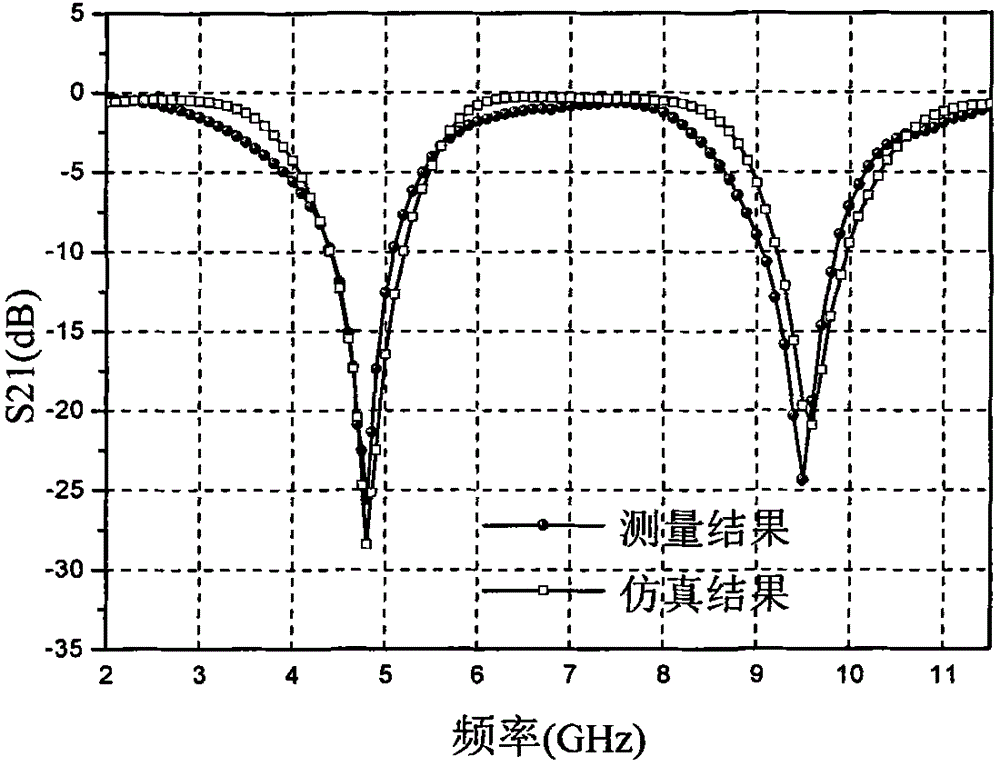

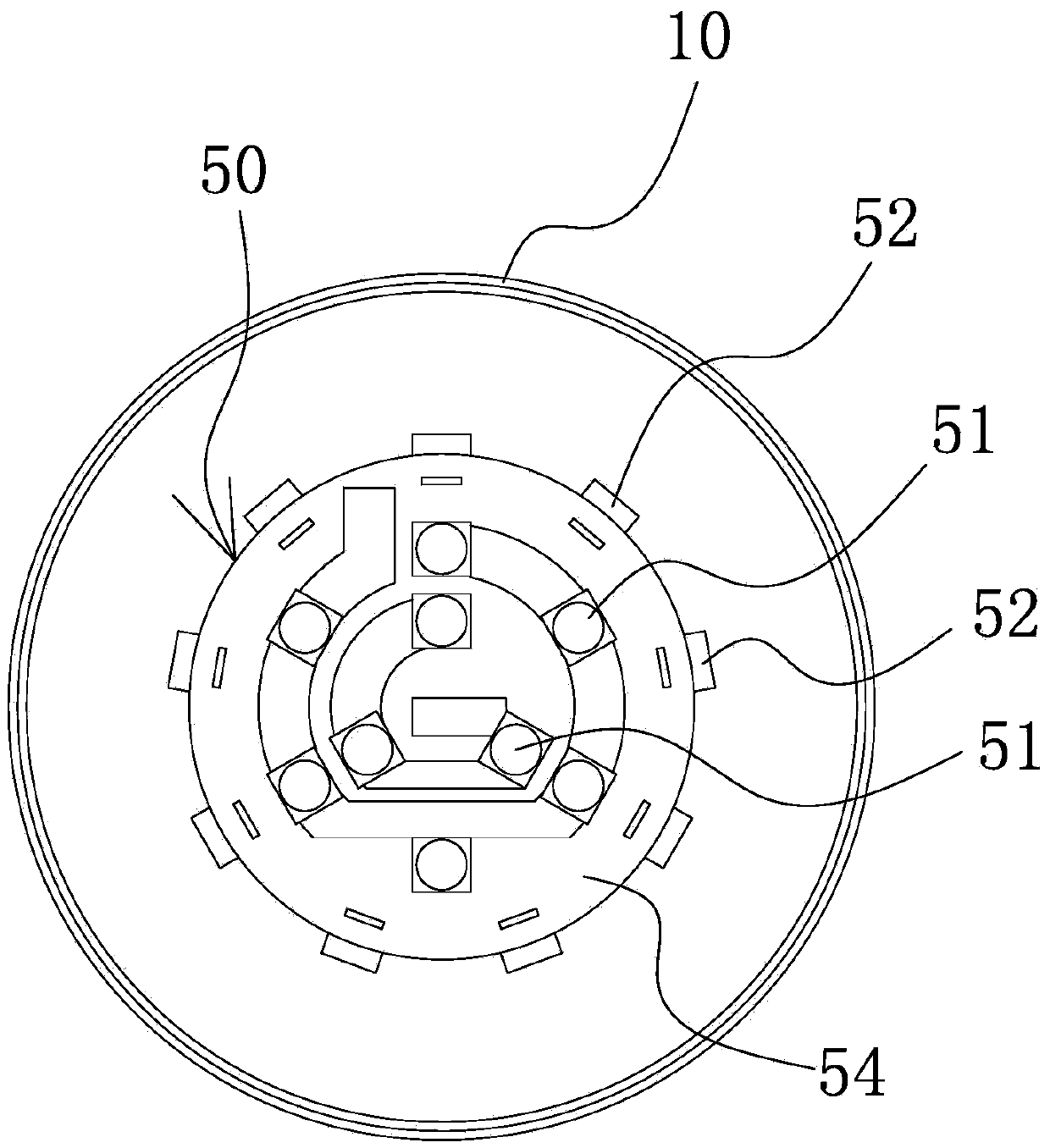

Design method for reverse class-F power amplifier based on 3/4 spiral virtual ground structure

ActiveCN102111114AReduce areaSimple designPower amplifiersAmplifier modifications to raise efficiencyAudio power amplifierHarmonic

A design method for a reverse class-F power amplifier based on 3 / 4 spiral virtual ground structure comprises the steps as follows: confirming the work frequency of the power amplifier and obtaining the harmonic frequency of a harmonic control circuit; changing the dimension of the 3 / 4 spiral structure and designing corresponding harmonic control circuit according to the needed harmonic frequency in the design; inserting the harmonic control circuit into the output end of a power amplifier tube and designing the input-output matching circuit of a power amplifier circuit; and designing the input-output parameters of the power amplifier through measurement, and adjusting the length of a magic line to reach the maximum work efficiency. The amplifier designed by adopting the method comprises an input matching circuit, a power amplifier circuit, a harmonic control circuit and an output matching circuit which are connected onto a microstrip line in sequence; the harmonic control circuit comprises a 3 / 4 spiral virtual ground structure arranged below the microstrip line, and the virtual ground structure is formed by a complete spiral virtual ground structure cut by 1 / 4; and the 3 / 4 spiral virtual ground structure comprises two spiral structure parts connected with each other and in axial symmetry along the microstrip line.

