Lead-free metallic luster glaze, ceramic thereof, and preparation method of the lead-free metallic luster glaze

A lead-free metal and lead metal technology, applied in the field of ceramics, can solve the problem of lead-containing metallic luster glaze harming human health and other problems, and achieve the effects of increasing the surface metallic luster, avoiding pollution and refining crystal grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

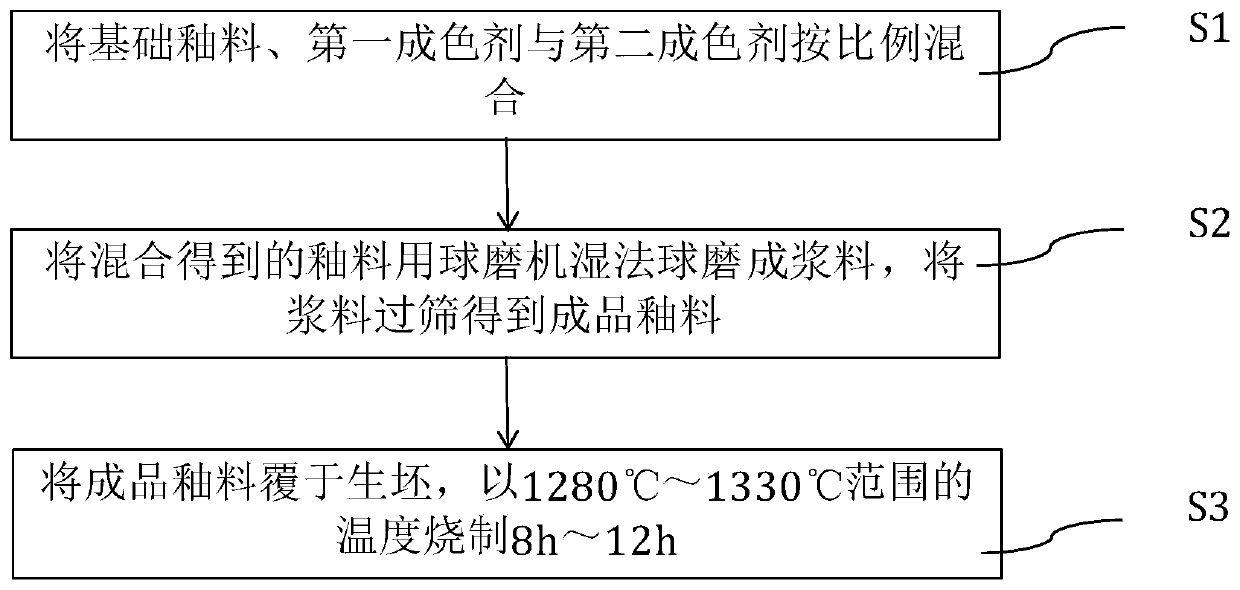

[0037] The embodiment of the second aspect of the present invention proposes a preparation method of lead-free metallic luster glaze, which is used to prepare the lead-free metallic luster glaze described in any of the above embodiments, such as figure 1 shown, including the following steps:

[0038] S1: mixing the basic glaze, the first coupler and the second coupler in proportion;

[0039] S2: The mixed glaze is wet-milled into a slurry with a ball mill, and the slurry is sieved to obtain a finished glaze;

[0040] S3: Cover the green body with the finished glaze, and fire at a temperature ranging from 1280° C. to 1330° C. for 8 hours to 12 hours.

[0041] The preparation method of the lead-free metallic luster glaze of the embodiment of the present invention, by selecting a reasonable formula composition, adopting high temperature one-time firing, produces uniformly sized crystal grains in the glaze layer, and can be adjusted by adding different rare earth oxides as requir...

Embodiment 1

[0054] The lead-free metallic luster glaze comprises the following components in terms of mass percentage: 89% of basic glaze, 6% of the first coupler, and 5% of the second coupler. Wherein, the first coupler is: Fe 2 o 3 , MnO, V 2 o 5 , NiO, the second coupler is: CeO 2 , Y 2 o 3 、Nd 2 o 3 , Yb 2 o 3 .

[0055] The basic glaze includes the following components in terms of mass percentage: 58.5% feldspar, 7% Suzhou kaolin, 18% quartz, 2% calcined talc, 12% calcite, and 2.5% bovine bone ash.

[0056] Preparation:

[0057] S1: mixing the basic glaze, the first coupler and the second coupler in the above ratio;

[0058] S2: Mix the mixed glaze, balls, and water in a ratio of 1:1.5:0.7, add a water reducer and a dispersant, ball mill for 10 hours, and pass the milled slurry through a 250-mesh sieve to obtain a finished glaze;

[0059] S3: Cover the finished glaze with a thickness of 0.5mm on the green body, dry the green body at a temperature of 60°C for 120 minutes ...

Embodiment 2

[0061] The lead-free metallic luster glaze comprises the following components in terms of mass percentage: 88% of basic glaze, 7% of the first coupler, and 5% of the second coupler. Wherein, the first coupler is: Fe 2 o 3 , CuO, MnO, V 2 o 5 , the second coupler is: La 2 o 3 , CeO 2 , Y 2 o 3 .

[0062] The basic glaze includes the following components in terms of mass percentage: 60% feldspar, 5% Suzhou kaolin, 24.3% quartz, 1.5% calcined talc, 8% calcite, and 1.2% bovine bone ash.

[0063] Preparation:

[0064] S1: mixing the basic glaze, the first coupler and the second coupler in the above ratio;

[0065] S2: Mix the mixed glaze, balls, and water in a ratio of 1:1.5:0.6, add a water reducing agent and a dispersant, ball mill for 12 hours, and pass the milled slurry through a 300-mesh sieve to obtain a finished glaze;

[0066] S3: Cover the finished glaze with a thickness of 0.35mm on the green body, dry the green body at a temperature of 50°C for 200 minutes aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com