Patents

Literature

62results about How to "High appreciation value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

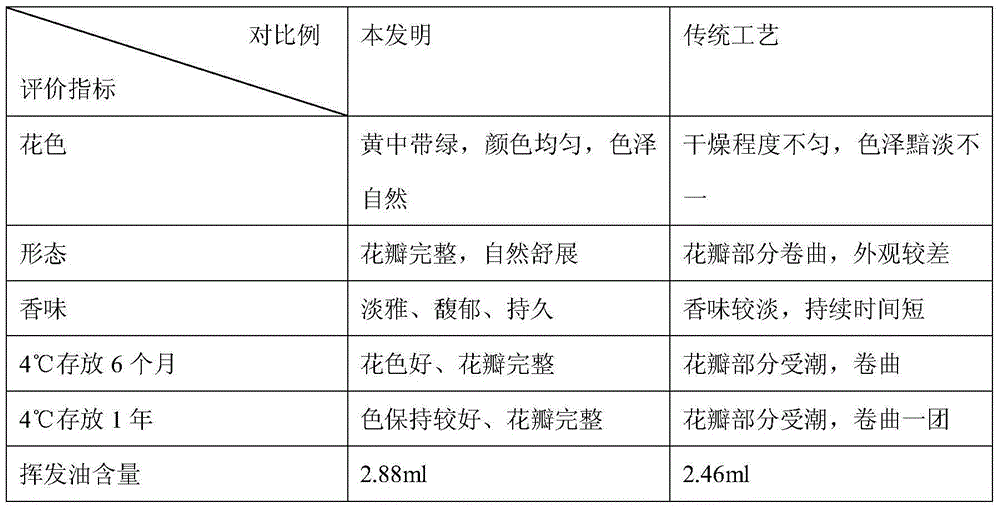

Making method of Dendrobium officinale Kimura et Migo flower tea

InactiveCN104920649ASimple processing technologyRetain nutritional valuePre-extraction tea treatmentTea substituesNutritive valuesAgroforestry

The invention provides a processing method of Dendrobium officinale Kimura et Migo flower tea. The method comprises the following steps: picking flowers, cleaning the flowers, spreading the cleaned flowers for drying, deactivating enzyme, stir-frying the obtained product, baking and shaping the fried product, and sorting and packing the final product. According to the invention, the processing method of the Dendrobium officinale Kimura et Migo flower tea is improved, so that the nutritive value of the Dendrobium officinale Kimura et Migo flower tea is retained, and when the Dendrobium officinale Kimura et Migo flower tea is brewed with water, strong fragrance lasts for a long time, the flowers are unfolded in water, and higher ornamental value is achieved.

Owner:ZHEJIANG YUNZHITANG BIOTECH

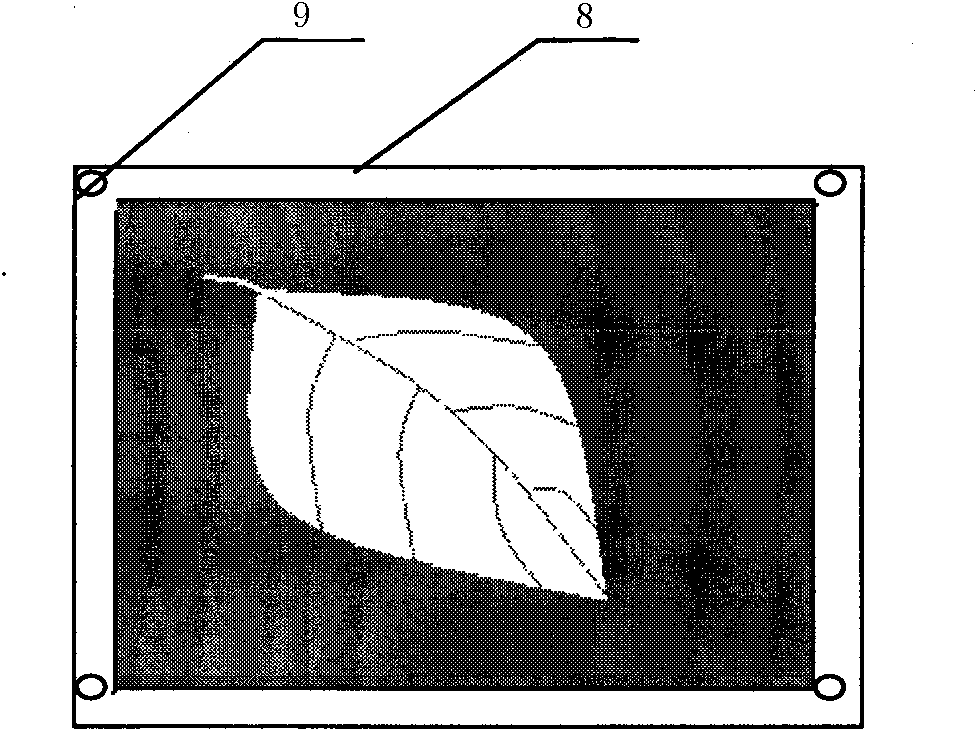

Wax print cloth wax veins producing prescription and technique

InactiveCN101144251AElasticFlexibleFibre treatmentDyeing processParaffin waxOxidation-Reduction Agent

The present invention discloses a print production prescription and a process of the wax print fabric. The production prescription used adopts rosin, paraffin wax, beeswax, and macromolecule resin as wax material. The process flow is as follows: firstly, an original grey cloth is processed through singeing, desizing, scouring, bleaching, mercerizing, stenter tentering of weft ripe or padding Naphthol liquid Naphthol, the wax liquid melted and mixed under the condition of 50 DEG C to 200 DEG C on a wax printing machine is uniformly printed on the fabric through a rotary screen on the condition of constant temperature, after the air-cooled or water-cooled solidification, the dyeing redox is dyed blue with flora on the indigo machine or the color flora machine is dyed with color through padding the azoic dyestuff, and then a wax swinging machine is pulled over the small circular hole in a rope shape. Under 40 DEG C, and by the machinery outside force, the wax membrane is cracked naturally, and through processing the wax-dyeing by using indigo, insoluble azo dyes, and India blue IBN etc., the wax print fabric with various glaze and different style of wax print can be obtained.

Owner:王化斌

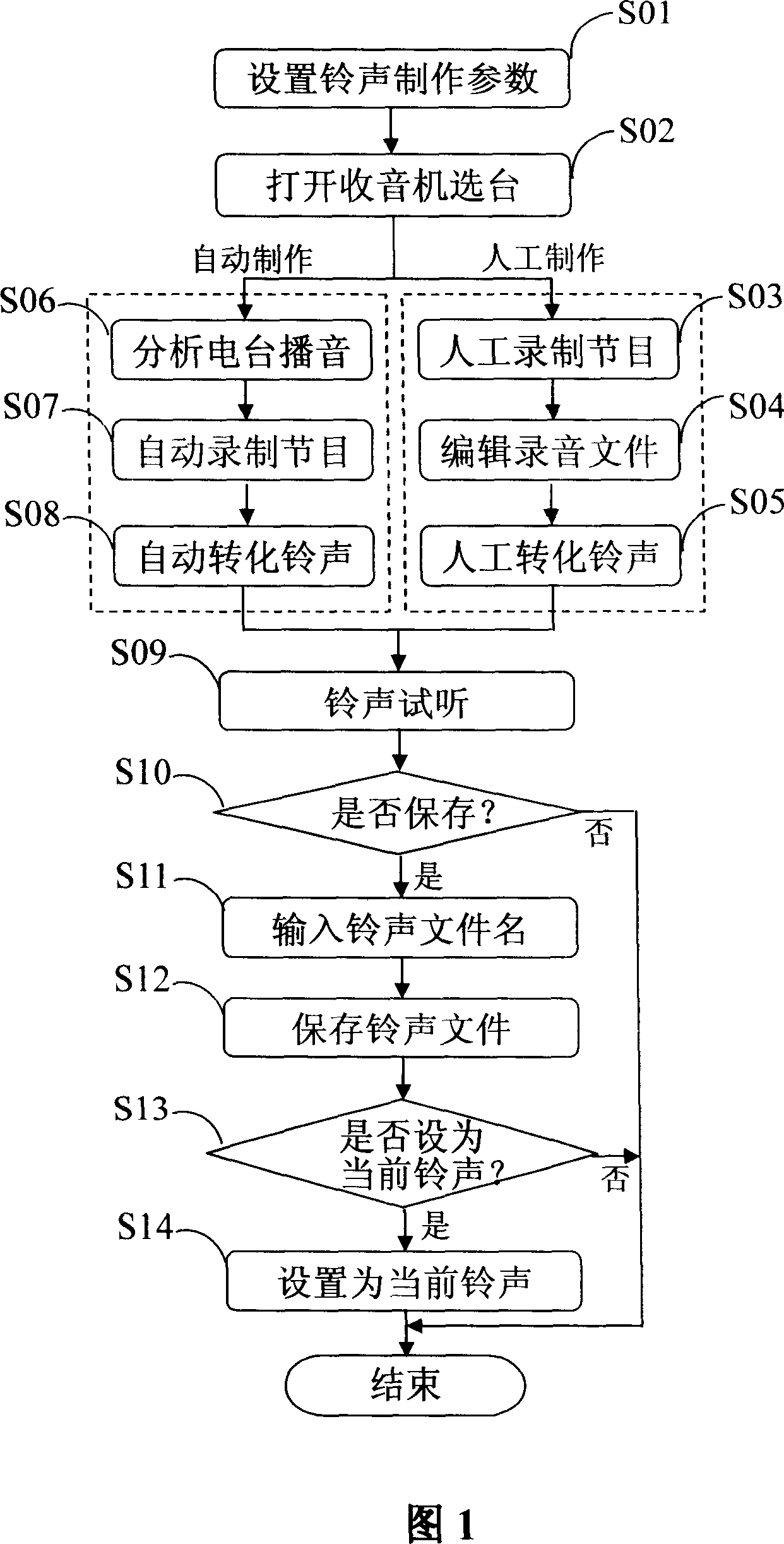

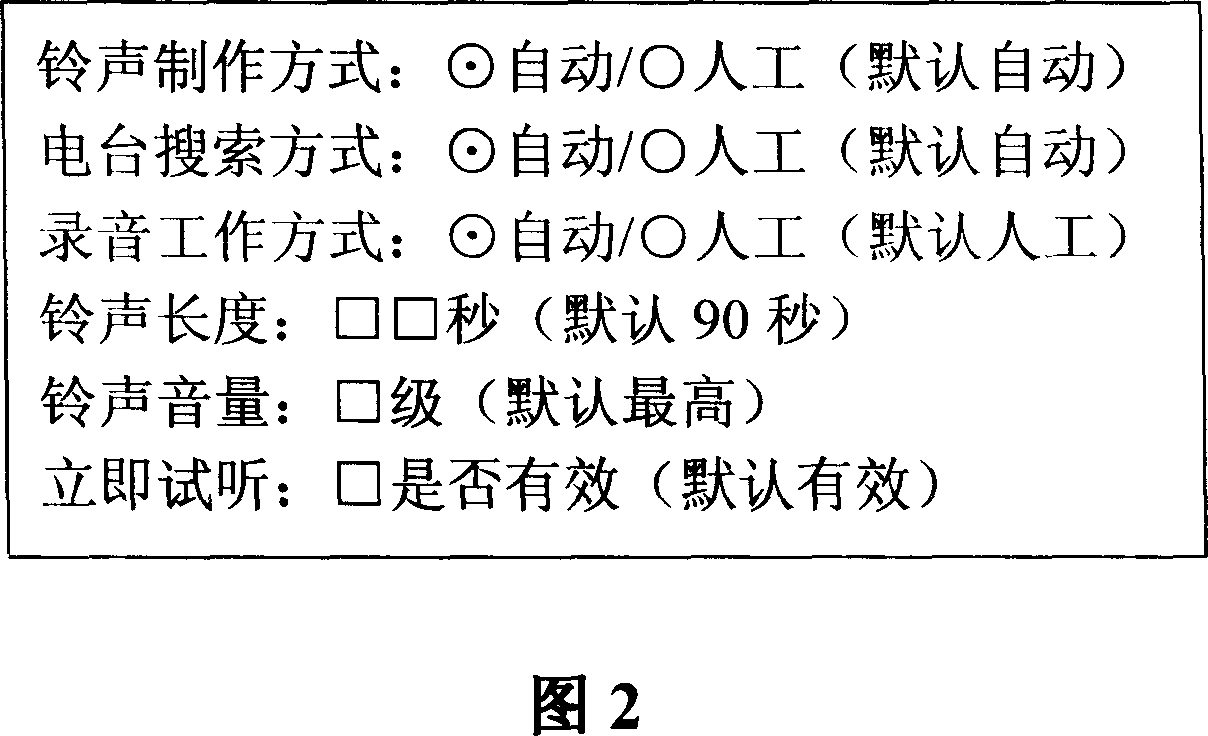

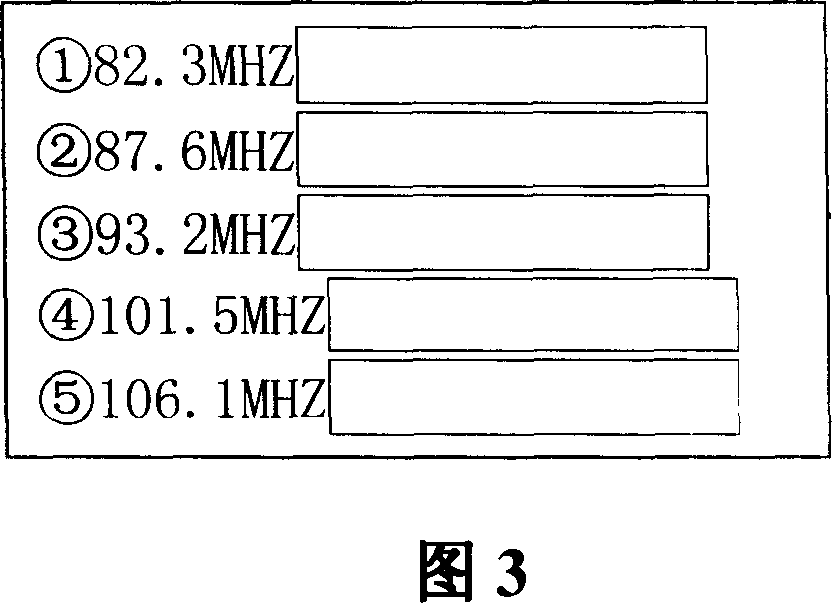

Ring making device of the mobile phone and its method

InactiveCN101035150AAbundant resourcesHigh appreciation valueCalling susbscriber number recording/indicationTransmissionPersonalizationProgram segment

The invention relates to a mobile phone ring making device and method. And the device comprises radio module, sound recording module and ring making module; and the method comprises the steps of: a user starts up the radio module and selects to receive the specific broadcasting station and plays a voiced program; the user starts up the sound recording module and selects to record one or more specific segments of the above voiced program; the ring making module converts the recorded program segments into mobile phone ring and its operating modes include automatic ring making mode and artificial ring making mode. And the invention can uses local materials to obtain rich ring material resources and reduces the ring making threshold so as to let common mobile phone users able to make individual rings with higher appreciation value.