Owner:SOUTHEAST UNIV

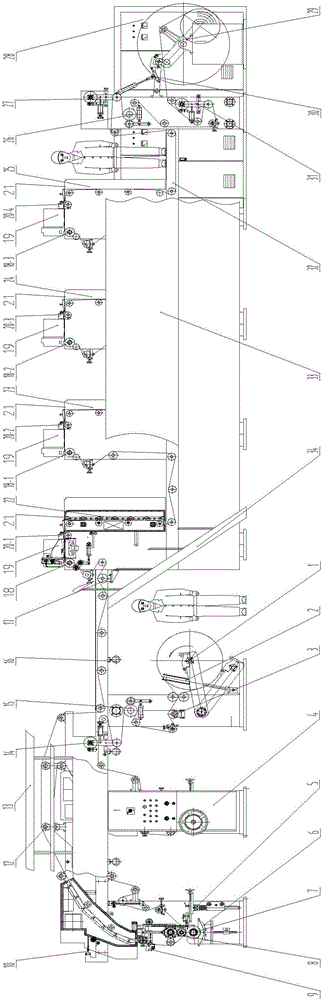

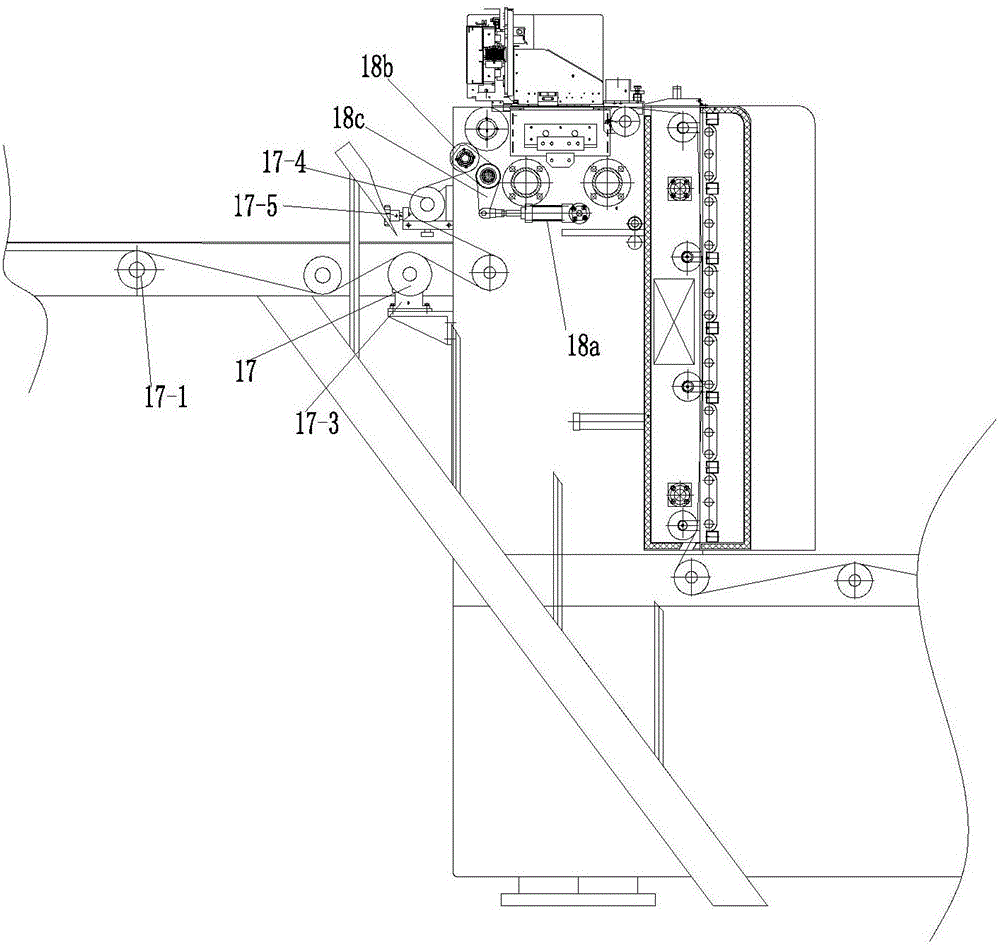

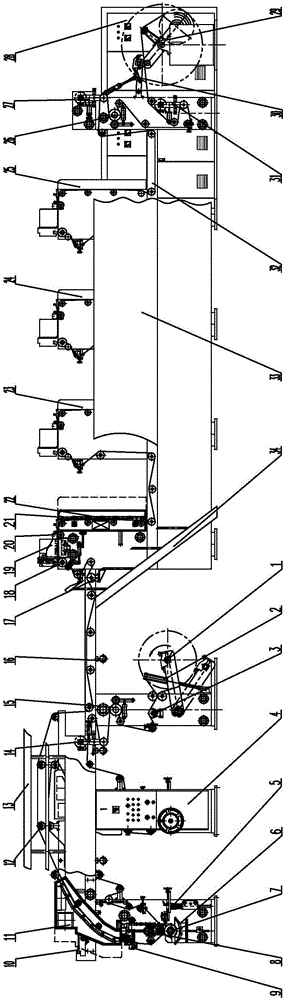

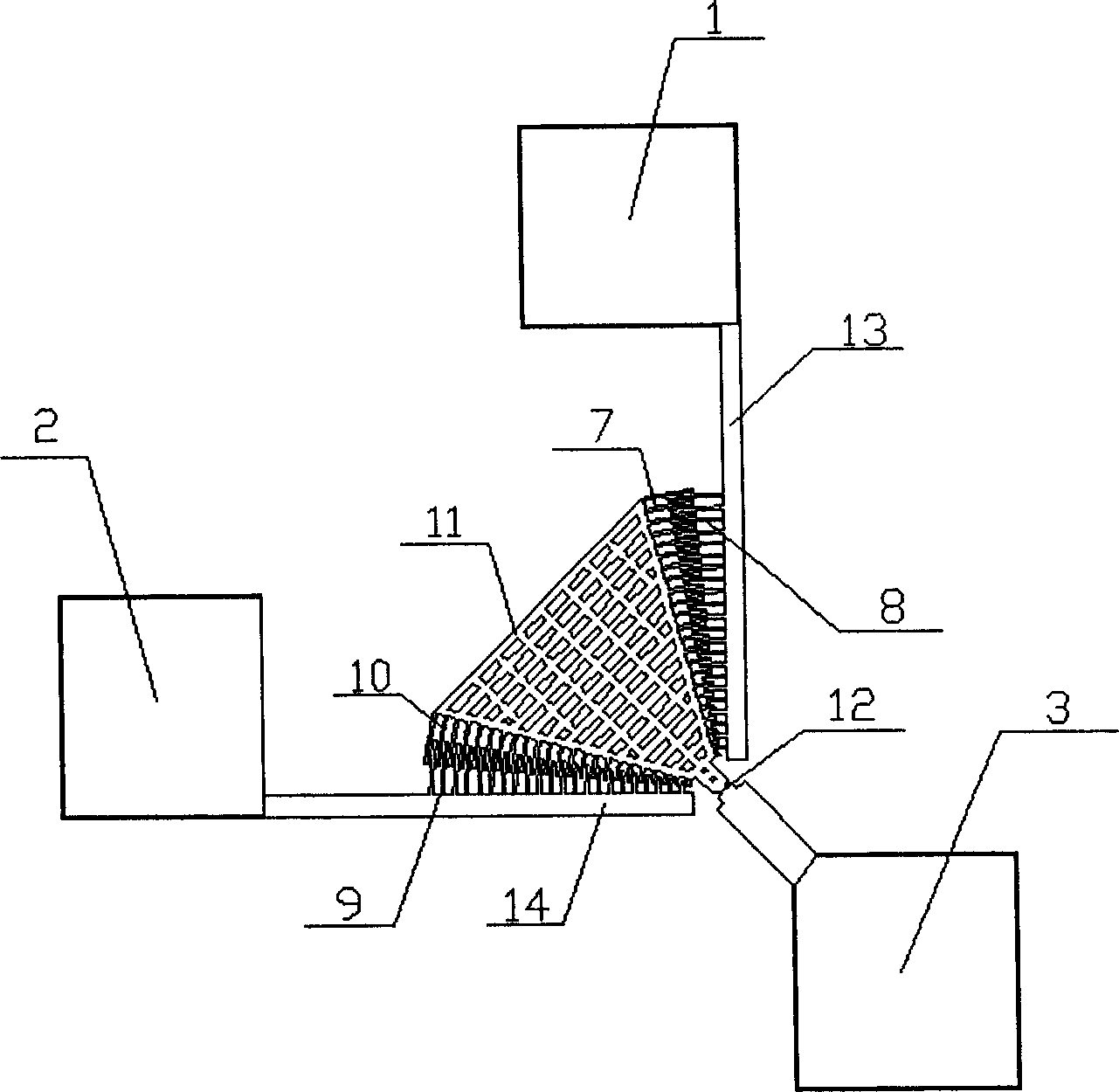

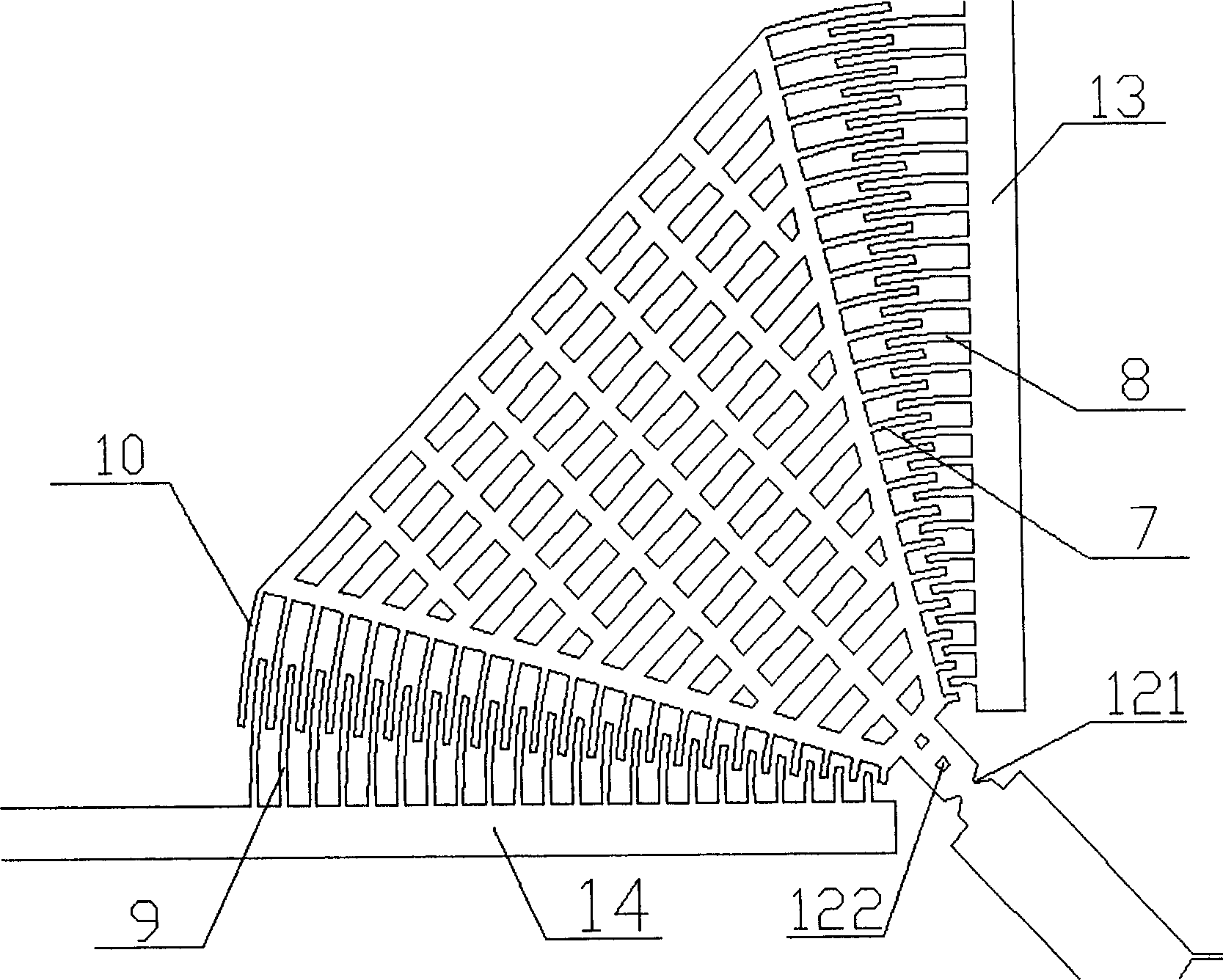

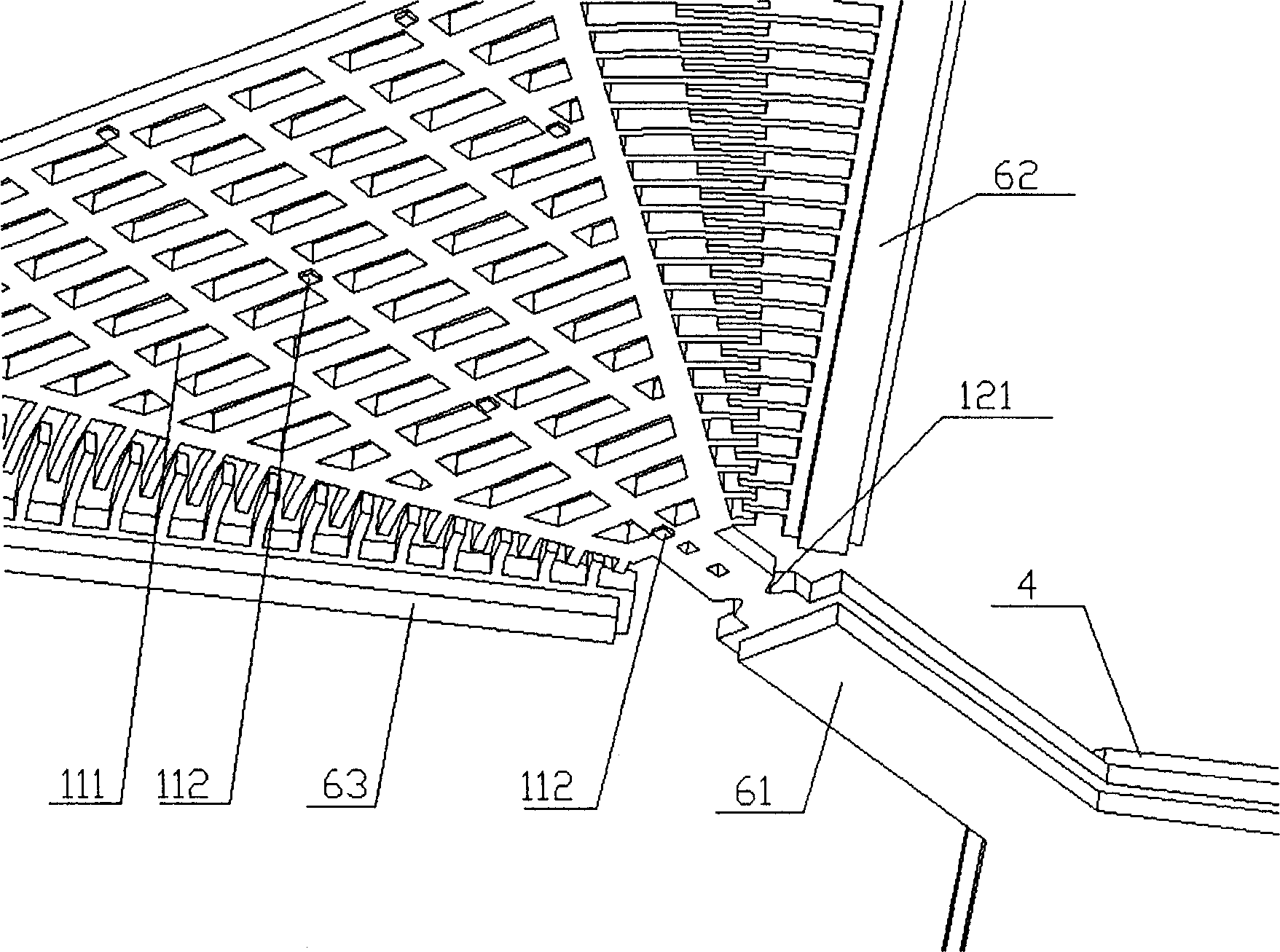

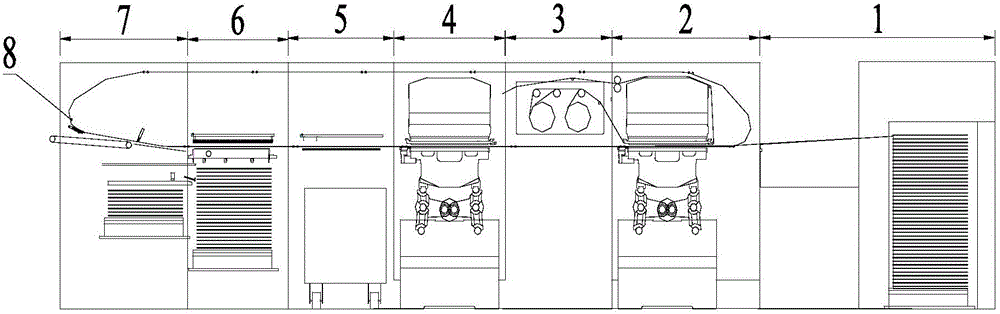

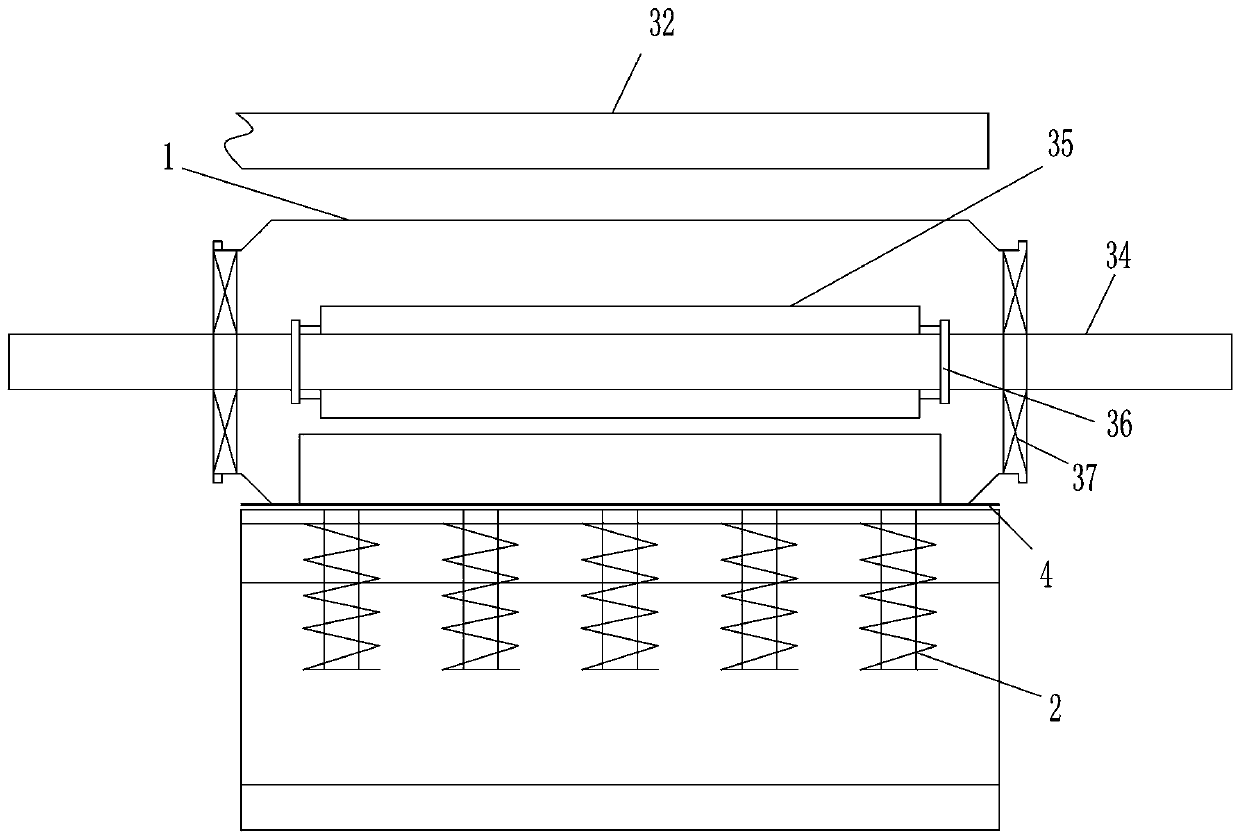

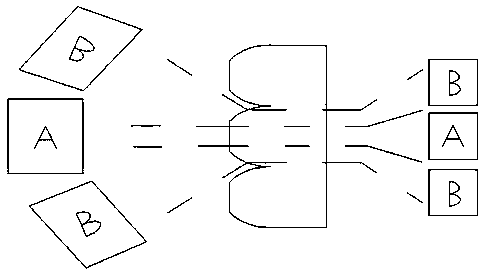

Gravure digital integral printing machine

ActiveCN106379043AReduce the amount of plate makingIncrease productionRotary pressesPrinting inkPrinting press

The invention provides a gravure digital integral printing machine. The gravure digital integral printing machine comprises a rack, an unreeling part, a combination printing unit, a reeling part and an electric control part, wherein the combination printing unit is combined by at least one gravure printing machine embossing unit and at least one digital ink-jet printing machine unit which are mixedly arrayed on a straight line; the unreeling part, the gravure printing machine embossing unit, the digital ink-jet printing machine unit and the reeling part are all electrically connected with the electric control part and are controlled by the electric control part; the gravure printing machine embossing unit and the digital ink-jet printing machine unit are arranged on the rack; and a conveying mechanism used for conveying a printed material to the digital ink-jet printing machine unit after printing of the gravure printing machine embossing unit is arranged between the gravure printing machine embossing unit and the digital ink-jet printing machine unit. The gravure digital integral printing machine with the combination characteristics also uses a one-printing and one-drying scheme of a traditional gravure printing machine; and advantages of capability of overprinting, large reprinting inking amount, wide expanding design range of gravure printing and advantages of three-dimensional beauty, forming rapidness and the like of digital ink-jet printing are integrated by the gravure digital integral printing machine.

