Patents

Literature

242results about How to "Exquisite pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device

InactiveUS20030006415A1Increase flexibilityReduce in quantityTransistorSolid-state devicesMOSFETInductor

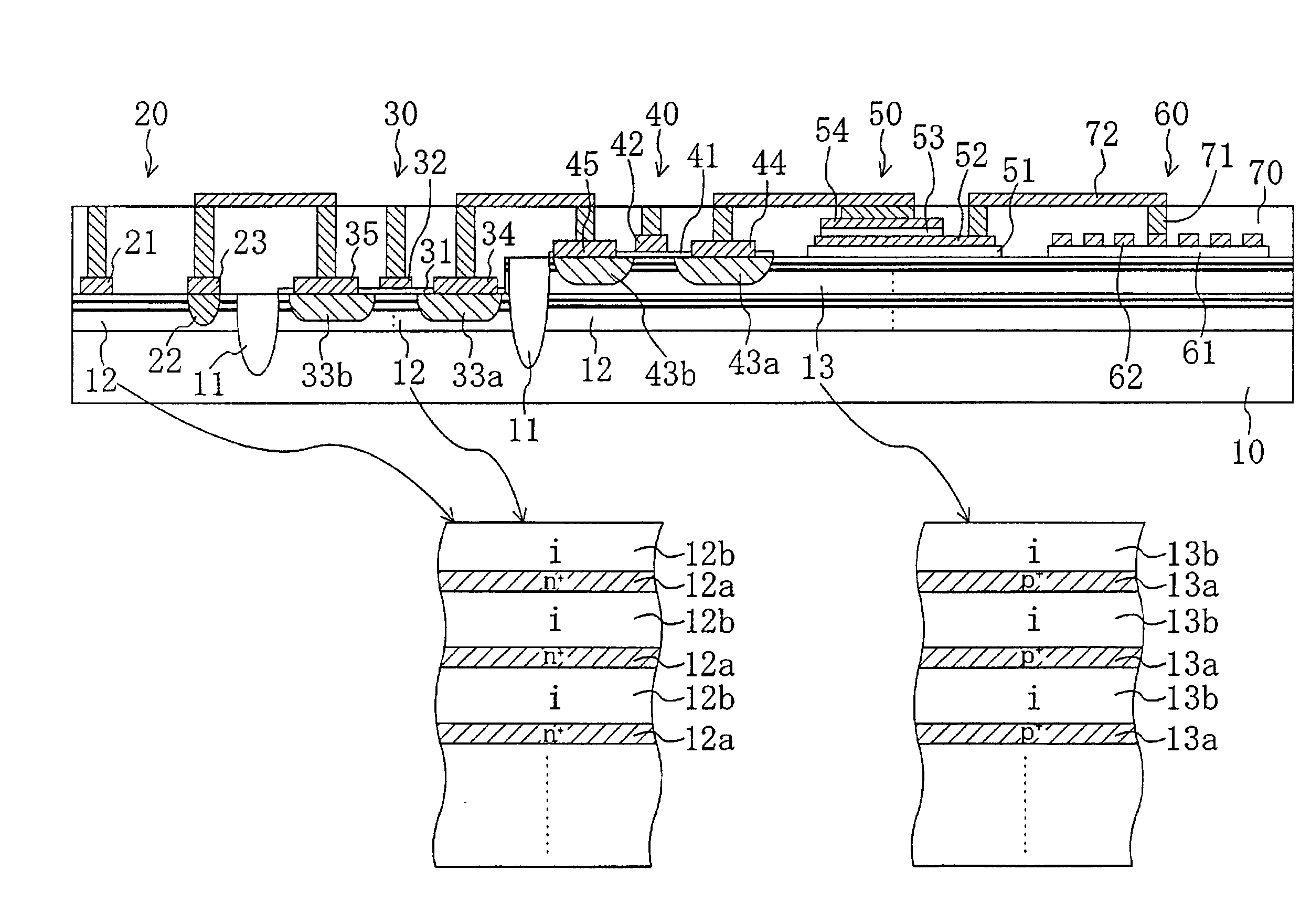

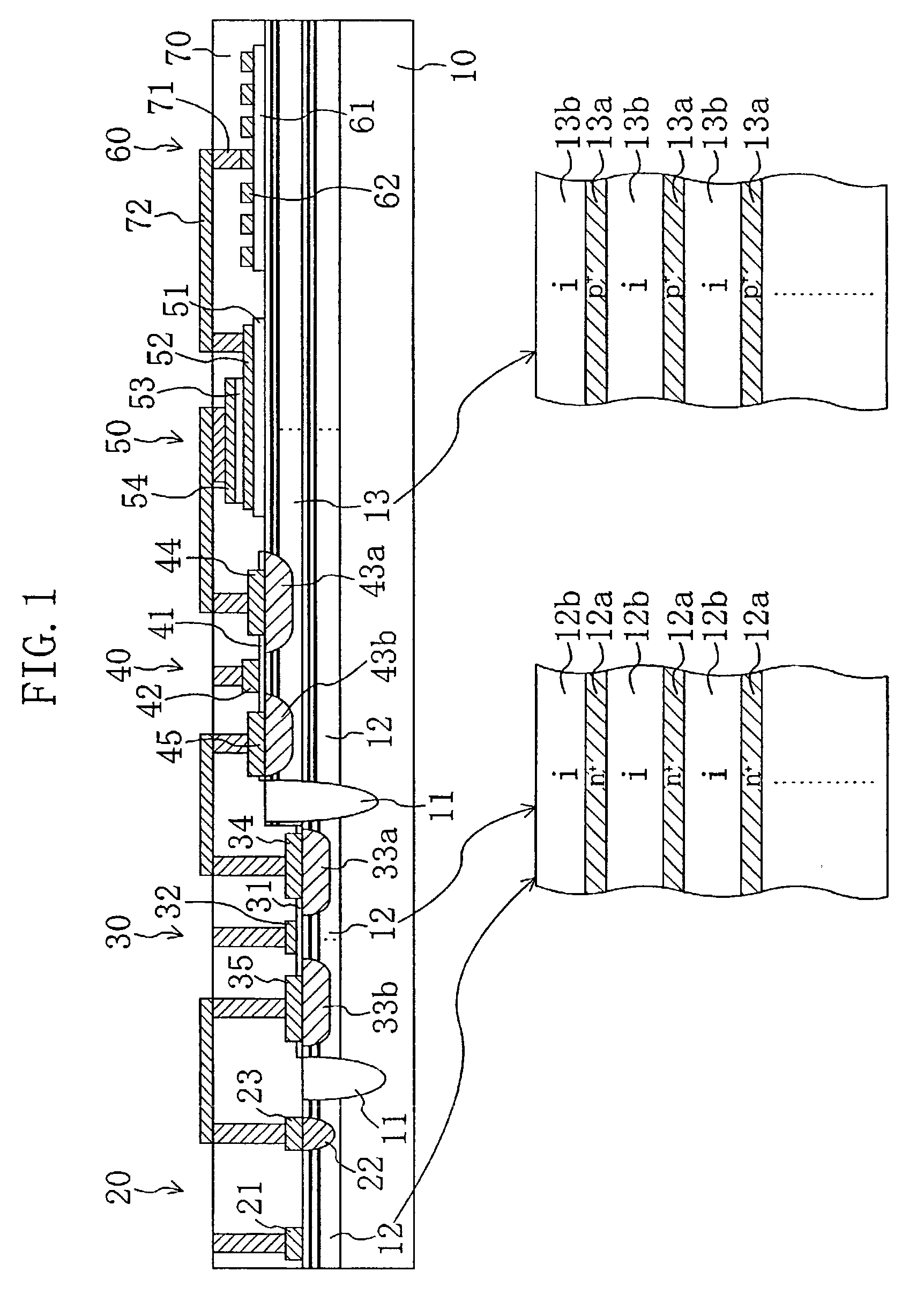

