Patents

Literature

35results about How to "Strong metallic luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray-free polyamide compound with metallic luster and preparation method thereof

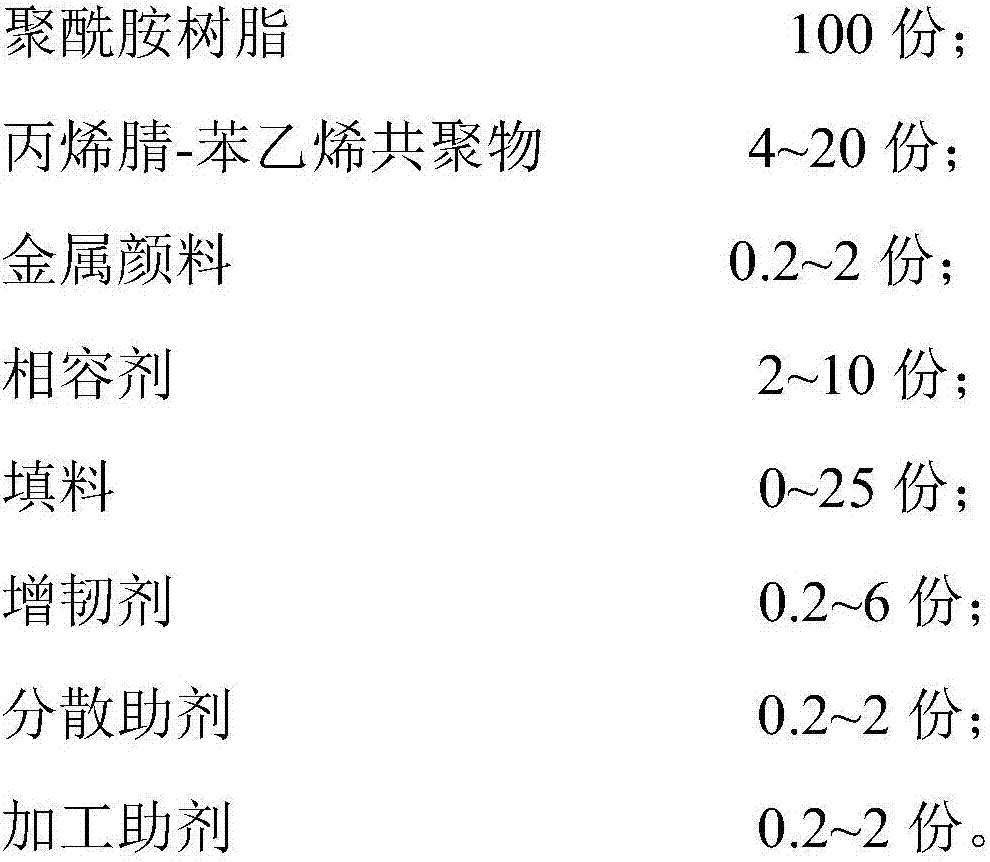

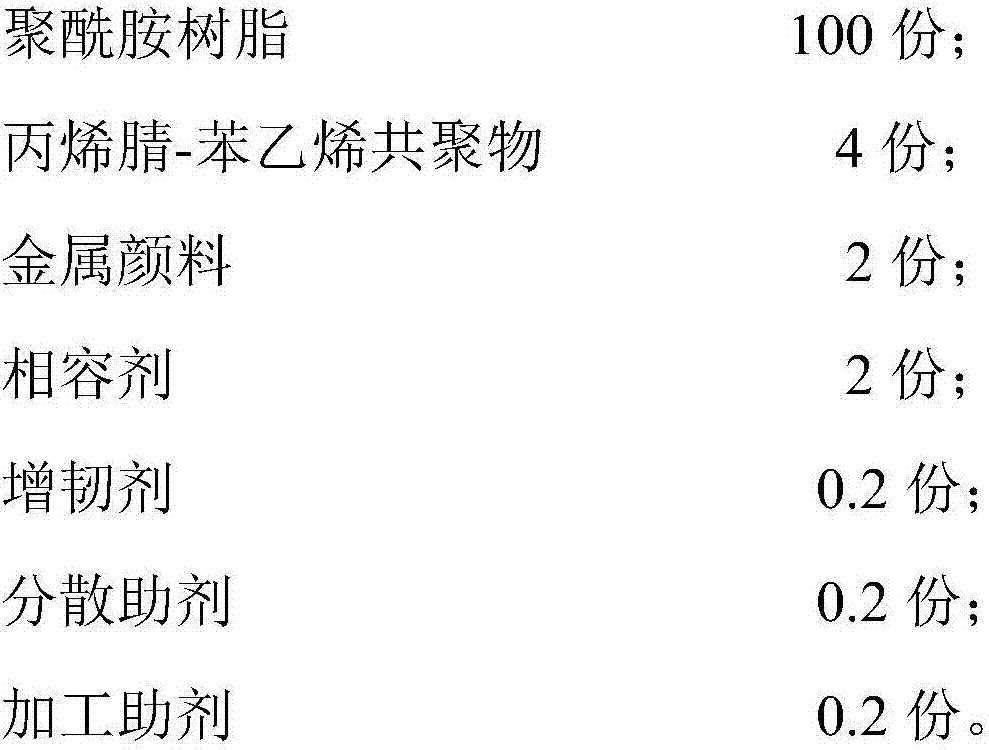

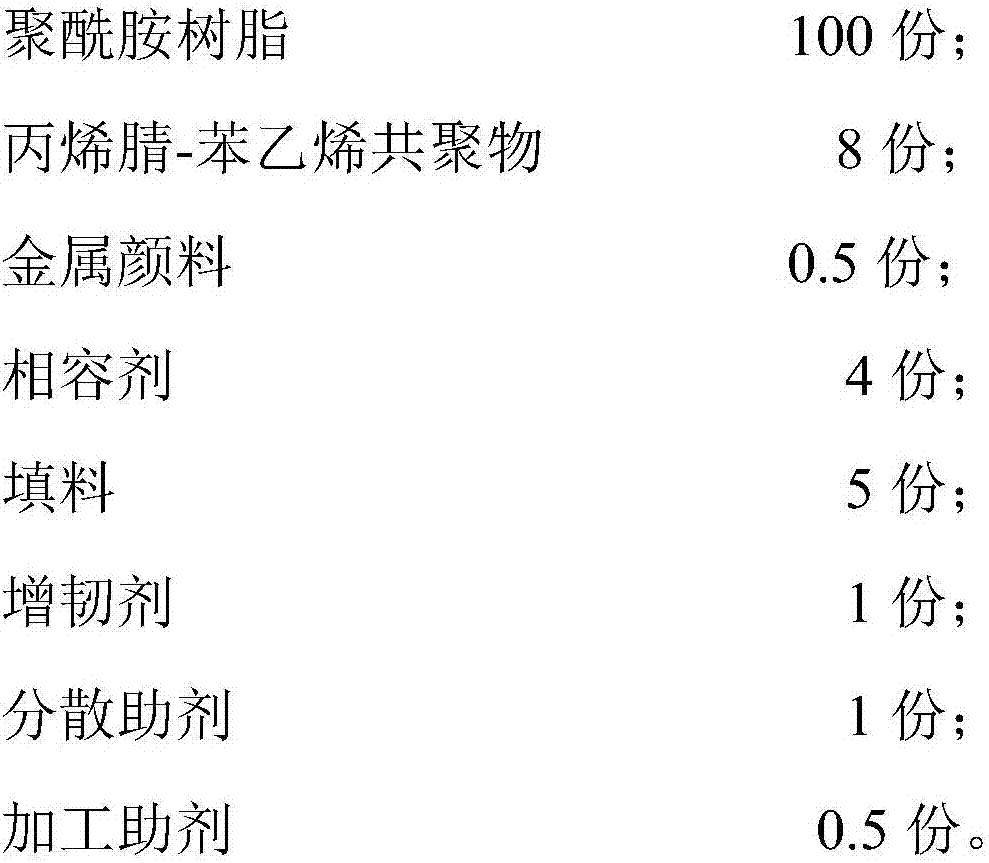

The invention discloses a spray-free polyamide compound with metallic luster. The spray-free polyamide compound is prepared from the following raw materials in parts by weight: 100 parts of polyamide resin, 4-20 parts of acrylonitrile-styrol copolymer, 0.2-2 parts of metallic pigment, 2-10 parts of compatilizer, 0-25 parts of filler, 0.2-6 parts of flexibilizer, 0.2-2 parts of dispersing auxiliary and 0.2-2 parts of processing agent. According to the invention, the acrylonitrile-styrol copolymer used as a modifier and the polyamide resin are compounded as a matrix resin of the compound, and meanwhile, the other raw material components are adjusted and the compatilizer, the dispersing auxiliary and the flexibilizer at a specific ratio are supplemented, so that the processing performance of the polyamide compound and the mechanical property and appearance effect of the formed polyamide compound are optimized.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

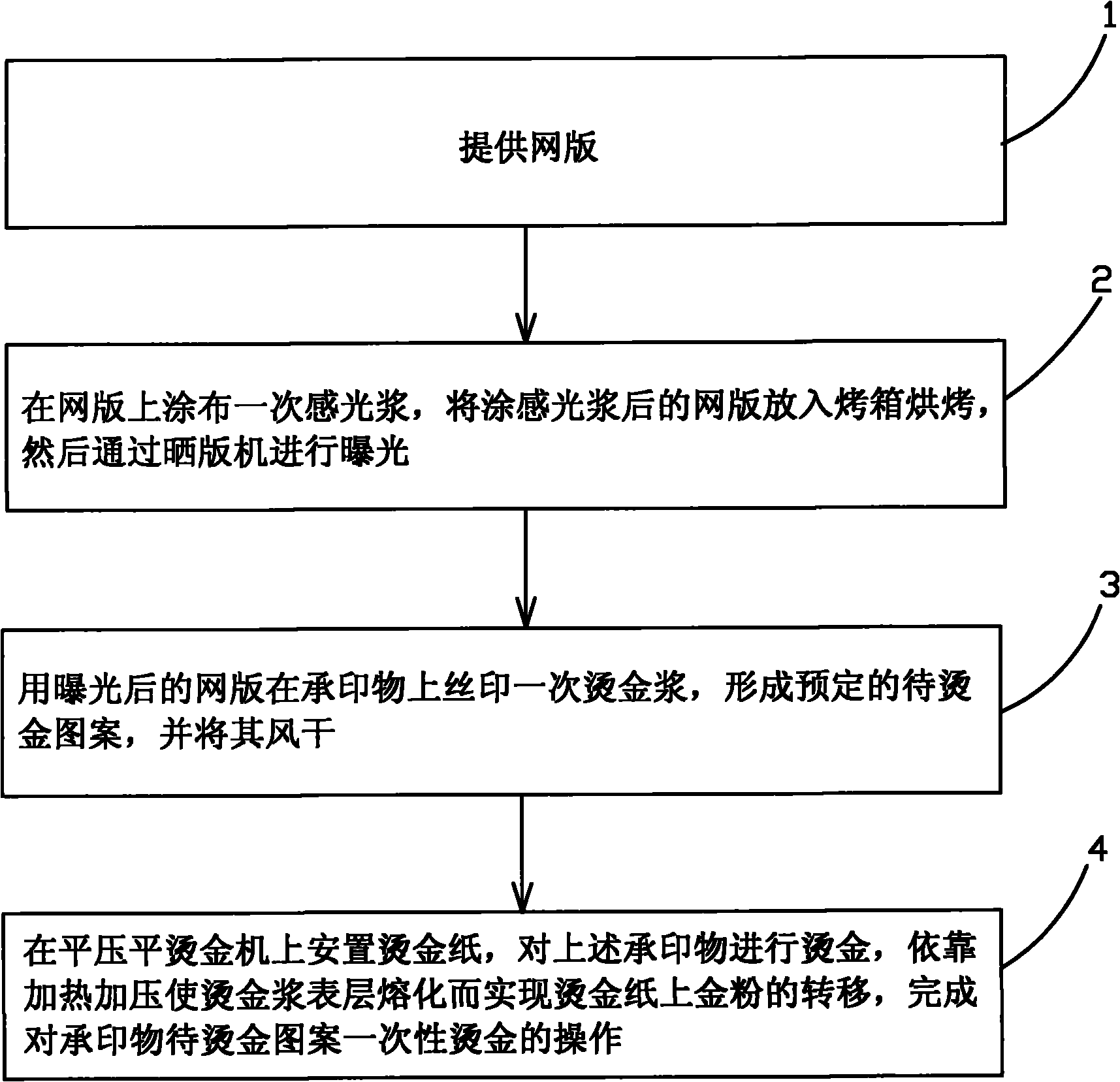

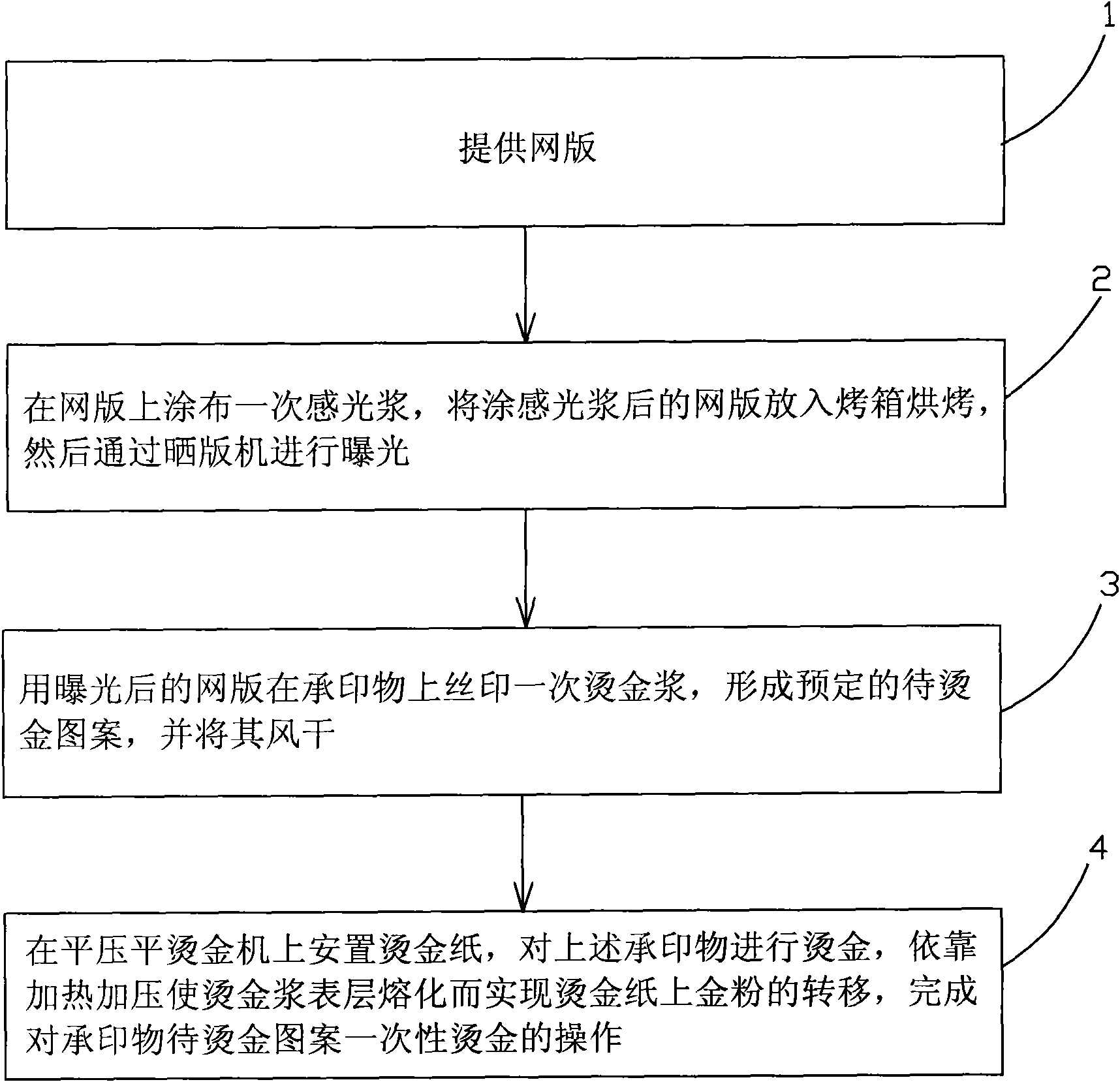

Three-dimensional bronzing method

ActiveCN101670719ATake advantage ofImprove the three-dimensional effectPhotosensitive materialsRotary pressesScreen printingSurface layer