Owner:ZHEJIANG MEIGE MACHINERY

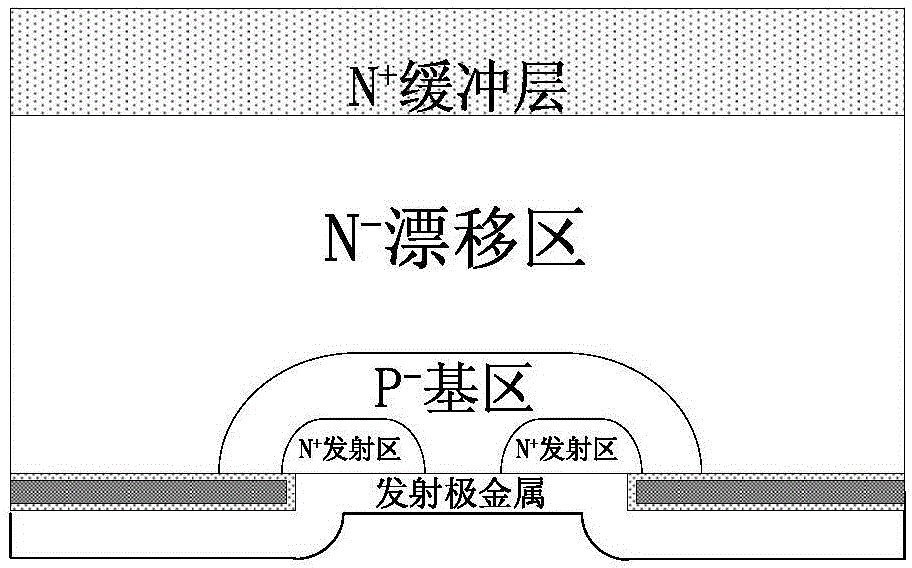

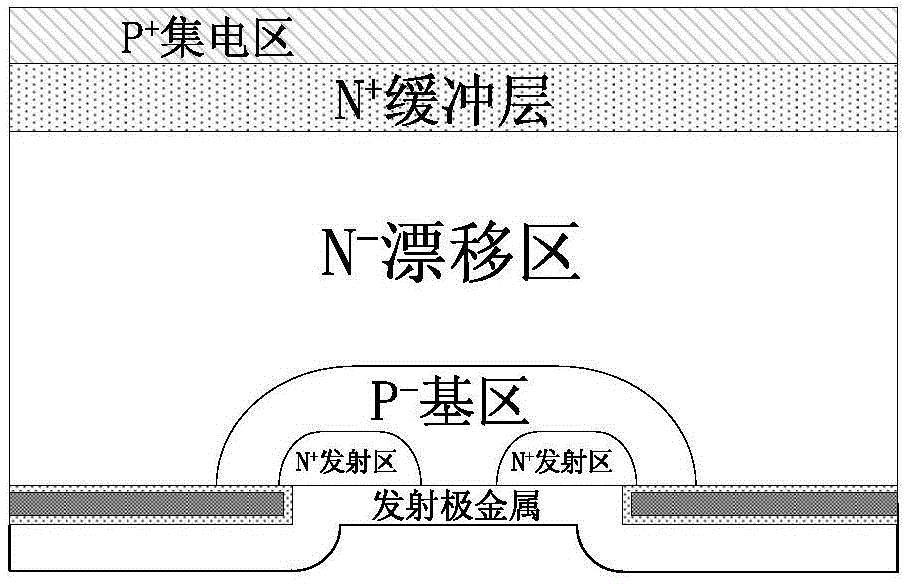

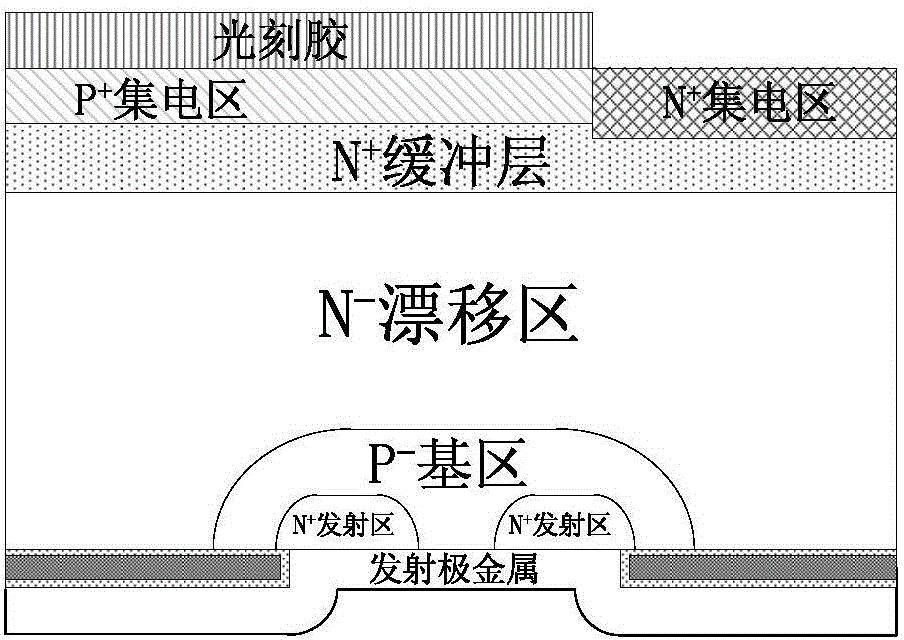

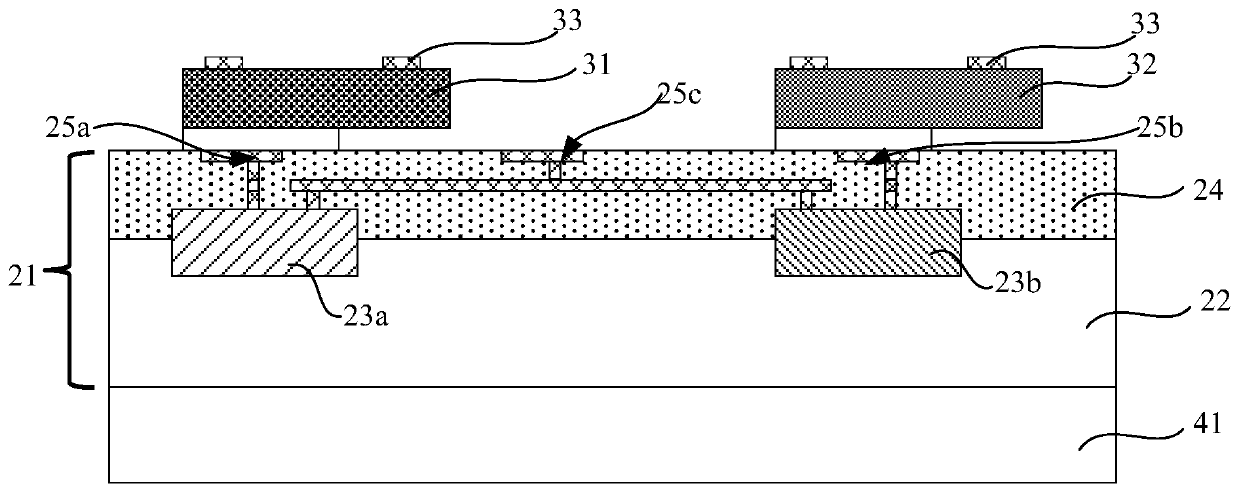

Method for machining TI-IGBT chip back structure

ActiveCN104022033AImprove consistencyImprove productivityTransistorSemiconductor/solid-state device manufacturingProduction rateBack structure

The invention discloses a method for machining a TI-IGBT chip back structure, and belongs to the technical field of the micro electronic. The method comprises the steps that after a wafer front structure is machined, P type doping is poured into the back face of a wafer; the back face of the wafer is coated with photoresist, and exposure is sequentially carried out on different areas, divided by a back mask plate, of the phototesist on the back face of the wafer, wherein the mask plate pattern comprises a plurality of pattern units symmetrically arranged in a horizontal movement mode; the relative position of the exposure areas is controlled, and the exposure patterns of the whole wafer are continuously symmetric in a horizontal movement mode based on the pattern units; N type doping is poured into the back face of the wafer after development, the photoresist on the back face is removed, and finally, back metallization is carried out after annealing activated doping. According to the method, TI-IGBT with different voltages and different current levels can share the same back mask plate, a large amount of plate making cost is saved, and production efficiency is improved.

