Three-dimensional bronzing method

A three-dimensional, hot stamping paper technology, applied in temperature recording method, printing, printing device and other directions, can solve the problems of increasing product defect rate, cumbersome process, reducing production efficiency, etc., to achieve full use of machine resources, strong metal luster, reduce The effect of plate making costs

Active Publication Date: 2010-12-01

SHENZHEN BAIXINGLONG CREATIVE PACKAGING

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the certain stretchability of the paper, it is difficult to form a pattern at the base of the embossed part, and because generally thinner paper is relatively soft, the embossed part is easily deformed under pressure. Therefore, the three-dimensional pattern formed by bronzing is very difficult. It is difficult to maintain the three-dimensional effect for a long time

The existing method of making the pattern on the anti-woven fabric have a three-dimensional effect usually uses silk screen printing to first screen the pattern to be bronzed on the cloth, and then bronzing on the pattern printed on the silk screen. In the process of making the screen, this method needs Water-adhesive films and prints have been printed many times, and it is necessary to repeat the screen printing many times to achieve a strong three-dimensional effect when printing the pattern. Therefore, the process is relatively cumbersome, and the problem of positioning is prone to occur during the repeated screen printing process, which increases product defects. The rate reduces the production efficiency, thereby increasing the actual production cost. Professional clothing heat transfer machines are required for hot stamping, and the investment cost is relatively high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