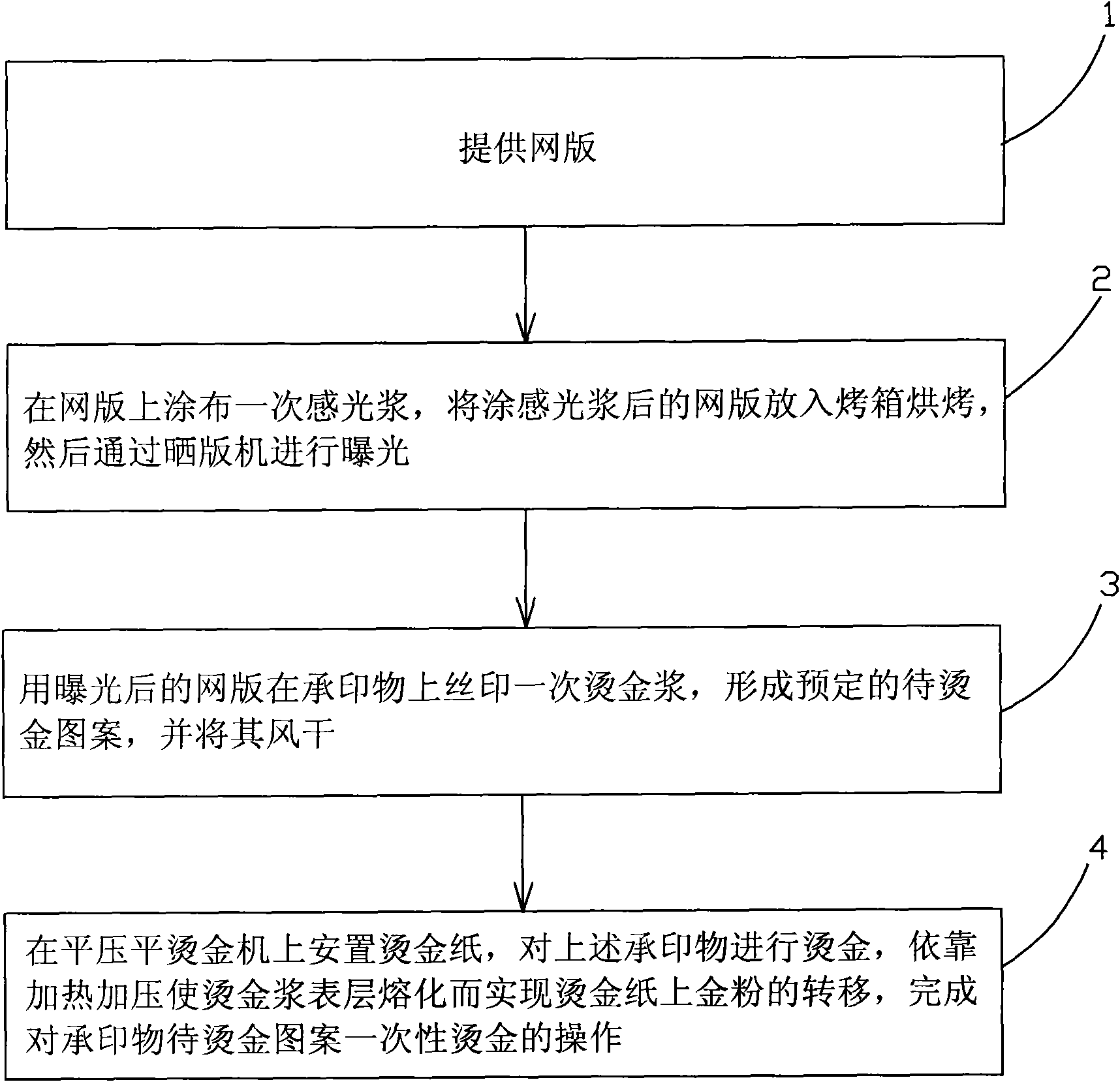

The inventio provides a three-dimensional bronzing method, comprising the steps of: 1. providing a screen printing plate; 2. coating disposable photosensory pulp on the screen printing plate, puttingthe screen printing plate coated with the photosensory pulp into an oven to be baked, and exposing by a printing-down machine; 3. printing disposable bronzing pulp on printed material with the exposedscreen printing plate to form a preset pattern to be bronzed, and drying; and 4. setting a bronzing paper on a flat pressing flat bronzing machine, bronzing the printed material, and melting the surface layer of the bronzing pulp by means of heating and pressing to convert the golden powder on the bronzing paper and complete the operation of disposable bronzing to the pattern to be bronzed of theprinted material. The three-dimensional bronzing method disposably produces the multicolour three-dimensional bronzing patterns and characters with good hand feel on the surface of textile or thin paper with the existing common equipment, thereby not only reducing the production cost but also improving the production efficiency to a certain degree.

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

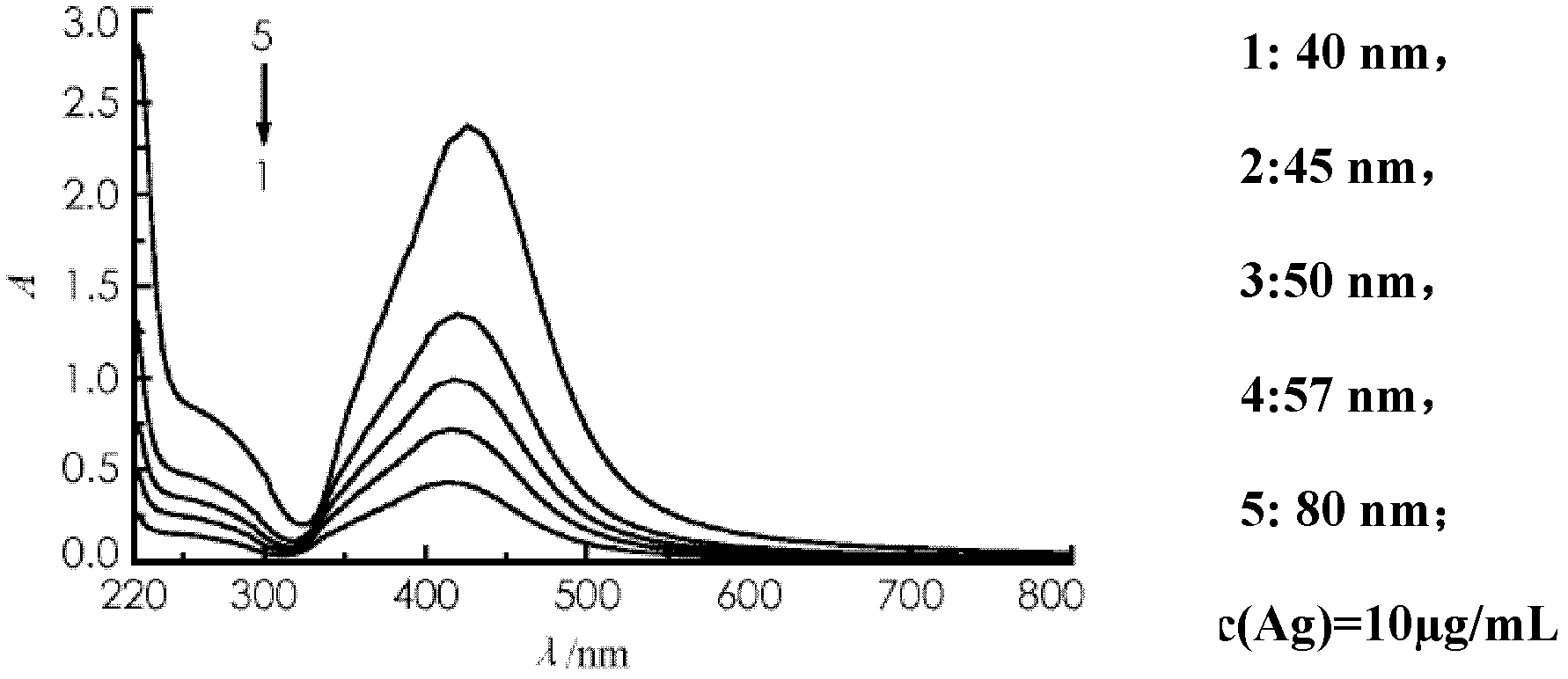

Aureous bead pigment having strong metallic texture and method for producing the same

ActiveCN101134850AStrong golden interference colorImprove vividnessInorganic pigment treatmentInterference colorHydrolysis

The present invention provides one kind of golden pearlescent pigment with strong metal texture. The golden pearlescent pigment includes flaky base with at least three layers of alternately coated ferric oxide layer of optical thickness 10-200 nm and silica layer of optical thickness 10-320 nm. The present invention provides also the pigment preparing process, which is one wet chemical hydrolysis process to deposit ferric oxide layers and silica layers on the flaky base. The golden pearlescent pigment has strong golden interference color and brilliancy and brightness greatly than common pearlescent pigments. It has low cost, simple preparation process and stable product quality.

Owner:SHANTOU LONGHUA PEARL LUSTRE PIGMENTS CO LTD

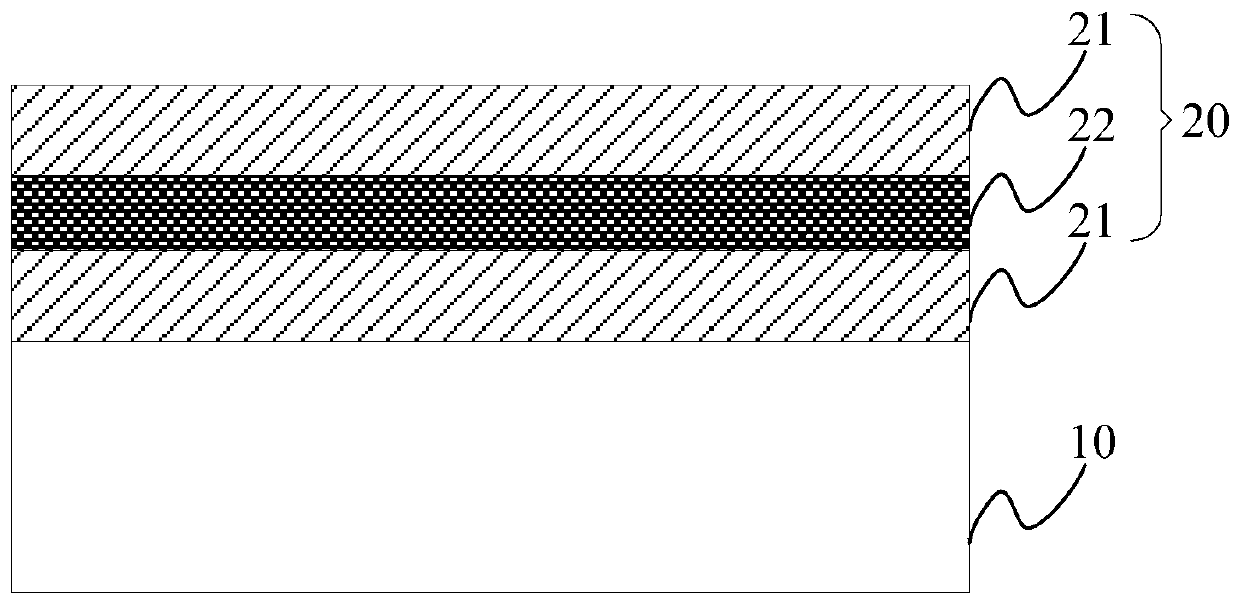

Colorful optical film, and preparation method and application structure thereof

InactiveCN110187581ADifferent colorful effectsReflection Spectrum BroadeningNon-linear opticsColor effectColor changes

The application discloses a colorful optical film, and a preparation method and an application structure thereof. Since the pitches of cholesteric liquid crystal layers in the colorful optical film can be adjusted, the reflection wavelength of the cholesteric liquid crystal layers can be adjusted accordingly to achieve different color effects. In addition, when the second coating in the coating group is in a laminated structure of multiple cholesteric liquid crystal layers, the reflection spectrum can be broadened by superposing the multiple cholesteric liquid crystal layers having different pitches. Because the optical rotation of the cholesteric liquid crystal layers can be adjusted, the colorful optical film has a high reflectance and thus a stronger metallic luster. Compared with the inorganic thin film layer, the cholesteric liquid crystal layers can be selected, for example, by a roll-to-roll process capable of preparing a coating on a large area, which is advantageous for reducing the overall preparation difficulty and preparation cost of the colorful optical film. Furthermore, a color dye, a color changing dye or other functional dyes may be added to the cholesteric liquidcrystal layers to further enhance the color effect of the colorful optical film.