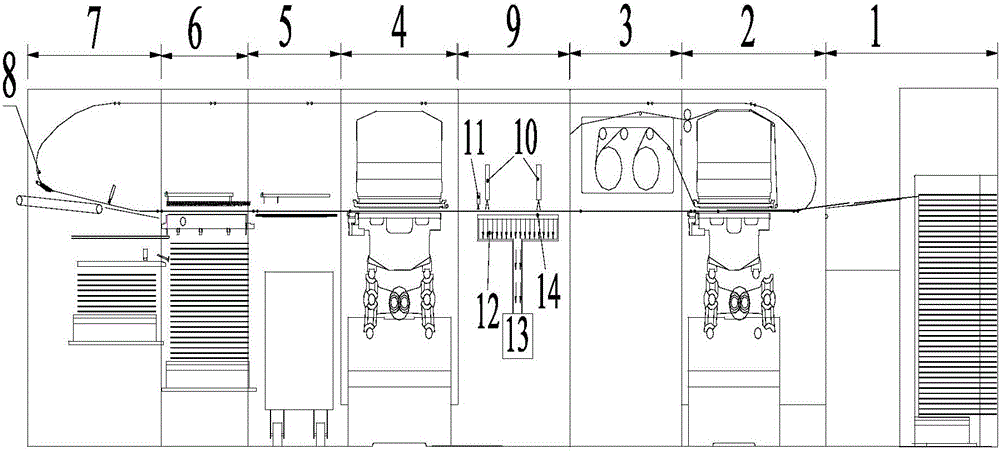

Gravure and digital integrated printing machine

InactiveCN106166892AReduce the amount of plate makingIncrease productionScreen printersElectrical controlDigital printing

The invention relates to a gravure and digital integrated printing machine. The printing machine can combine the advantages of gravure printing and digital ink jet printing and can reduce the defects of the gravure printing and the digital ink jet printing so as to adapt to the technology trend and meet the production requirement. The technical scheme of the printing machine is that the gravure and digital integrated printing machine is characterized by comprising a discharging part, a combined printing unit, a receiving part and an electrical control part; the combined printing unit is formed by combining at least one gravure printing unit and at least one digital ink jet printing unit which are arranged in a straight line; the discharging part, the gravure printing units, the digital ink jet printing units and the receiving part are all electrically connected with and controlled by the electrical control part.

Owner:ZHEJIANG MEIGE MACHINERY

Method for manufacturing holographic moulded plate

ActiveCN103481637ARich varietyRealize the anti-counterfeiting function of holographic paper dotsForme preparationMaterials scienceElectroforming

The invention relates to a method for manufacturing a holographic moulded plate. The method comprises the following steps: (1) forming a moulded nickel plate in an electric casting way; (2) arranging at least one fine adjustment region on the moulded nickel plate; (3) reducing the heights of part or all of moulded stripes in the fine adjustment region to form pattern or text shapes. The pattern or text shapes are formed in the fine adjustment region by arranging the fine adjustment region on the moulded nickel plate and reducing the heights of the moulded stripes in the fine adjustment region according to the customized information, so that the customized information can be implanted in the fine adjustment region, a holographic paper point type anti-fake function can be achieved, a good invisible or visible anti-fake effect can be obtained, and the anti-fake function is better; different customized information are implanted without replacing a mother plate, so that the plate manufacturing cost is reduced; the operation is also very easy.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

Microstructure resonance single direction bending pulling multiaxle fatigue experimental device

InactiveCN1793827AAvoid clamping and centeringIncreased stress levelsMaterial strength using repeated/pulsating forcesMicrostructureTest sample

A resonant one¿Cway bending and multiaxial fatigue test device of microstructure is prepared as fixing the driving electrode on outer side wall of silicon substrate through anchored layer then connecting it to driving broach pair; fixing the detecting electrode on outer side wall of silicon substrate through anchored layer then connecting it to detecting broach pair; connecting end portion of suspension vibrating block between driving broach and detecting broach to one end of test sample generating alternative stress; connecting another end of test sample to earthing electrode and forming test sample, driving unit and detecting unit to be an integral structure.

Owner:BEIJING UNIV OF TECH

Environment-friendly type on-press-coating ink-jet CTP offset master, pigment ink and preparation method thereof

InactiveCN101081952BPlate making process is simpleNo pollution in the processInksPrintingCross-linkPulp and paper industry

The present invention relates to printing technology, and is one kind of environment friendly ink jetted CTP offset plate, color ink and its making process. The color ink comprising pigment, dispersed polymer emulsion, water soluble cosolvent, surfactant, cross-linking agent and deionized water is prepared through emulsifying and high speed dispersing. The color ink may be printed fluently without ink jet jamming, and the printed ink may be adhered to the plate fast without flowing. Through printing on aluminum base with one ink jet printer and the color ink and plate settling treatment, one environment friendly ink jetted CTP offset plate may be made without need of further treatment. The plate making process is time saving and environment friendly.

Owner:石深泉

Making method of cardboard craft New year pictures

InactiveCN1861425AInnovation of traditional production methodsPlate making process is convenientDecorative surface effectsPattern printingCardboardPulp and paper industry

A technology for preparing the paper plate type artistic Spring Festival picture includes such steps as drawing the rough sketch of a Spring Festival picture, preparing its concave-convex zinc plate by etching, copying paper plate by pressing a color ironing paper on heated zinc plate, sticking paper on the back of said paper plate for thickening it, coloring and shearing according to the profile of pattern.

Owner:胡光葵

Method for producing hard plate poplar and willow green craftwork new year picture

InactiveCN101209645APlate making process is convenientReduce the cost of plate makingDecorative surface effectsSpecial ornamental structuresLine drawingsGypsum

A manufacturing method of a hard board Yang Liuqing pictures of New Year is characterized in that the pattern of a picture of New Year is drawn by line drawing at first, then a figure with third dimension is made by plaster; a concavo-convex eroded metal plate is made by a reverse imitating method; by taking the metal plate as a pressing sharper, a motherboard to be painted is put on a punch to be punched with pattern, and then the processed pattern is finished by outline drawing, coloring up and shape cutting. The invention has the advantages that the mask-making technique is convenient, fast and accurate; the mask-making cost is low; the invention is durable and adapts to the requirements of modern decorations; the Yang Liuqing pictures can be conveniently applied to various decorating occasions.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE

Design method for reverse class-F power amplifier based on 3/4 spiral virtual ground structure

ActiveCN102111114BReduce areaSimple designPower amplifiersAmplifier modifications to raise efficiencyAudio power amplifierHarmonic

A design method for a reverse class-F power amplifier based on 3 / 4 spiral virtual ground structure comprises the steps as follows: confirming the work frequency of the power amplifier and obtaining the harmonic frequency of a harmonic control circuit; changing the dimension of the 3 / 4 spiral structure and designing corresponding harmonic control circuit according to the needed harmonic frequency in the design; inserting the harmonic control circuit into the output end of a power amplifier tube and designing the input-output matching circuit of a power amplifier circuit; and designing the input-output parameters of the power amplifier through measurement, and adjusting the length of a magic line to reach the maximum work efficiency. The amplifier designed by adopting the method comprises an input matching circuit, a power amplifier circuit, a harmonic control circuit and an output matching circuit which are connected onto a microstrip line in sequence; the harmonic control circuit comprises a 3 / 4 spiral virtual ground structure arranged below the microstrip line, and the virtual ground structure is formed by a complete spiral virtual ground structure cut by 1 / 4; and the 3 / 4 spiral virtual ground structure comprises two spiral structure parts connected with each other and in axial symmetry along the microstrip line.