Owner:深圳市经纬科技有限公司

Ornamental banyan tree shaping method

InactiveCN1931608AHigh appreciation valueSpecial ornamental structuresHorticulture methodsSeedlingCladodes

The ornamental banyan tree shaping method includes the following steps: forming various animal model casing with sheets and fixing; setting one inner container inside the casing with interval of 8-15 cm in between and filling the interval with fertilizer soil; planting banyan tree seedling, watering, spraying fertilizer liquid; eliminating the casing after the root system can bear the weight of the shaped banyan tree; and cropping. The present invention makes it possible to shape banyan tree for raised ornamental value.

Owner:莫永红

Simulation animal specimen and making method thereof

This invention relates to artificial animal specimen and its process method, which is to solve the problem to hunter the animals in traditional specimen process. The process comprises sculpture, mold processing, and mode turnover, sticking and repairing steps. The artificial animal specimen comprises birds and animals.

Owner:华兴宏

Combining technology of ceramic wafer and precious metal

ActiveCN105599522AImprove finenessTightly boundDecorative surface effectsSpecial ornamental structuresMetallurgyPrecious metal

A combining technology of a ceramic wafer and precious metal comprises the steps of firstly performing primary moulding on the ceramic wafer, and forming a blind hole in the side wall of the ceramic wafer; then fitting the precious metal around the edge of the ceramic wafer, and meanwhile forming a through hole, matched with the blind hole in the ceramic wafer, in the precious metal; finally enabling a precious metal wire to pass through the through hole, putting the precious metal wire into the blind hole, welding the precious metal wire with the precious metal, and performing secondary moulding to obtain a finished product combining the ceramic wafer and the precious metal. According to the technology, the ceramic wafer and the precious metal are remoulded and are combined into a new whole in a welding way, the technology is fine and concise, too much time does not need to be consumed in the whole technological process, a characteristic that the modern technology is high in manufacturing efficiency is accorded with, and the finished product as new works of art endows the ceramic wafer with new appreciation value, artistic value and economic value.

Owner:河南弘宝汝瓷坊有限公司

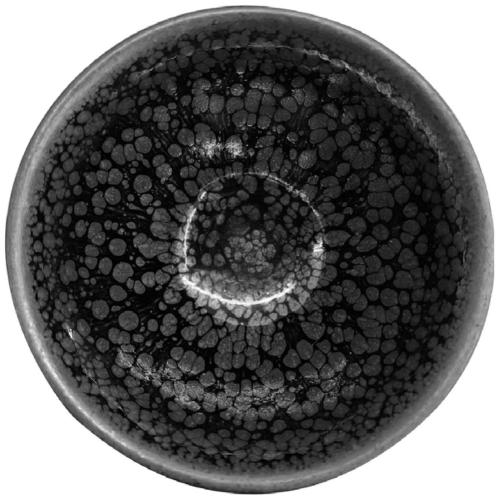

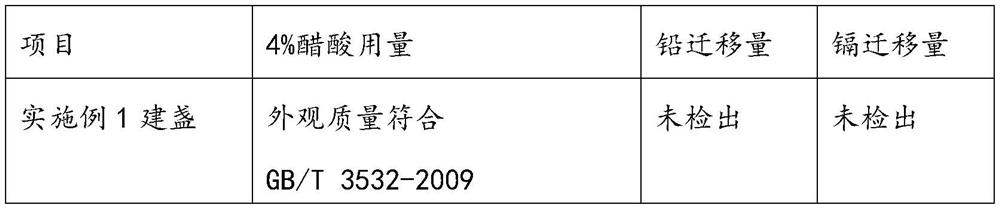

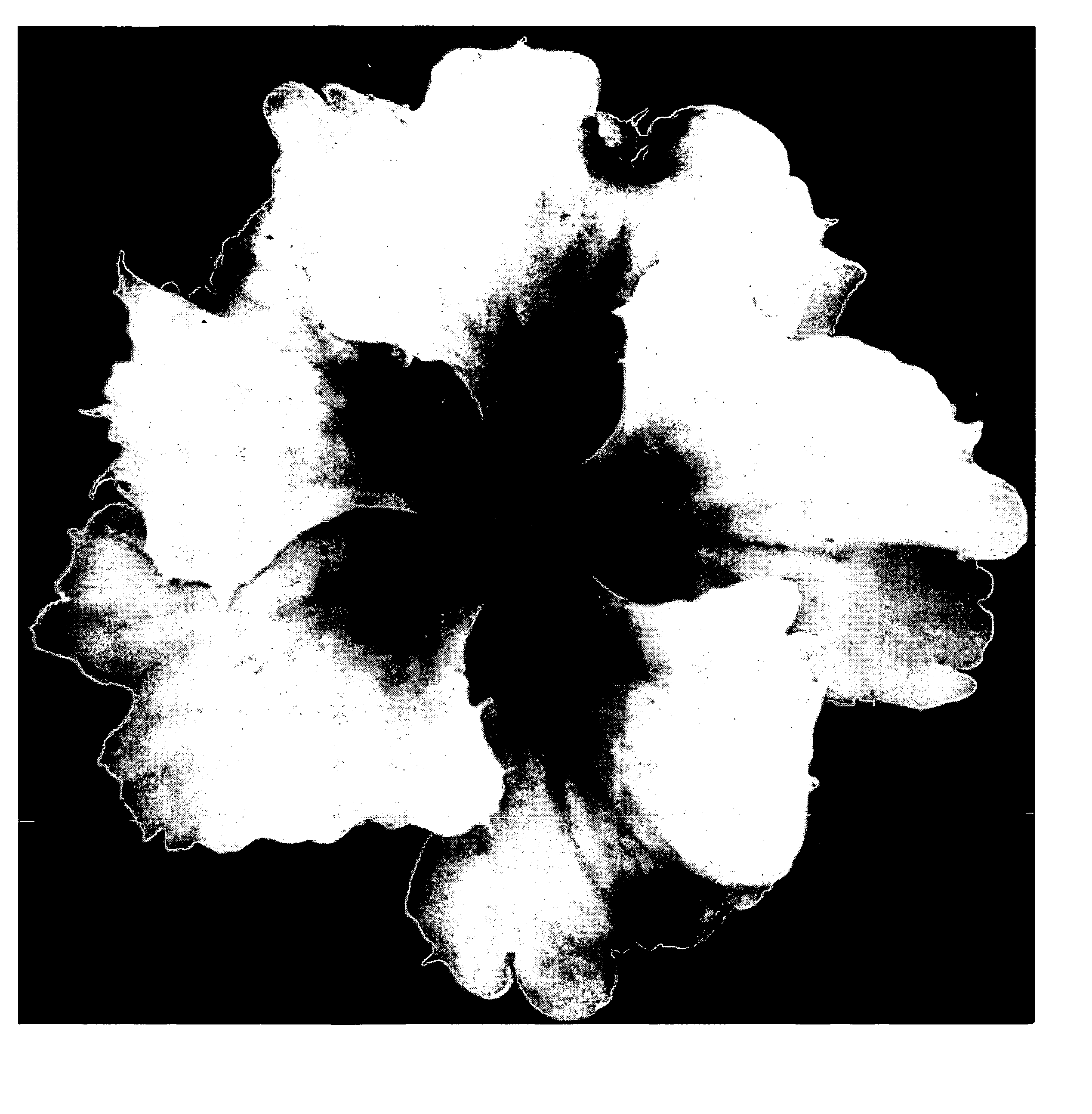

Black-base red-speckle oil-drop temmoku glaze ceramic and a preparing process thereof

The invention belongs to the field of ceramic products, and particularly relates to black-base red-speckle oil-drop temmoku glaze ceramic and a preparing process thereof. The ceramic includes an iron matrix blank and a red-spotted oil-drop glaze material. According to the ceramic and the method, the fired ceramic has a purple black matrix, the red-spotted oil-drop glaze material shows dark red speckles from inside to outside, crystallized particles are preserved in a glaze layer, and a flowing sense during high-temperature molding of the glaze can be observed obviously when the ceramic is observed with a magnifying lens. During firing, a reducing atmosphere is used and nitrogen is fed during firing to perform a reaction, and elements in the red-spotted oil-drop glaze material and the iron matrix blank are extracted to help combustion so that glaze raw materials are changed and recombined. The ceramic has beautiful colors, warm and humid hand feel, and high value of appreciation and artistic value.

Owner:福建德化陶知然陶瓷文化创意有限公司

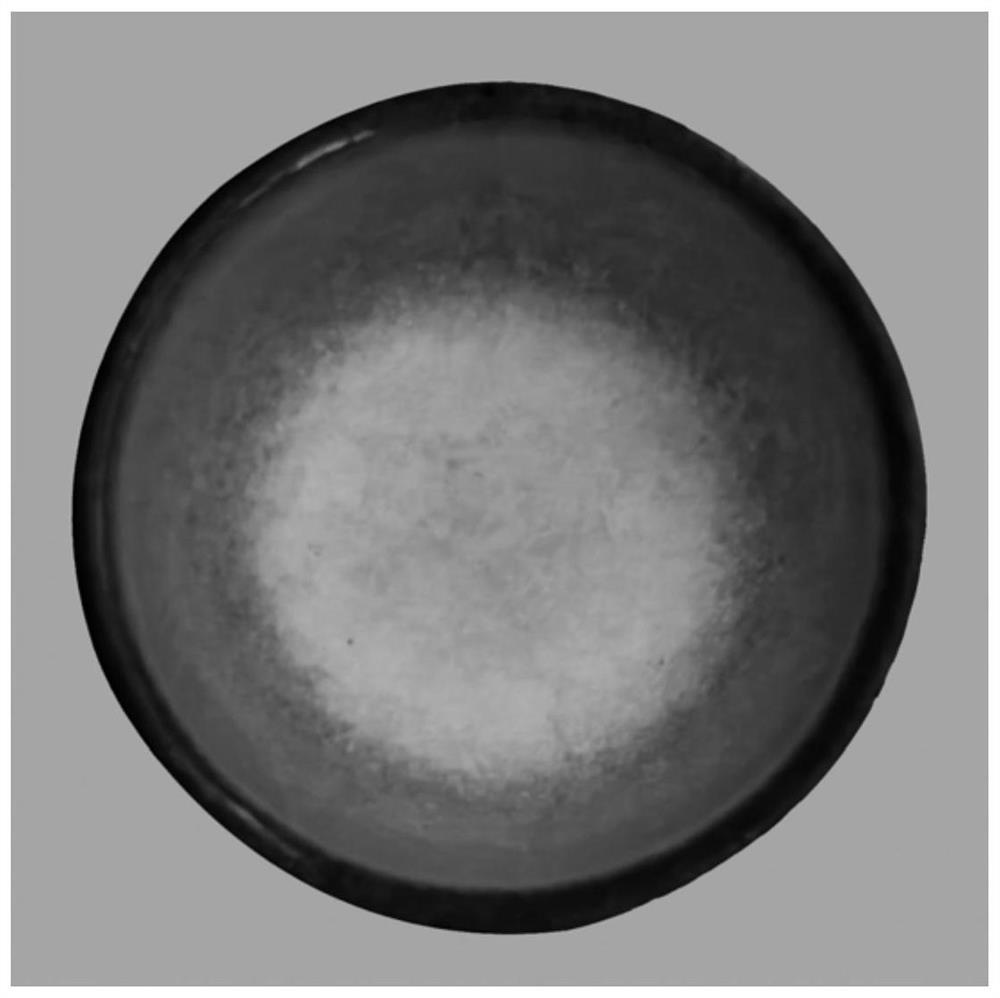

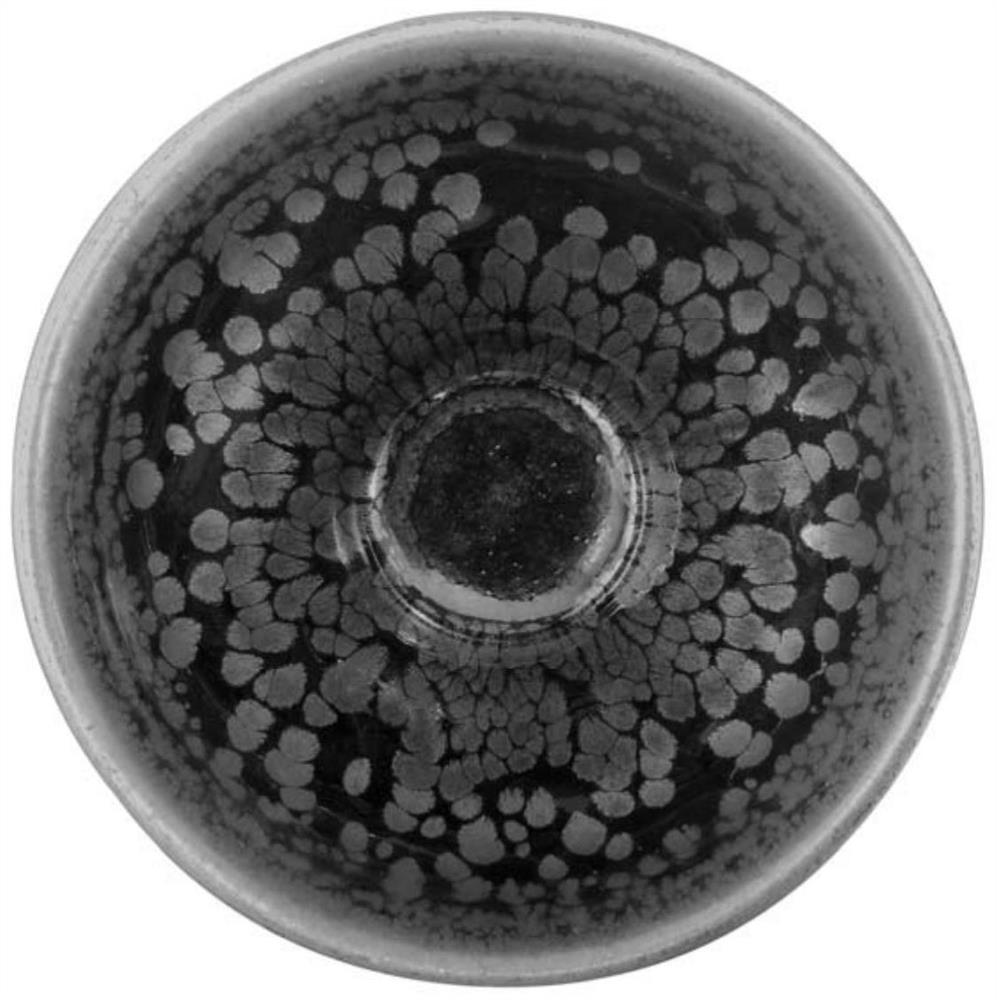

Jian tea bowl firing process

The invention discloses a Jian tea bowl firing process which comprises the following steps: preparing a green body raw material and glaze slip, drawing and forming the green body raw material, performing trimming to obtain a green body, glazing the green body, firing the green body for the first time, putting the qualified green body into a kiln again, roasting the green body, naturally cooling the product and discharging the product. The process flows such as the formula, the firing atmosphere and the temperature curve are clear and easy to control, the stability is good, and the rate of finished products is high. Uniform and fine hairs penetrate through a black glaze layer of a fired rabbit hair Jian tea bowl, are clear, have proper density and are radial, the stripes are attractive, andthe Jian tea bowlhas extremely high artistic value and appreciation value.