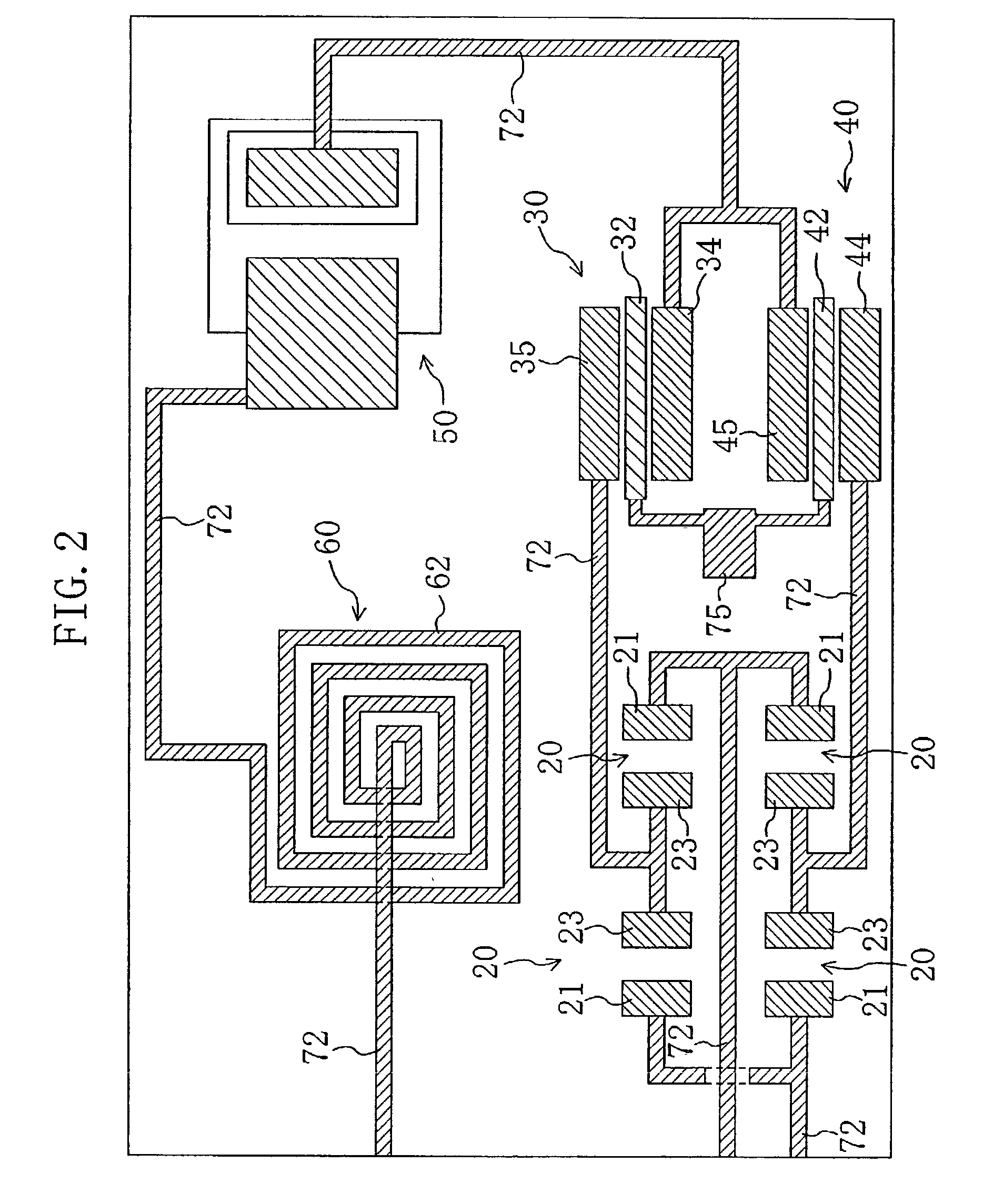

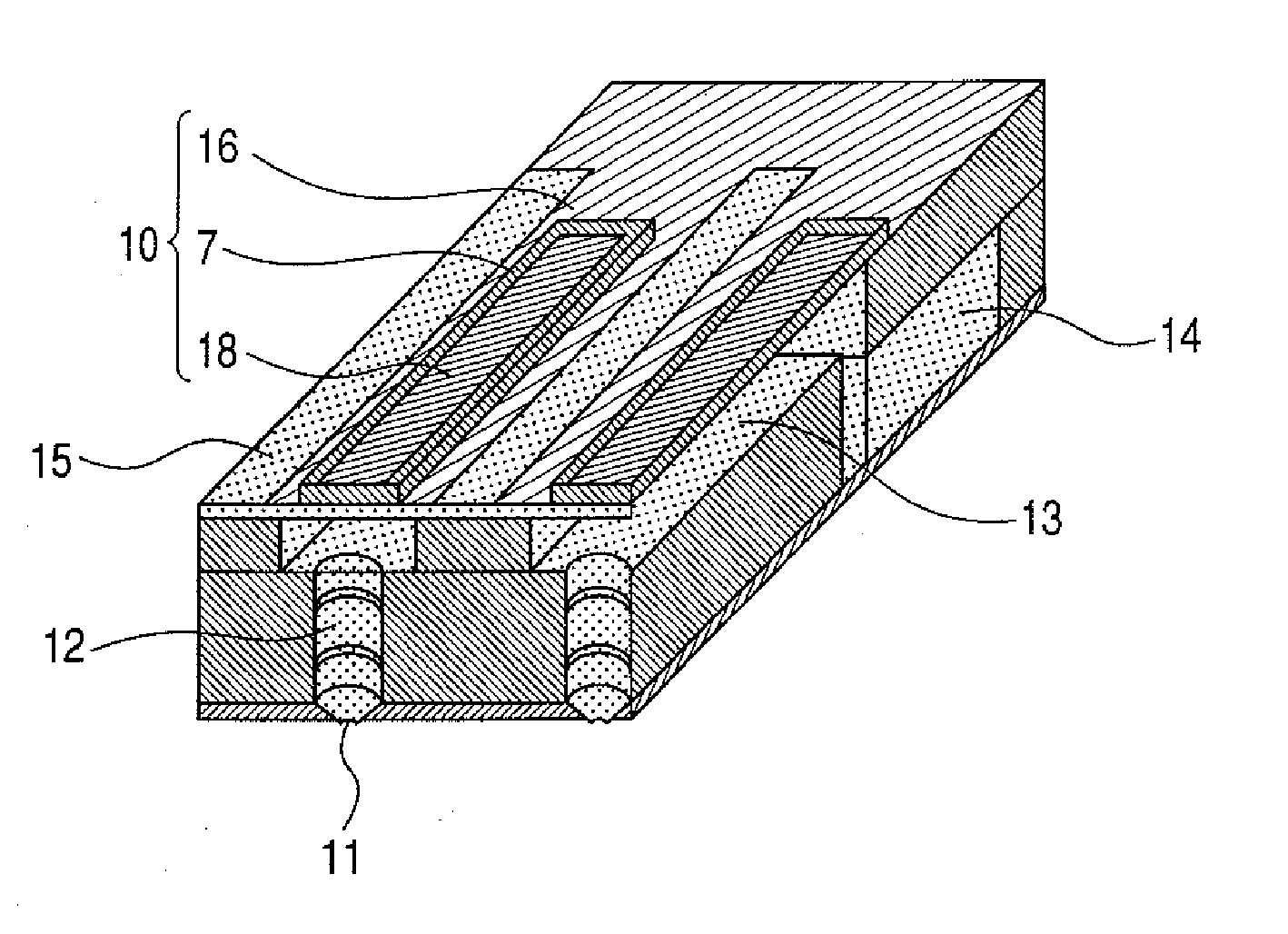

In a SiC substrate (10), a first active region (12) composed of n-type heavily doped layers (12a) and undoped layers (12b), which are alternately stacked, and a second active region (13) composed of p-type heavily doped layers (13a) and undoped layers (13b), which are alternately stacked, are provided upwardly in this order. A Schottky diode (20) and a pMOSFET (30) are provided on the first active region (12). An nMOSFET (40), a capacitor (50), and an inductor (60) are provided on the second active region (13). The Schottky diode (20) and the MOSFETs (30, 40) have a breakdown voltage characteristic and a carrier flow characteristic due to a multilayer structure composed of delta-doped layers and undoped layers and are integrated in a common substrate.