Owner:SOUTHEAST UNIV

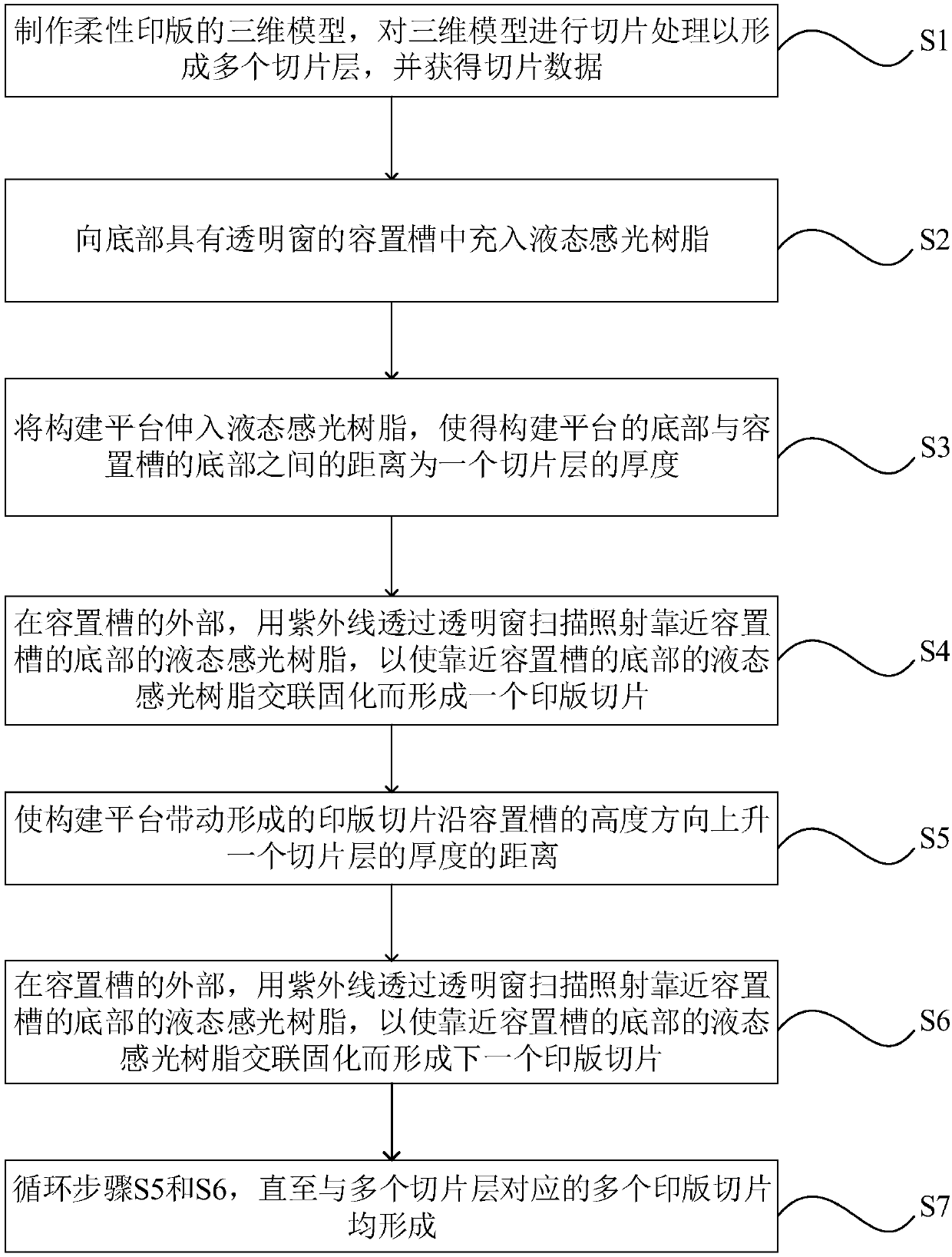

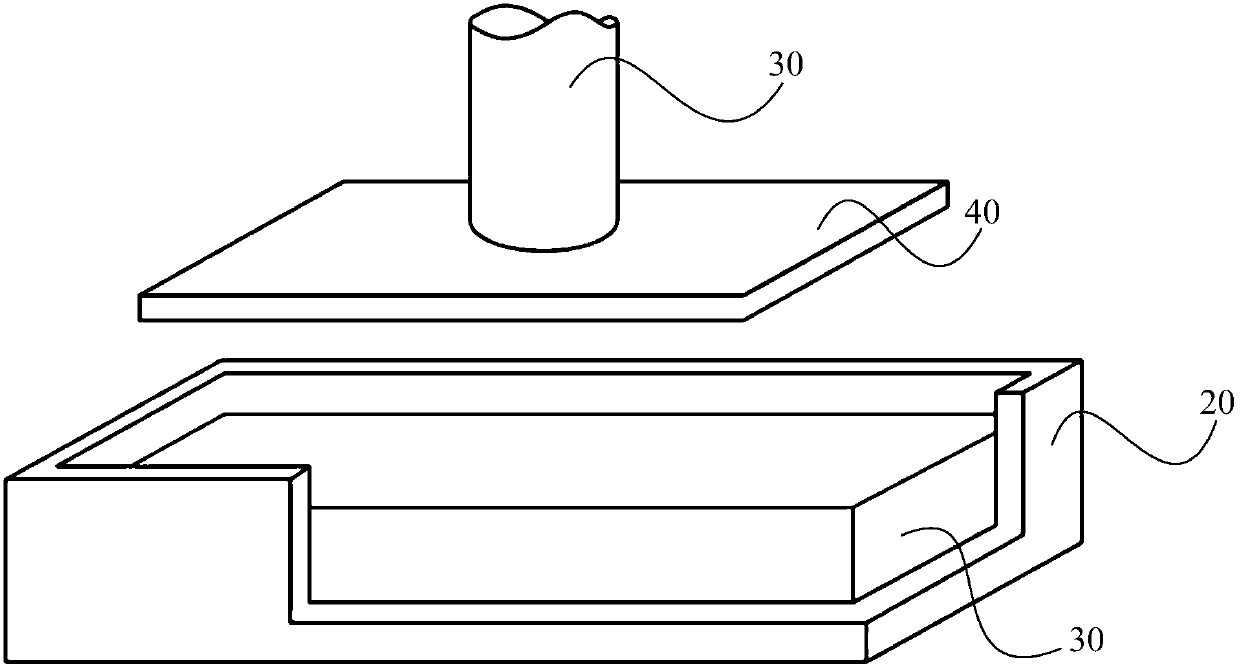

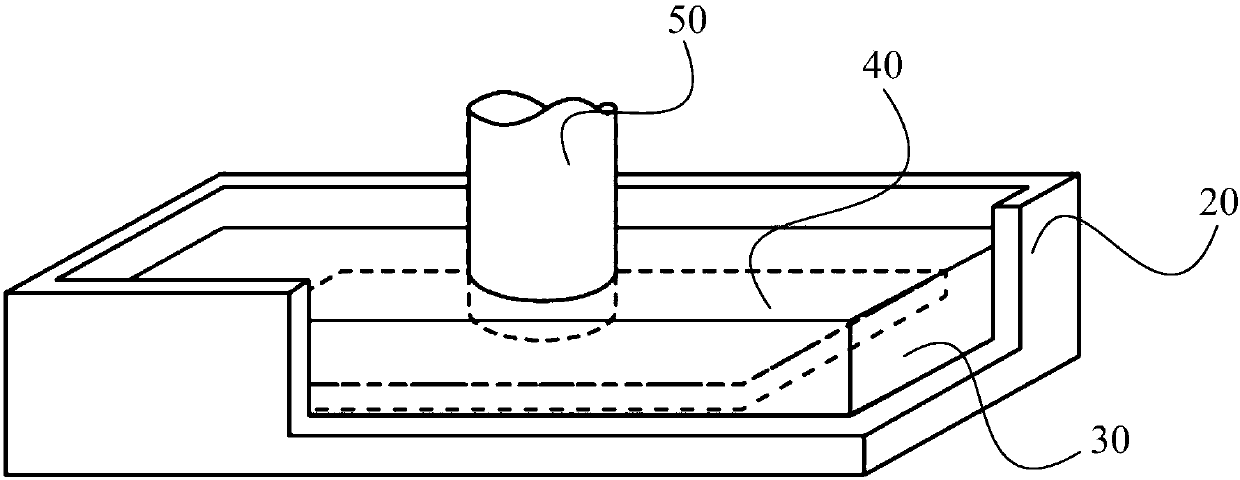

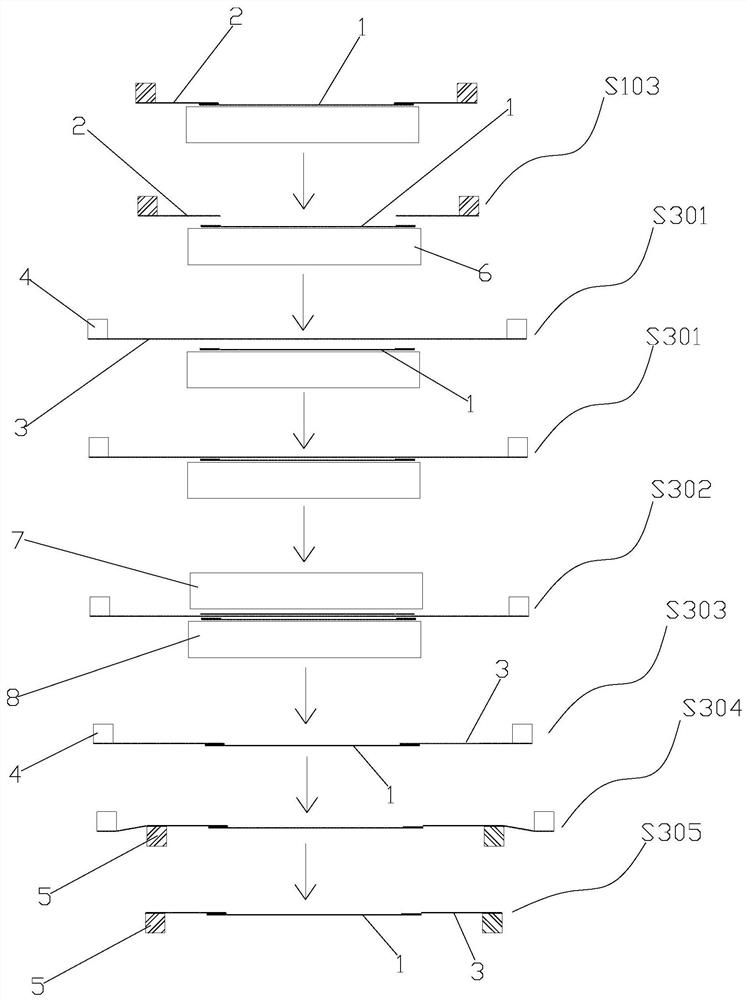

Plate making method of flexible printing plate based on three-dimensional photo-curing molding method

InactiveCN110142960ARandom combinationEasy to manufacture3D object support structuresDomestic articlesUltravioletEngineering

The invention discloses a plate making method of a flexible printing plate based on a three-dimensional photo-curing molding method. The method comprises the following steps that S1, a three-dimensional model of the flexible printing plate is made, the three-dimensional model is subjected to slicing treatment to form a plurality of slicing layers, and slicing data is obtained; S2, a container groove is filled with liquid photosensitive resin; S3, a construction platform is extended into the liquid photosensitive resin, so that the distance between the bottom of the construction platform and the bottom of the container groove is the thickness of one slicing layer; S4, the liquid photosensitive resin at the bottom of the container groove is scanned and irradiated by using ultraviolet rays toform a printing plate slice; S5, the construction platform drives the formed printing plate slice to rise to the distance of the thickness of one slicing layer; S6, the liquid photosensitive resin atthe bottom of the container groove is scanned and irradiated by using the ultraviolet rays to form the next printing plate slice; and S7, the step 5 and the step 6 are repeated until the plurality ofprinting plate slices are formed. The method has the advantages of being few in working procedures, saving in materials, and beneficial to environmental protection.

Owner:SHANGHAI PUBLISHING & PRINTING COLLEGE

Multi-position laser die pressing process and die cutting hot stamping machine

InactiveCN106079873AReduce the number of paper passesControl scrap rateBronze printingRotary pressesHot stampingEngineering

Disclosed is a multi-position laser die pressing process. The multi-position laser die pressing process comprises the steps that (1) a sheet obtained after indentation or hot stamping through a first die pressing unit enters a laser unit after passing an aluminum foil control unit; (2) the laser unit conducts die cutting on a product so as to reduce the platemaking cost and save time of halt plate replacement; and (3) the die-cut product enters a second die pressing unit for a indentation or hot stamping process. A die cutting hot stamping machine comprises the first die pressing unit, the aluminum foil control unit and the second die pressing unit, is characterized in that the laser unit is installed behind the aluminum foil control unit, and has the advantages that die cutting of the laser unit is cutting through a laser, a die cutting tool does not need to be made, and thus the platemaking cost is reduced effectively. During laser die cutting, automatic transformation of the cutting shape, position and size can be achieved in the nonstop state according to the needs of the machined sheet, and thus the production efficiency can be improved effectively.