Owner:安徽屹珹新材料科技有限公司

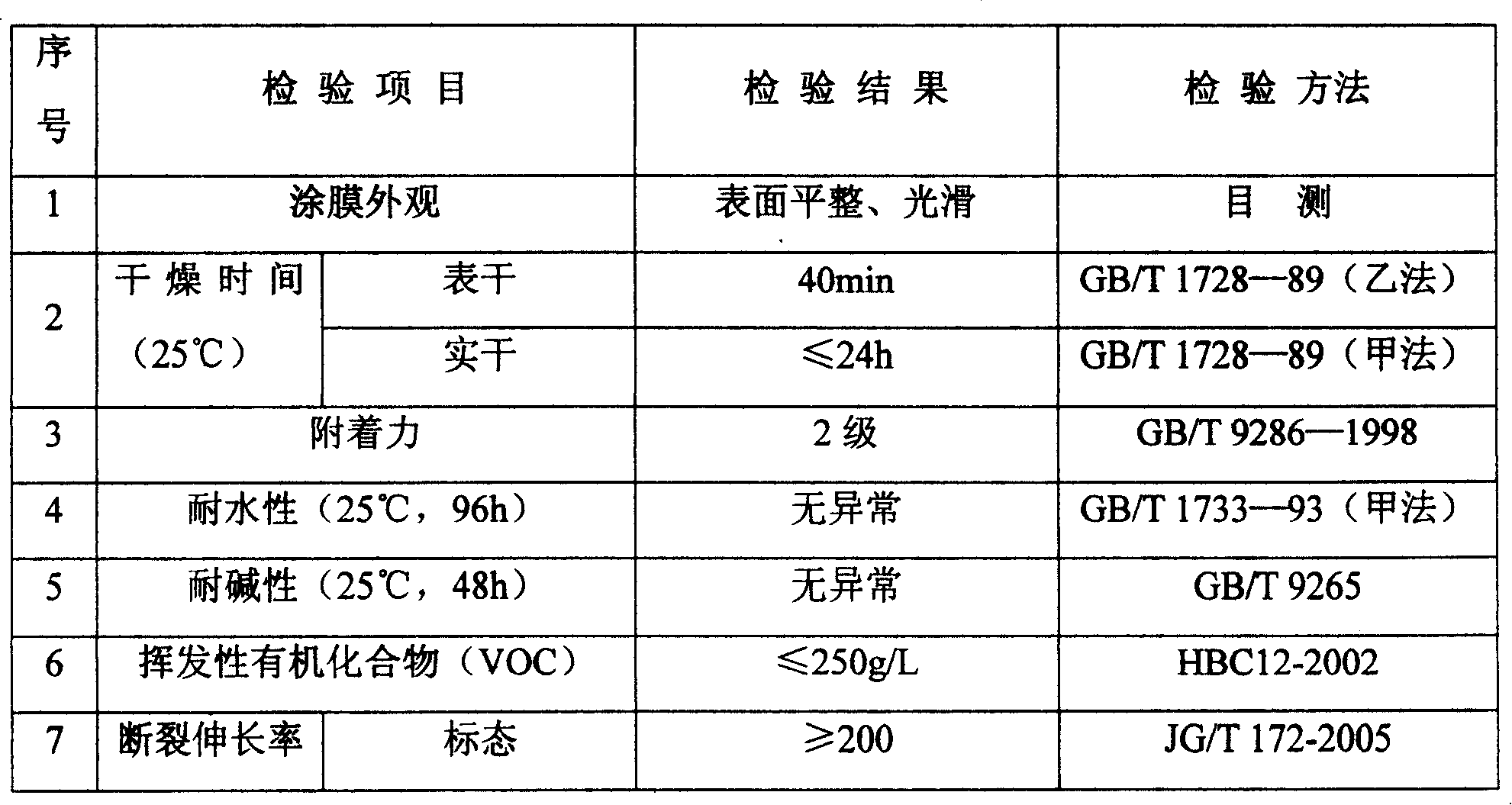

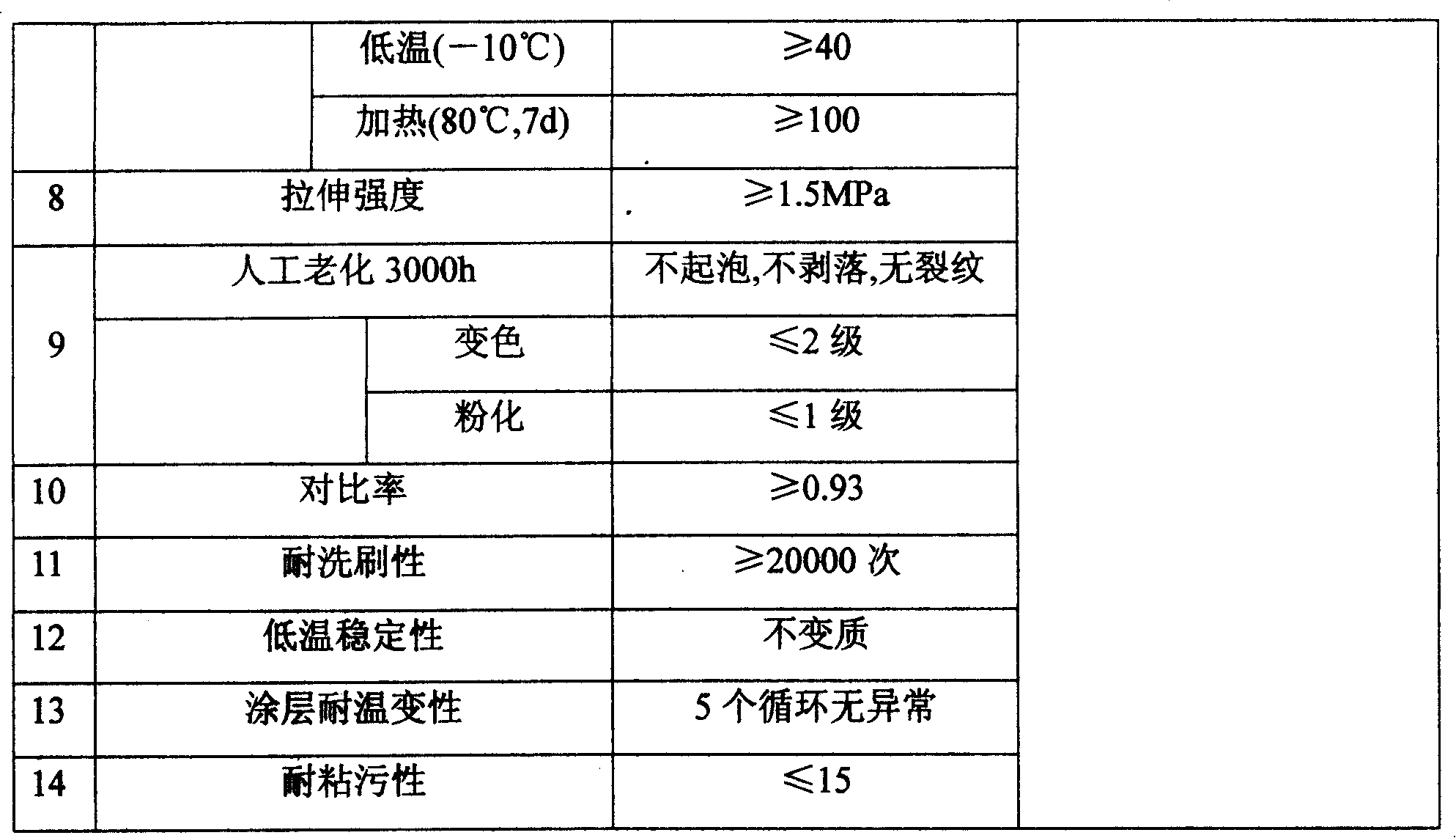

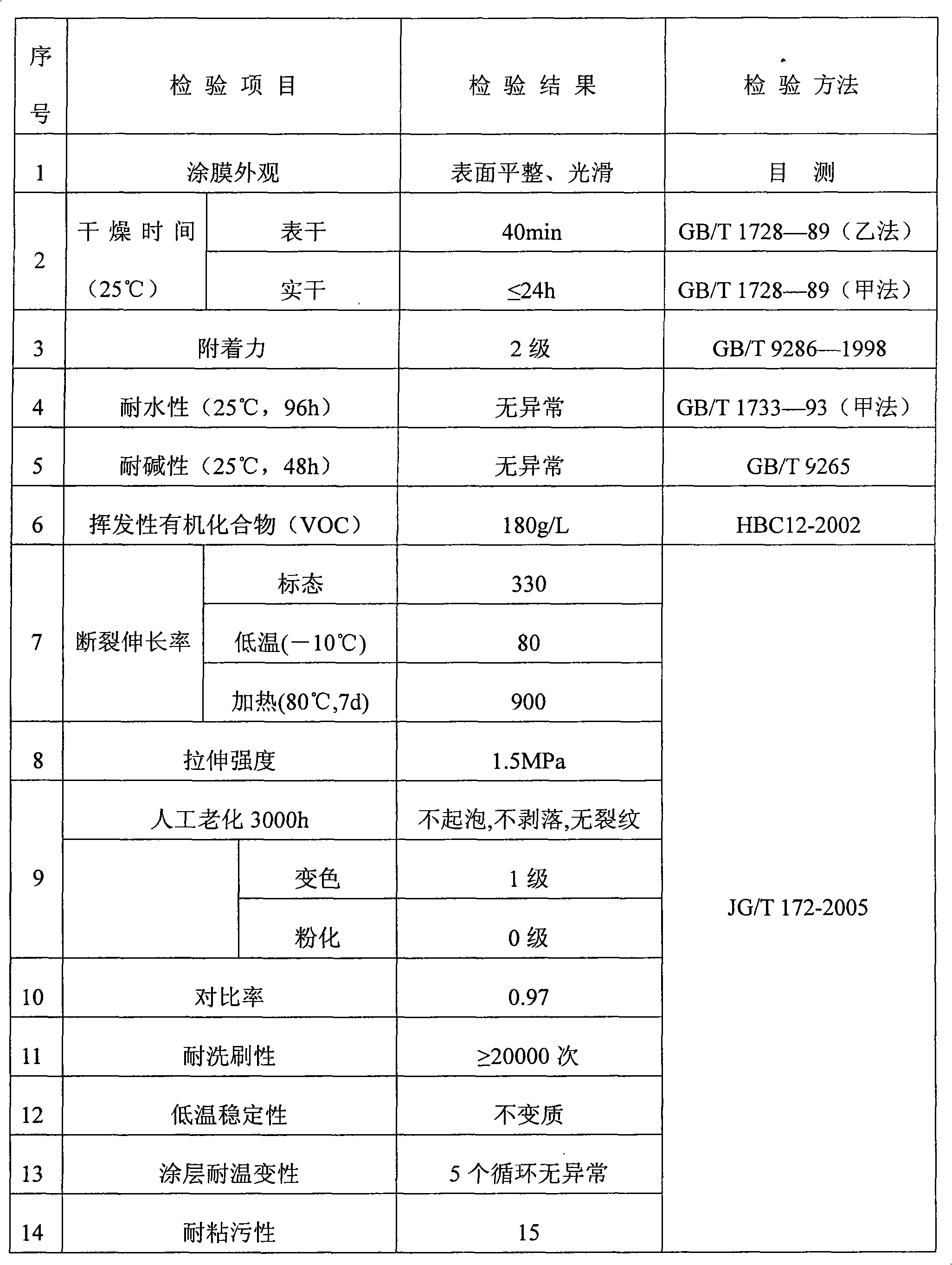

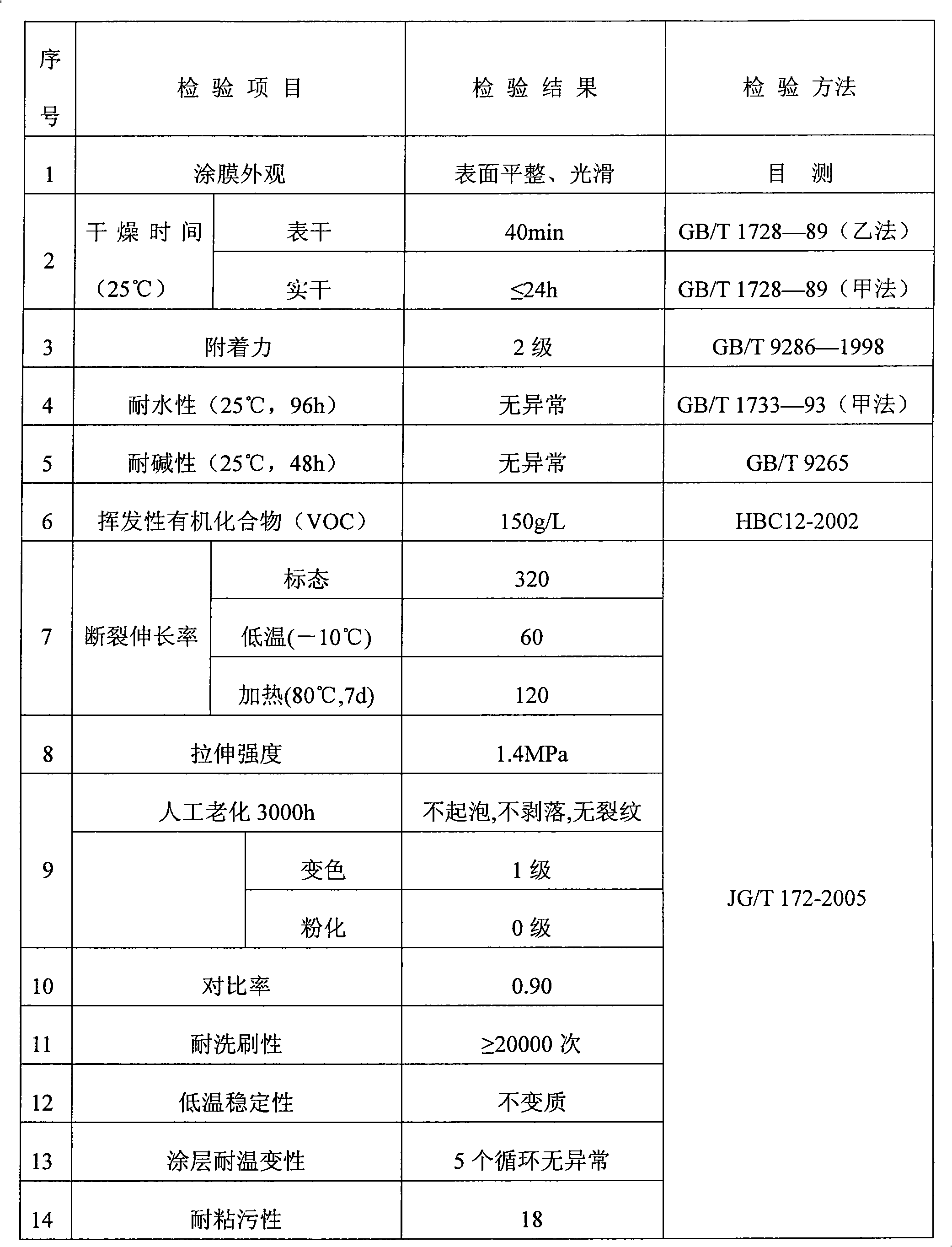

Aqueous elastic metallic luster paint

InactiveCN101161738AStrong metallic lusterImprove the decorative effectEmulsion paintsWater basedLacquer

The invention discloses a water-based elastic metal luster paint which comprises the following main components according to the following proportions by weight: water-based resin 40-80 percent with 50 percent of solid content, antifoam agent 0.05-0.8 percent, disperser 0.05-1.0 percent, metal effect coloring agent 5-35 percent, thickener 0.1-1 percent, anti-crinkling agent 0.1-1 percent, leveling agent 0.1-1 percent, antifreeze agent 1-3 percent, anti-bacterial agent 0.5-2 percent, and water 0-40 percent. The water-based elastic metal luster paint provided by the invention can be applied onto the surfaces of cement products like external and internal walls of buildings to form a metal luster elastic coating. The invention has closing effect for common wall cracks, high-efficiency mildew proof and anti-alga effect, endurable elasticity, waterproof and pervious function for breathing, low cost, intense metal texture, good ornamental effect and convenient construction, as well as high anti-soil anti-weathering performance, thereby being widely applicable to external wall coating for modern buildings with high requirements and internal wall decoration for hotels and offices.

Owner:上海展辰涂料有限公司 +2

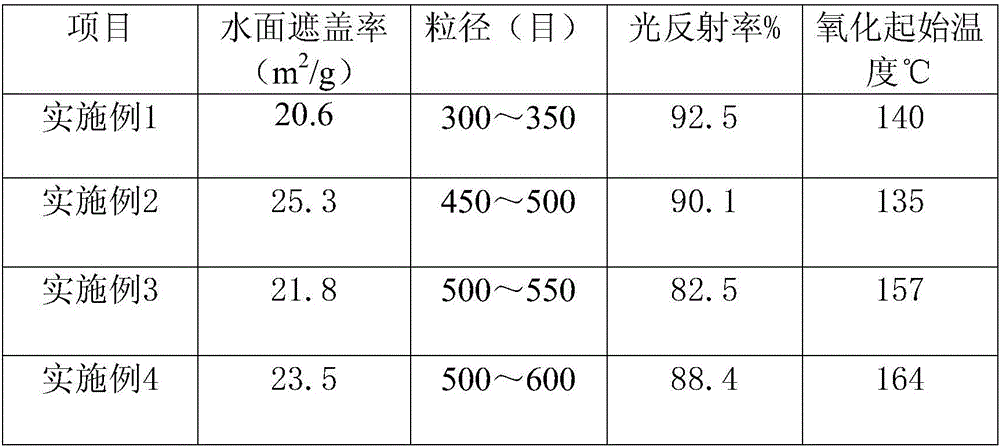

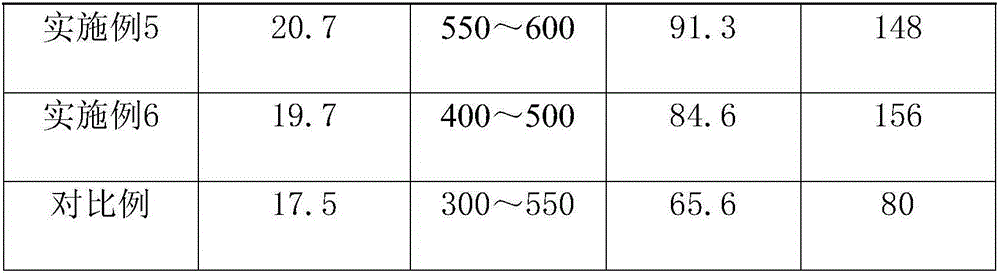

Gravure copper gold powder preparation method

InactiveCN106424742AStrong metal feelingNot easy to change colorTransportation and packagingMetal-working apparatusCopperTemperature resistance

The invention discloses a gravure copper gold powder preparation method for solving the problems of weak oxidation resistance high-temperature resistance and easy color change of copper gold powder in the prior art. The gravure copper gold powder preparation method comprises the steps of raw material weighing, raw material fusion, preparation of metal powder by water atomization, drying, ball milling, polishing and screening; the prepared copper gold powder resists oxidation through adding ball milling assistant in the ball milling process and adding polishing assistant in the polishing process; and the prepared product is high in metal luster, excellent in product quality, excellent in high-temperature resistance, high in production process stability and high in production efficiency.

Owner:RUIAN CHENGXUAN IND & TRADE CO LTD

Electrophoresis display particle comprising metal component and preparation method as well as functions thereof

InactiveCN103217847AHigh light reflectivityHigh fluorescence emission propertiesLuminescent compositionsPigment treatment with macromolecular organic compoundsElectrophoresisFluorescence

The invention relates to an electrophoresis display particle comprising a metal component and a preparation method as well as functions thereof. Particularly, the invention relates to the electrophoresis display particle comprising the metal component, and the electrophoresis particle comprises a particle nucleus and a decorative layer which is randomly selected for wrapping the surface of the particle nucleus. The invention further relates to a method for preparing the electrophoresis display particle, electrophoresis display liquid of the electrophoresis display particle, and functions of the electrophoresis particle for preparing an electrophoresis display device. According to the electrophoresis display particle, an electro-optical display device is endued with one or multiple extra characteristics, such as high optical reflectance, strong colors, good metal gloss and fluorescent emitting property.

Owner:GUANGZHOU OED TECH INC

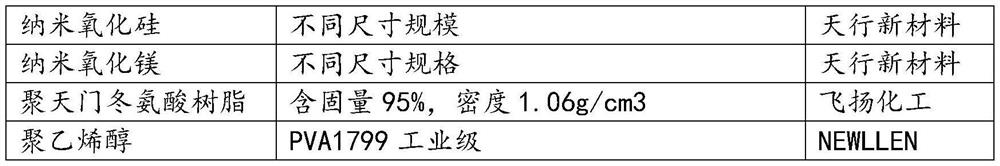

Nano aqueous elastic paint with metal luster

The invention provides a nano aqueous elastic paint with metal luster, which mainly comprises the following components in percentage by weight: 40 to 80 percent of nano aqueous resin which contains 50percent of solid, 0.05 to 1.5 percent of nano antifoaming agent, 0.05 to 3 percent of dispersant, 0 to 15 percent of nano dulling agent, 5 to 35 percent of pigment, 0.1 to 1 percent of nano thickening agent, 0.1 to 1 percent of anti-shrinkage agent, 0.1 to 1 percent of flatting agent, 1 to 10 percent of antifreezing agent, 0.5 to 10 percent of nano antibacterial agent, 1 to 8 percent of nano antifoulant and 0 to 40 percent of water. The nano aqueous elastic paint can be widely applied to inner and outer walls of brick and stone structures and concrete structures, and is a novel dope which hasthe advantages of low cost, strong metal luster, good decorative effect and simple and convenient construction. The system for coating the aqueous elastic paint with metal luster of the invention caneffectively and perfectly combine three themes of decorative performance, crack resistance and environment protection.