Owner:蔡炳盛

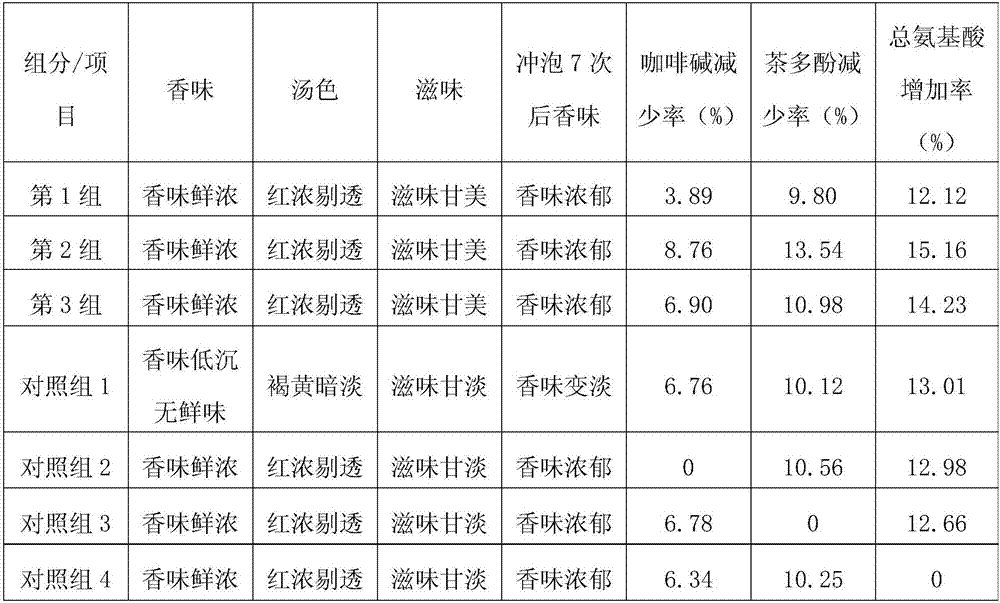

Manufacture method of stomach nourishing rose flower tea

InactiveCN107125360AReduce contentIncrease varietyPre-extraction tea treatmentDigestive systemPresent methodTotal amino acids

The present method discloses a manufacture method of stomach nourishing rose flower tea and relates to the field of flower tea manufacturing and processing. The manufacture method of the stomach nourishing rose flower tea comprises the following steps: rose flower picking, rose flower pretreating, tea base pretreating, scenting, rose flower fermenting, drying and packaging. The manufacture method of the stomach nourishing rose flower tea reduces content of caffeine and tea polyphenols in the tea by fermenting the rose flowers and tea bases, improves content of total amino acids, extends freshness of the fragrance of the flower petals and improves a fragrance dispersing ability of the flower petals, so that the prepared stomach nourishing rose flower tea is fresh, mellow, lasting, and mellow and mild in mouthfeel, also has effects of nourishing the stomach, and is suitable for patients with gastrointestinal diseases to drink.

Owner:广西凌云县绿贵茶业有限公司

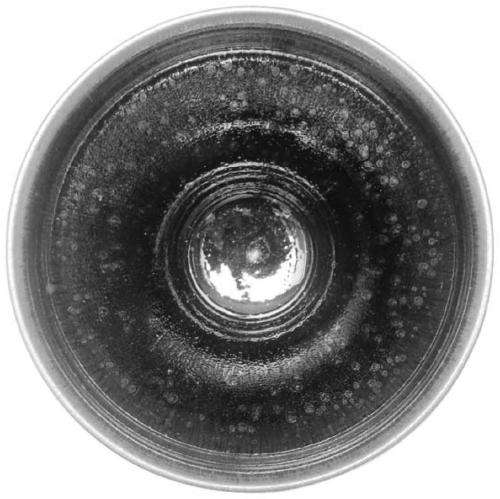

Firing process for Yaobian Jianzhan bowl

The invention discloses a firing process for a Yaobian Jianzhan bowl. The firing process comprises the following steps: preparing a green body raw material and a glaze material, drawing and molding the green body raw material, carrying out fettling, biscuiting and cooling so as to obtain a green body, carrying out glazing, putting a glazed and air-dried green body into a kiln for calcination, carrying out natural cooling, and taking a product out of the kiln. The firing process provided by the invention is clear in process flows like a formula, a firing atmosphere and a temperature curve, is easy in control, good in stability and high in a finished product rate. According to the invention, oil drops with different sizes emerge on the surface of the Yaobian Jianzhan bowl fired by using thefiring process provided by the invention, colored halos including red, green and sky-blue halos and the like are formed around the outer edges of the oil drops, and vertical fantastic filaments with flowing light and colors are formed outside the halos, so an image resembling groups of stars in the sky and the changing, vast and deep universe is formed; thus, the Yaobian Jianzhan bowl has extremely high artistic value and appreciation value.

Owner:陆金喜

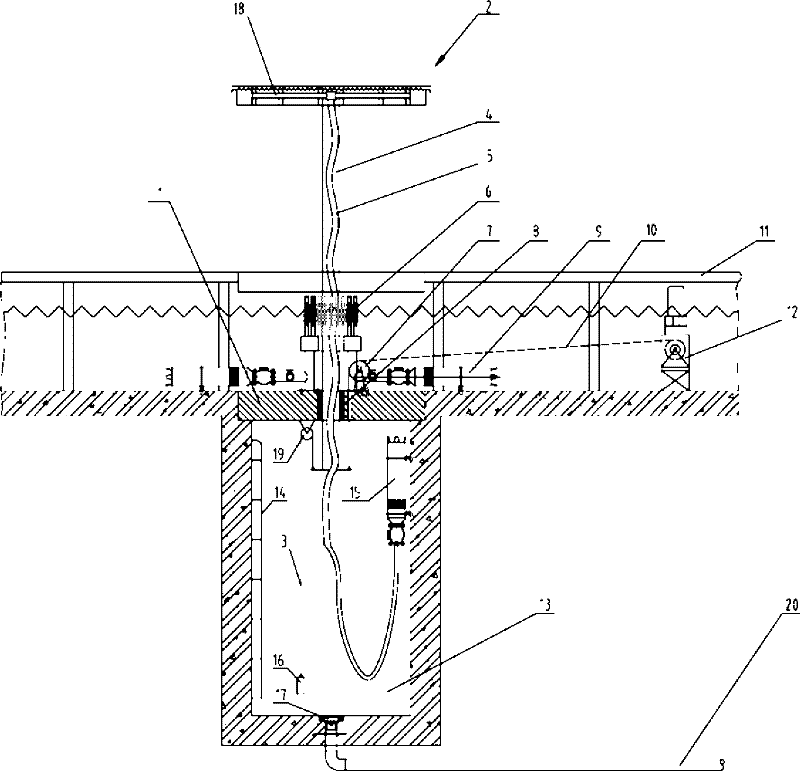

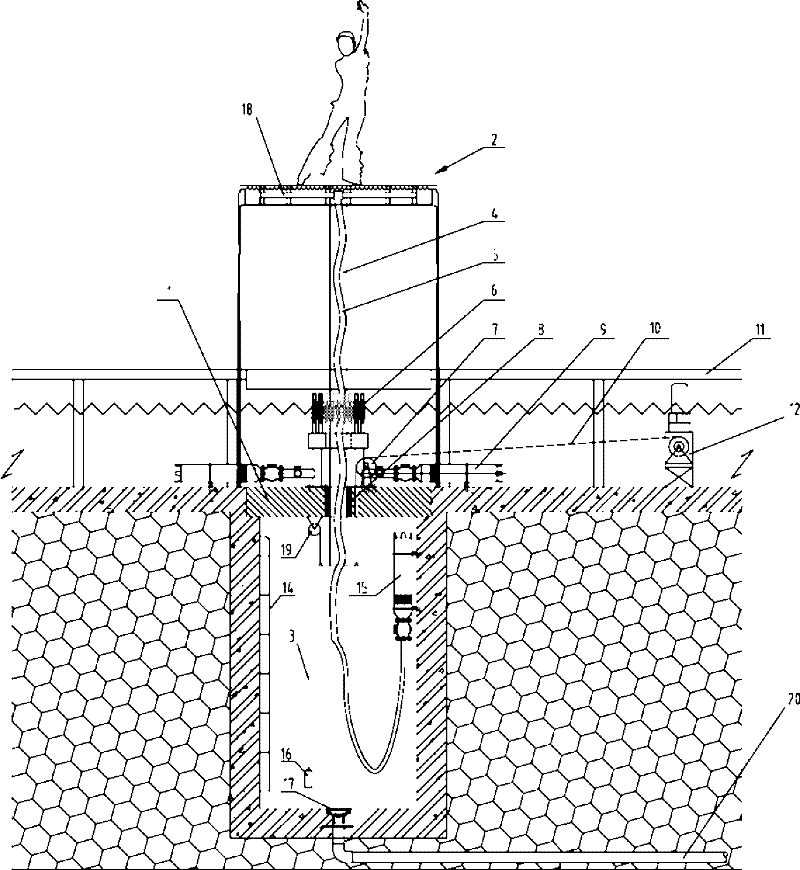

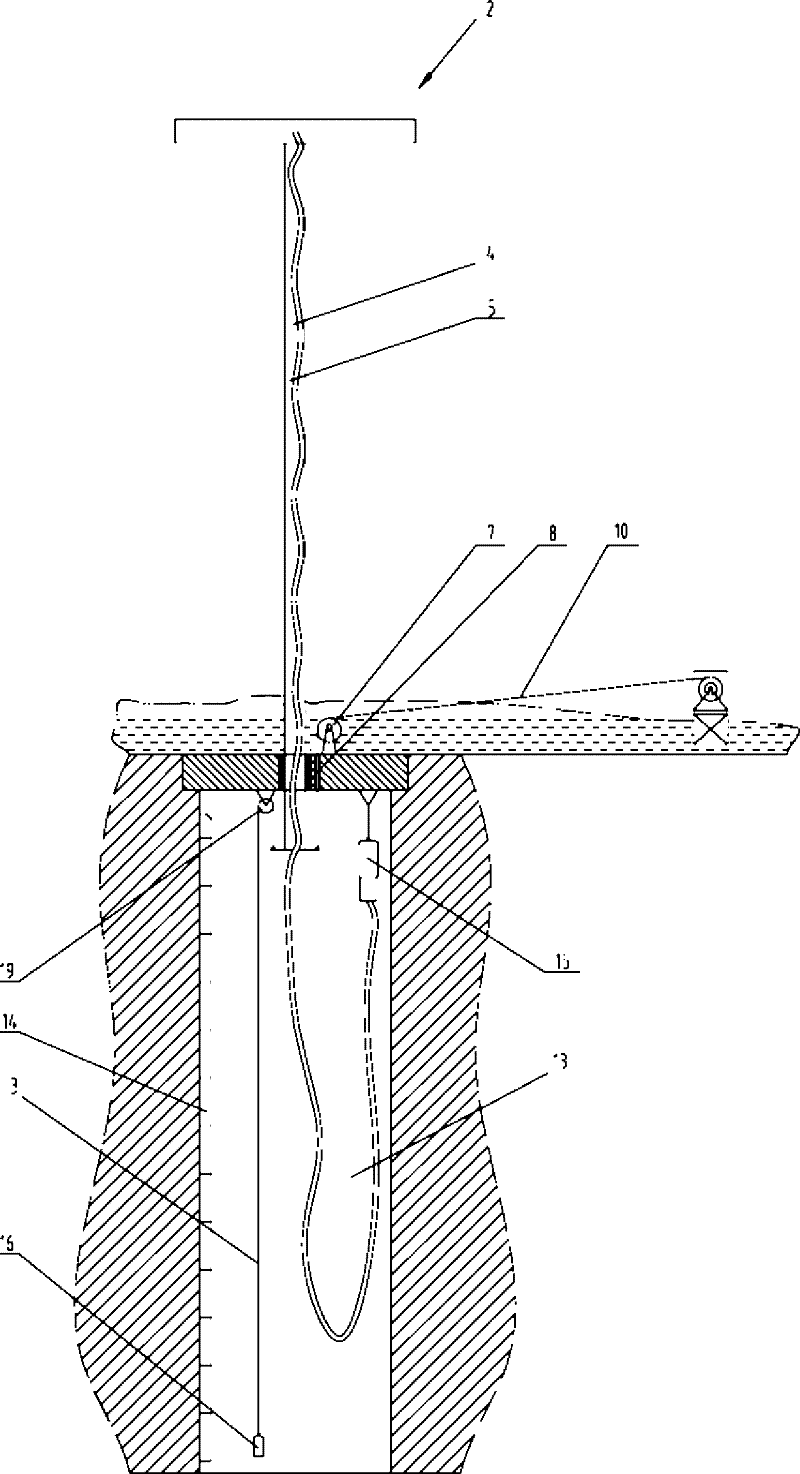

Elevating fountain stage

ActiveCN102031881BAdd funImprove visibilityLiquid spraying apparatusTheatresPlate columnSpray nozzle

The invention relates to the technical field of performance stages, in particular to an elevating fountain stage, which comprises a fixed stage, a turbine pit, a supporting plate and a driving mechanism, wherein the supporting plate is provided with a through hole; an elevating stage is arranged right above the supporting plate; the driving mechanism is used for driving the elevating stage to move up and down; the lower surface of the elevating stage is provided with a hollow guide post; a water current channel is formed inside the elevating stage; the turbine pit is provided with a first water pump and a flexible water pipe; the supporting plate is provided with a plurality of spray nozzles and a second water pump; the plurality of spray nozzles are annularly and uniformly distributed onthe hollow guide post; and the water outlet of the second water pump is communicated with the water inlets of the plurality of spray nozzles. Dancers standing on the elevating stage for performance seem like being supported by a water column which is sprayed upwards, so that the interestingness and appreciation of stage performance are enhanced greatly, dynamic impression formed by dynamic stage change is enhanced, practicability is high and appreciation value is high.

Owner:东莞市环宇文化科技有限公司

Firing method for Jianzhan with colored ground coat, colored oil drops and gold edge

The invention provides a firing method for Jianzhan with a colored ground coat, colored oil drops and a gold edge. The firing method comprises the following steps: preparing a green body raw materialand a glaze, carrying out throwing molding on the green body raw material, then successively conducting fettling, heating and glazing, putting a glazed and air-dried green body into a kiln, conductingroasting, performing natural cooling, and taking the prepared Jianzhan out of the kiln. Technological processes such as a formula, a firing atmosphere and a temperature curve are clear in the invention; the firing method is easy to control, good in stability and high in yield; the sintered Jianzhan has the and glossy gold edge; the ground coat is has a color varying with light rays; the Jianzhanhas vertical hair which have flowing light color and partly hidden and partly visible; oil drops which are different in size and changing in color emerge on the surface of the Jianzhan, and look likestars gathering into groups in the sky; and the Jianzhan has extremely high artistic value and appreciation value.