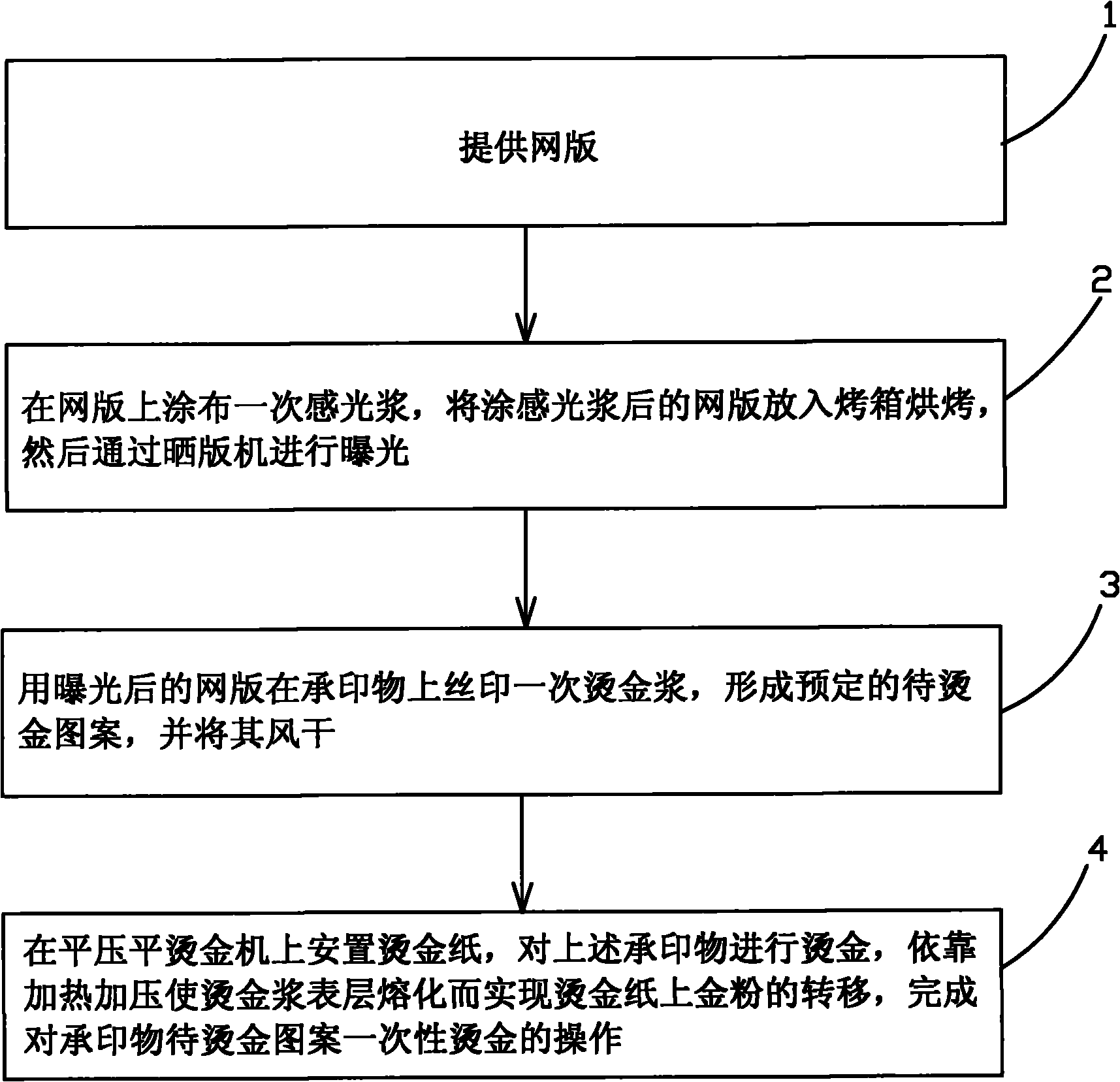

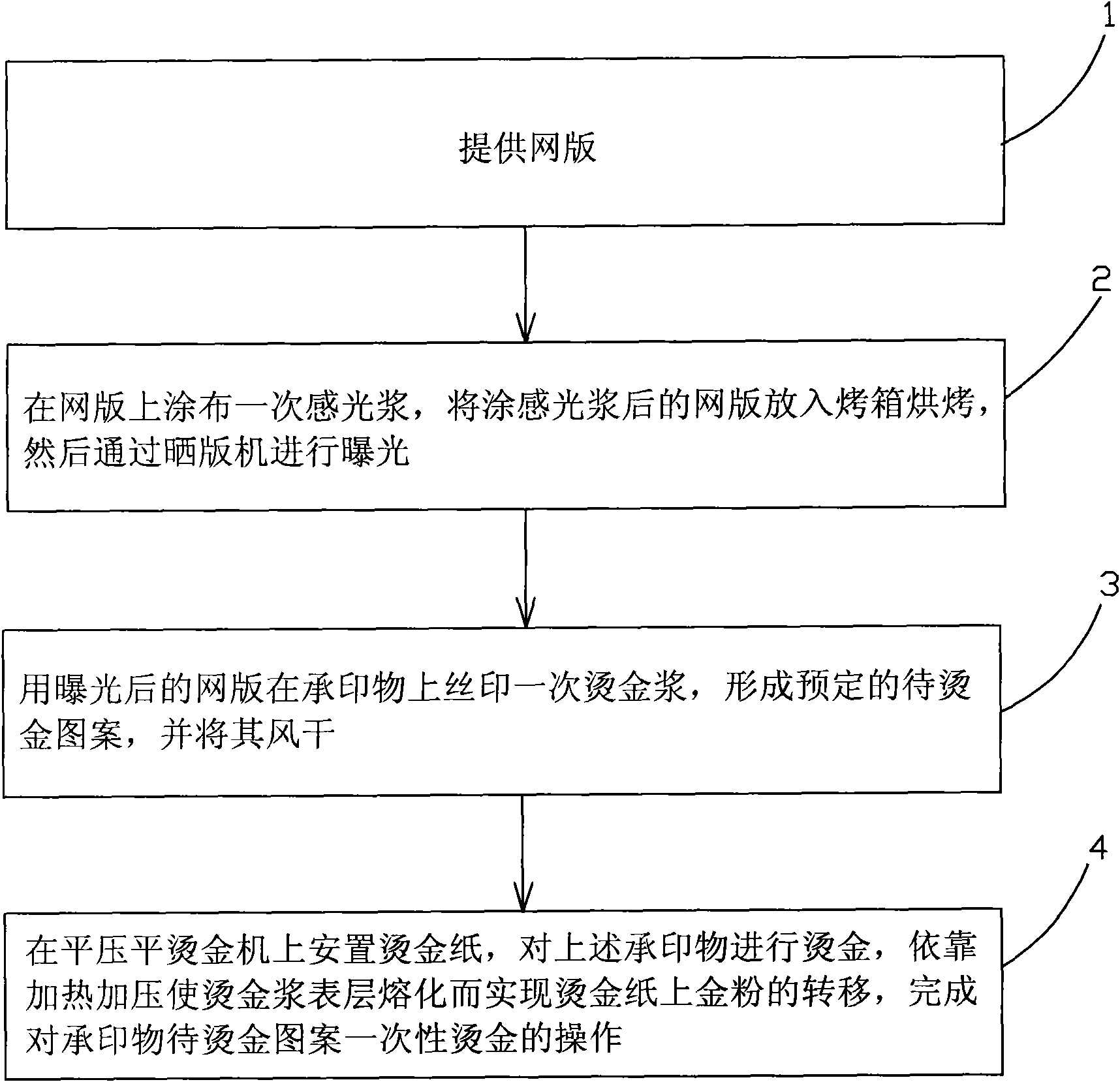

The inventio provides a three-dimensional bronzing method, comprising the steps of: 1. providing a screen printing plate; 2. coating disposable photosensory pulp on the screen printing plate, putting the screen printing plate coated with the photosensory pulp into an oven to be baked, and exposing by a printing-down machine; 3. printing disposable bronzing pulp on printed material with the exposed screen printing plate to form a preset pattern to be bronzed, and drying; and 4. setting a bronzing paper on a flat pressing flat bronzing machine, bronzing the printed material, and melting the surface layer of the bronzing pulp by means of heating and pressing to convert the golden powder on the bronzing paper and complete the operation of disposable bronzing to the pattern to be bronzed of the printed material. The three-dimensional bronzing method disposably produces the multicolour three-dimensional bronzing patterns and characters with good hand feel on the surface of textile or thin paper with the existing common equipment, thereby not only reducing the production cost but also improving the production efficiency to a certain degree.

Description

Three-dimensional bronzing method technical field The invention relates to a three-dimensional bronzing method, in particular to a method for performing three-dimensional bronzing on the surface of textile cloth and paper. Background technique With the progress of society and the improvement of aesthetics, people have higher and higher requirements for printed products. In order to beautify the packaging, the printing color should not only be smooth and colorful, but also need a more advanced metallic luster and a three-dimensional effect to show its magnificence and nobility. If printing with metal ink, not only the printing effect is not good, but also the cost is high, and the ink is in contact with the air for a long time, which is prone to oxidation and darkens the color. Therefore, we use the hot stamping process to carry out hot stamping on textile fabrics and papers, which can make the product color lasting, beautiful and elegant, and play a finishing touch. It is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B41M1/22B41M5/26B41F19/06G03C1/73

Inventor 武瑞军

Owner SHENZHEN BAIXINGLONG CREATIVE PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com