Owner:上海展辰涂料有限公司 +2

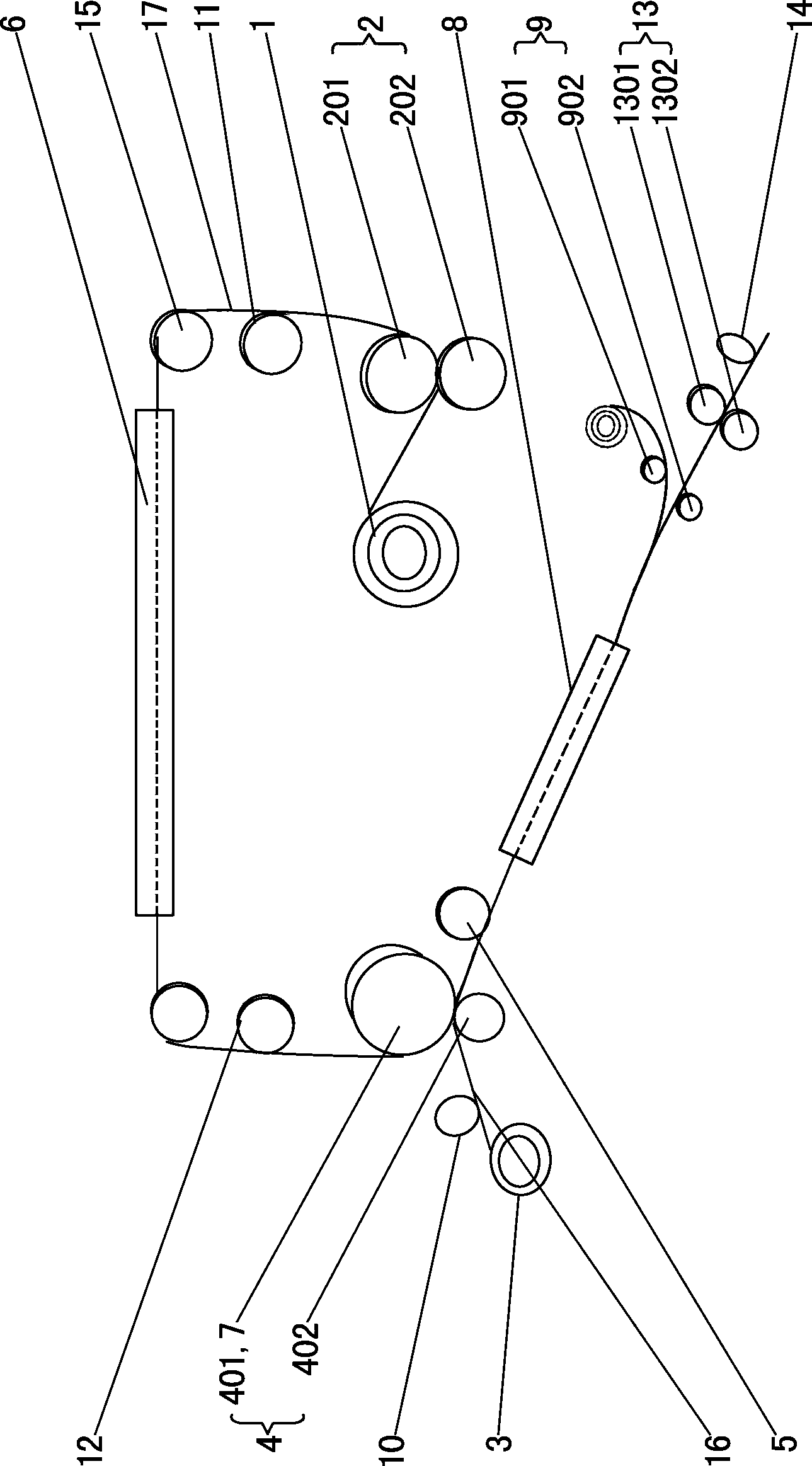

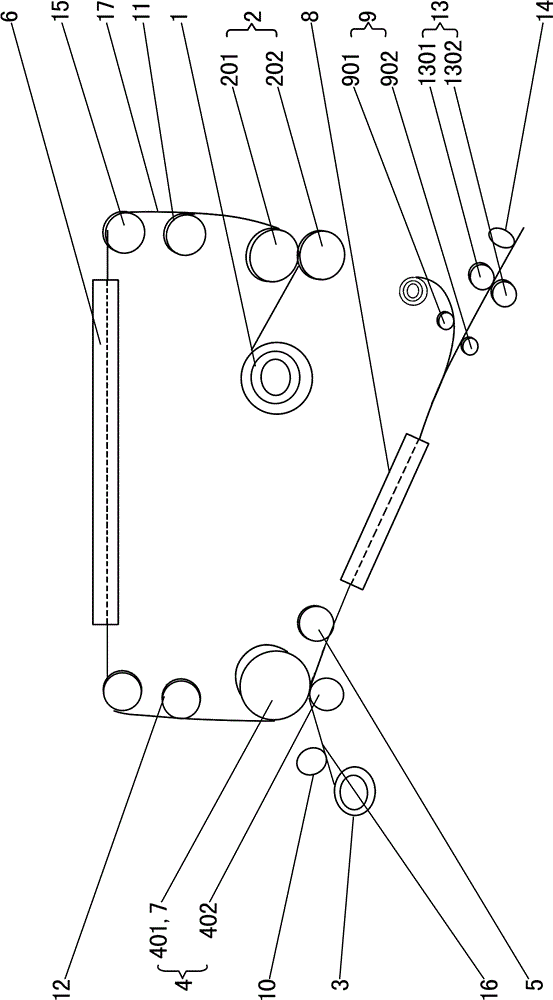

Method for compounding metal membrane by transfer-type film as well as production equipment thereof

ActiveCN103847217AImprove adhesionImprove smoothnessLamination ancillary operationsLaminationCompound aTransfer mode

The invention relates to a method for compounding a metal membrane by a transfer-type film as well as production equipment thereof. The method comprises the following steps: pretreating the surface of a plastic film; coating mucilage on the surface of a metal layer on a carrier film; drying up the carrier film; precooling the carrier film; compounding the plastic film and the carrier film by a lamination mode; carrying out hot-pressing and drying; stripping a base material layer of the carrier film. The mucilage is coated on the carrier film and is compounded with the plastic film, and finally the base material layer of the carrier film is stripped off, so that the original surface of the metal layer of the carrier film is attached to the plastic film by the mucilage, and the surface of the metal layer, which is attached to the base material layer, is converted into the surface of a metal compound film. The surface of the metal compound film after being compounded is provided with an even mirror surface, and has high metallic luster; the metal film is compounded by a transfer mode without being performed at high-temperature environments; the plastic film cannot be deformed, and the waste rate of the plastic film is reduced to be less than 0.5%; the finished product rate of the metal compound film is improved greatly.

Owner:广东东南薄膜科技股份有限公司

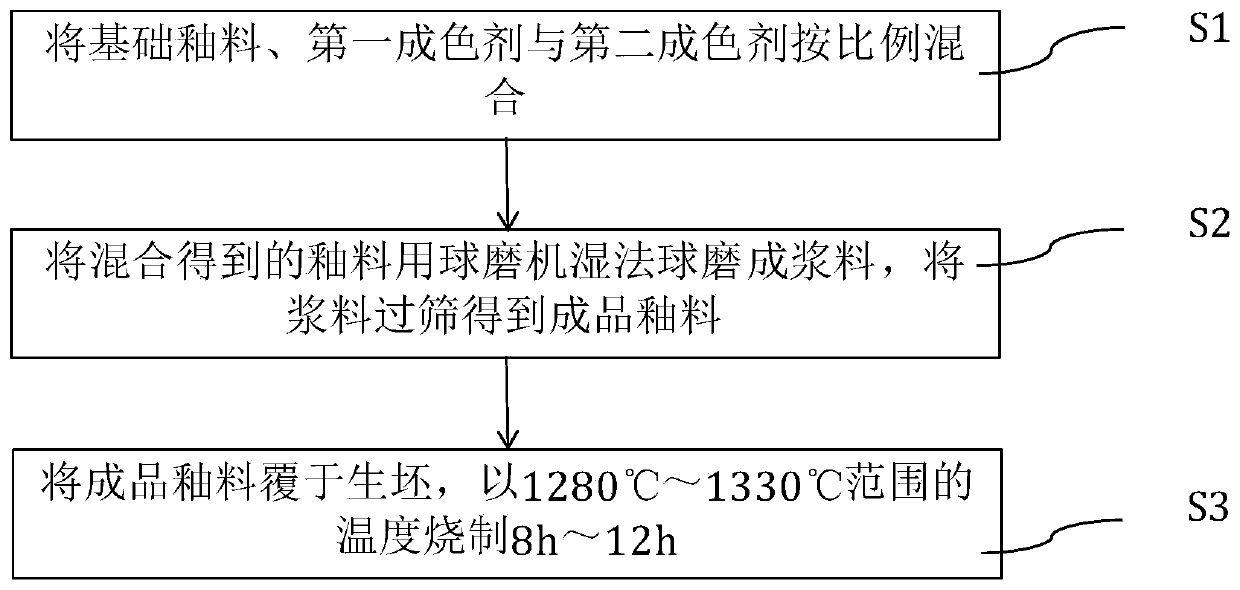

Metal glaze as well as preparation method and application method thereof

The invention belongs to the technical field of ceramic glaze, and relates to metal glaze as well as a preparation method and an application method thereof. The metal glaze comprises the following raw materials in percentage by weight: 30-37% of albite, 8-15% of quartz, 0-4% of wollastonite, 9-16% of calcined kaolin, 4-6% of calcined zinc oxide, 19-23% of calcined iron phosphate and 13-20% of self-made high-phosphorus frit powder. On the basis of calcined iron phosphate, self-made high-phosphorus frit powder is added as a crystallization accelerant into the metal glaze, so that the metal luster is more easily presented. The element P is introduced into the self-made high-phosphorus frit powder in a frit form, and compared with a high-phosphorus raw material system, the self-made high-phosphorus frit powder has a wider firing temperature range, and the metal effect is more stably presented. By finely adjusting the ratio of the self-made high-phosphorus frit powder to the silicon-aluminum of the metal glaze, the adjustment of metal to different colors can be realized. In addition, the metal glaze is combined with a roller printing process, so that the glaze surface can present a good three-dimensional effect.

Owner:FOSHAN SANSHUI CREATE TIDE

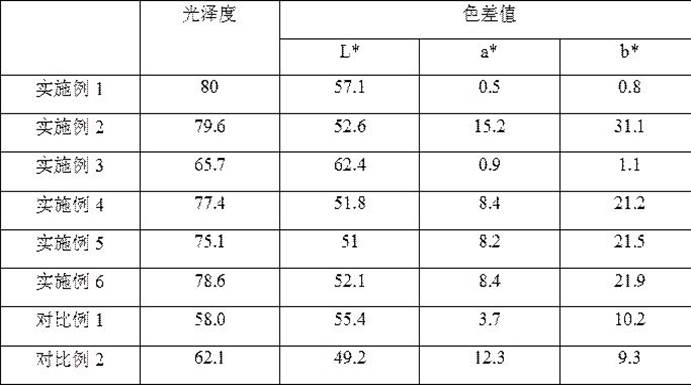

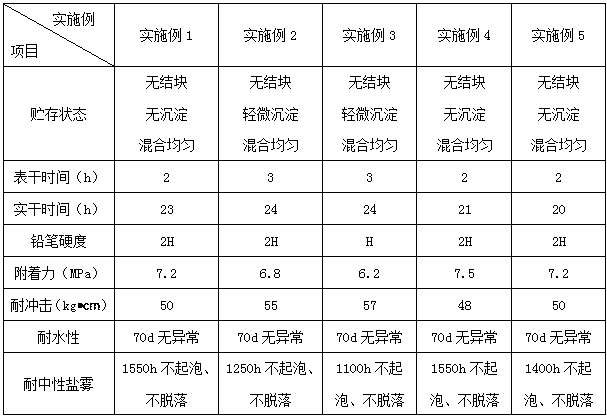

Metal flake type single-component water-based heavy-duty paint and preparation method thereof

InactiveCN110041830AMake up for corrosionMake up for stabilityAnti-corrosive paintsElectrically-conductive paintsWater basedHeavy duty

The invention relates to the field of heavy-duty paint, and discloses metal flake type single-component water-based heavy-duty paint and a preparation method thereof. The water-based heavy-duty paintis prepared from the following raw materials in parts by mass: 40-60 parts of carbon titanium cage resin, 8-15 parts of rust-proof pigment, 20-30 parts of deionized water, 2-3 parts of a directional alignment agent, 1-3 parts of a dispersant, 1-2 parts of a defoamer, 0.5-1 part of a thickener and 0.5-1 part of a leveling agent. Selected metal flake such as aluminum flake and zinc aluminum alloy flake or aqueous aluminum silver paste with solid content higher than 70% have the double functions of cathodic protection and physical shielding in the paint, and corrosion resistance of a paint film is greatly improved. The prepared heavy-duty paint is novel carbon titanium cage water-based paint, has excellent corrosion resistance and strong adhesive force, and can be used alone or in combinationwith other intermediate paint and primer.