Owner:南平市曜变陶瓷研究院

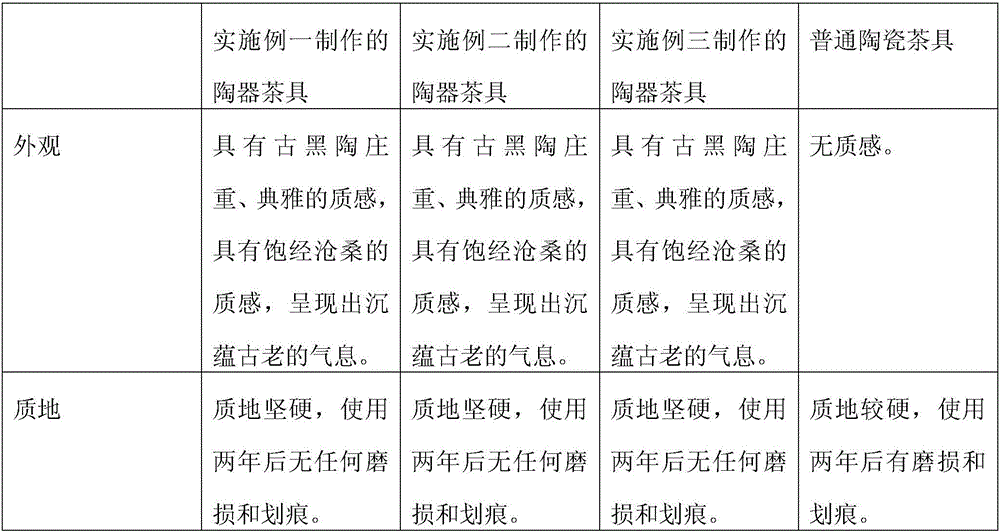

Making technology of pottery ware

The invention provides a making technology of pottery ware. The pottery ware is made through steps as follows: selection of raw materials, making of a porcelain body, first firing and second firing. The making technology has the beneficial effects as follows: a pottery tea set is fired by adopting gold red mud as a raw material, other raw materials for blending are not needed, glaze application is omitted, so that natural effect is shown, the pottery ware has the texture of vicissitudes, has solemn and elegant texture of ancient black pottery, is high in appreciation value, is harder than the ancient black pottery, can avoid wearing and scratching after long-term use and is high in practical value, fragrance of tea is heavy and long-lasting and is not scattered after the tea is made by the aid of the pottery ware, tea oil in tea soup can be absorbed if the pottery ware is used for a long time, the tea is in a soft and smooth state like jade, ancient ambience is represented, the appreciation value of the pottery ware is improved, the pottery ware has double values of appreciation and practicability, the making technology is simple, trouble of dosing is omitted, the use effect is good, and popularization is facilitated.

Owner:夏利长

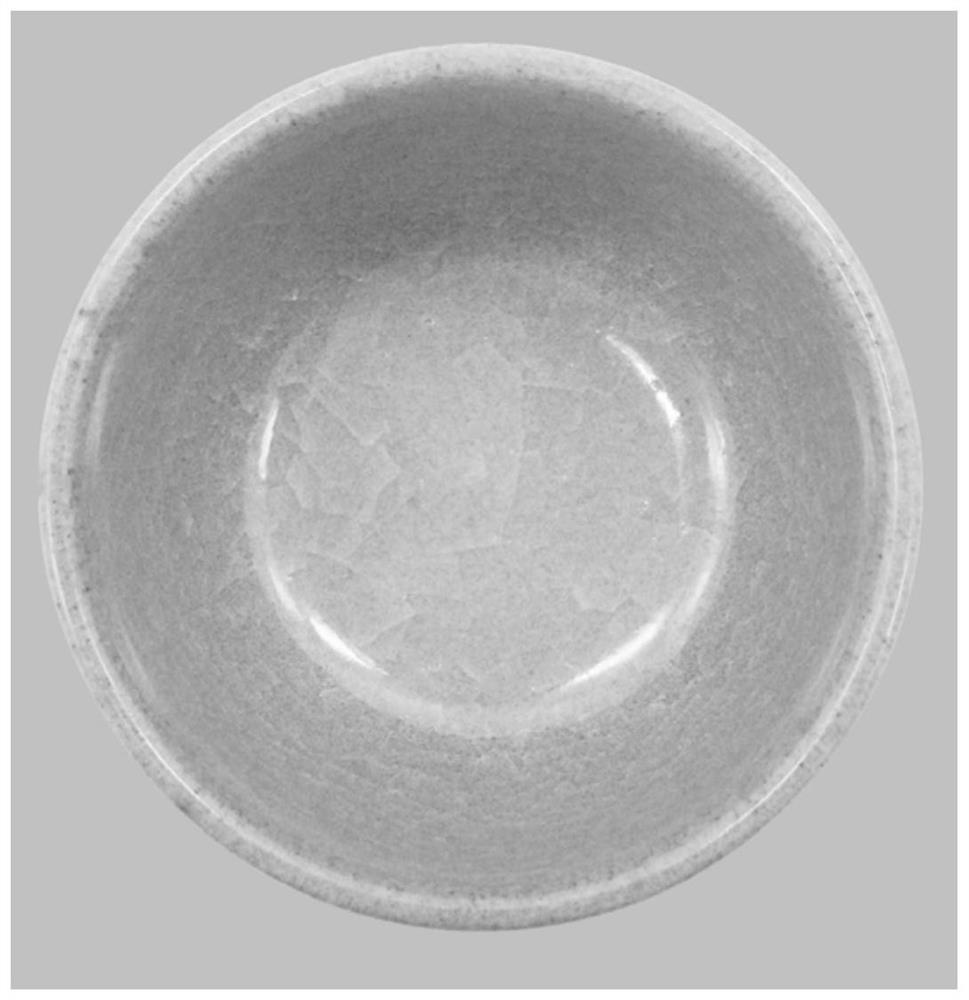

Firing process of noctilucent Jianzhan cup

The invention discloses a firing process of a noctilucent Jianzhan cup, and the method comprises the following steps: preparing a green body raw material and glaze slip, drawing and molding the greenbody raw material, and trimming to obtain a green body; glazing; and putting the glazed green body into a liquefied gas kiln for roasting. The noctilucent Jianzhan cup fired by the method is fine andsmooth in texture, smooth and flat, almost free of needle holes, greenish in glaze color grey, greenish in green, uniform, clean and elegant in glaze surface, has ice cracks and is full of jade feeling. The noctilucent Jianzhan cup is weak in light emitting day and strong in light emitting night, emits green light and glittering light in a dark environment, and has extremely high artistic value and appreciation value.

Owner:吴金根

Manufacturing method of Aluminumaluminum-plastic plate engraving artwork manufacturing method and finished products thereof

InactiveCN101905624ANon-deformableExquisite patternDecorative surface effectsSpecial ornamental structuresAlloyEngineering

The invention relates to a manufacturing method of an aluminum-plastic plate artwork manufacturing method and finished products thereof. The aluminum-plastic plate artwork manufacturing method comprises the following steps of: 1. removing the a film covered covering on the uppermost surface of the aluminum-plastic plate to expose the color of the surface baking paint; 2. applying a cutter by hands, scraping and engraving dents on the surface by using the special cutter along different directions and sequence, and exposing the aluminum alloy color until to the deepest layer; 3. controlling the force when the cutter is used, and carving different layers between the surface paint bakinga color layer of the surface baking paint and an aluminum alloy layer by applying methods of scraping, spotting, upsetting, shoveling, scratching and the like; and 4. ensuring that the manufactured artworks having have frames or no frames. The invention has the advantage that the aluminum-plastic plate artworks made by the process manufacturing method has no reproducibility, particular style, beautiful attractive pattern, and strong stereo feeling, can reflect light rays of different layers along the change of light rays, and has high appreciation value and collection value.

Owner:王钢

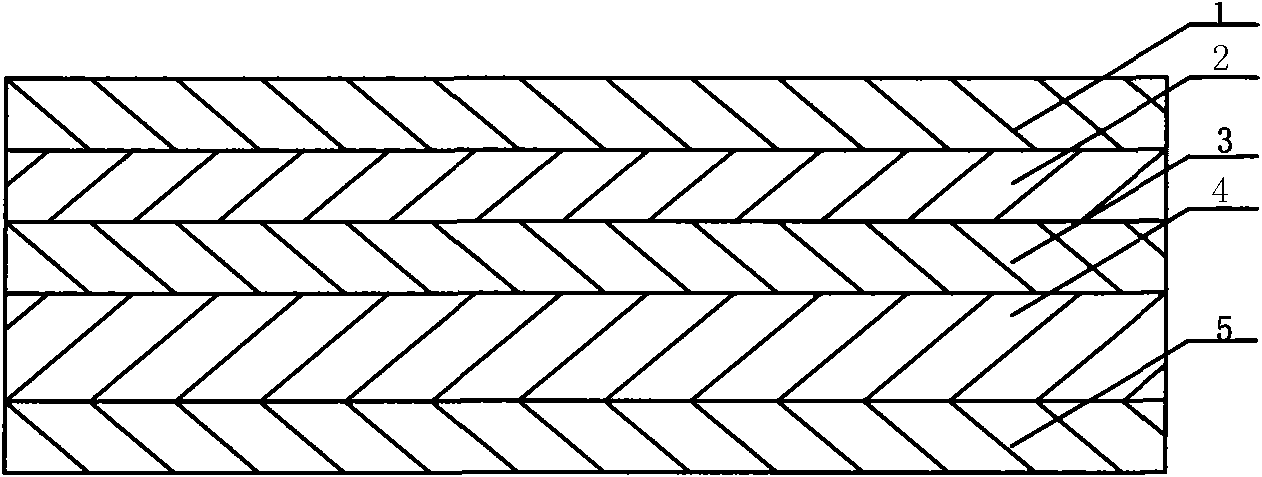

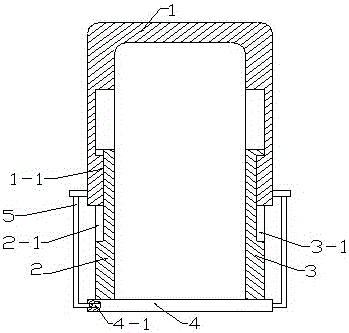

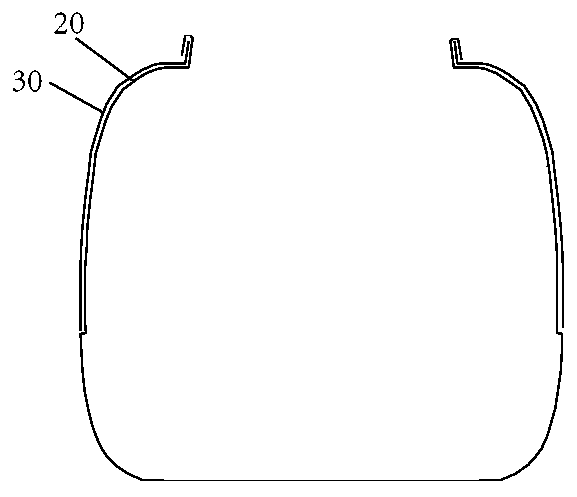

Multifunctional plastic protective shell for mobile phone

InactiveCN105007347AEasy size adjustmentAppearance color changeTelephone set constructionsEngineeringMobile phone

The invention discloses a multifunctional plastic protective shell for a mobile phone. The multifunctional plastic protective shell comprises a shell and a fixing plate. Protruded steps are arranged at the left side and the right side of the shell. The fixing plate comprises a left side plate, a right side plate and a connecting plate. Strip-type grooves are arranged at the left side plate and the right side plate. The connecting plate is fixed at the ends of the left side plate and right side plate. The fixing plate is connected with the protruded steps via a strip-type groove and could be moved along the protruded steps. The shell is composed of a surface decoration layer, a wearing layer and an inner layer. The surface decoration layer, the wearing layer and the inner layer are stuck with each other from outside to inside in turn. Through the above manner, the multifunctional plastic protective shell for the mobile phone of the invention could be used for protecting different mobile phones with a plurality of sizes via a rational structural design. The size of the multifunctional plastic protective shell for the mobile phone is convenient to adjust, and the color of outward appearance is changeable, so the multifunctional plastic protective shell for the mobile phone has relative high appreciating value.

Owner:SUZHOU CITY XIANGCHENG DISTRICT MINGDA COMPOSITE MATERIAL FACTORY

Board or artware produced through marble leftover materials

ActiveCN105271944ATake advantage ofNo emissionsSolid waste managementCompression moldingChemical composition

The invention relates to a board or artware produced through marble leftover materials. Raw materials comprise marble powder, polyurethane, silane coupling agents, pigment and quartz powder. A machining method includes the steps that the marble leftover materials are broken, broken stone of the marble leftover materials and quartz powder are ground into fine powder through a Raymond mill, chemical composition components are added, and the marble board or artware can be obtained through compression molding. The board or artware produced through the marble leftover materials has the advantages that the marble leftover materials can be fully utilized, natural energy is saved, waste can be reused, the manufactured board is economical, practical, solid and durable, and the manufactured artware is exquisite and high in appreciation value.