Owner:MASTERWORK GROUP CO LTD

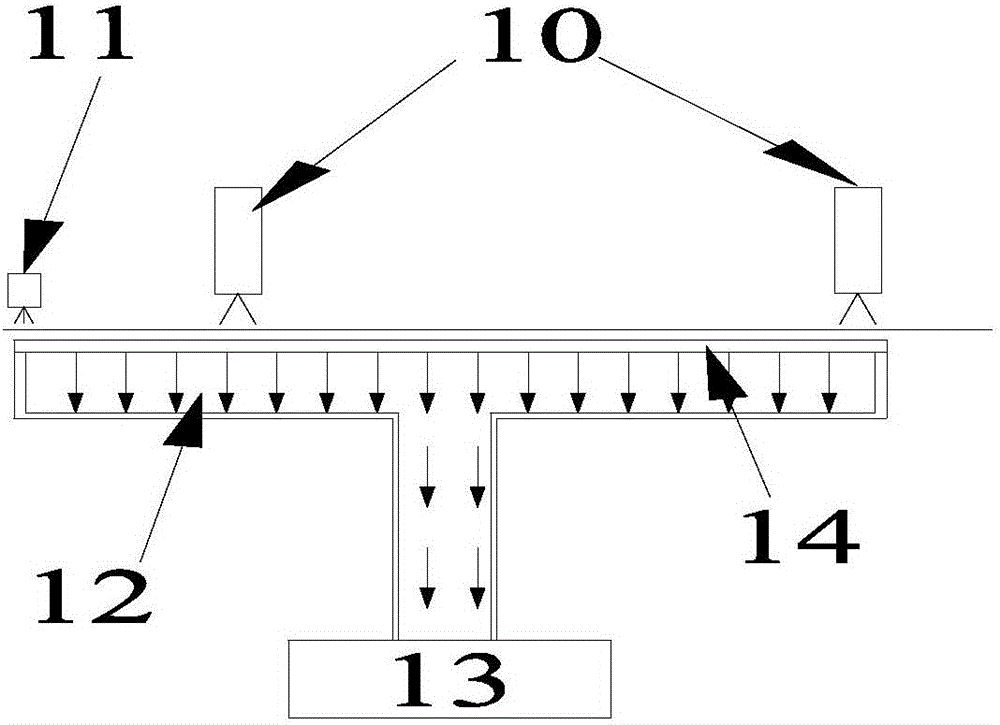

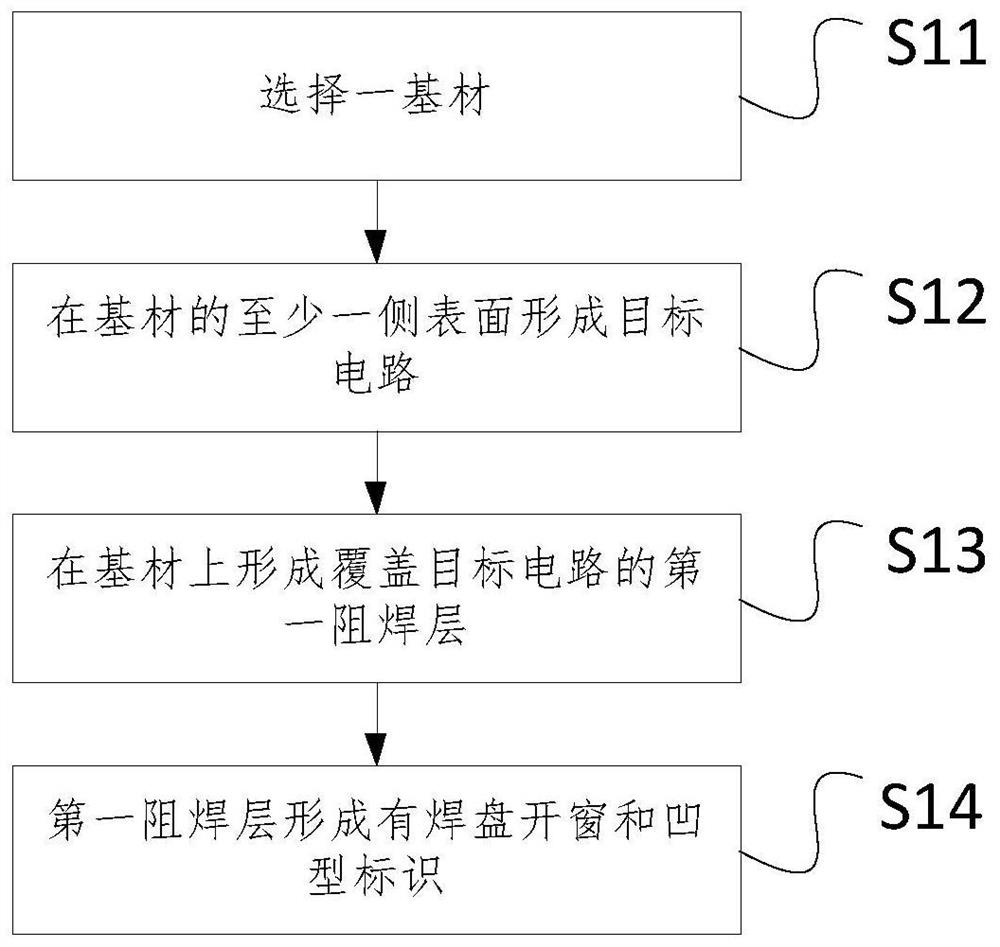

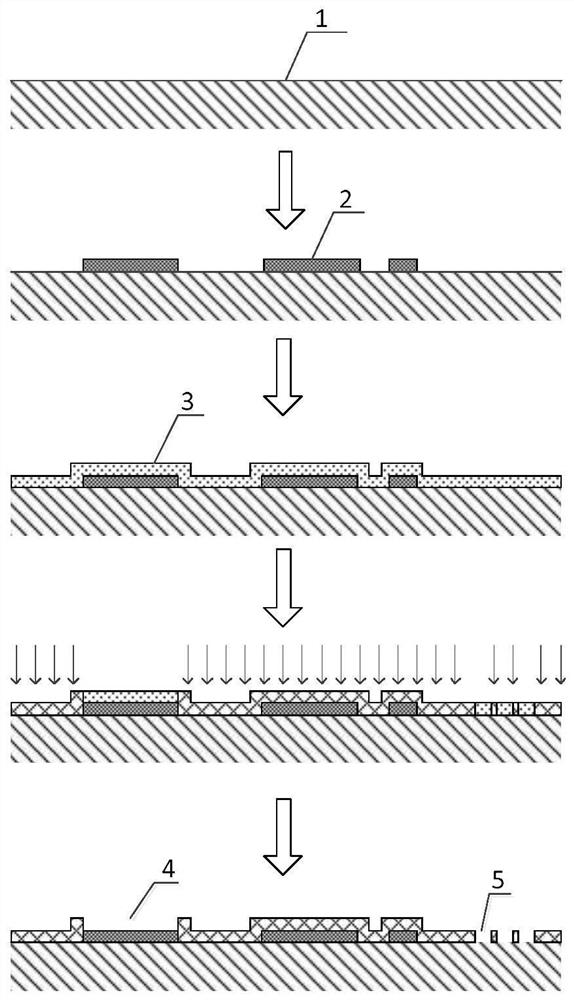

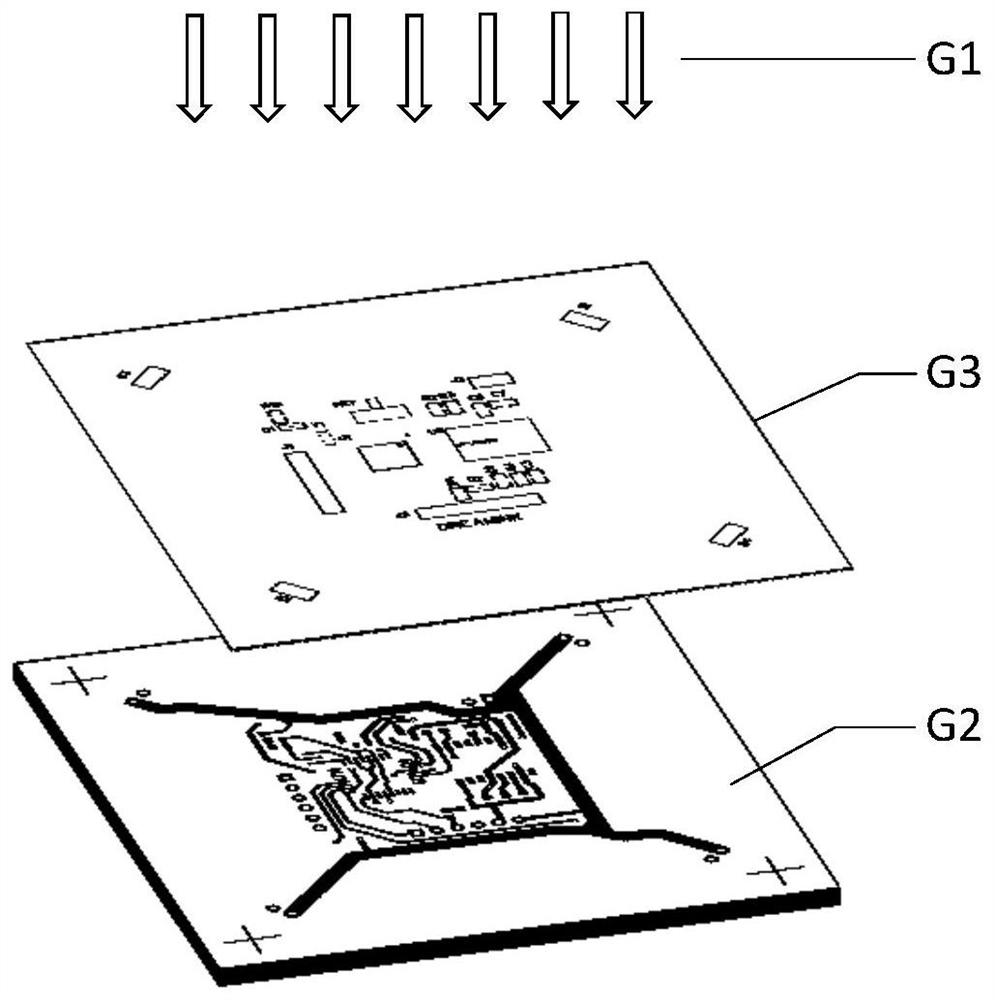

Circuit board and manufacturing method thereof

PendingCN114666994AImprove plate making efficiencySimplify the plate making processInspection/indentification of circuitsNon-metallic protective coating applicationSolder maskHemt circuits

The invention discloses a circuit board and a manufacturing method thereof, and relates to the technical field of electronic circuit manufacturing. The manufacturing process of the circuit board comprises the following steps: selecting a base material; forming a target circuit on at least one surface of the substrate; forming a first solder mask layer covering the target circuit on the substrate; and selectively exposing a partial region of the first solder mask layer, and forming a pad window for exposing the target circuit pad and a concave identifier for indicating the target circuit information on the first solder mask layer after development. According to the embodiment of the invention, the silk-screen mark and the solder resist windowing are integrally formed in a concave mark mode, so that the plate-making process is simplified, the plate-making efficiency of the circuit board is improved, and the plate-making cost is reduced.

Owner:BEIJING DREAM INK TECH CO LTD

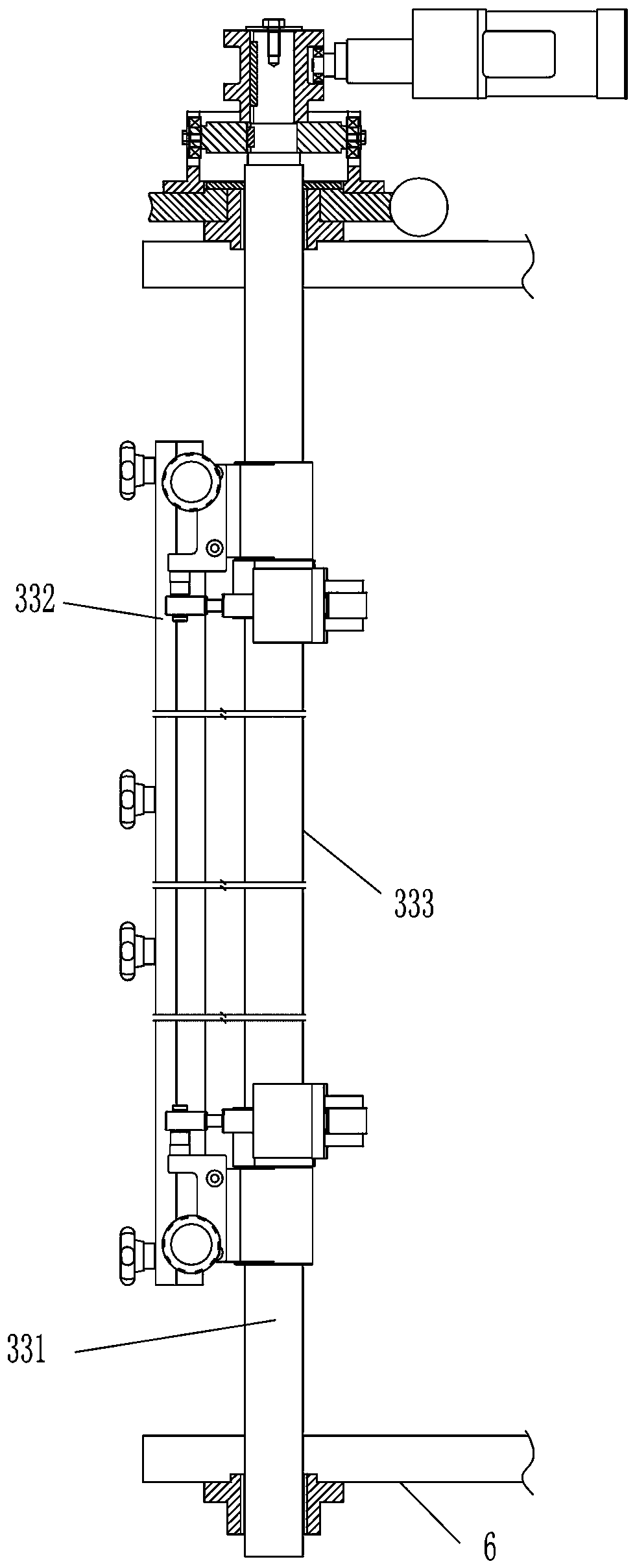

Dual-purpose printing equipment

PendingCN111409349AEasy to engrave patternReduce the cost of plate makingRotary intaglio printing pressScreen printersScreen printingTextile printer

The invention discloses dual-purpose printing equipment. The dual-purpose printing equipment comprises a magnetic platform, a replaceable printing plate and a scraping and printing device; the printing plate is any one of rotary screen and hollow gravure rollers; when the printing plate is the hollow gravure roller, the gravure roller is a metal cylinder without an open hole in the surface and with a thickness of 0.5 to 1 mm; a scraper mechanism is mounted outside the gravure roller; a supporting roller bracket is fixedly mounted in the gravure roller in an axial direction of the gravure roller; two shaft ends of a supporting roller are fixedly mounted on the supporting roller bracket through connecting plates; and the supporting roller is tangent to the inner wall of the gravure roller atthe position where the scraper abuts against the outer wall of the gravure roller. On the basis of not changing parts below a rotary screen printing machine guide belt on a production line, a replaceable rotary screen gravure roller and a scraper assembly cooperating with the gravure roller are arranged at the mounting station of a rotary screen, the transformation cost is low and the productionline is optimized, so that an existing production line can flexibly switch the printing plate according to production requirements.

Owner:FUJIAN JINJIANG JILONG MACHINE IND

Preparation method of clothes prism structure

InactiveCN107503201ANo pollution in the processIncrease productivityLaminationInksCold airCushioning

The invention provides a preparation method of a clothes prism structure. The preparation method is characterized by comprising the following steps: S1, preprocessing: sequentially aligning a processed product, a hot ironing adhesive and a non-woven fabric to a hot ironing machine processing platform to conduct hot ironing; S2, silk-screen processing: locating the processed product on a working table surface, placing a silk-screen template, aligning, conducting silk-screen processing, spraying dry with cold air after silk-screen processing; S3, cushioning and pressing: sequentially placing a bottom surface protection layer, a paper layer and the processed product above a processing mold to cushion and press to mold; S4, ironing and pressing a surface layer, aligning the bottom surface of the processed product with the non-woven fabric, ironing on the hot ironing machine processing platform, and obtaining a finished product. The preparation method is suitable for the large-scale processing and production of three-dimensional dress patterns.

Owner:HUI DONG WORLD BRANDS MANUFACTORY CO LTD

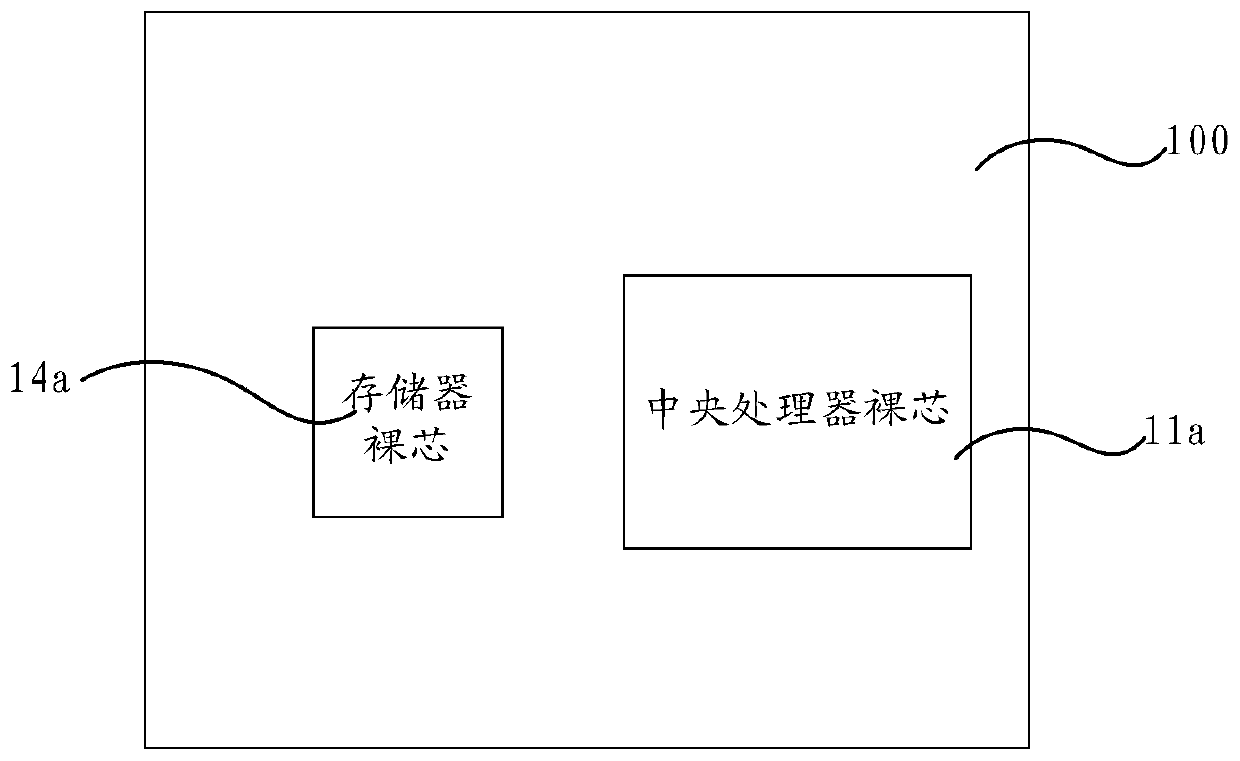

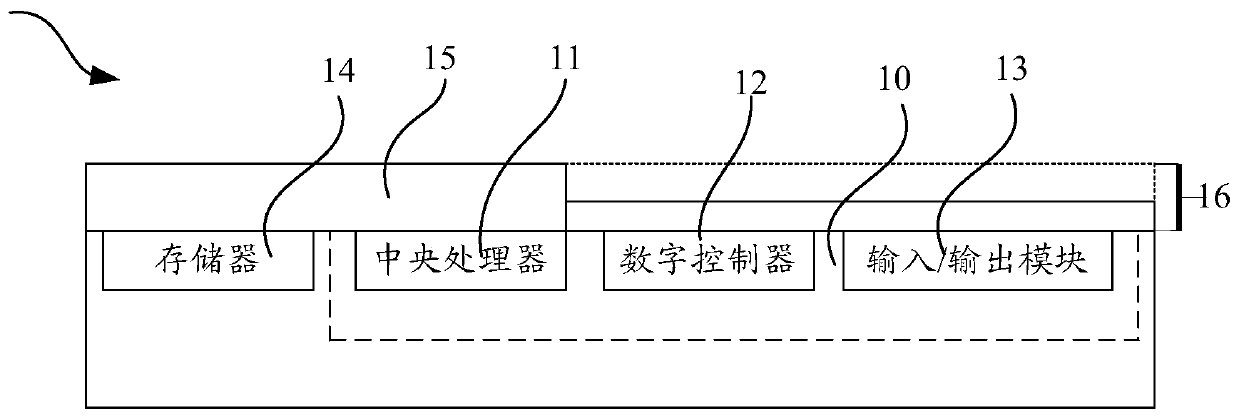

Microcontroller and manufacturing method thereof

ActiveCN111384053AReduce the number of layoutsAvoiding problems with making dummy structuresTransistorMicrocontrollerDevice material