Owner:华能国际电力股份有限公司海门电厂 +2

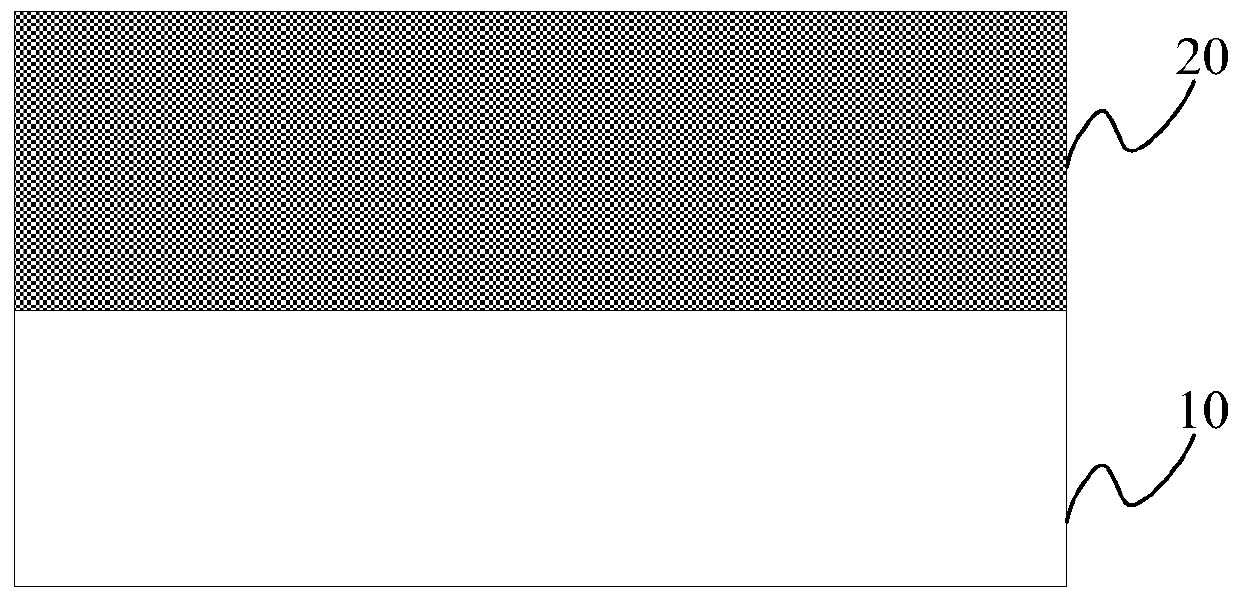

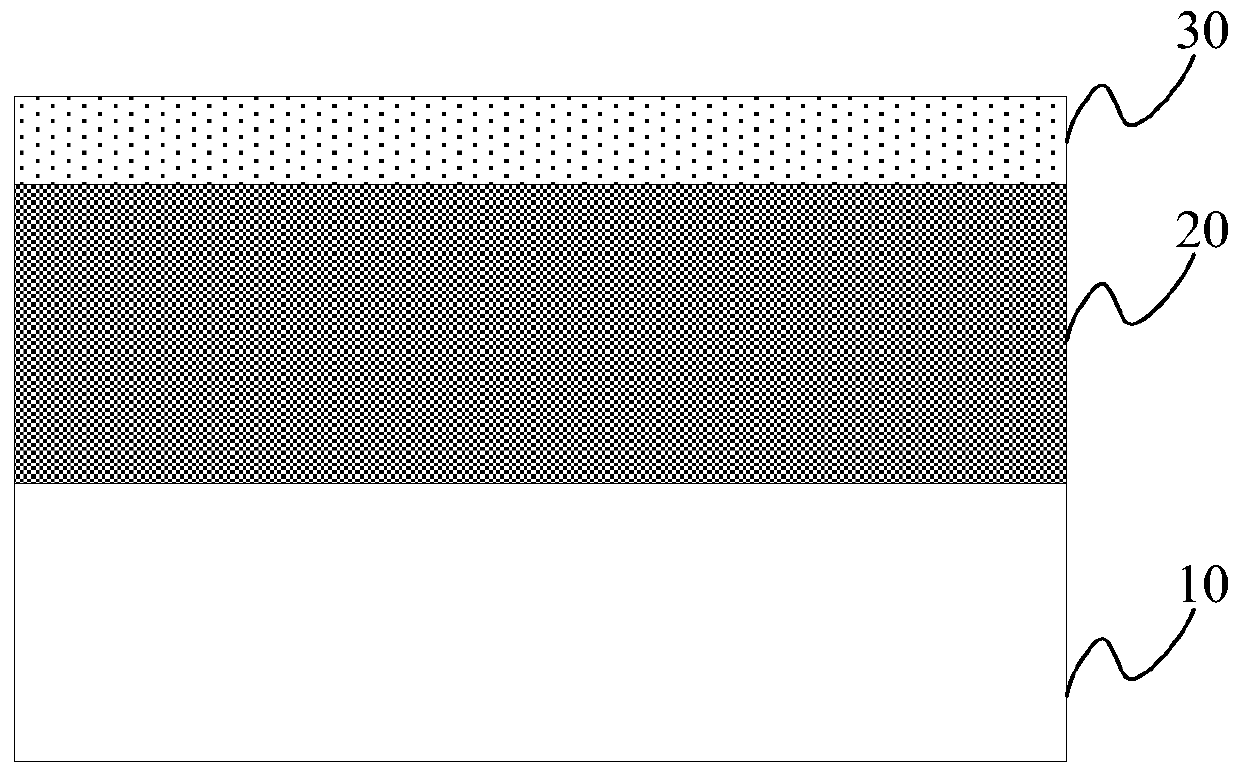

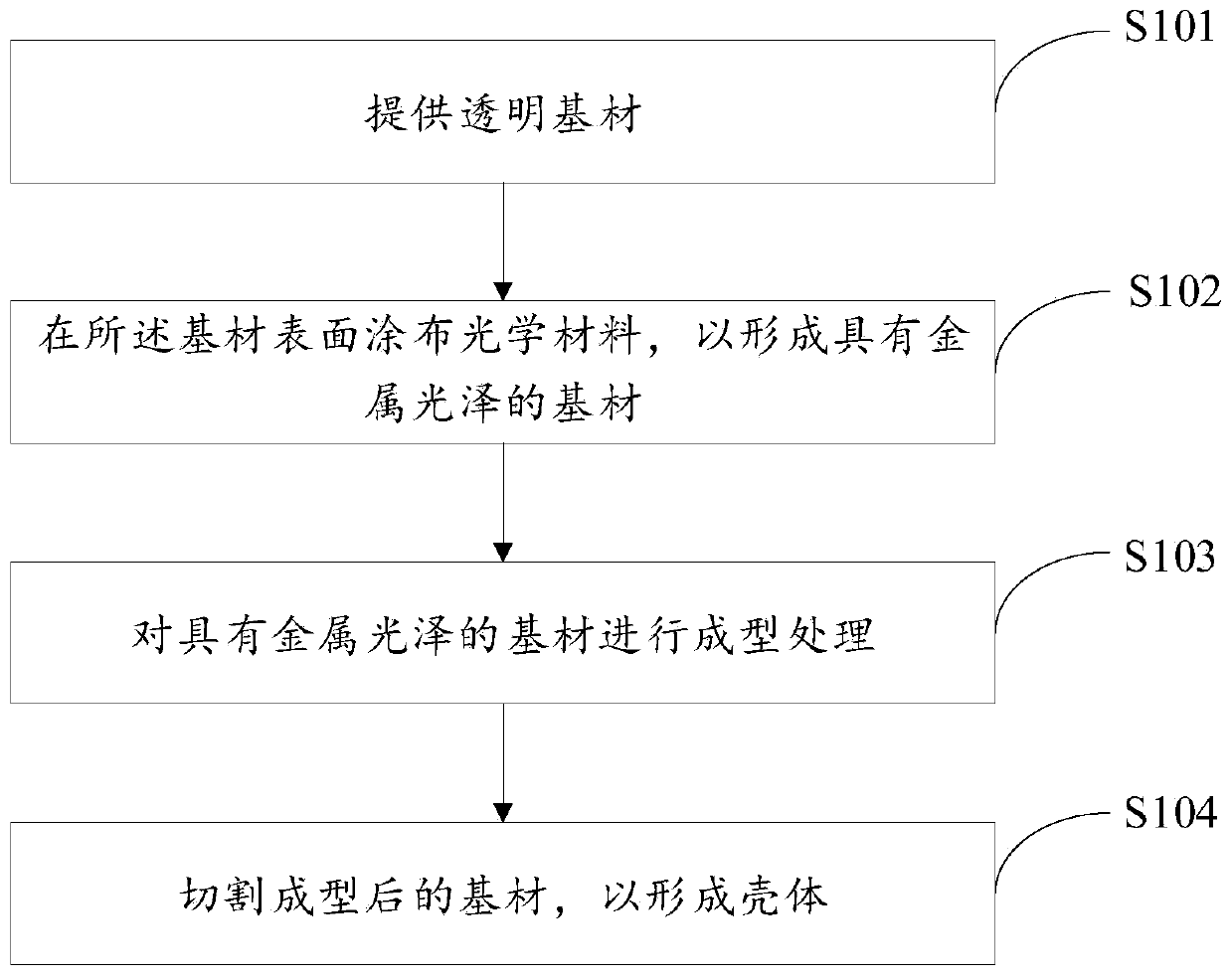

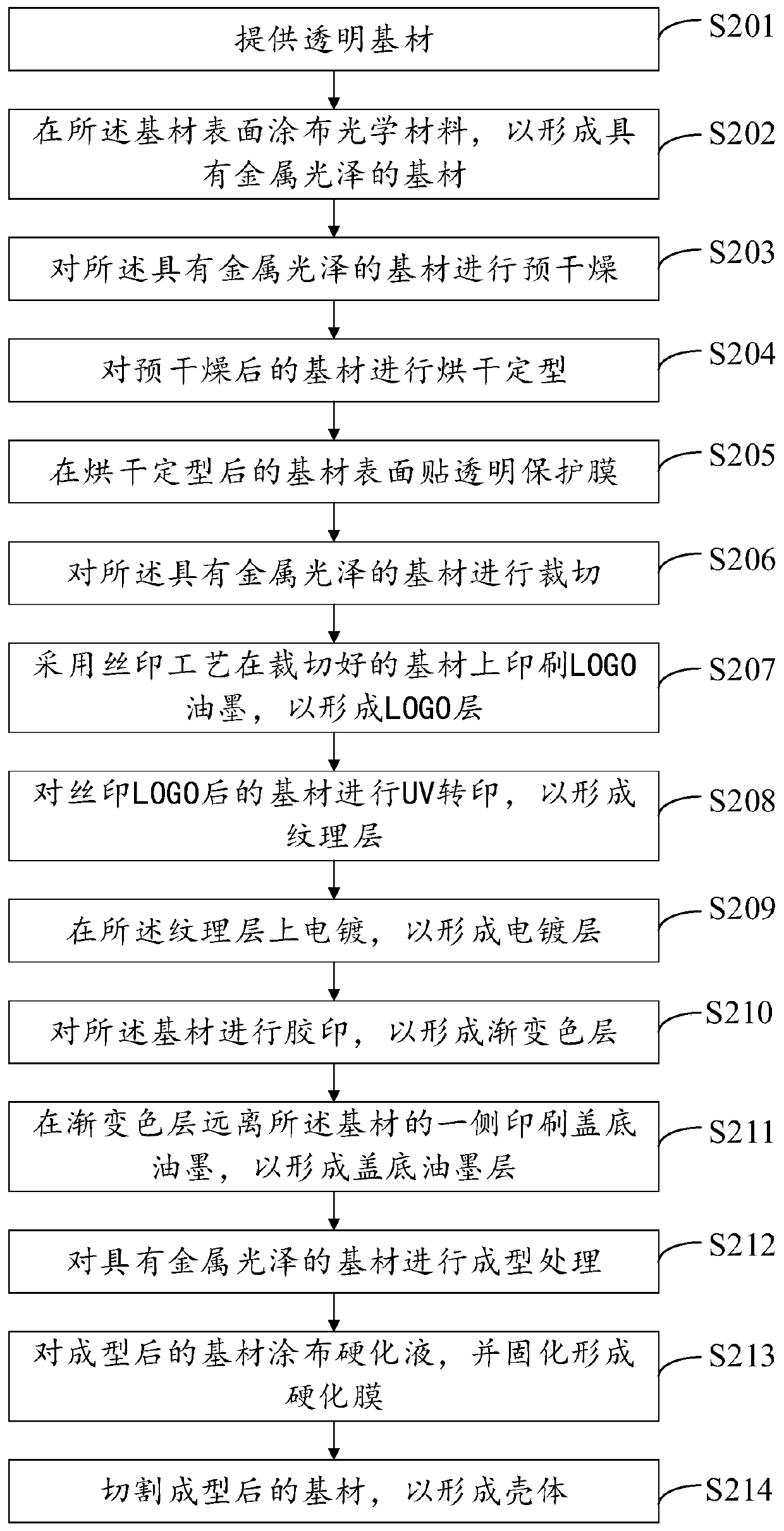

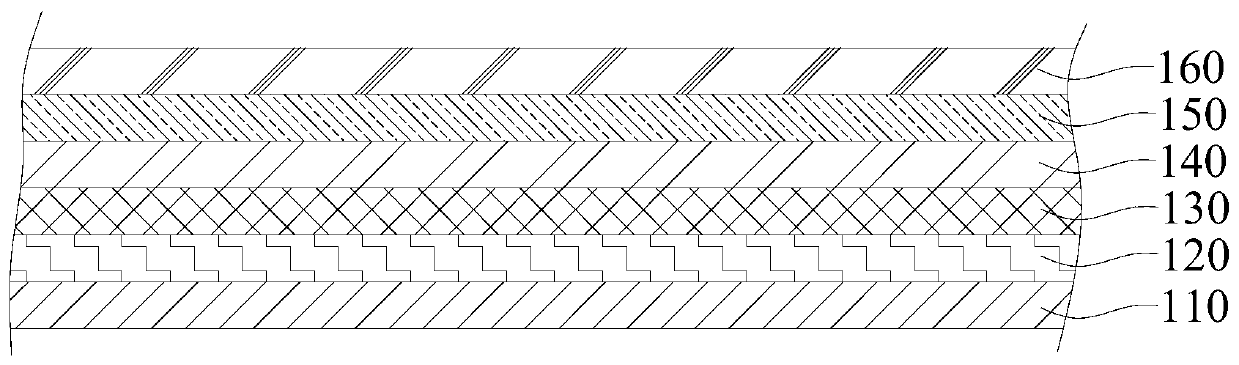

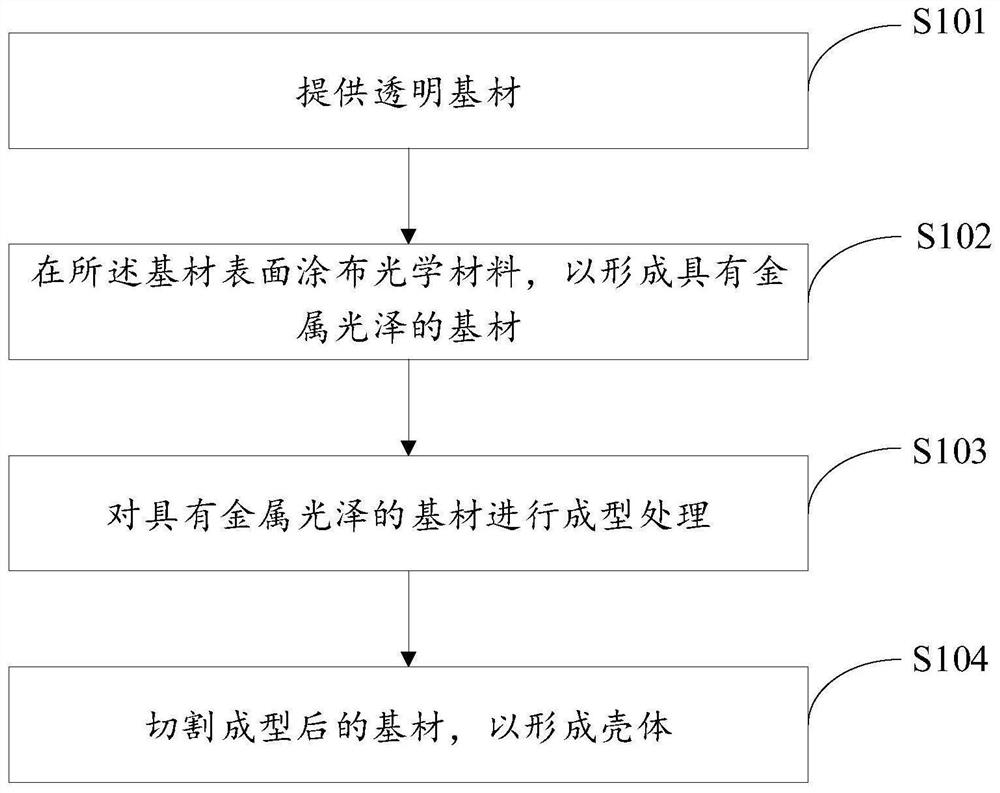

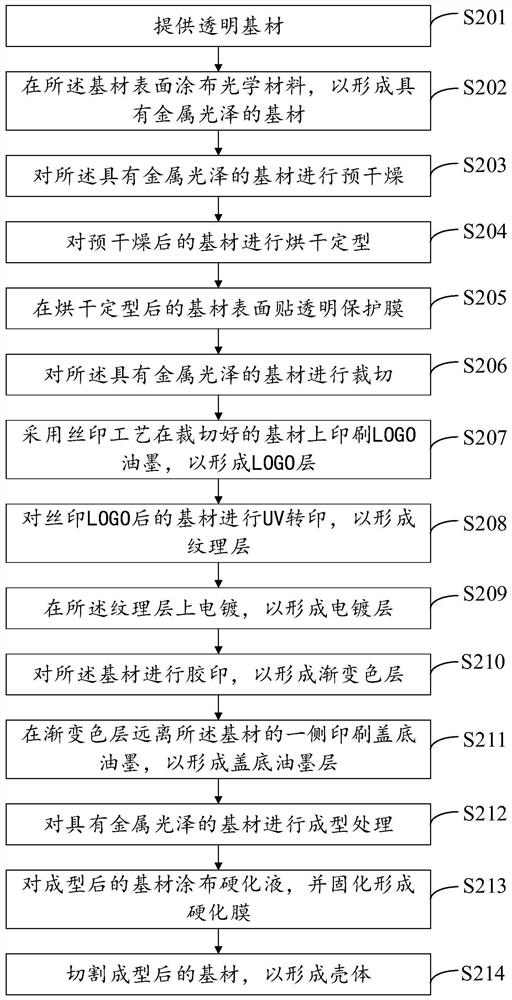

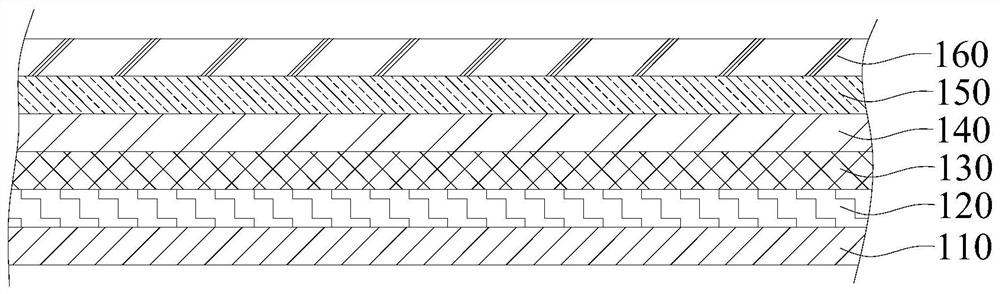

Shell processing method, shell and electronic equipment

ActiveCN111212538AStrong metallic lusterOvercome the defect of weak metallic lusterCasings/cabinets/drawers detailsPattern printingElectronic equipmentComposite material

The invention provides a processing method of a shell, the shell and electronic equipment. The processing method comprises the following steps: providing a transparent base material; coating an optical material on a surface of the base material to form the base material with metallic luster; carrying out forming treatment on the base material with the metallic luster; and cutting the formed base material to form the shell. The invention provides the processing method of the shell. The shell manufactured through the processing method can show high metal luster.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