Owner:武宣县宝信石材有限公司

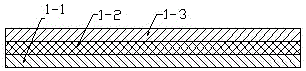

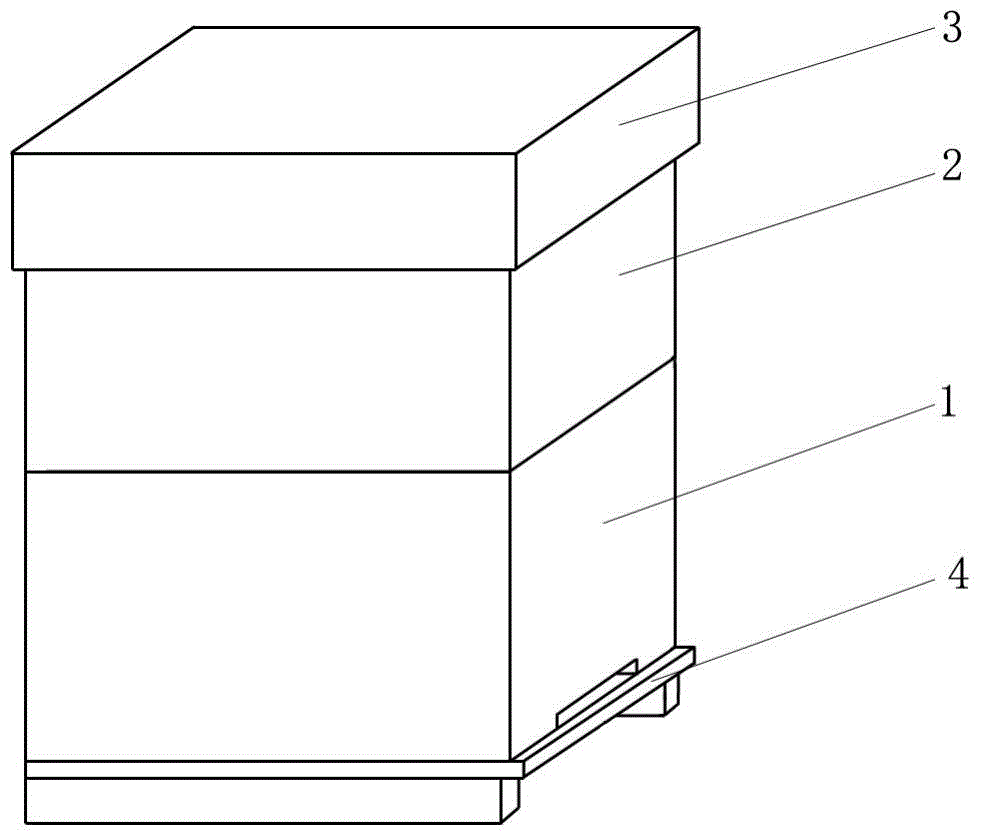

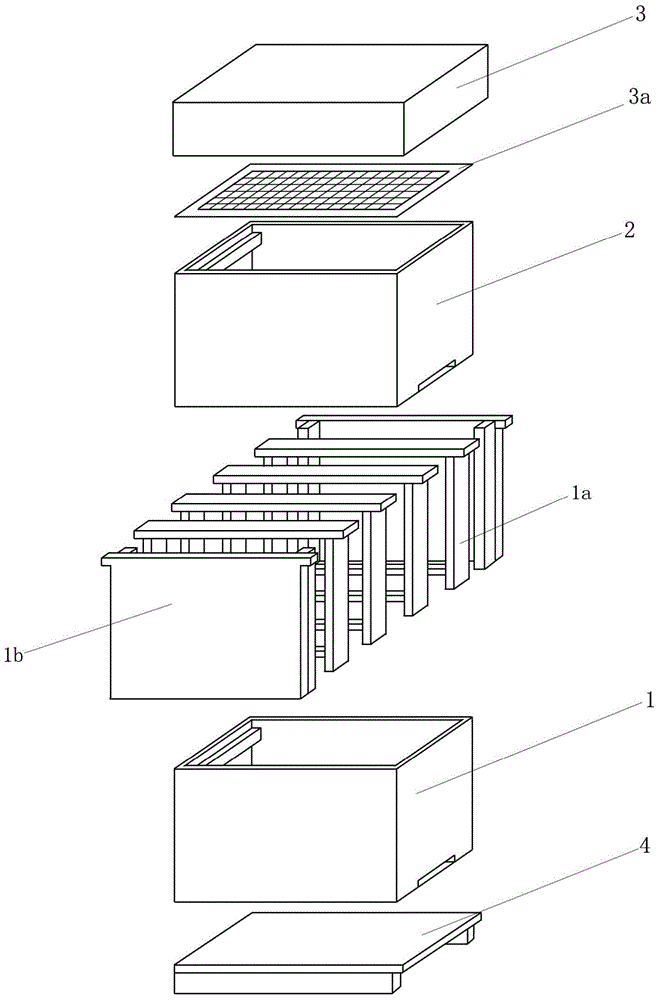

Honeycomb sculpturing method

The invention relates to a sculpturing method and in particular relates to a honeycomb sculpturing method utilizing a bee nesting behavior. The method disclosed by the invention comprises the following steps: (1) arranging multiple honeycomb frames in a honeycomb box, wherein separators are arranged at two ends of the honeycomb frames, multiple strip-shaped combs with the same width are arranged on the upper surfaces of the honeycomb frames according to conceived patterns of people, separating walls are arranged above the honeycomb frames to enclose the combs, and a honey super communicated with the honeycomb box is arranged above the honeycomb box; (2) putting a queen bee into the honeycomb box for breeding, and shading and covering the opening in the top of the honey super by a box cover; and (3) periodically checking the bee nesting condition, and taking out the sculptured honeycomb after the honeycomb sculpture is finished. The method provided by the invention provides a novel sculpture category, and the unique honeycomb sculpture is formed by nesting on the preset patterns formed by the strip-shaped combs by utilizing the special nesting capacity of bees and has extremely high appreciation value.

Owner:张连朝

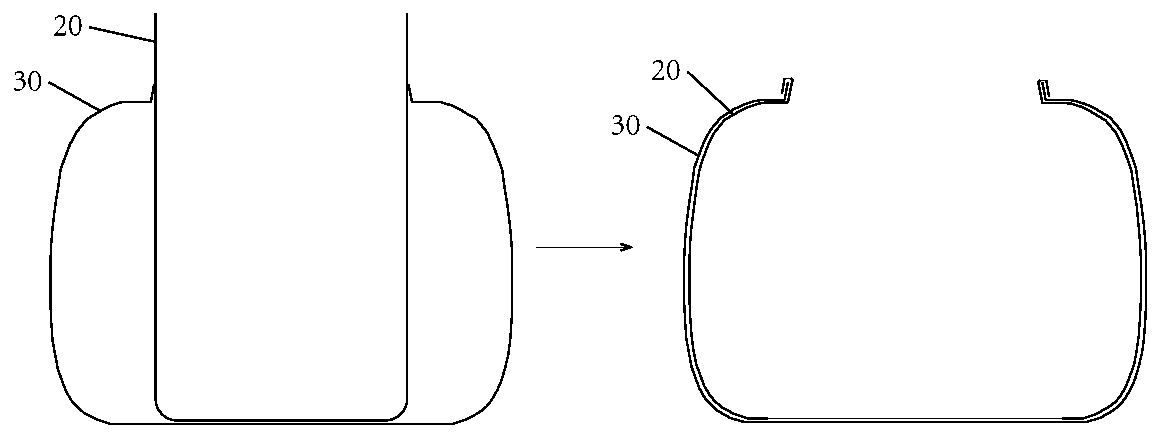

Manufacturing technology of iron covering silver kettle

ActiveCN109746642ASolve the industry problem that it is impossible to produce non-cast iron iron-clad silver potsGood effectWater-boiling vesselsSilver plateManufacturing technology

The invention belongs to the technical field of processing of metal kettles, and provides a manufacturing technology of an iron covering silver kettle. The technology comprises the following steps: S1, feeding material; cutting to obtain a circular sliver plate; and cutting to obtain a circular or an annular iron plate; S2, forming the silver kettle, namely, forming the silver plate into an arc surface type silver kettle core; S3, forming and covering an iron kettle, namely, forming the iron plate into an arc surface type or barrel type iron kettle; sleeving the iron kettle cover with the ironkettle; or directly forming the iron plate on the silver kettle core; S4, shaping a kettle body, namely closing up the upper part of the kettle body; and shaping into kettle shape, wherein the innerwall of an iron kettle housing is close to the outer wall of the silver kettle core during shaping; and S5, processing to obtain a kettle product, namely, arranging a cover, a port and lugs to obtainthe iron covering silver kettle. The technology solves the technical problems that iron covering silver kettles in the prior art are all processed through cast iron and are heavy, and the outer surfaces of the cast iron cannot be carved and chiseled, and the artistry of the iron covering silver products is low.

Owner:张广韶

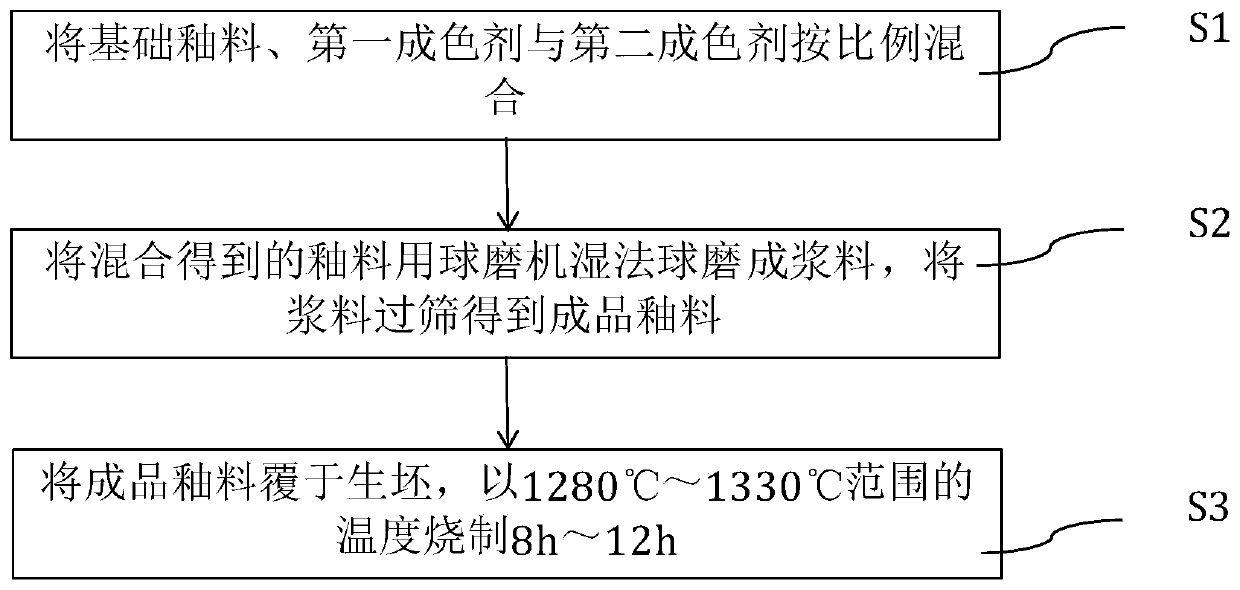

Lead-free metallic luster glaze, ceramic thereof, and preparation method of the lead-free metallic luster glaze

The invention relates to a lead-free metallic luster glaze and ceramic thereof, and a preparation method of the lead-free metallic luster glaze. The lead-free metallic luster glaze comprises the following components: 88%-96% of basic glaze; 3%-11% of a first coloring agent, including at least two of Fe2O3, CuO, MnO, V2O5 and NiO; 1-5% of a second coloring agent comprising at least two of Pr2O3, Sm2O3, La2O3, CeO2, Y2O3, Nd2O3 and Yb2O3. According to the lead-free metallic luster glaze, by adding a second color former into a mixed glaze of a basic glaze and a first color former, the surface metallic luster of the lead-free metallic luster glaze is improved; wherein the first color former comprises at least two of Fe2O3, CuO, MnO, V2O5 and NiO, that is, the lead frit is not added, so that environmental pollution and damage to production workers in the production process of the glaze are avoided, and the lead-free metallic luster glaze is prevented from being eroded by acid in the use process to dissolve out lead elements and seriously endanger human health.

Owner:JINGDEZHEN CERAMIC UNIV

Square wall lamp veneer inlaid with Beihong agate

InactiveCN106004212AImprove viewabilityImprove artistic tasteDecorative surface effectsSpecial ornamental structuresEngineeringTroffer

The invention discloses a square wall lamp veneer inlaid with Beihong agate. The square wall lamp veneer inlaid with the Beihong agate comprises a square wall lamp veneer body and Beihong agate sheets. The square wall lamp veneer body is formed by a transparent acrylic plate in certain specifications, a traced drawing of patterns are drawn on the upper surface of the square wall lamp veneer body, grooves are cut in the pattern part corresponding to the patterns, Beihong agate raw materials corresponding to the colors of the patterns are cut corresponding to the size of the grooves, the cutting thickness of Beihong agate sheets is consistent with the depth of the grooves, and the Beihong agate sheets are inlaid in the grooves in the square wall lamp veneer body according to the colors and the patterns of the square wall lamp veneer body.