Owner:PANASONIC CORP

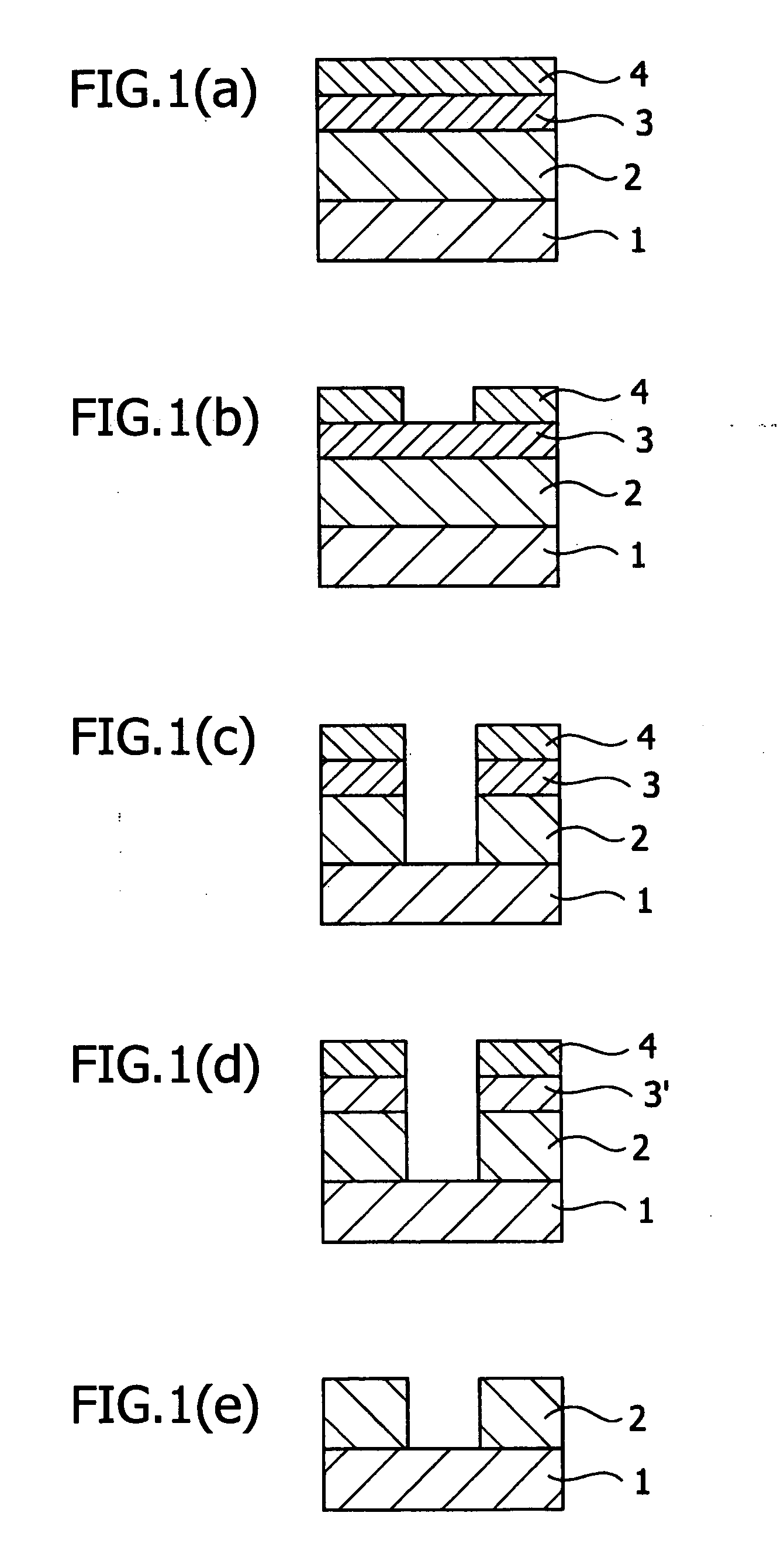