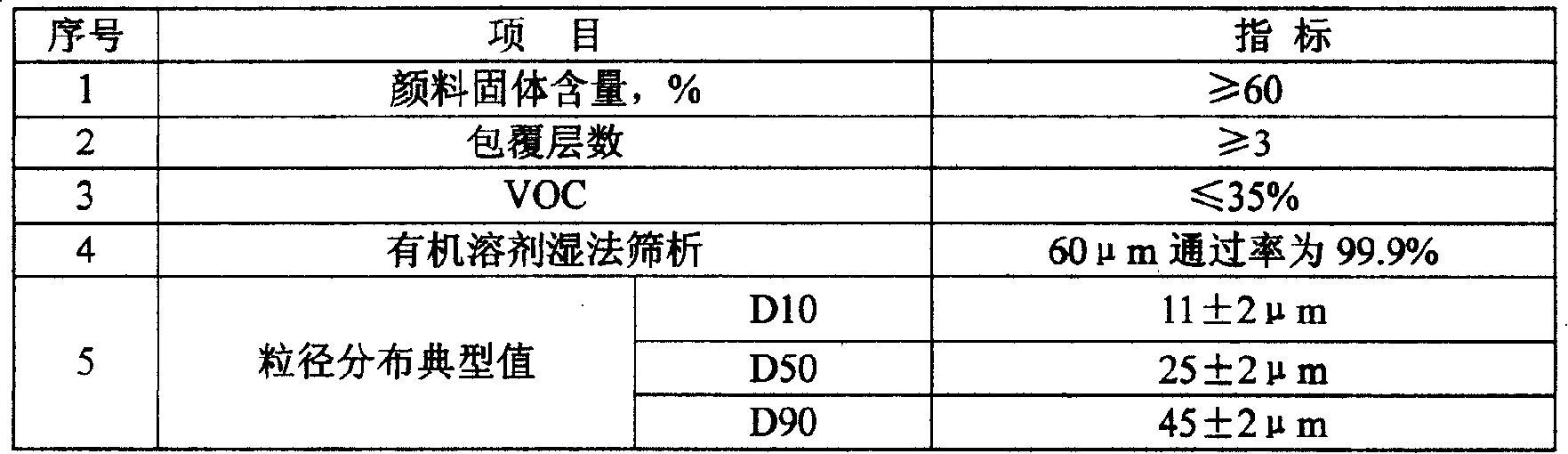

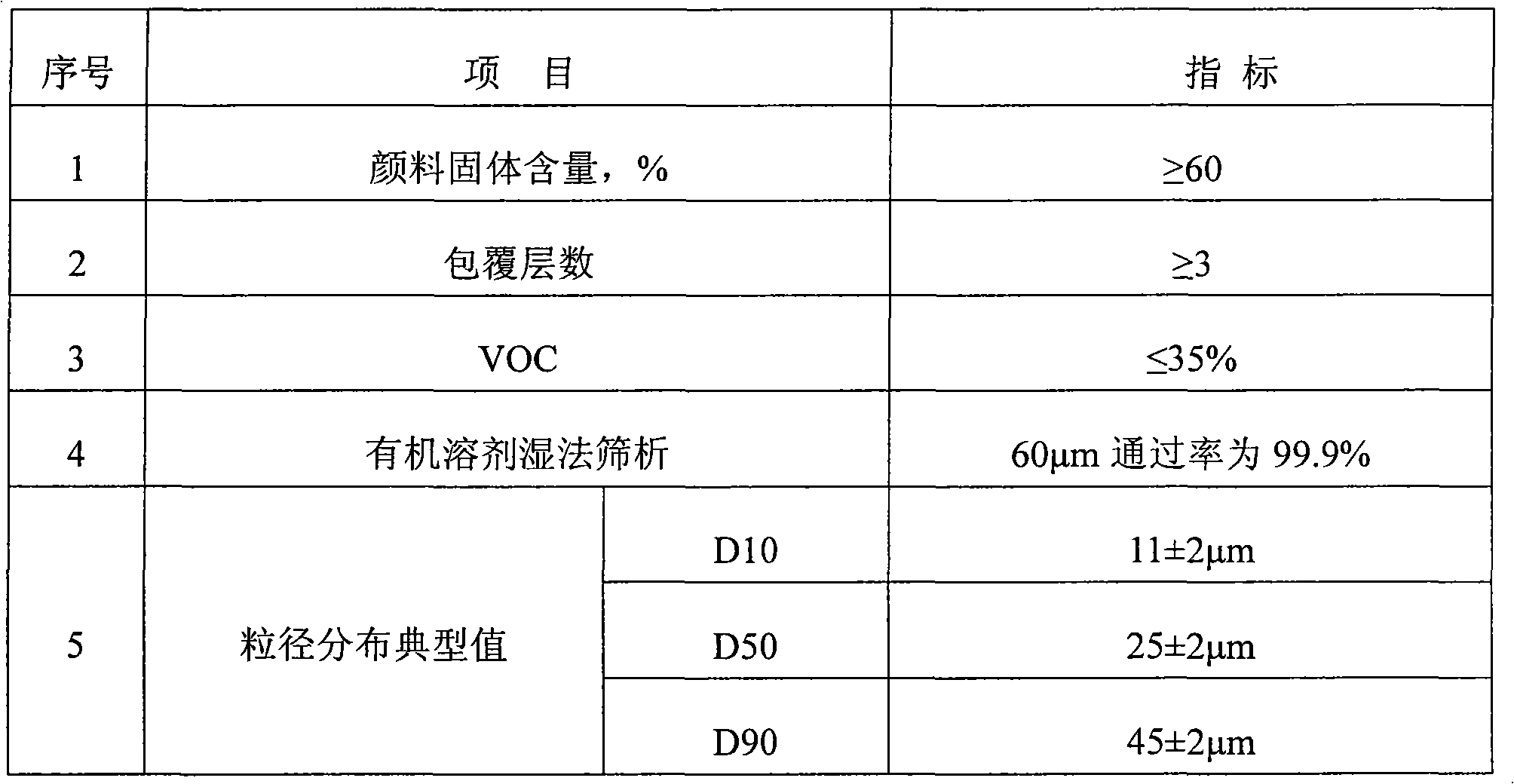

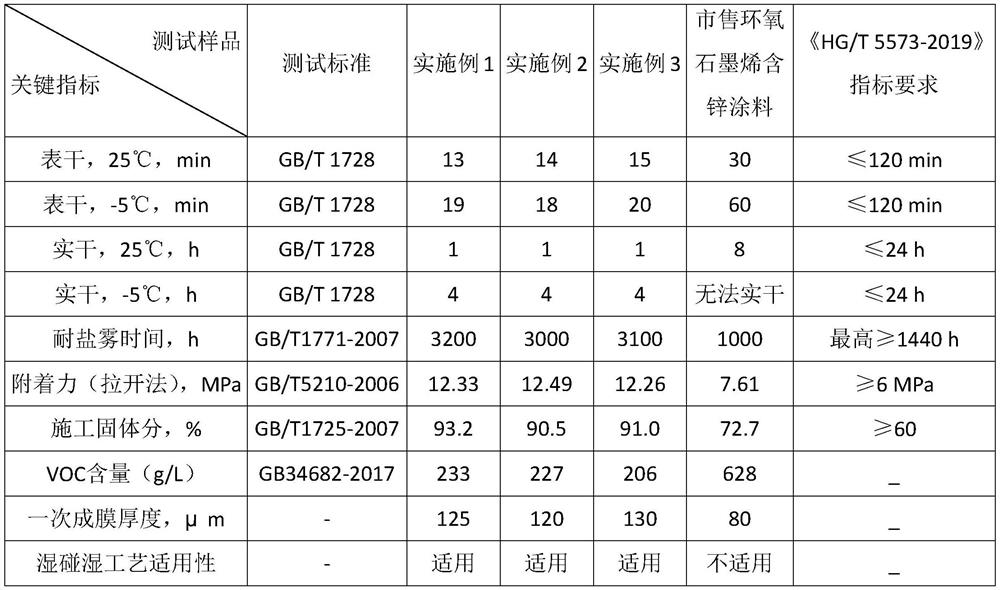

Graphene modified polyaspartic acid ester zinc-containing coating and preparation method thereof

InactiveCN112143360AImprove performanceEasy to dryAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidOrganosolv

The invention relates to a graphene modified polyaspartic acid ester zinc-containing coating and a preparation method thereof. The coating comprises a component A capable of curing to form a film anda component B containing a curing agent, the component A comprises high solid content low viscosity polyaspartic acid ester resin, an organic solvent, a dispersant, graphene, zinc powder, an antirustpigment, a leveling agent and an anti-settling agent; and the component B is isocyanate or a mixture of isocyanate and an organic solvent. The graphene modified polyaspartic acid ester zinc-containingcoating belongs to an environment-friendly green product, is higher in drying speed compared with an existing common epoxy zinc powder coating, and can meet the wet-to-wet spraying process requirements, and the one-time film forming thickness can reach 120 [mu]m or above, so that the construction efficiency is greatly improved; the salt spray resistance is better, and the adhesive force is good;the method provided by the invention is environment-friendly in production process, simple in process, free of sanding process, low in cost and beneficial to industrial large-scale production.

Owner:湘江涂料科技有限公司

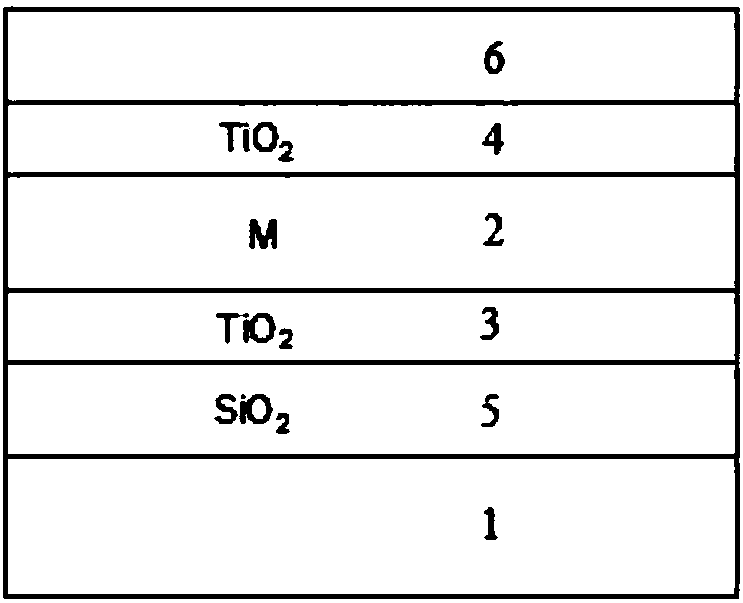

Preparing method for high-temperature and high-humidity resisting golden film

InactiveCN108220884AStrong metallic lusterCompact structureVacuum evaporation coatingSputtering coatingOxideSilicon oxide

The invention provides a preparing method for a high-temperature and high-humidity resisting golden film. The golden film comprises a metal layer arranged on a transparent substrate and further comprises a first titanic oxide layer and a second titanic oxide layer which are arranged on the two sides of the metal layer. The first titanic oxide layer is closer to the transparent substrate. The golden film further comprises a silicon oxide layer which is arranged on the other sides / the other side of the first titanic oxide layer and / or the second titanic oxide layer. The preparing method comprises the steps that various films are plated through evaporation coating equipment, argon is added in a coating cavity for deposition assisting during metal layer plating, and oxygen is added in the coating cavity after metal layer plating and before second titanic oxide layer plating so as to conduct bombarding treatment on the metal layer. According to the method, the density of the metal layer inthe golden film can be improved, the metal layer is passivated, and activity of the metal layer is reduced. Thus, the color changing problem of the prepared golden film under the high-temperature andhigh-humidity conditions can be greatly solved.

Owner:LENS TECH CHANGSHA

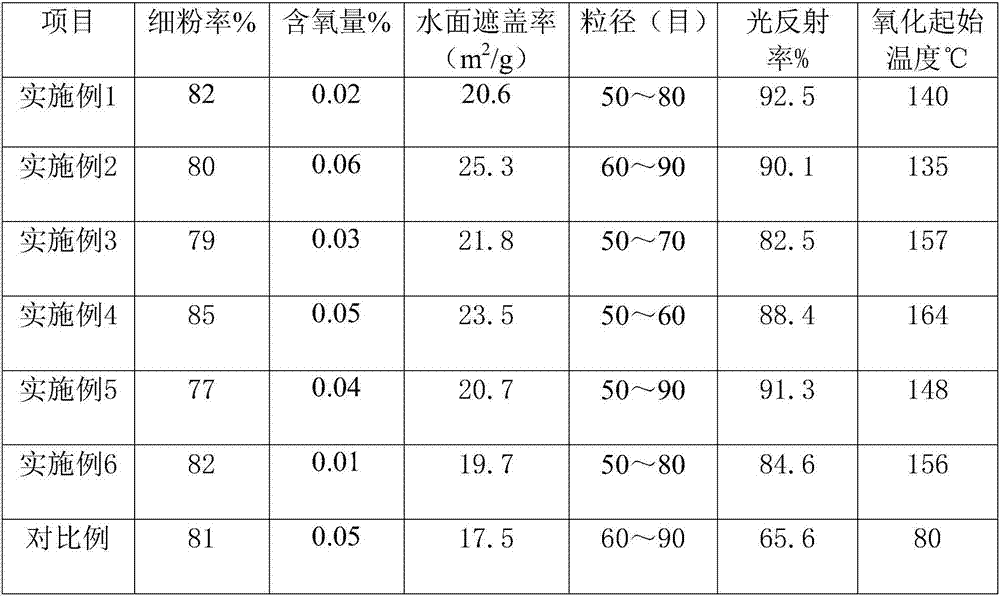

Preparation method of gravure bronze powder

InactiveCN107022693AGood high temperature resistanceStrong metallic lusterTemperature resistanceSodium bicarbonate

The invention discloses a preparation method of gravure bronze powder. The technical problems that bronze powder prepared in the prior art is high in oxygen content, low in fine powder rate, low in metal luster and unstable in product quality are solved. The preparation method mainly comprises the steps of raw material weighing, raw material melting, water atomization powder preparation, cleaning, drying, polishing and screening. Since sodium oxide and sodium bicarbonate are added in the raw material meting process, the oxygen content of the bronze powder is reduced, and the microcosmic shape of particles is more regular. Since a polishing assisting agent is added in the polishing process, the obtained bronze powder is good in oxidization resistance and high-temperature resistance, and high in metal luster. According to the preparation method, the production technological stability is high, and the prepared bronze powder is low in oxygen content, high in fine powder rate and high in metal luster.

Owner:邱秘

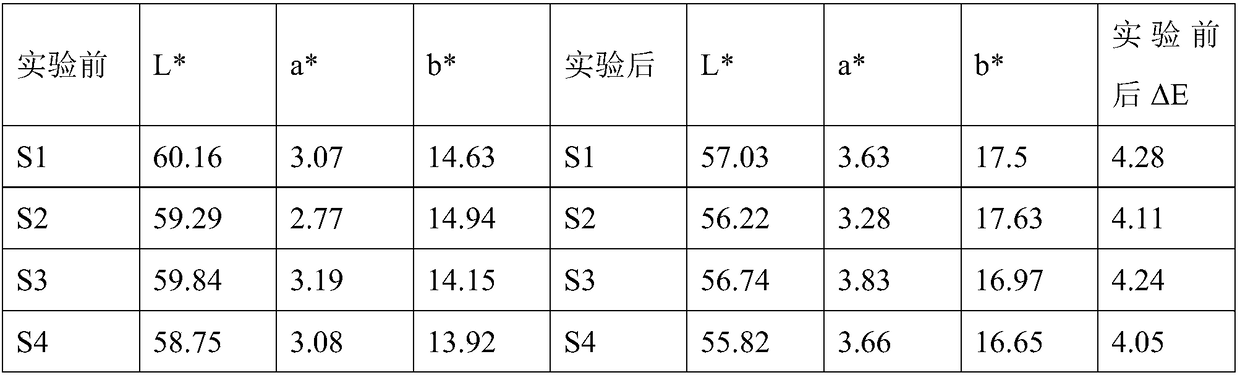

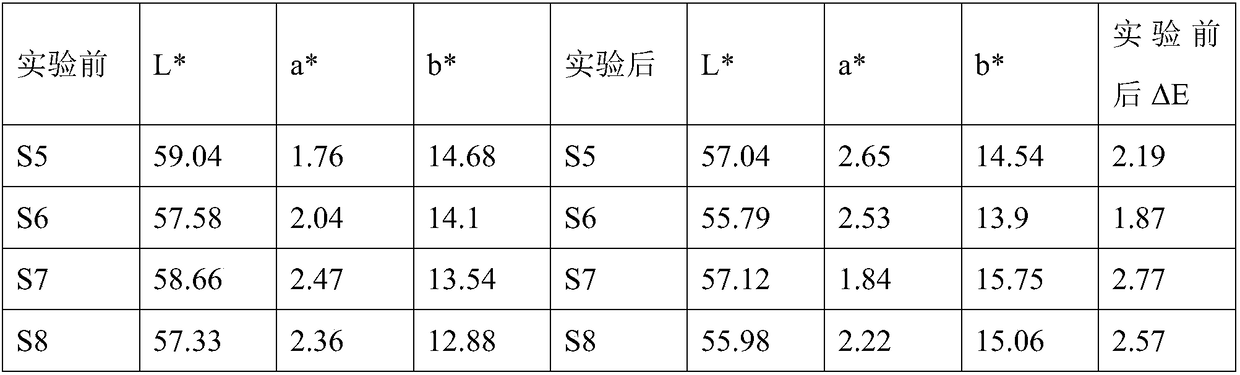

Lead-free metallic luster glaze, ceramic thereof, and preparation method of the lead-free metallic luster glaze

The invention relates to a lead-free metallic luster glaze and ceramic thereof, and a preparation method of the lead-free metallic luster glaze. The lead-free metallic luster glaze comprises the following components: 88%-96% of basic glaze; 3%-11% of a first coloring agent, including at least two of Fe2O3, CuO, MnO, V2O5 and NiO; 1-5% of a second coloring agent comprising at least two of Pr2O3, Sm2O3, La2O3, CeO2, Y2O3, Nd2O3 and Yb2O3. According to the lead-free metallic luster glaze, by adding a second color former into a mixed glaze of a basic glaze and a first color former, the surface metallic luster of the lead-free metallic luster glaze is improved; wherein the first color former comprises at least two of Fe2O3, CuO, MnO, V2O5 and NiO, that is, the lead frit is not added, so that environmental pollution and damage to production workers in the production process of the glaze are avoided, and the lead-free metallic luster glaze is prevented from being eroded by acid in the use process to dissolve out lead elements and seriously endanger human health.

Owner:JINGDEZHEN CERAMIC UNIV

Three-dimensional bronzing method

ActiveCN101670719BChange the status quo that cannot form a strong three-dimensional effect patternTake advantage ofPhotosensitive materialsRotary pressesScreen printingSurface layer

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

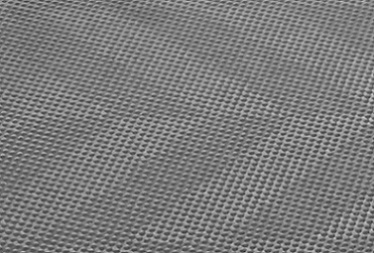

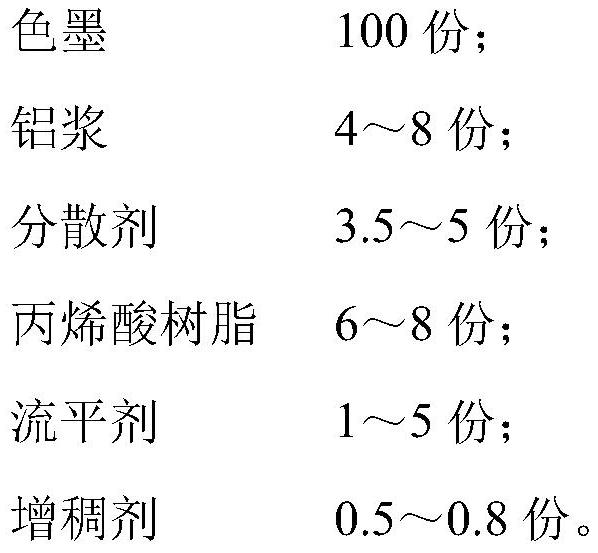

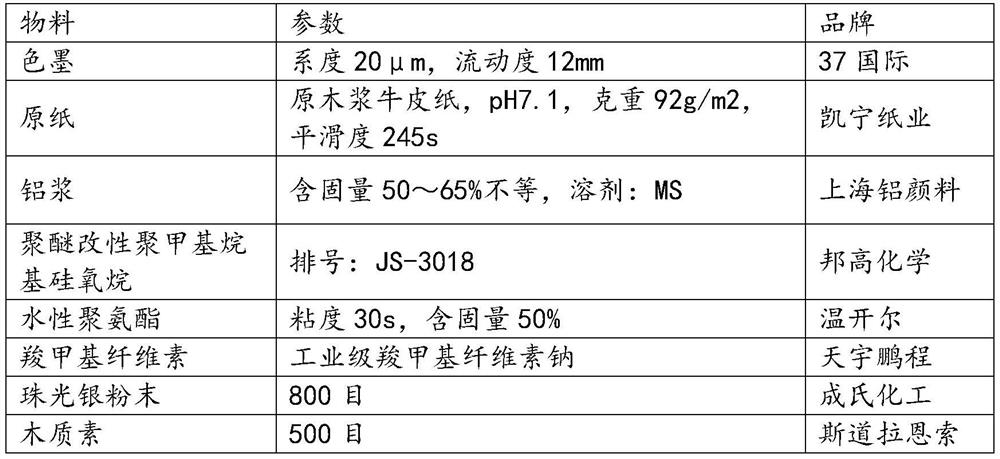

Printing ink for grainy paper, grainy paper and preparation method of grainy paper

PendingCN113861757AStrong metallic lusterImprove wear resistanceSurface covering paperCoatings with pigmentsPolymer scienceAcrylic resin

The invention relates to the field of decorative paper, in particular to grainy paper, ink for the grainy paper and a preparation method of the grainy paper. The printing ink for the grainy paper comprises color ink, aluminum paste, a dispersing agent, acrylic resin, a flatting agent and a thickening agent. The aluminum paste is adopted as a color matching agent, and the dispersing agent, the acrylic resin, the flatting agent and the thickening agent are matched, so that the grainy paper has relatively good glossiness and relatively strong wear resistance.