The invention provides a microcontroller and a manufacturing method thereof. The microcontroller comprises a logic control substrate, at least one memory bare chip and at least one non-memory bare chip, wherein the memory bare chips and the non-memory bare chips are arranged on the logic control substrate. The logic control substrate comprises a semiconductor device layer and an interconnection dielectric layer, a central processing unit and at least one logic controller are formed in the semiconductor device layer, all the memory bare cores are arranged on the interconnection dielectric layerside by side or in a stacked mode, and at least one memory bare core is electrically connected with the central processing unit through a corresponding electric interconnection structure in the interconnection dielectric layer; and all the non-memory bare cores are arranged on the interconnection dielectric layer side by side or in a stacked manner, and are electrically connected with the corresponding logic controllers through the corresponding electric interconnection structures in the interconnection dielectric layer. According to the invention, layouts and unnecessary virtual structures required in the manufacturing process stage of the integrated circuit device can be reduced, and the cost can be reduced.

Owner:NINGBO SEMICON INT CORP

Three-dimensional bronzing method

ActiveCN101670719BChange the status quo that cannot form a strong three-dimensional effect patternTake advantage ofPhotosensitive materialsRotary pressesScreen printingSurface layer

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

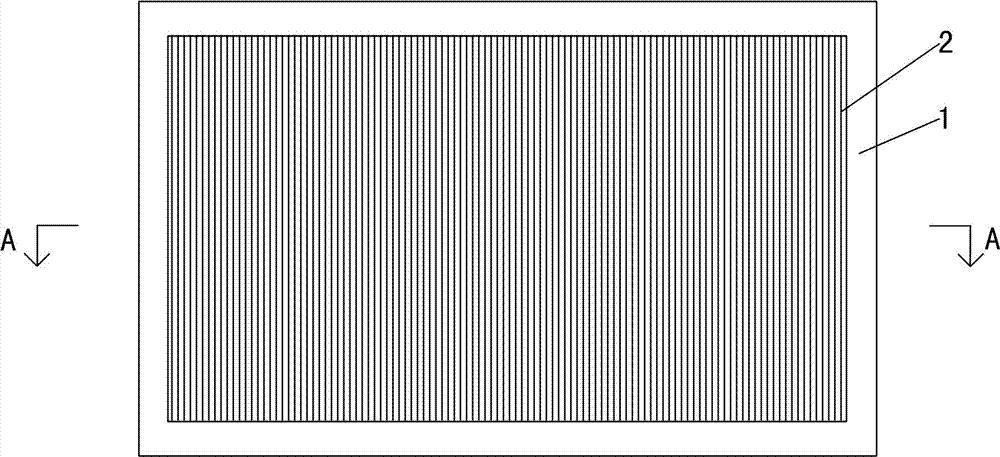

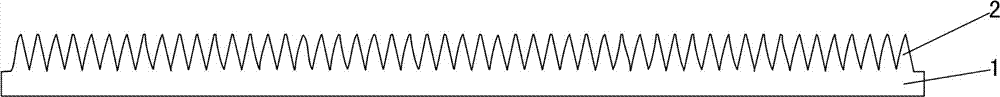

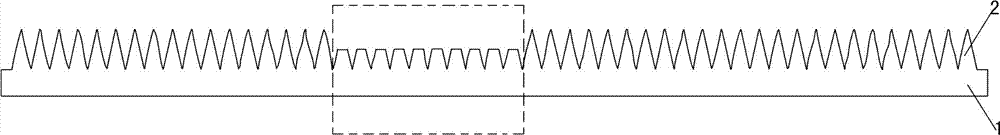

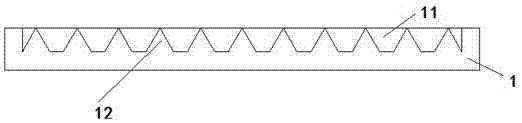

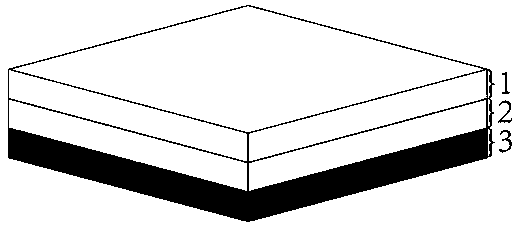

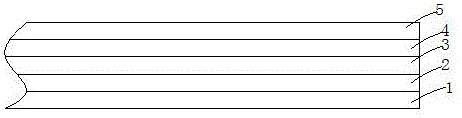

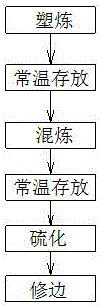

Rubber flexographic engraving plate and manufacturing method thereof

ActiveCN109849547AReduce the cost of plate makingImprove reproducibilityPlate printingFoil printingEngineeringHazardous waste

The invention provides a rubber flexographic engraving plate and a manufacturing method thereof. The rubber flexographic engraving plate is of a three-layer structure and comprises an engraving layer,a bonding layer and a lining supporting layer which are sequentially arranged from top to bottom, the rubber flexographic engraving plate can be subjected to laser direct engraving forming, the flexible resin plate manufacturing manner is changed, in the rubber flexographic engraving plate manufacturing process, industrial hazardous waste cannot be generated, and meanwhile, the reappearing property of lattice points below 5% in the printing process can be improved.

Owner:KOMPASS TECH INC +1

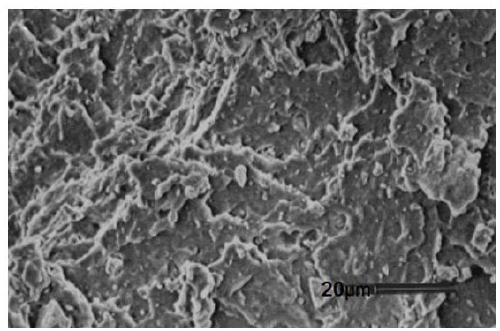

Method for manufacturing nonwoven metal porous plate used for printing

ActiveCN101644897BAvoid unproducible problemsIncrease the number of weavesPhotomechanical apparatusElectroplatingMetal

The invention discloses a method for manufacturing a nonwoven metal porous plate used for printing, relating to the field of printing and plate making and aiming at solving the problem that the porous plate used for printing in the prior art is hard to realize precise patterns. The method comprises the following steps: designing a plate sample of the metal porous plate with patterns on a computer; arranging and manufacturing the plate sample into split films by an imagesetter connected with the computer; coating photosensitive glue on a master plate base for manufacturing the metal porous plate; covering the split films on the master plate base coated with the photosensitive glue for plate burning, then developing and displaying the plate sample on the photosensitive glue; corroding the master plate base and manufacturing the master plate of the metal porous plate with patterns; and manufacturing the metal porous plate used for printing on a machine by electroplating of the master plate. The method not only can improve the precision degree of the patterns with porous plate printing and durability of the porous plate, but also can further improve anti-counterfeit performance of porous plate printing products and reduce plate-making cost.

Owner:CHINA BANKNOTE PRINTING & MINTING

Preparation method of clothing prism structure

InactiveCN107554108ANo pollution in the processIncrease productivityPattern printingInksHot stampingComing out

The invention provides a preparation method of a clothing prism structure. The preparation method comprises the following steps: S1, pretreatment: placing a machined product, hot stamping glue and nonwoven cloth on a machining platform of a hot stamping machine in sequence in an alighning manner for hot stamping treatment; S2, silk screen machining: on a working tabletop, locating the machined product, placing a silk screen template for alignment for silk screen machining, and after the silk screen machining, blowing the product to dry with cold air; S3, cushion pressing machining: placing a bottom surface protection layer, a paper layer and the machined product in sequence above a machining die for cushion pressing molding; and S4, aligning the bottom surface of the machined product withthe nonwoven cloth, and placing the machined product on the machining platform of the hot stamping machine for hot stamping treatment, thus obtaining a finished product. According to the preparation method, a stereoscopic vision and a unique vision of change of different edges can be shown through an image subjected to plane printing; and a stereoscopic vision picture shows a texture that the picture is at fingertips of a person, and achieves a coming-out stereoscopic effect.