Owner:陈昌同

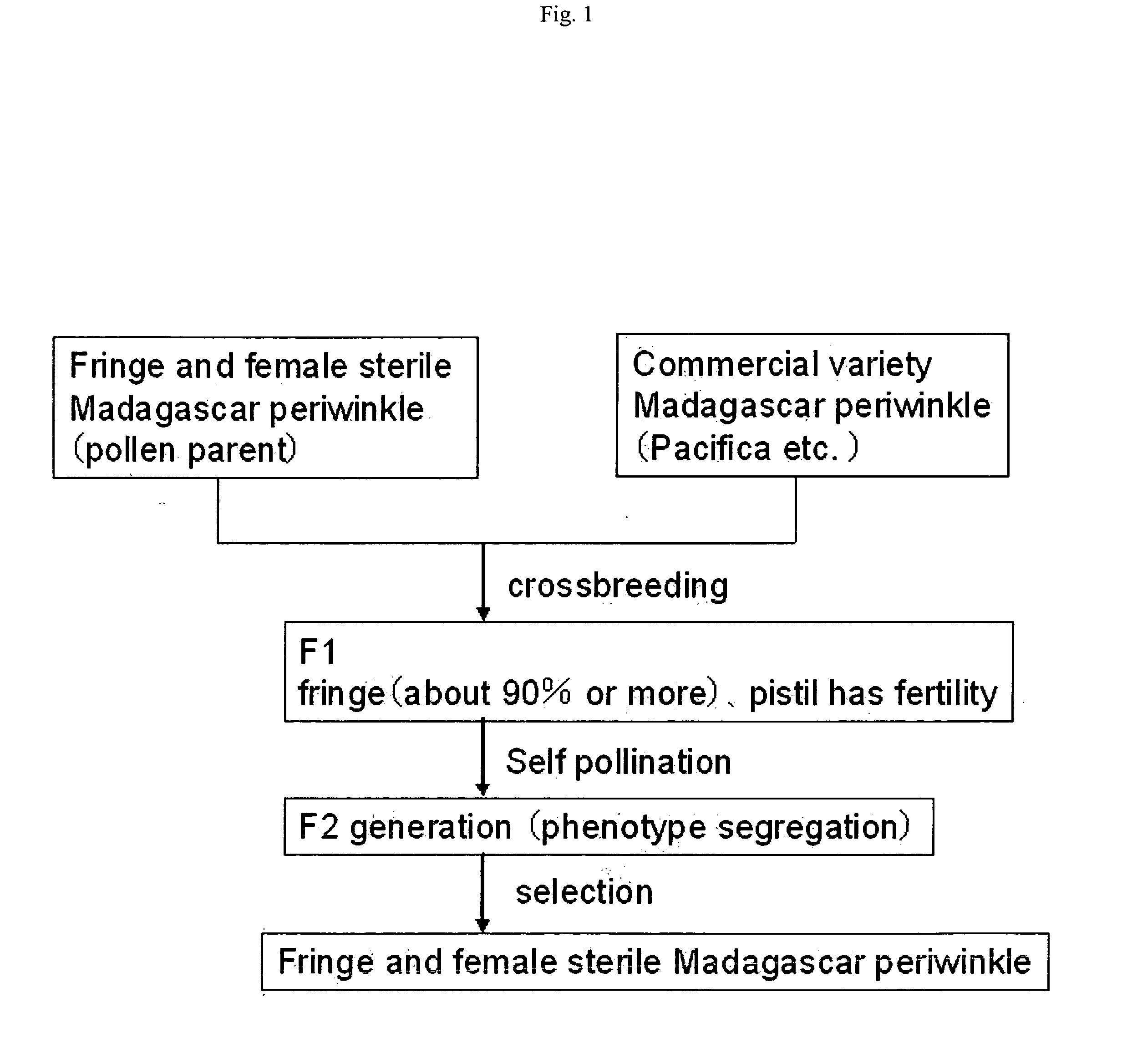

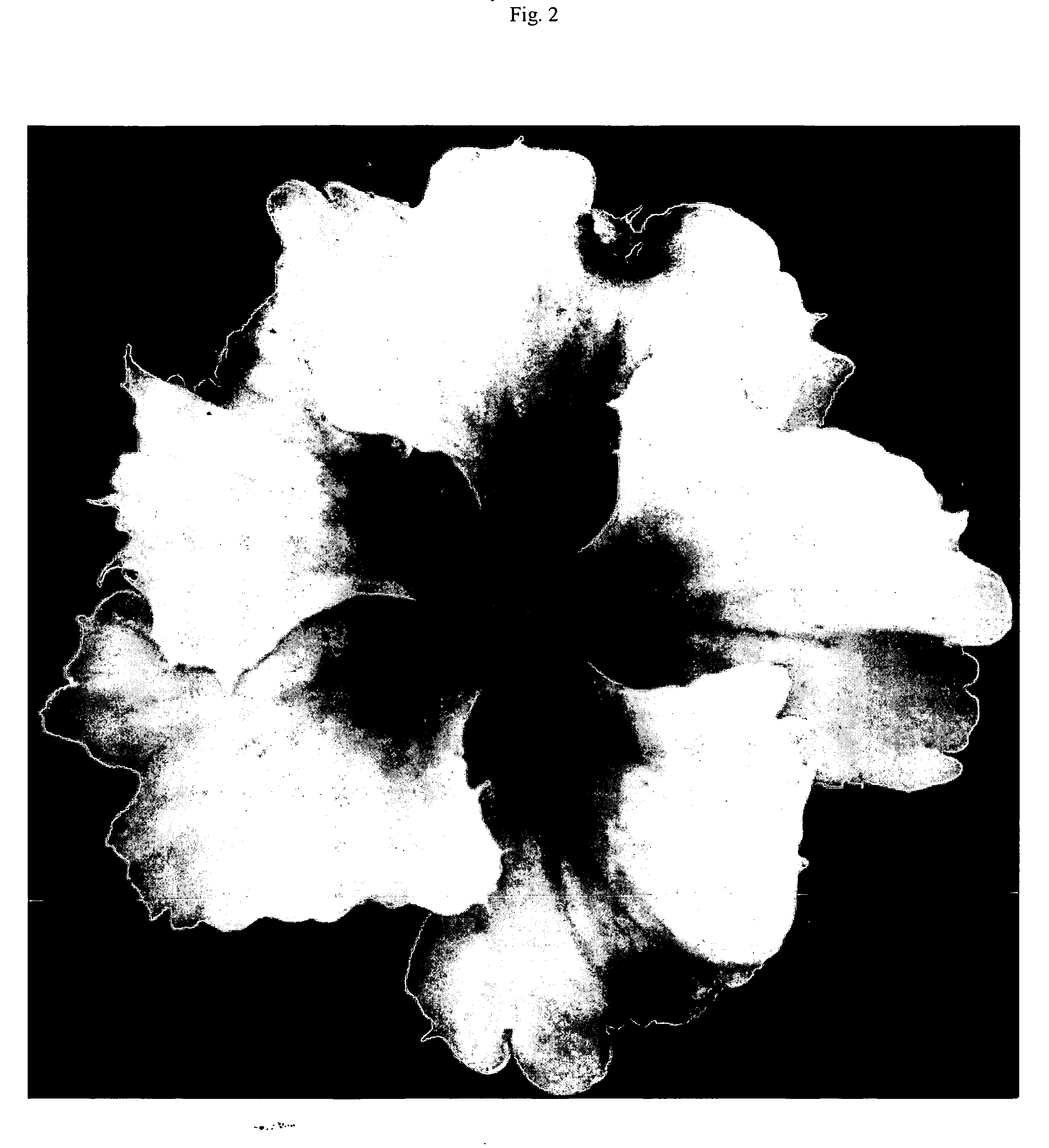

Madagascar Periwinkle With Fringe Type Flower And Method Of Breeding The Same

ActiveUS20070283454A1High appreciation valueGood characterPlant phenotype modificationPlant genotype modificationSelf-pollinationMarginella

A fringe flowered Madagascar periwinkle, especially a long blooming Madagascar periwinkle whose pistil does not have pollination ability is provided and a method for producing fringe flowered long blooming Madagascar periwinkle is provided as a purpose. A fringe flowered Madagascar periwinkle was bred by pollinating a pollen of a fringe flowered Madagascar periwinkle comprising a sterile pistil to a commercial variety. Moreover, by a self pollination of the fringe flowered Madagascar periwinkle a fringe flowered and pistil sterile Madagascar periwinkle is obtained.

Owner:KITAJIMA OSAMU

Ornamental banyan tree shaping method

InactiveCN100522658CHigh appreciation valueSpecial ornamental structuresHorticulture methodsCladodesSeedling

The ornamental banyan tree shaping method includes the following steps: forming various animal model casing with sheets and fixing; setting one inner container inside the casing with interval of 8-15 cm in between and filling the interval with fertilizer soil; planting banyan tree seedling, watering, spraying fertilizer liquid; eliminating the casing after the root system can bear the weight of the shaped banyan tree; and cropping. The present invention makes it possible to shape banyan tree for raised ornamental value.

Owner:莫永红

Manufacturing process of fully-glazed Jianzhan

PendingCN112062539ALess warping and blistering defectsClear markingsClaywaresComposite materialAqueous droplet

The invention discloses a manufacturing process of a full-glazed Jianzhan. The process comprises the following steps: preparing a green body and glaze slip, glazing, putting the glazed green body intoan electric kiln, roasting, cooling, and discharging. According to the prepared full-glaze-coated Jianzhan, glaze does not flow to adhere to the bottom, the full-glaze-coated Jianzhan is fleshy, plump and right in coverage, the green and black glaze bottom color is provided with yellowish-brown partridge spot oil drops, the partridge spot oil drops are in oval water drop shapes and have feather-shaped grains, the stripes are clear and well-arranged, the mouth edge is golden and glossy, and the prepared full-glaze-coated Jianzhan has extremely high artistic value and appreciation value.