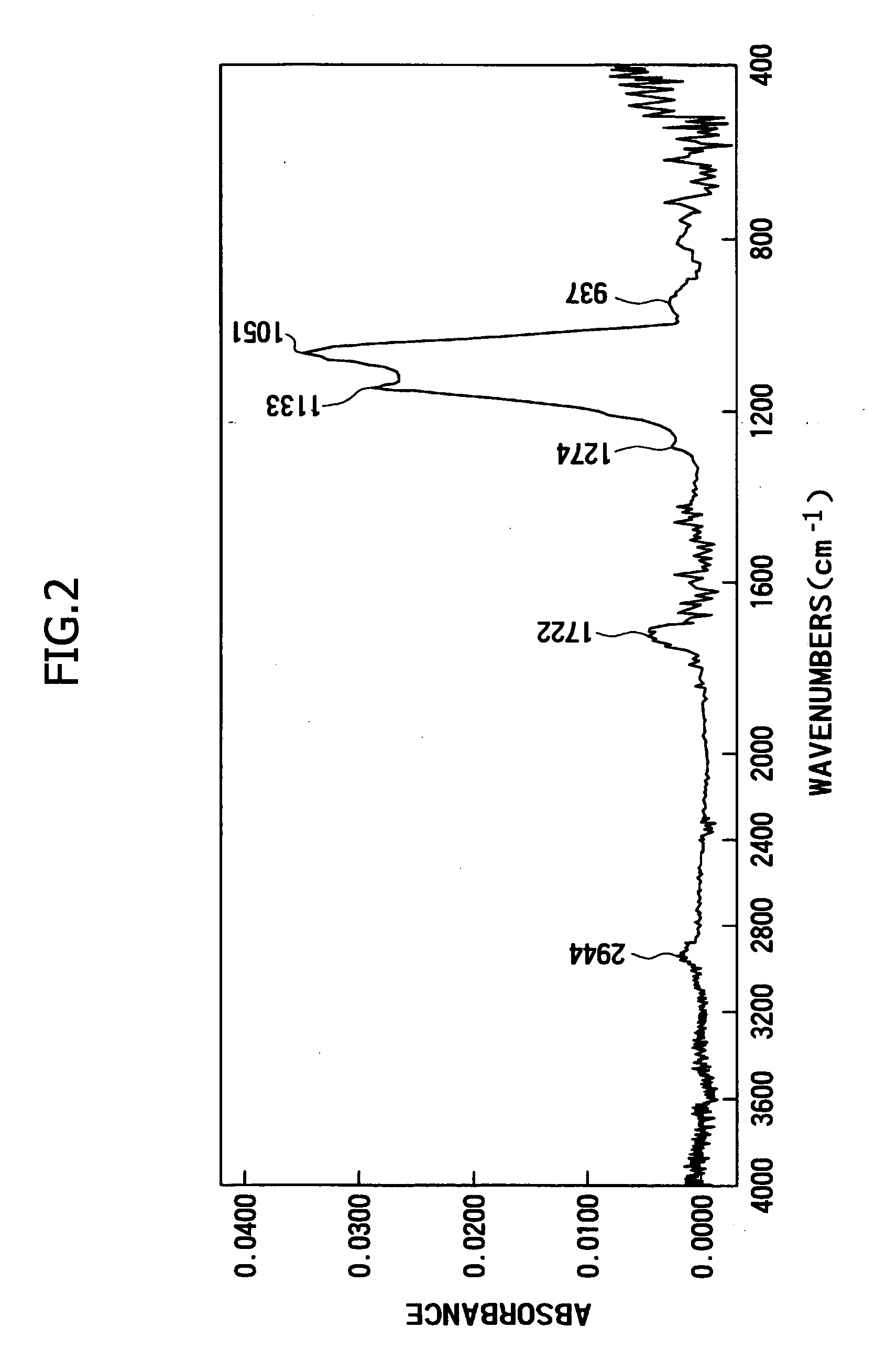

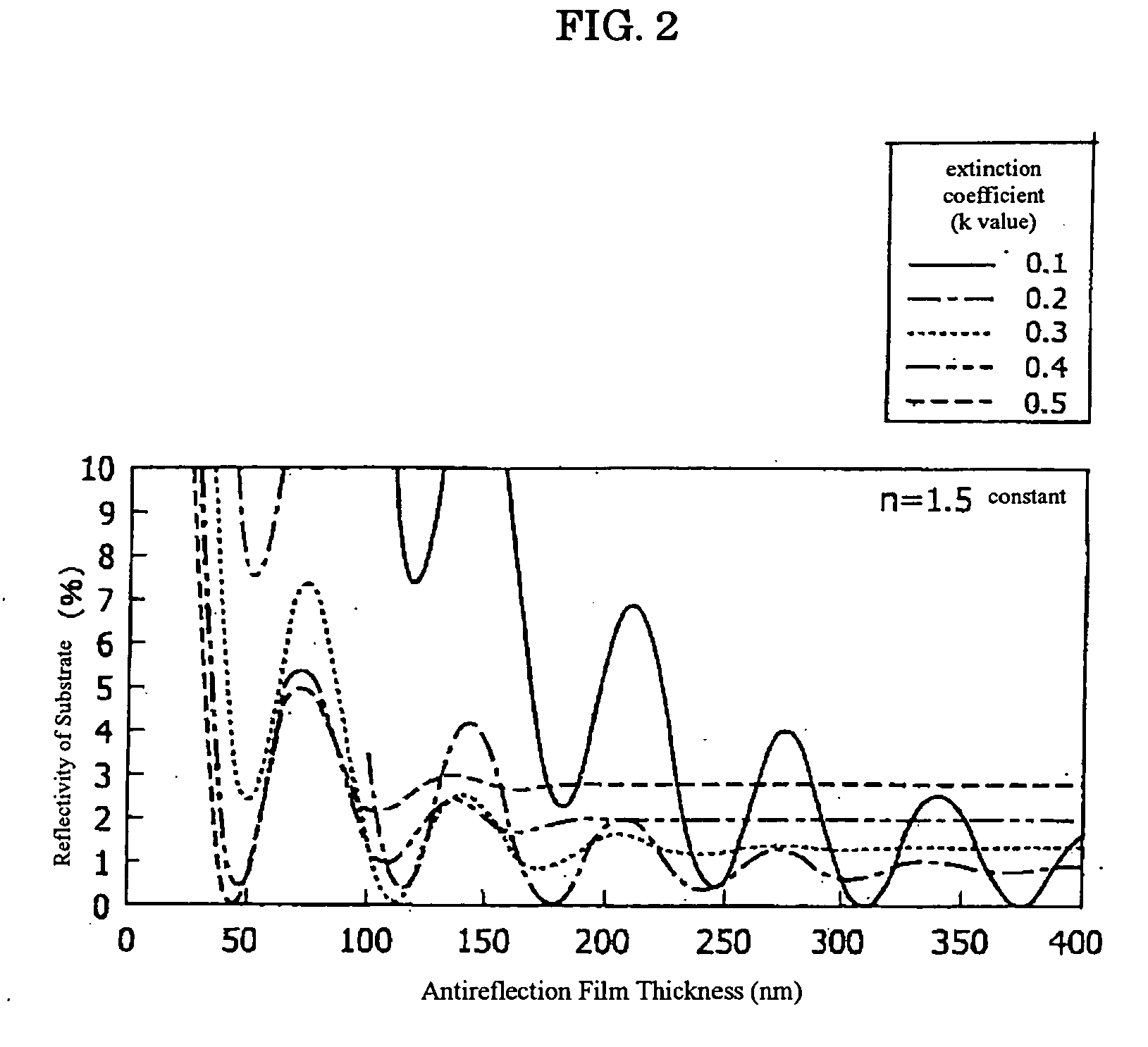