Owner:杭州博思特装饰材料有限公司

Lamellar flaky heavy anti-corrosion coating and preparation method thereof

InactiveCN111647334AStrong metallic lusterImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentSolvent

The invention discloses a lamellar flaky heavy anti-corrosion coating and a preparation method thereof. The coating comprises the following components in parts by weight: a component A: 5-20 parts ofbasalt scales, 5-20 parts of aluminum paste, 15-40 parts of epoxy resin, 0.5-1 part of a thickener, 0.5-1 part of a dispersing agent, 0.5-1 part of a leveling agent, 0.5-1 part of an antifoaming agent, 0.5-1 part of a coalescing agent and 15-40 parts of a solvent; the component B comprises 20-40 parts of a curing agent and 15-40 parts of a solvent; wherein the weight ratio of the component A to the component B is 4:1. When a base material is coated with the coating, an external corrosive medium can corrode the base material, i.e., a labyrinth effect, only by walking over a longer path; the basalt flakes can also increase the wear resistance and the chemical stability of the coating; the aluminum paste has the properties of strong metallic luster, good heat resistance, corrosion resistanceand the like, so that the coating generates an angle-dependent different-color effect, and the combination of the basalt flakes and the aluminum paste greatly improves the performance of the coating.

Owner:中国南方电网有限责任公司超高压输电公司柳州局

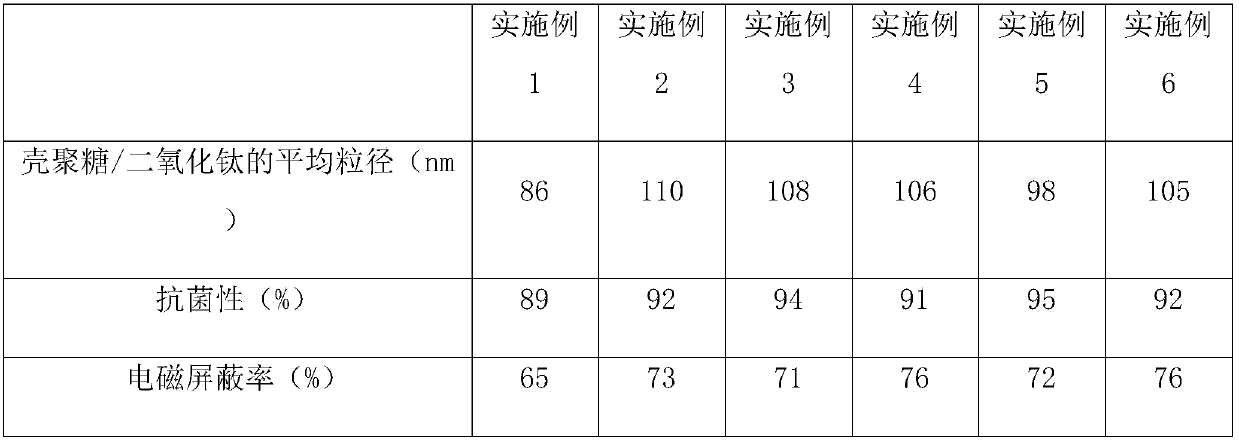

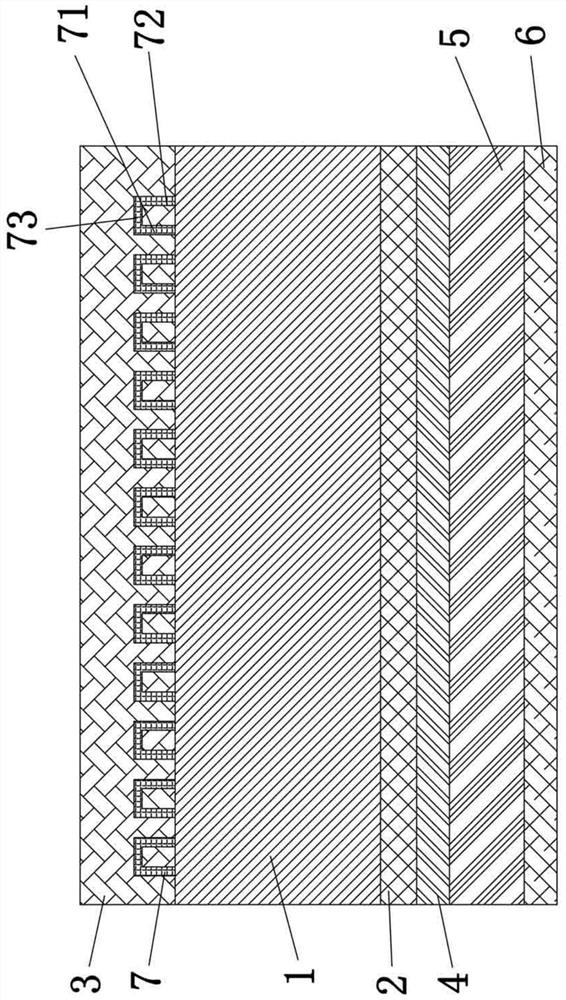

A kind of lace fabric with metallic luster and preparation method thereof

InactiveCN106087415BImprove adhesionFacilitate cross-linkingLamination ancillary operationsSynthetic resin layered productsMetal fiberUltraviolet

The invention provides a preparation method of lace fabric with metallic luster. The preparation method comprises steps as follows: chitosan is dissolved in a citric acid water solution and sufficiently stirred until chitosan is completely dissolved to form a chitosan solution, nano titanium dioxide particles are added, a glutaraldehyde cross-linking agent is added after ultrasonic dispersion, the mixture is heated and stirred, and a chitosan / titanium dioxide solution is obtained; silk fibers and metal fibers are taken as raw materials, a base layer is prepared, nylon, spandex and metal fibers are taken as raw materials, a decoration layer is prepared, and lace gray fabric is obtained; the lace gray fabric is immersed in the chitosan / titanium dioxide solution, vibrated at the constant temperature under the ultraviolet irradiation condition, taken out, washed with water and dried, and the lace fabric with the metallic luster is obtained. The lace fabric prepared with the method has high elasticity, is skin-friendly, antibacterial and anti-static and further has intensive metallic luster.

Owner:深圳市诗恩纺织品有限公司

Imitation metal back plate of refrigerator and processing technology of imitation metal back plate

PendingCN113978075AHigh fire ratingComposite firmSynthetic resin layered productsPigment treatment with organosilicon compoundsPunchingIcebox

The invention discloses a processing technology of an imitation metal back plate of a refrigerator, wherein the processing technology comprises the following steps: S1, compounding coloring powder on the lower surface of a surface layer film to obtain an imitation metal film with the thickness of 20-50 [mu]m; S2, uniformly stirring and mixing the raw materials of a base material, feeding into an extruder, plasticizing and extruding, feeding the extruded base material into a calender, and calendering to obtain a base plate; S3, compounding the imitation metal film and the base plate through a composite roller at the temperature of 160-180 DEG C, then feeding into a plastic suction machine, and after forming, slitting, to obtain an imitation metal plate; S4, attaching an aluminum foil to the other side face of the imitation metal plate, and forming a back plate blank; and S5, punching and bending the back plate blank, and then welding and assembling the back plate blank. The defects in the prior art are overcome, the appearance metal glossiness of the imitation metal back plate of the refrigerator is high, the imitation metal film is firmly compounded on the surface of the base plate, coloring powder is not prone to disengagement, and the fireproof grade is high.

Owner:合肥晨乐塑胶有限公司

Method for manufacturing plastic identifier by adopting gold stamping and laser etching technology

ActiveCN101727774BGood adhesionReduce manufacturing costStampsDuplicating/marking methodsLaser etchingPolymer science

The invention discloses a method for manufacturing a plastic identifier by adopting gold stamping and laser etching technology. The method comprises the following steps: firstly, adopting a gold stamping film material with wiredrawing effect on injection molding products; processing by multi-face wiredrawing gold stamping technology to obtain the plastic products with strong metal luster and wiredrawing effect on the surface; and achieving an expected value of the laser etching depth of the product surface by adjusting laser etching technological parameters so as to realize the three-dimensional effect of imitated salient point printing on the surface of the products. Therefore, identification nameplates or other plastic products which have the advantages of clear patterns, beautiful appearance, garish color and good performance of high adhesion, wear resistance, weather resistance and the like are obtained, and further metal materials with high cost are replaced.

Owner:通达创智(厦门)股份有限公司

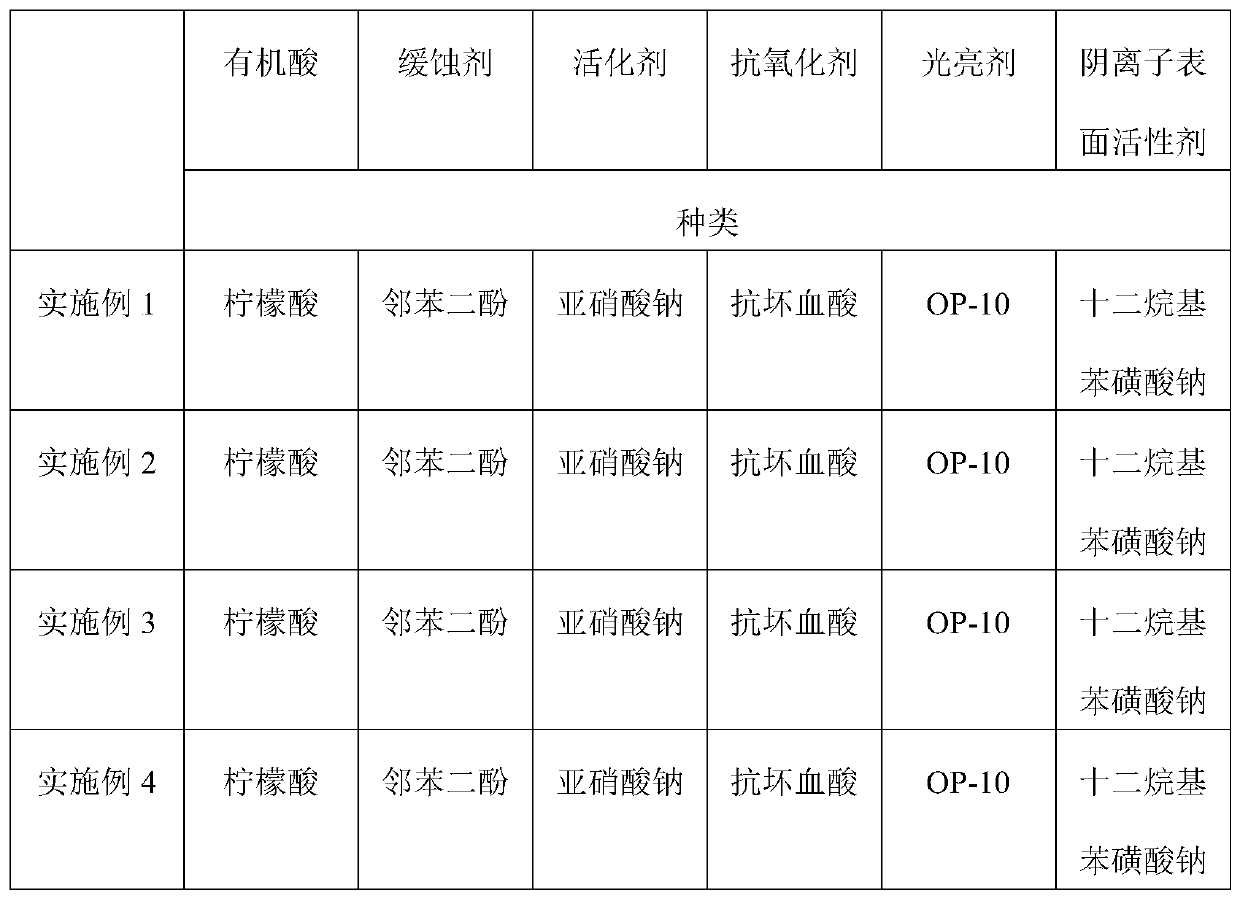

Lead frame deoxidizer and preparation method and application thereof

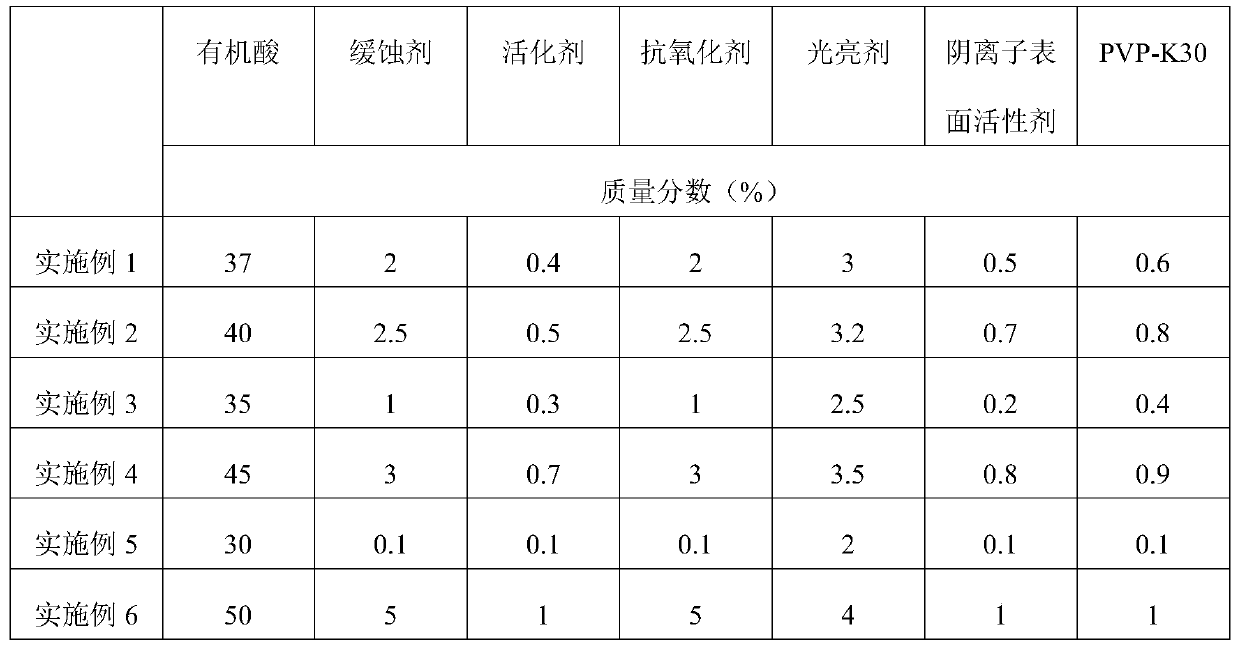

The invention discloses a lead frame deoxidizer and a preparation method and application thereof. The deoxidizer comprises, by mass, 30%-50% of organic acid, 0.1%-5% of corrosion inhibitor, 0.1%-1% ofactivator, 0.1%-5% of antioxidant, 2%-4% of brightener, 0.1%-1% of anionic surfactant, 0.1%-1% of polyvinylpyrrolidone and water, and the total mass fraction of the components is 100%; and the K value of the polyvinylpyrrolidone is 30. The deoxidizer is mild and free of toxicity and has high environmental friendliness; and the deoxidizer is suitable for deoxidization of copper-based lead frames and iron-nickel-based lead frames at the same time, and after deoxidization, the surfaces of base materials are bright and smooth and have a polished effect with high metallic luster.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