Owner:HUI DONG WORLD BRANDS MANUFACTORY CO LTD

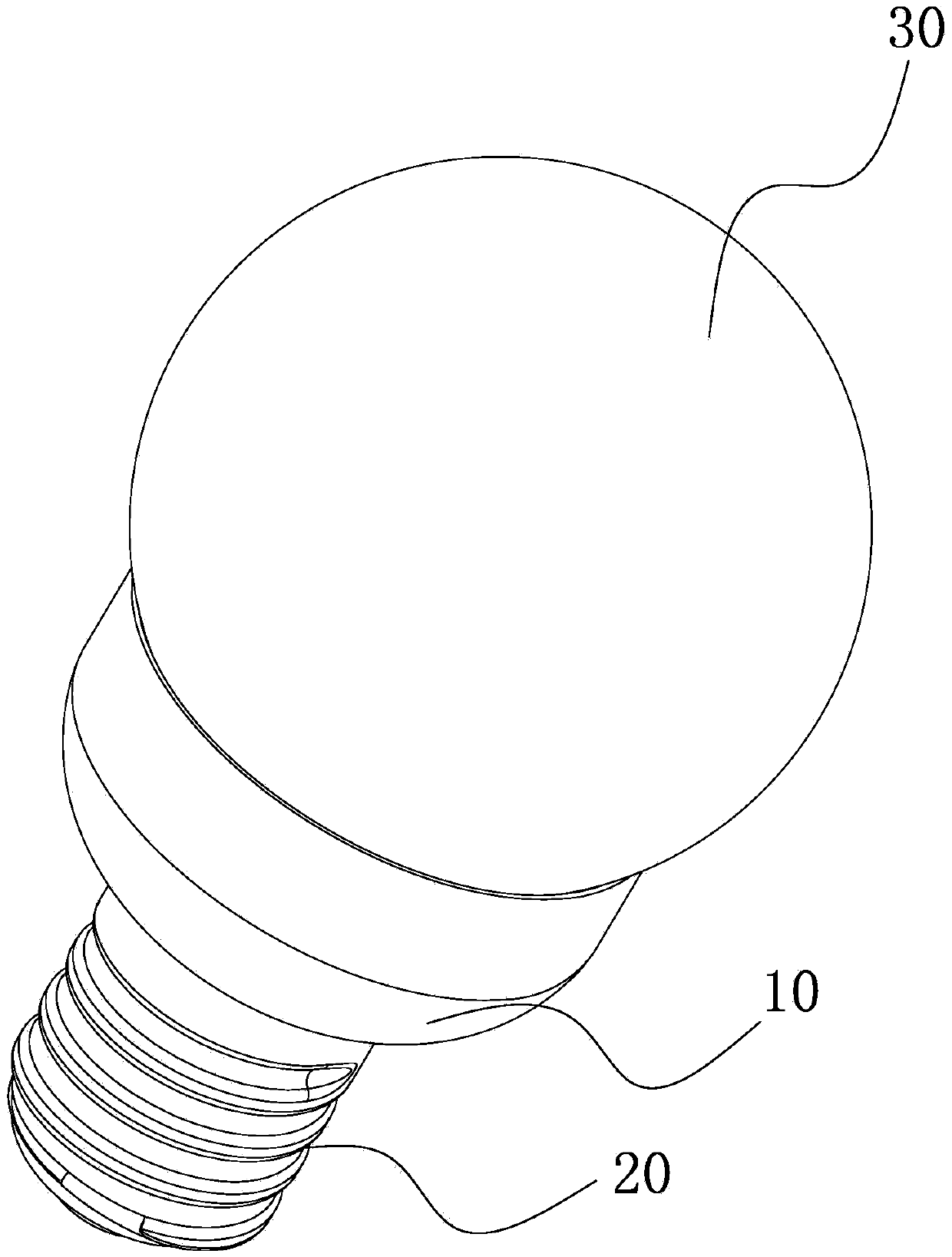

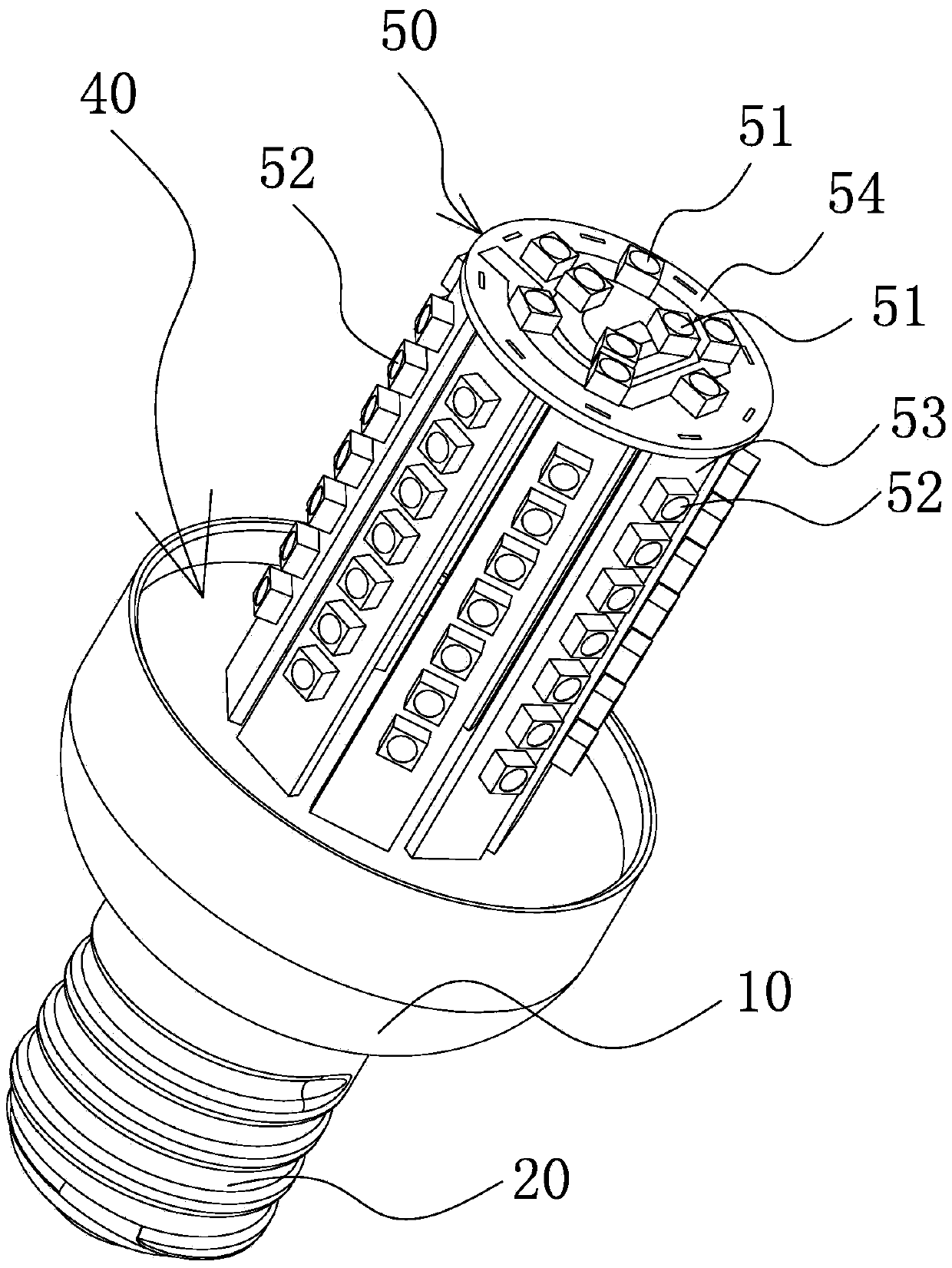

Convenient bulb lamp

InactiveCN105371128AHigh strengthReduce mass percentageElectric circuit arrangementsLighting heating/cooling arrangementsRare-earth elementHeat conducting

The invention provides a convenient bulb lamp. The convenient bulb lamp comprises a lamp holder, a lamp cap, a lampshade and a light-emitting mechanism. The lamp cap is arranged under the lamp holder and made of aluminum alloy material. The aluminum alloy material comprises, by weight, 110-150 parts of Al, 0.1-0.45 part of Si, 0.46-0.65 part of Fe, 4.5-8 parts of Cu, 0.45-0.8 part of Mn, 15-25 parts of Mg, 1.8-4.5 parts of Cr, 1.5-2.3 parts of Zn, 0.8-1.3 parts of Ti, 2.5-3.8 parts of Zr, 1.5-3 parts of PbS and 15-28 parts of rare earth element. A holding cavity is formed by the lampshade and the lamp holder in a surrounded mode. The light-emitting mechanism is arranged in the holding cavity. The light-emitting mechanism comprises a plurality of first light-emitting sources placed horizontally and a plurality of second light-emitting sources placed vertically. The convenient bulb lamp has the advantages of being good in lighting effect and excellent in heat-conducting property.

Owner:NINGBO DUOLIPU IND & TRADE CO LTD

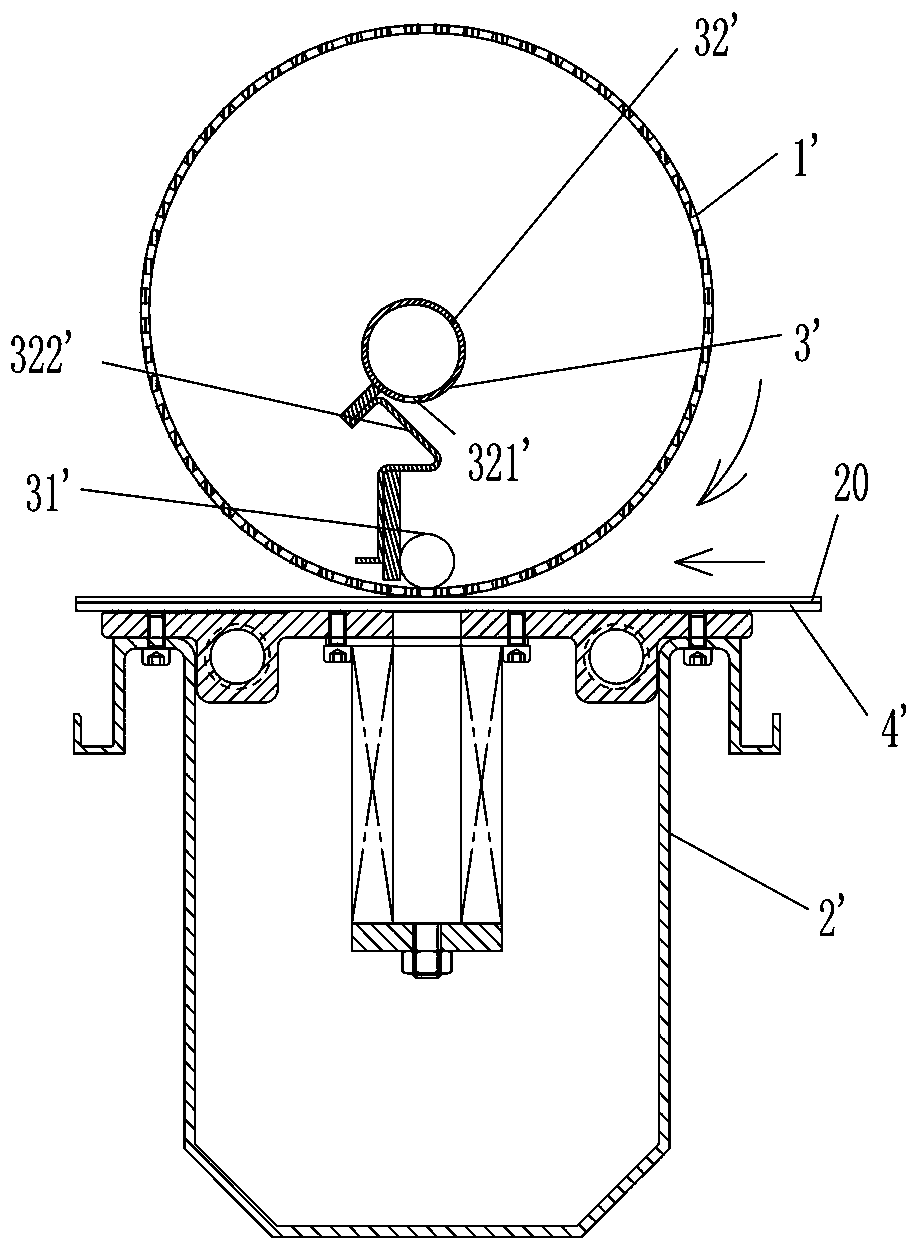

A solar cell composite material screen secondary stretching net reuse process

The invention discloses a secondary screen tensioning and reusing technology of a solar cell sheet composite material screen plate. The technology comprises the following steps that an old screen plate is stripped, hot melt adhesive stripping is carried out on the screen plate needing to be reused by utilizing a plane stripping machine, so that a stainless steel wire mesh is separated from an oldpolyester screen; a combined false frame is manufactured, a new polyester screen and a fixing frame are prepared, the new polyester screen is adhered to the fixing frame, and the new polyester screenand the fixing frame are combined into the combined false frame; a new screen plate is manufactured, the stainless steel wire mesh stripped from the old screen plate is utilized for the second time, the stainless steel wire mesh is adhered to the polyester screen in the combined false frame through hot melt adhesive, and the polyester screen at the middle position of the stainless steel wire meshis removed, then an upper frame is bonded on the polyester screen, and the fixing frame in the combined false frame is removed. According to the technology, the stainless steel wire mesh of the screenplate can be secondarily tensioned and reused, the plate making cost is reduced, and the waste is reduced.

Owner:昆山良品丝印器材有限公司

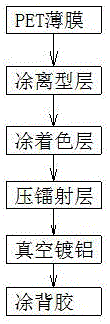

Cold ironing film

InactiveCN106515247AReduce the cost of plate makingHigh stamping precisionNatural rubber adhesivesNon-macromolecular adhesive additivesSurface layerStearic acid

The invention relates to a cold ironing film. The film comprises a PET thin film, the PET thin film is coated with a release layer, the release layer is coated with a coloring layer, a laser layer is arranged on the coloring layer in a mould pressing manner, a vacuum aluminizing layer is arranged on the laser layer, and is coated with gum, and the material of the gum comprises, by weight, 80 parts of natural rubber, 20 parts of butadiene rubber br9000, an auxiliary material and an addition agent; the auxiliary material comprises, by weight, 5 parts of indirect zinc oxide, 1 part of stearic acid, 0.2 part of coumarone resin and 7 parts of solar oil Sunpar2280; the strength of the gum on the surface layer of the cold ironing film is high, and impact resistance is achieved.

Owner:谢志明

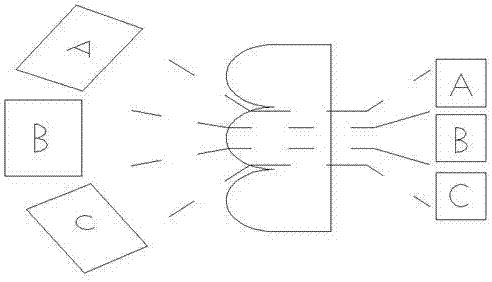

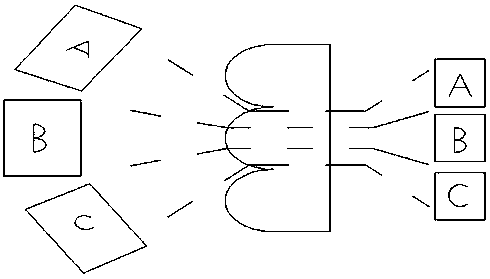

Pattern product with prism effect, and processing method thereof

The invention provides a pattern product with a prism effect. The pattern product with the prism effect is characterized by comprising cambered surfaces which are symmetrically arranged; the camberedsurfaces comprise a surface A, a surface B and a surface C; the surface B is arranged on one side of the surface A; the surface C is arranged on the other side of the surface A; the surface A, the surface B and the surface C are integrally connected. The pattern product with the prism effect can take on stereoscopic vision and different side change strange vision through a plane printing image, the stereoscopic vision picture enables people to have accessible texture and feel a vividly portrayed stereoscopic effect, and very lifelike psychological feeling is brought to people, so that aesthetic requirements of people on costume and requirements of pursuing tide of the times and meeting individuality can be met.

Owner:HUI DONG WORLD BRANDS MANUFACTORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com