Owner:福建省鼎吉建盏陶瓷有限公司

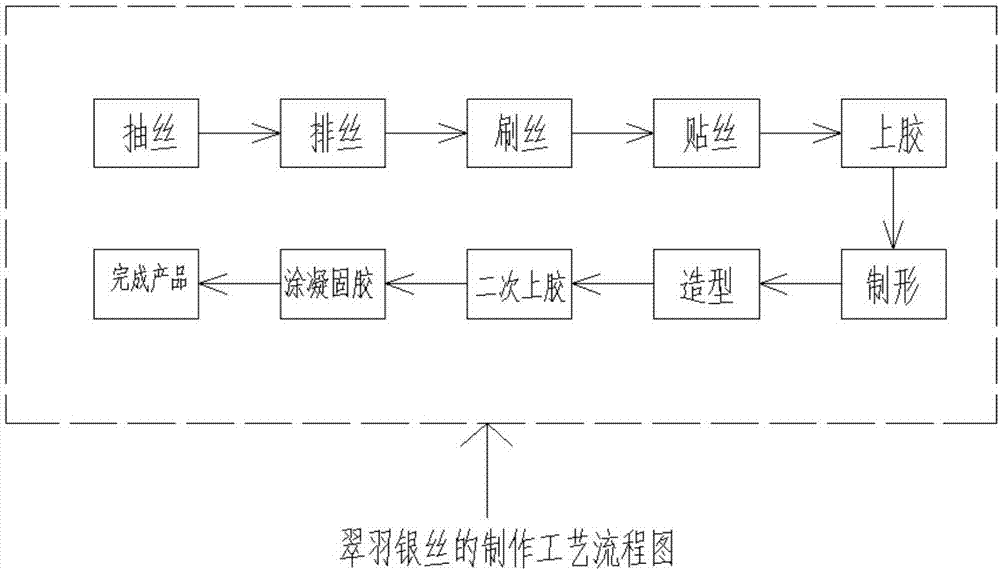

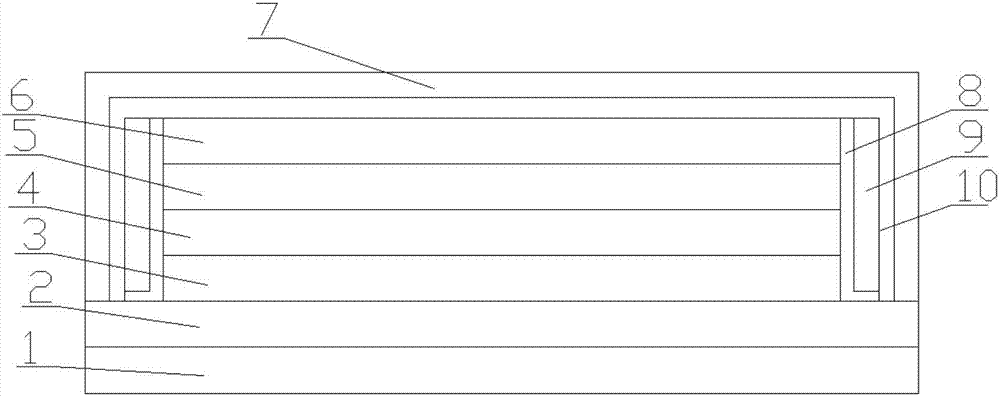

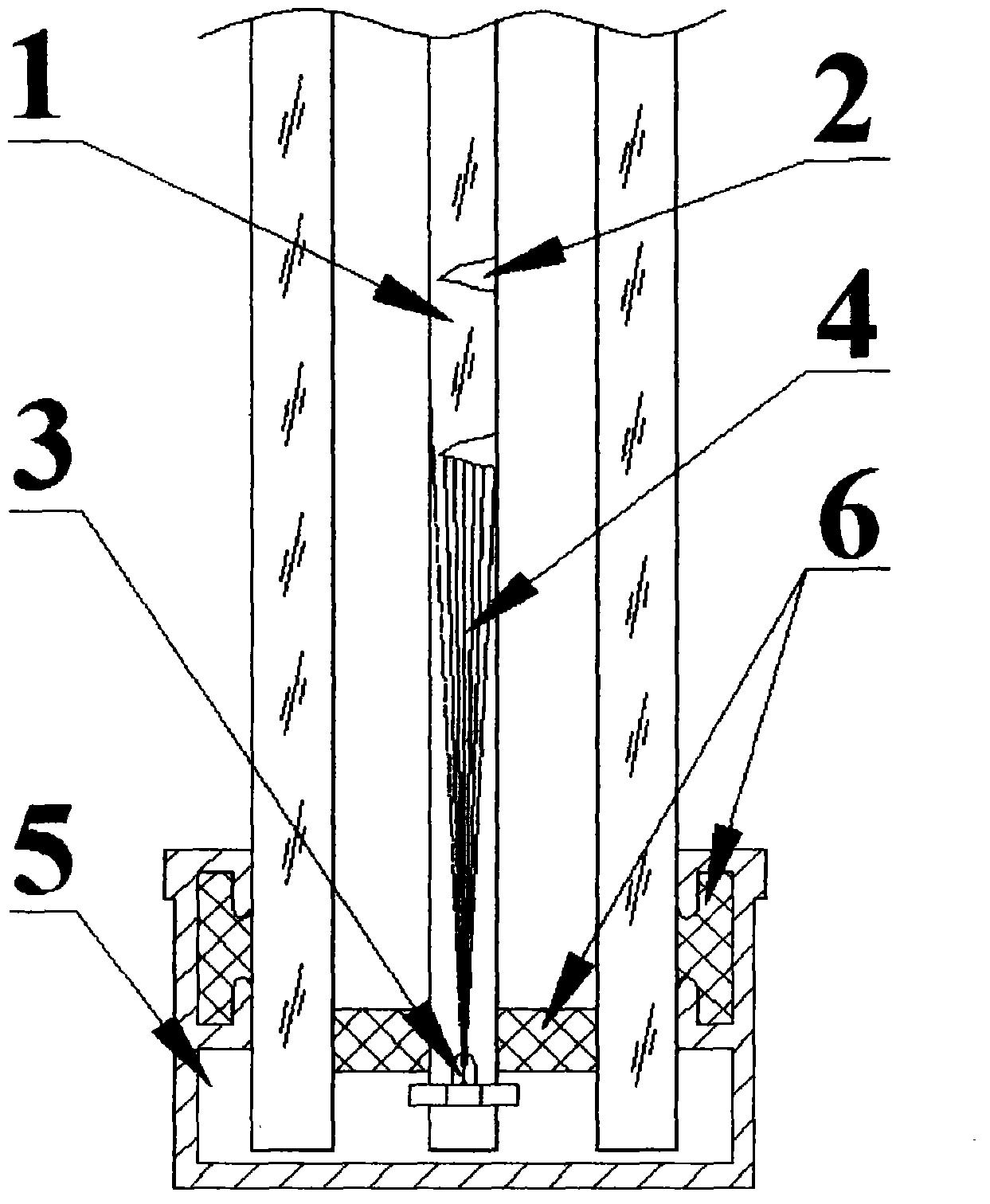

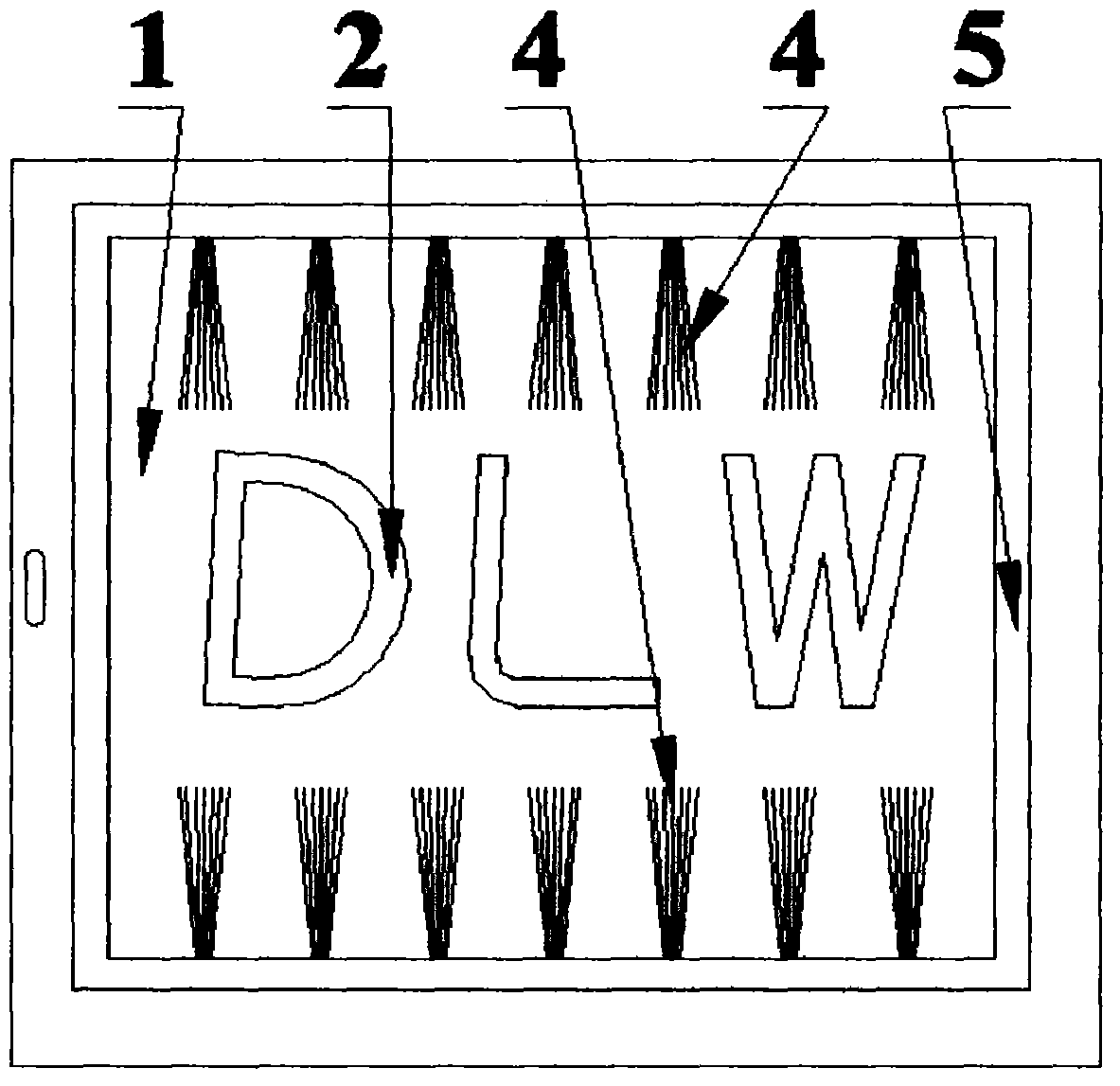

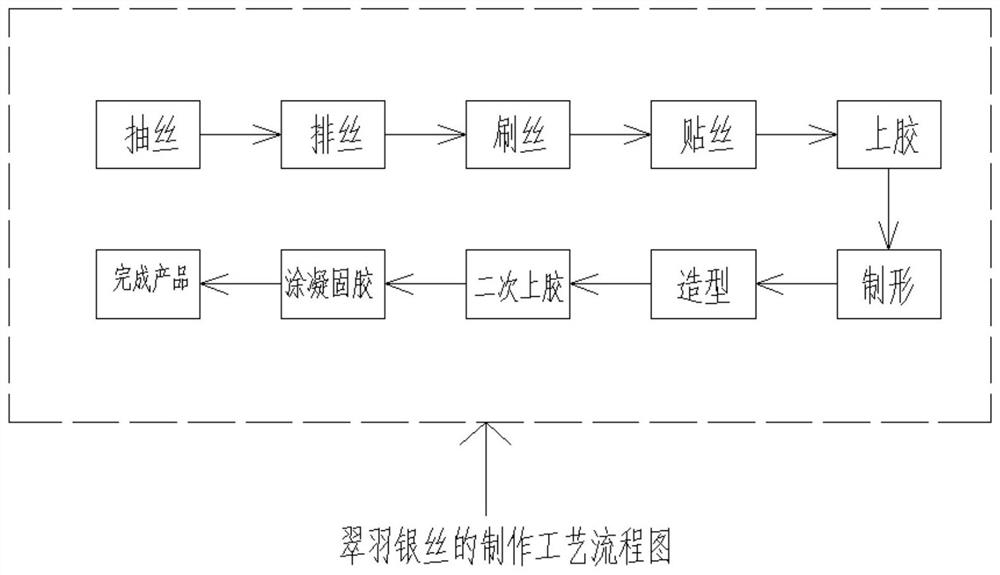

Manufacturing technology of green feather silver wire and green feather silver wire

ActiveCN106956543AHigh appreciation valueImprove the decorative effectDecorative surface effectsSpecial ornamental structuresManufacturing technologySurface layer

The invention discloses a manufacturing technology of a green feather silver wire and the green feather silver wire. The manufacturing technology of the green feather silver wire comprises the technological procedures of wire drawing, wire arranging, wire painting, wire bonding, glue coating, forming, shaping, secondary glue coating, solidification glue coating and pattern manufacturing. The green feather silver wire comprises a base layer, a first glue layer, a ribbon layer, a second glue layer, a silk face layer, a first coating glue layer, a metal wire, a second coating glue layer and a solidification glue layer. By the adoption of the manufacturing technology of the green feather silver wire, the yield is improved, the manufacturing process is simplified, the raw material cost is greatly saved, and the manufacturing technology is easier to grasp. The green feather silver wire technology is fused with multiple traditional technologies and combined with traditional patterns and national and regional culture, the problems that on the market, by the adoption of a kingfisher feather simulating art, lousiness and disengagement are prone to happen, friction resistance is poor, the glossiness is not high enough can be solved, and the effects that lousiness is avoided after the green feather silver wire is twisted, the green feather silver wire cannot disengage after being trimmed, and the green feather silver wire is glossy can be achieved.

Owner:谢晶

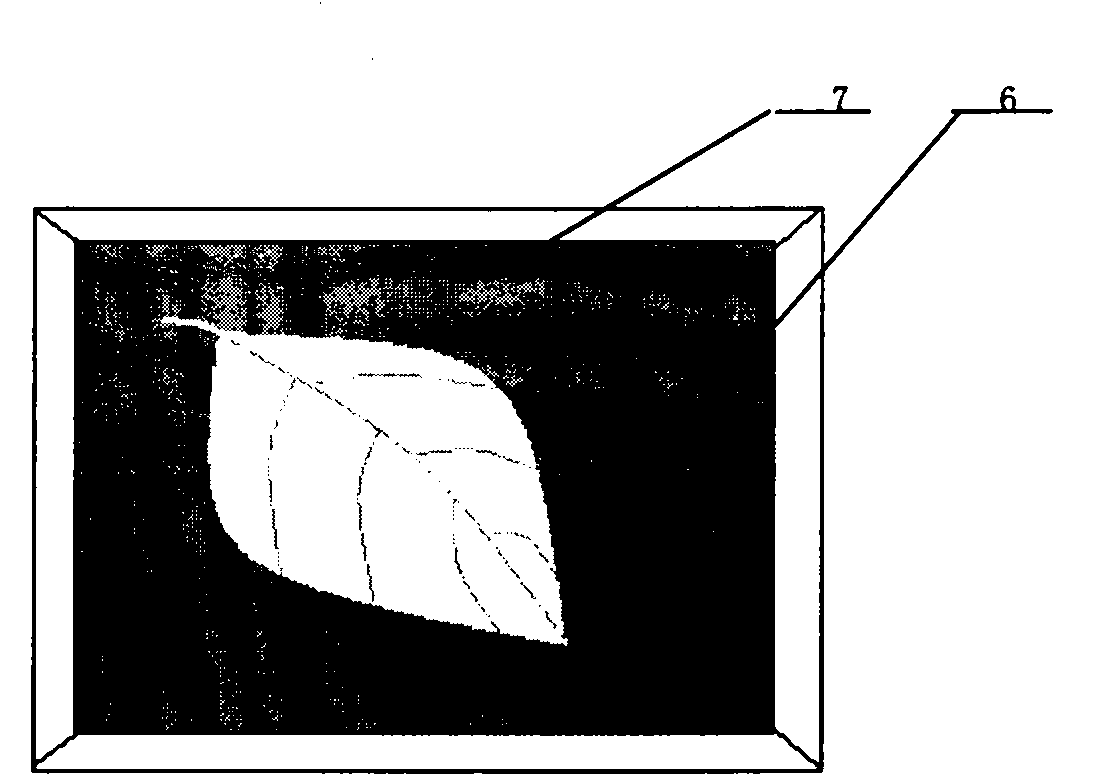

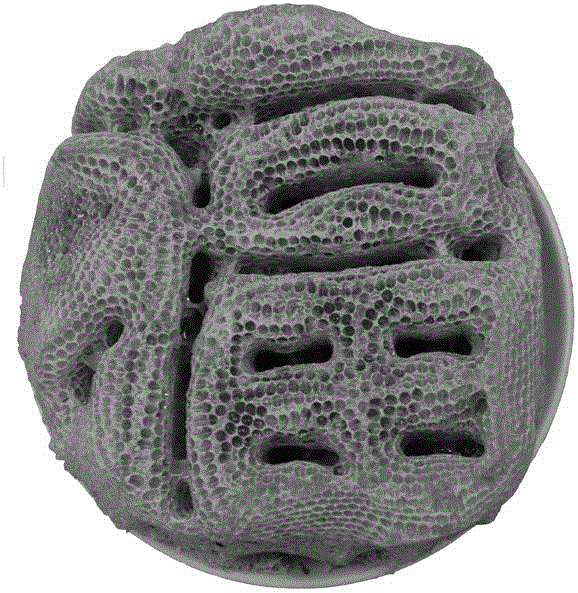

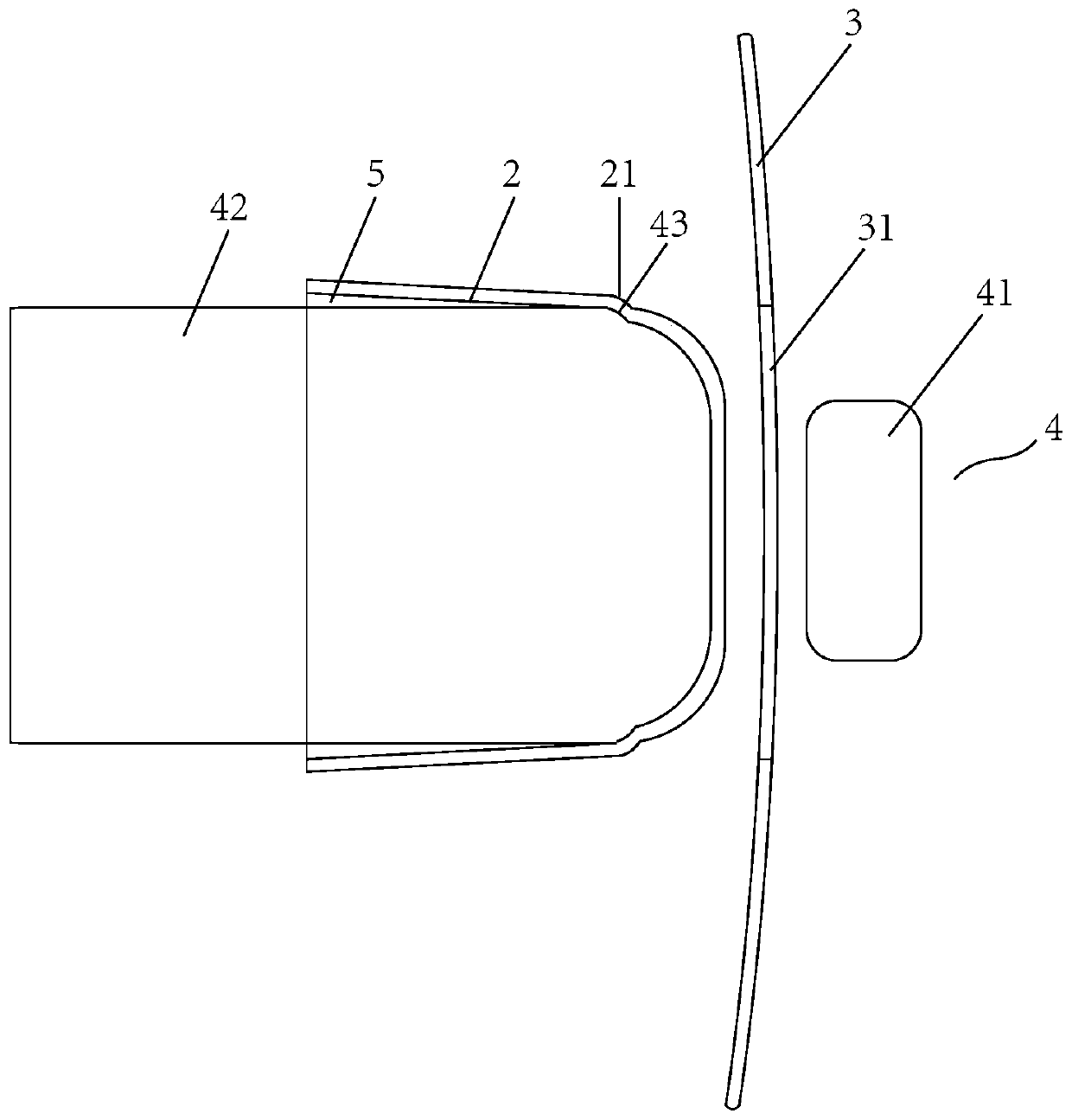

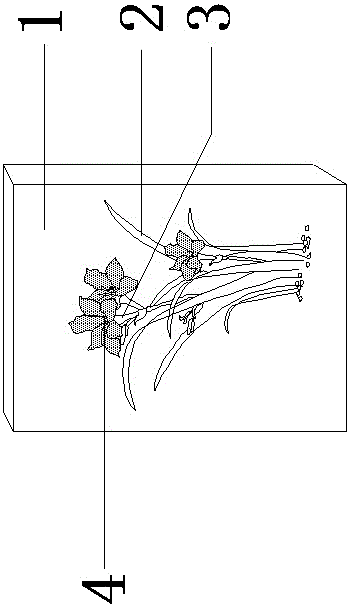

Preparation scheme for improving exhibition effect of refrigerator

InactiveCN103629883AColorfulImprove practicalityLighting and heating apparatusLighting arrangementThermal insulationLight beam

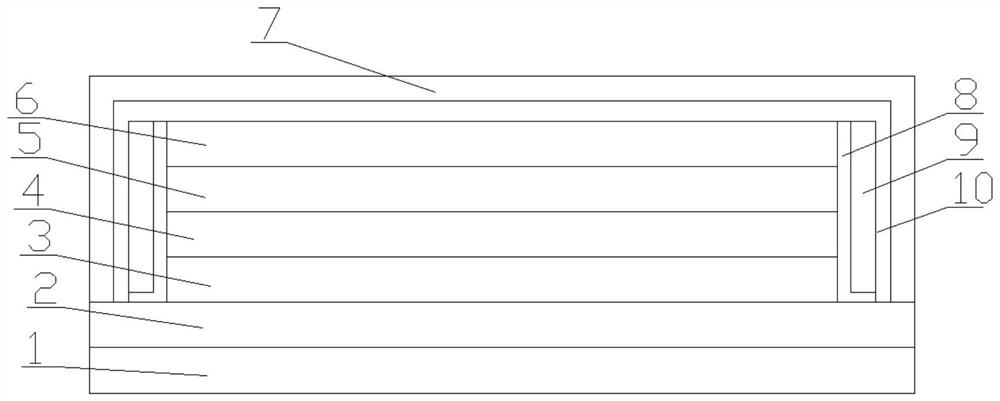

The invention relates to a structure used for mounting an LED lamp on an exhibition refrigerator door, so that enterprise brand logos or information content needing to be advertised deliberately is more visual and striking. According to the technical scheme, a transparent material 1 is additionally arranged in the middle of the refrigerator door, an LED light source lamp set 3 is mounted on the end face of the cross section of the transparent material, three-dimensional groove patterns 2 which have different depths and are formed by coating different colors are carved on the transparent material 1, the three-dimensional patterns 2 are opaque or semitransparent, the mounted LED light source lamp set 3 is arranged at a hidden position inside a refrigerator door frame 5, the mounted LED light source lamp set 3 gives out light beams 4 through a thermal insulation material 6 inside the refrigerator door frame 5 and a crack of the transparent material 1, and the light beams 4 are transmitted through the inside of the transparent material 1. After the refrigerator door is assembled and powered up, for the reason that the light emitted from the LED light source lamp set 3 penetrates through the transparent material through the inside of the transparent material, light refraction happens at the positions of the opaque or semitransparent three-dimensional patterns 2 which are formed by coating different colors, and thus the opaque or semitransparent three-dimensional patterns 2 coated with different colors on the transparent material are colorful and more striking.