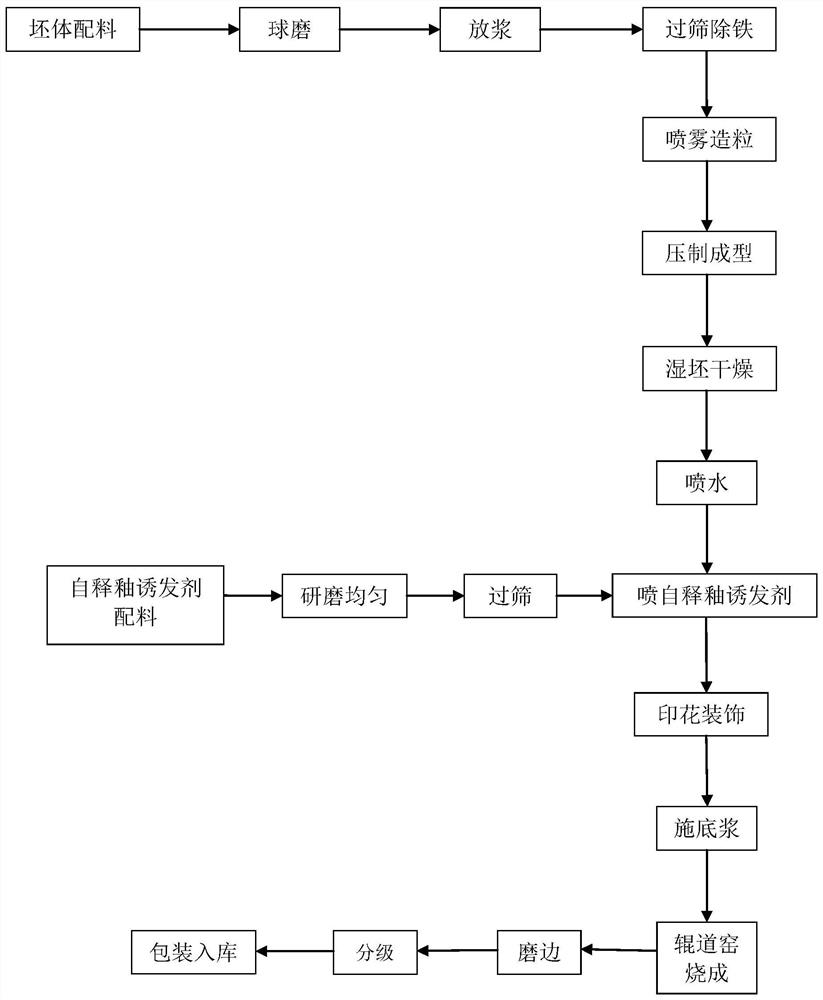

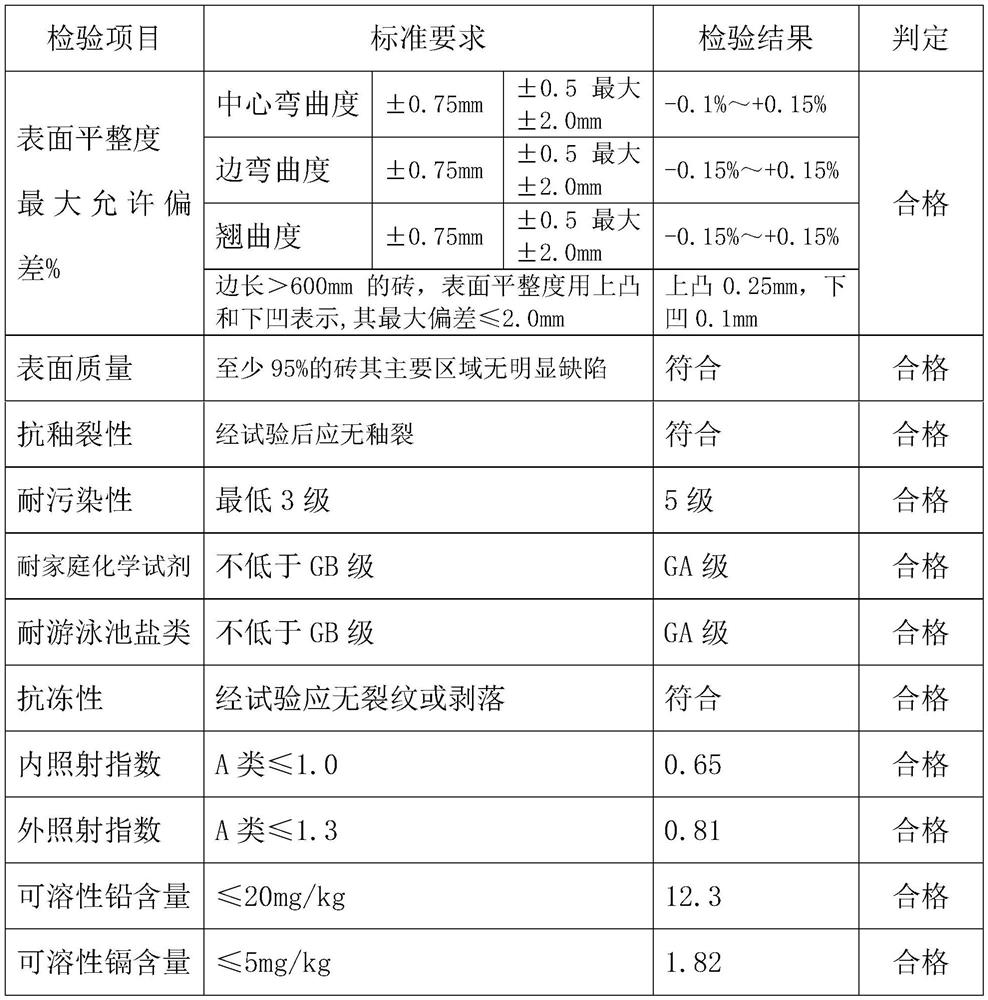

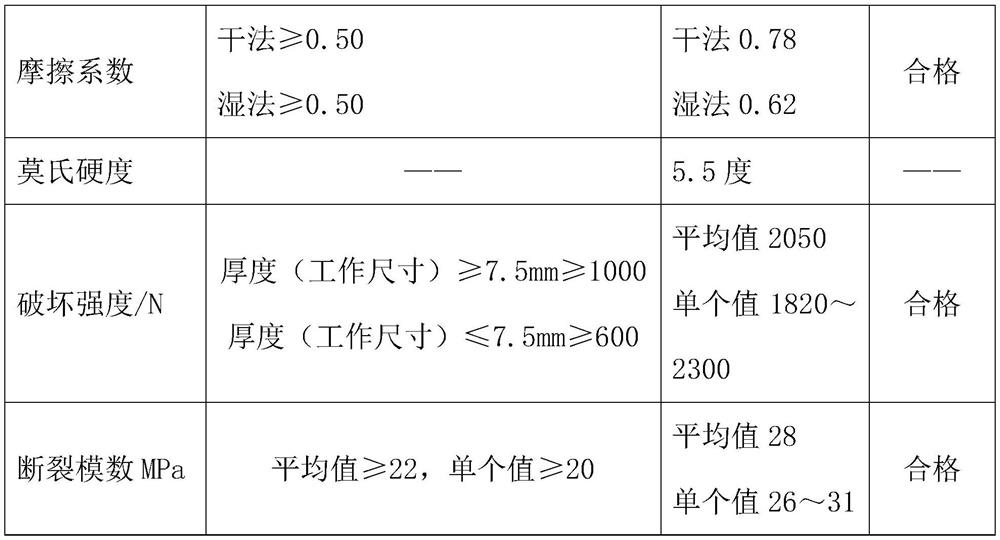

Self-release glaze inducer, self-release glaze ceramic tile and preparation method thereof

The self-release glaze inducer, the self-release glaze ceramic tile and the preparation method thereof of the present invention focus on the formulation of the green body and the self-release glaze inducer without making significant changes to the production process of the existing ceramic tile. Adjust and optimize the spray amount, so that the surface of the prepared product is smooth and delicate, with slight unevenness. The surface gloss is measured with a WGG60‑E4 gloss meter to be 4-8, and the cross section of the product is observed with a 30 times magnifying glass. The glaze boundary layer, the product has good flatness, high strength, strong stain resistance, clear and natural pattern texture, bright color, realistic stone imitation, no pinholes, bubbles and other defects. Because the product does not need glazing, and the surface after high temperature calcination fully achieves the performance and decorative performance of glazed ceramic tiles, thus reducing the processing links of traditional glazed ceramic tiles and saving resources; at the same time, this technology has strong universality. It is easy to promote in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

A method and production equipment of a transfer type thin film composite metal film

ActiveCN103847217BImprove adhesionImprove smoothnessLamination ancillary operationsLaminationCompound aTransfer mode

The invention relates to a method for compounding a metal membrane by a transfer-type film as well as production equipment thereof. The method comprises the following steps: pretreating the surface of a plastic film; coating mucilage on the surface of a metal layer on a carrier film; drying up the carrier film; precooling the carrier film; compounding the plastic film and the carrier film by a lamination mode; carrying out hot-pressing and drying; stripping a base material layer of the carrier film. The mucilage is coated on the carrier film and is compounded with the plastic film, and finally the base material layer of the carrier film is stripped off, so that the original surface of the metal layer of the carrier film is attached to the plastic film by the mucilage, and the surface of the metal layer, which is attached to the base material layer, is converted into the surface of a metal compound film. The surface of the metal compound film after being compounded is provided with an even mirror surface, and has high metallic luster; the metal film is compounded by a transfer mode without being performed at high-temperature environments; the plastic film cannot be deformed, and the waste rate of the plastic film is reduced to be less than 0.5%; the finished product rate of the metal compound film is improved greatly.

Owner:广东东南薄膜科技股份有限公司

Polyimide film externally coated with metal conductive layer and preparation method thereof

InactiveCN101630540BNot easy to damage and failStrong metallic lusterConductive layers on insulating-supportsMagnetic/electric field screeningElectromagnetic shieldingGraphite

The invention relates to a polyimide film externally coated with a metal conductive layer and a preparation method thereof. The polyimide film is provided with a polyimide insulating layer and a metal conductive layer and is characterized in that a middle bonding layer playing a role of bidirectional bonding is arranged between the polyimide insulating layer and the metal conductive layer. The middle bonding layer comprises the following components in percentage by weight: 35-50 percent of polyimide as a main component, 3-12.5 percent of graphite, 3-12.5 percent of conductive black carbon, 0.6-6 percent of silane coupling agent, 2-10 percent of nickel-silver curing agent, 4-16 percent of conductive paint conductivity promoting agent and 2-10 percent of leveling agent. The preparation method comprises the steps of coating, drying, curing for molding, polishing, and the like. The polyimide film externally coated with the metal conductive layer can be widely applied to the high-tech field of protective devices with special purposes, and the like of electronics, electrical appliances, electromagnetic shielding, electromagnetic radiation and power transmission and transformation projects.

Owner:陈贤斌

Golden stamping ribbon for barcode printer and preparation method of gold stamping ribbon

The invention discloses a golden stamping ribbon for a barcode printer. The golden stamping ribbon comprises a release layer and a heat-resistant layer which are arranged on the front surface and the rear surface of a base film, wherein the release layer is correspondingly connected with a coloring layer, the coloring layer is correspondingly connected with an aluminum plating layer, and the aluminum plating layer is correspondingly connected with a bonding layer; a plurality of connecting frames are correspondingly arranged between the base film and the heat-resistant layer, each connecting frame comprises a first connecting leg and a second connecting leg, the lower ends of the first connecting legs and the lower ends of the second connecting legs are correspondingly connected with the upper surface of the base film, and the upper ends of the first connecting legs and the upper ends of the second connecting legs are correspondingly connected with cross rods. The golden stamping ribbon has the advantages of being high in printing speed, free of platemaking, convenient to operate, wide in application range, bright in color, high in metal luster and the like.

Owner:福建鸣友新材料科技有限公司

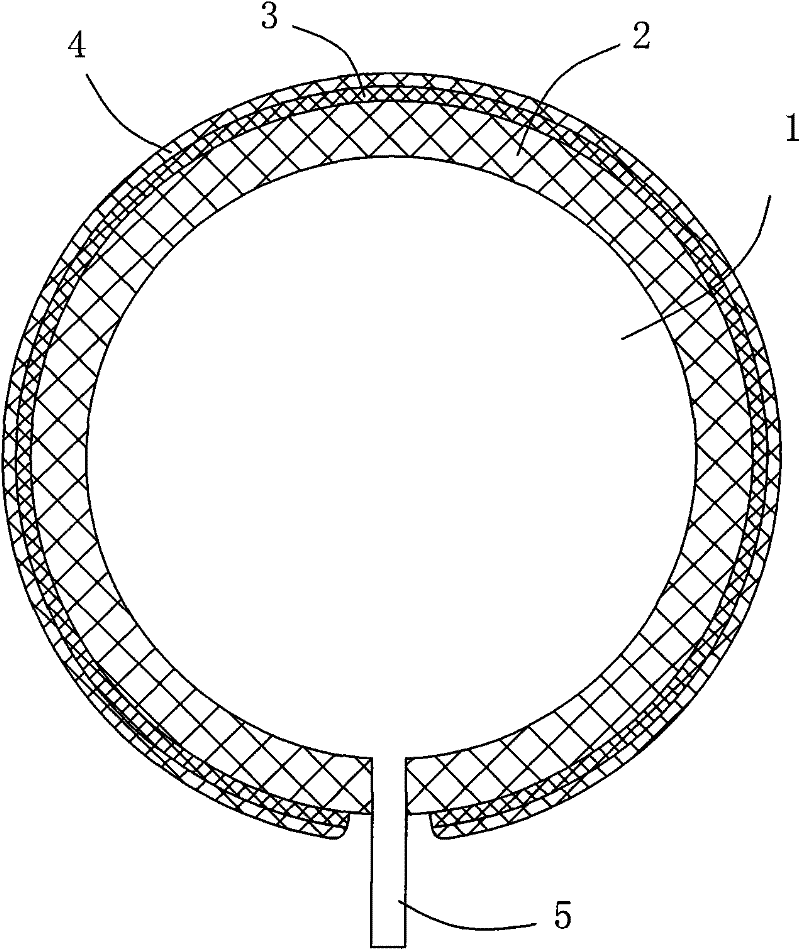

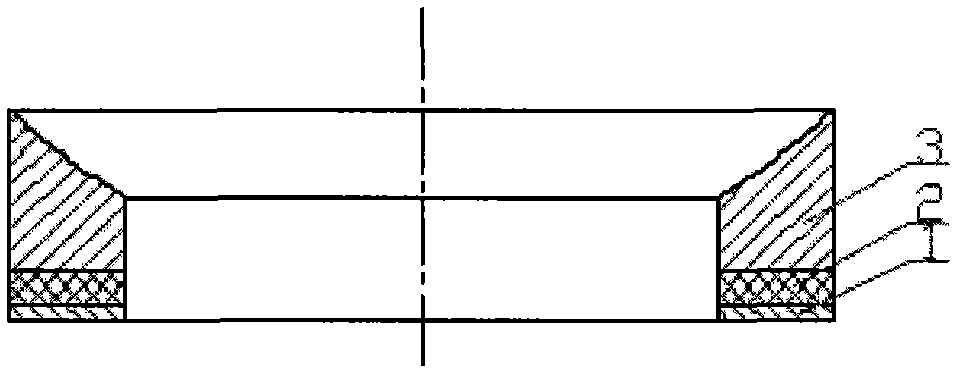

Combined type heat-insulating baffle for increasing monocrystal solidification temperature gradient

ActiveCN102400206BLow thermal conductivityStrong coefficient of thermal expansionFrom frozen solutionsGraphiteHeight difference

The invention relates to a combined type heat-insulating baffle which is applied to directional solidification equipment and is used for increasing monocrystal solidification temperature gradient. The combined type heat-insulating baffle comprises graphite rings and a flexible graphite felt, wherein the graphite rings and the flexible graphite felt are combined into an annular body, the inner diameter of which is more than the outer diameter of a shell mould to be cast; and the graphite rings are divided into two layers, the upper-layer graphite ring is directly placed on a water cooling sleeve in a directional solidification furnace, the flexible graphite felt is filled between the two layers of graphite ring, a height difference exists between the height of the inner diameter of the upper-layer graphite ring and the height of the outer diameter of the upper-layer graphite ring, and the height from the inner diameter to the outer diameter is increased in a smooth transition manner. The combined type graphite high-temperature heat-insulating baffle disclosed by the invention is convenient to manufacture by just clipping the flexible graphite felt according to dimensions and placing the clipped flexible graphite felt on the graphite rings on the water cooling sleeve as well as directly placing the second-layer graphite ring on the graphite felt, no bolts and nuts are needed for fixation, the placement is convenient and the price cost is low. Compared with the prior art in which a hard graphite felt is used as the heat-insulating baffle, the combined type heat-insulating baffle has the advantage that the temperature gradient is increased by almost 50%.

Owner:GUIYANG AVIC POWER PRECISION CASTING

A water-based roll-spray paint with water washability and high metallic luster and preparation method thereof

ActiveCN110054946BEasy to cleanReduce dosagePolyurea/polyurethane coatingsPaints with free metalsAcrylic resinDiethylene glycol

The invention discloses a water-based roll-spray paint with water-resistance and high metallic luster and a preparation method thereof, wherein the water-base roll-spray paint is prepared by mixing the following raw materials in weight percentage: 30%-40% of acrylic resin, water-based polyurethane Grease 7%‑9%, water-based aluminum pigment 7%‑9%, water-based transparent color paste 5%‑7%, coupling agent 1%‑2%, surface slip agent 1%‑2%, diethylene glycol butyl Ether 14%‑18%, deionized water 25%‑33%. The water-based roller spray paint proposed by the invention has fast film formation and fast curing, high surface strength, smooth surface, good metallic gloss, excellent hiding power, and high hardness, water resistance, abrasion resistance and scrub resistance of the paint film. The preparation method of the water-based roller spray paint provided by the invention has the advantages of simple process, high production efficiency, easy cleaning, little environmental pollution, small volume of equipment used, and low price.

Owner:清远市绚淳环保新材料有限公司

Housing processing method, housing and electronic equipment

ActiveCN111212538BStrong metallic lusterOvercome the defect of weak metallic lusterCasings/cabinets/drawers detailsPattern printingStructural engineeringMechanical engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com