Owner:QINGDAO DELLCOOL ELECTRICAL APPLIANCE CO LTD

Cuiyu Silver Filament Production Technology and Cuiyu Silver Filament

ActiveCN106956543BHigh appreciation valueImprove the decorative effectDecorative surface effectsSpecial ornamental structuresEmeraldRegional culture

The invention discloses a production process of Cuiyu silver thread and Cuiyu silver thread, including drawing, arranging, brushing, pasting, gluing, shaping, modeling, secondary gluing, coagulation coating and mosaic The technological process of making, Cuiyu silver silk of the present invention comprises bottom layer, the first adhesive layer, ribbon layer, the second adhesive layer, silk surface layer, the first lamination adhesive layer, metal wire, the second lamination adhesive layer and The coagulation glue layer, a kind of production process of Cuiyu silver thread provided by the present invention, improves the yield, simplifies the production process, greatly saves the cost of raw materials, and the production process is simpler and easier to master. Cuiyu silver thread technology integrates a variety of traditional crafts, combined with traditional patterns and ethnic and regional cultures, can solve the problems of imitation dots on the market, such as easy fluff, easy to fall off, not resistant to friction, insufficient gloss, etc., can achieve rubbing without fluff, trimming Non-flaking, glossy glossy effect.

Owner:谢晶

A kind of bronze glaze and preparation method thereof

The invention discloses a bronze glaze, which comprises the following components in terms of mass fraction: 45-49% of potassium feldspar, 10-13% of calcite, 15-19% of barium carbonate, 15-17% of kaolin, and 2-2% of aluminum oxide 3%, copper carbonate 3-4%; the invention discloses a preparation method of bronze glaze at the same time, comprising the following steps: Step 1, weighing various raw materials in proportion, adding water to mix after grinding, and passing through a screen to obtain uniform and delicate Glaze slurry; step 2, choose different glazing methods and thickness according to the size and thickness of the body; step 3, put the glazed body into the kiln, and fire it according to the following heating curve in an oxidizing atmosphere, and stop the fire after 20 minutes of heat preservation Allow to cool naturally. The beneficial effect of the present invention is that the formulation and preparation method of the bronze glaze disclosed by the present invention can stably achieve a bronze glaze color effect. Its color is simple, thick and elegant, with a dignified sense of history, strong artistic expression and high artistic value.

Owner:SHANGHAI UNIV

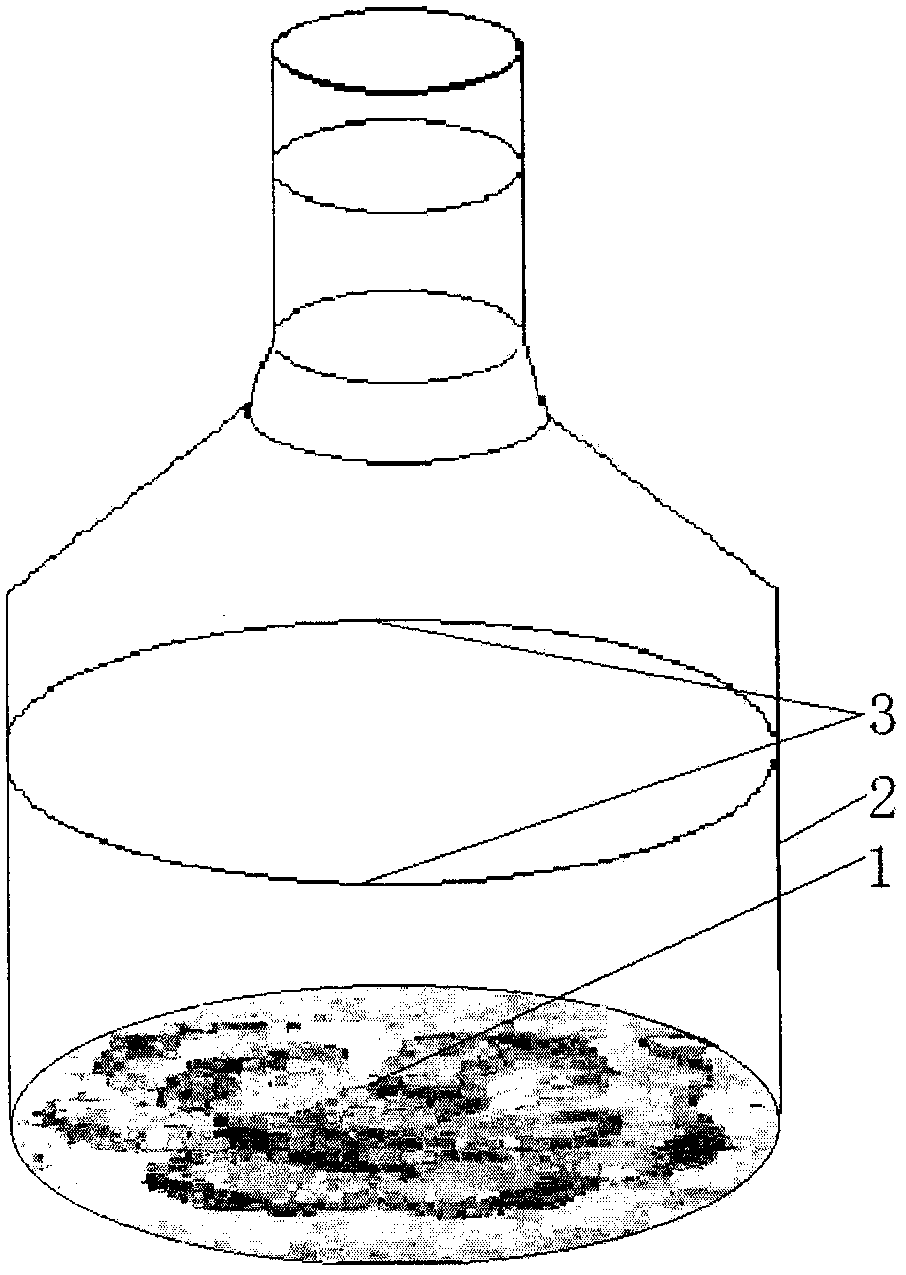

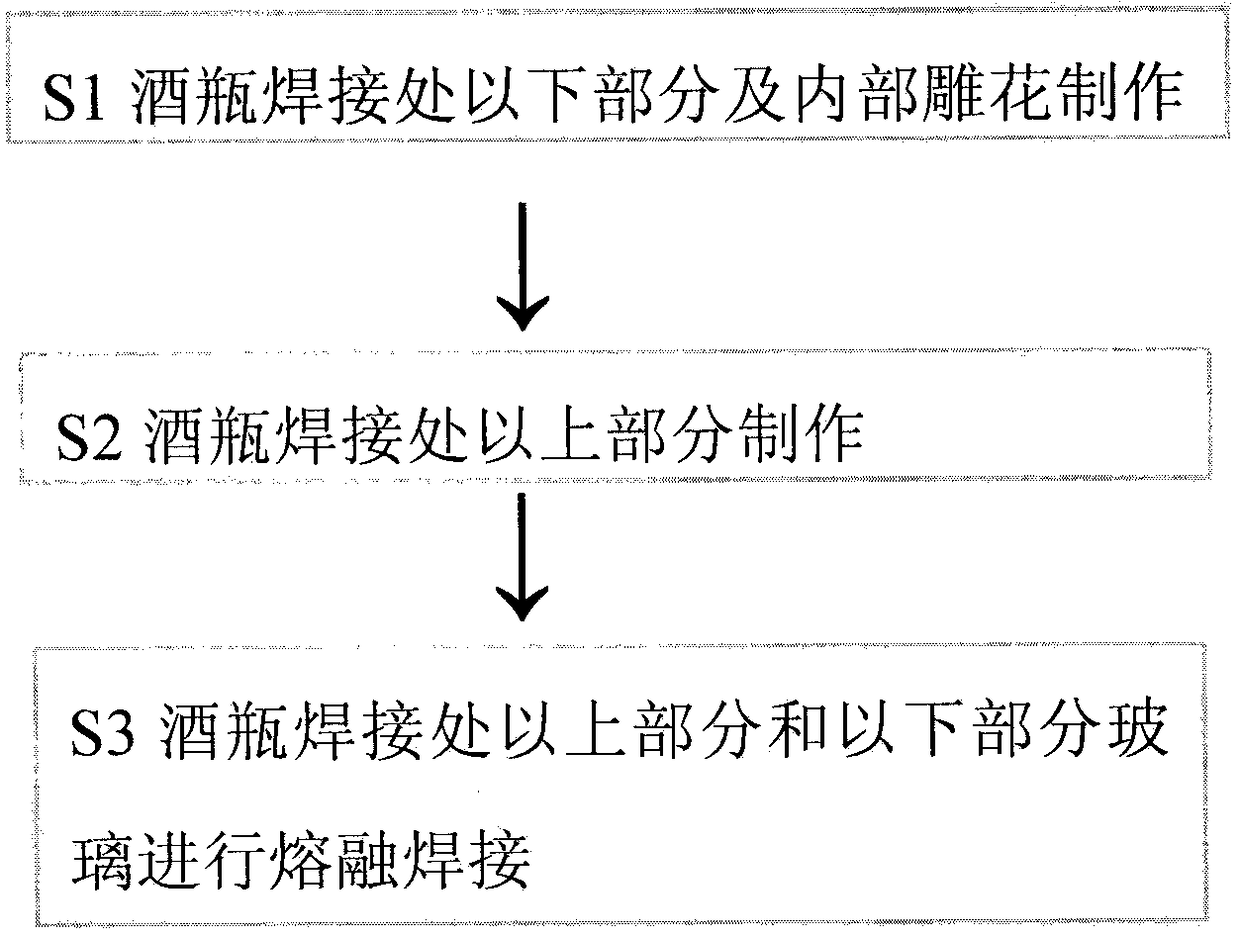

Transparent wine bottle with carve patterns at inner wall and production process thereof

InactiveCN108314297AHigh appreciation valueHigh collection valueDecorative surface effectsGlass pressing apparatusMolten stateWine bottle

The invention discloses a transparent wine bottle with carve patterns at the inner wall and a production process thereof. The wine bottle consists of a transparent wine bottle body (1) and inner wallcarve patterns (2), and is characterized in that the inner wall carve patterns (2) can be positioned in the bottle bottom position in the wine bottle or the periphery of the inner wall of the wine bottle. The production process uses a glass secondary welding formation technology; firstly, the part with the carve patterns in the bottle is pressed and formed by a mold; then, glass in a bottle body and bottle neck connector part is connected into a whole in a molten state; finally, cooling and forming are performed.

Owner:罗小兵

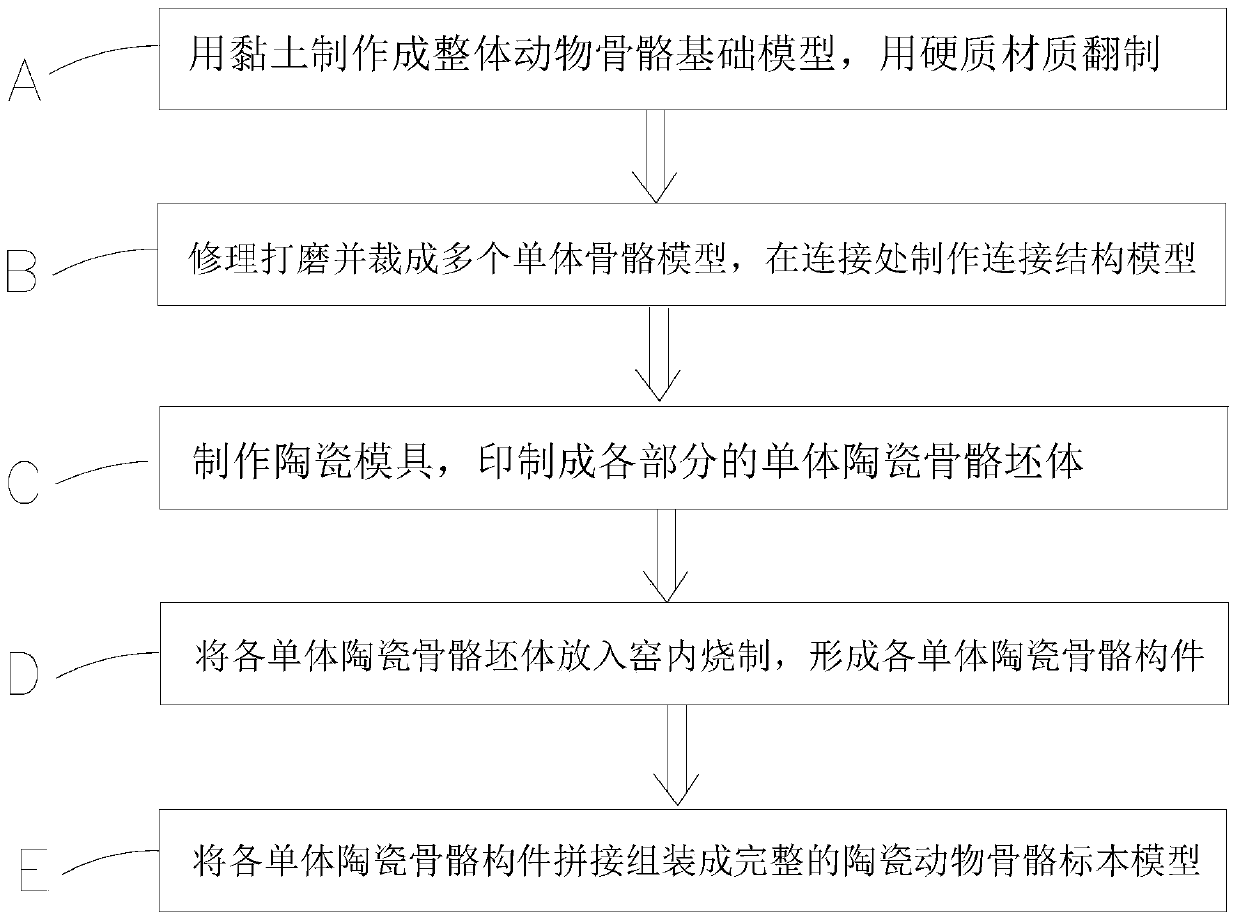

Method for making animal bone specimen model

InactiveCN106816076BImprove stabilityImprove antioxidant capacityEducational modelsMortise and tenonEngineering

The invention discloses an animal skeleton specimen model manufacturing method. The method includes a step A of model manufacture; a step B of mending and polishing including mending and polishing a manufactured integral animal skeleton basic model, cutting off the integral animal skeleton basic model subjected to mending and polishing into a plurality of skeleton model individuals and making connection structure models between junctions of two to-be-connected skeleton model individuals; a step C of ceramic model manufacture; a step D of ceramic component manufacture; a step E of assembly. The animal skeleton specimen model made of ceramic material is good in stability and anti-oxidization performance and can be in permanent preservation, and is low in cost and good in environment protection. By adopting the manufacturing method provided by the invention, animal skeleton specimen models of different sizes can be manufactured and the original appearance of animal skeletons can be represented. The naturalness, the artistic value and the appreciation value are high. According to the invention, mortise and tenon joint structures are arranged, so that stability is ensured and assembly is facilitated.

Owner:李晓林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com