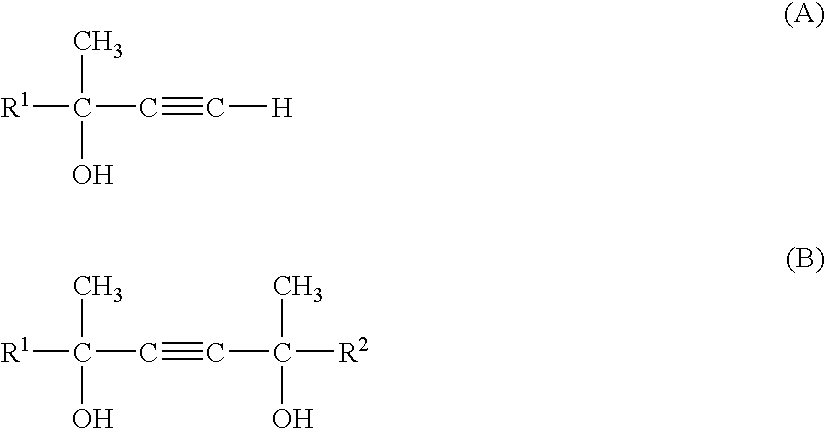

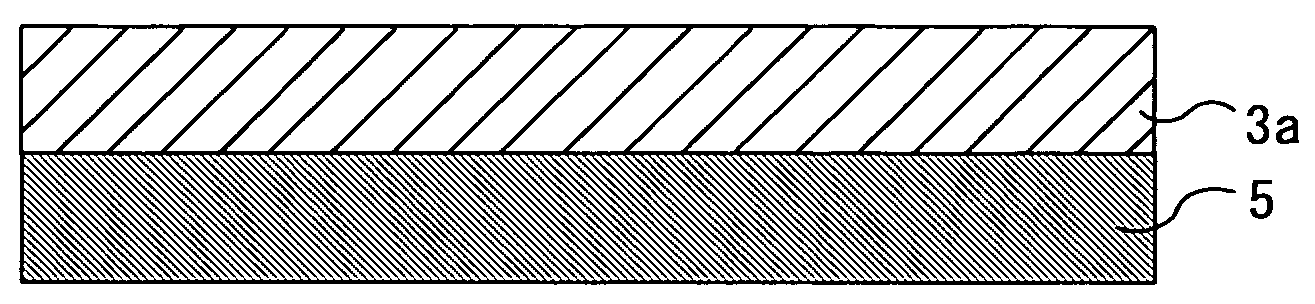

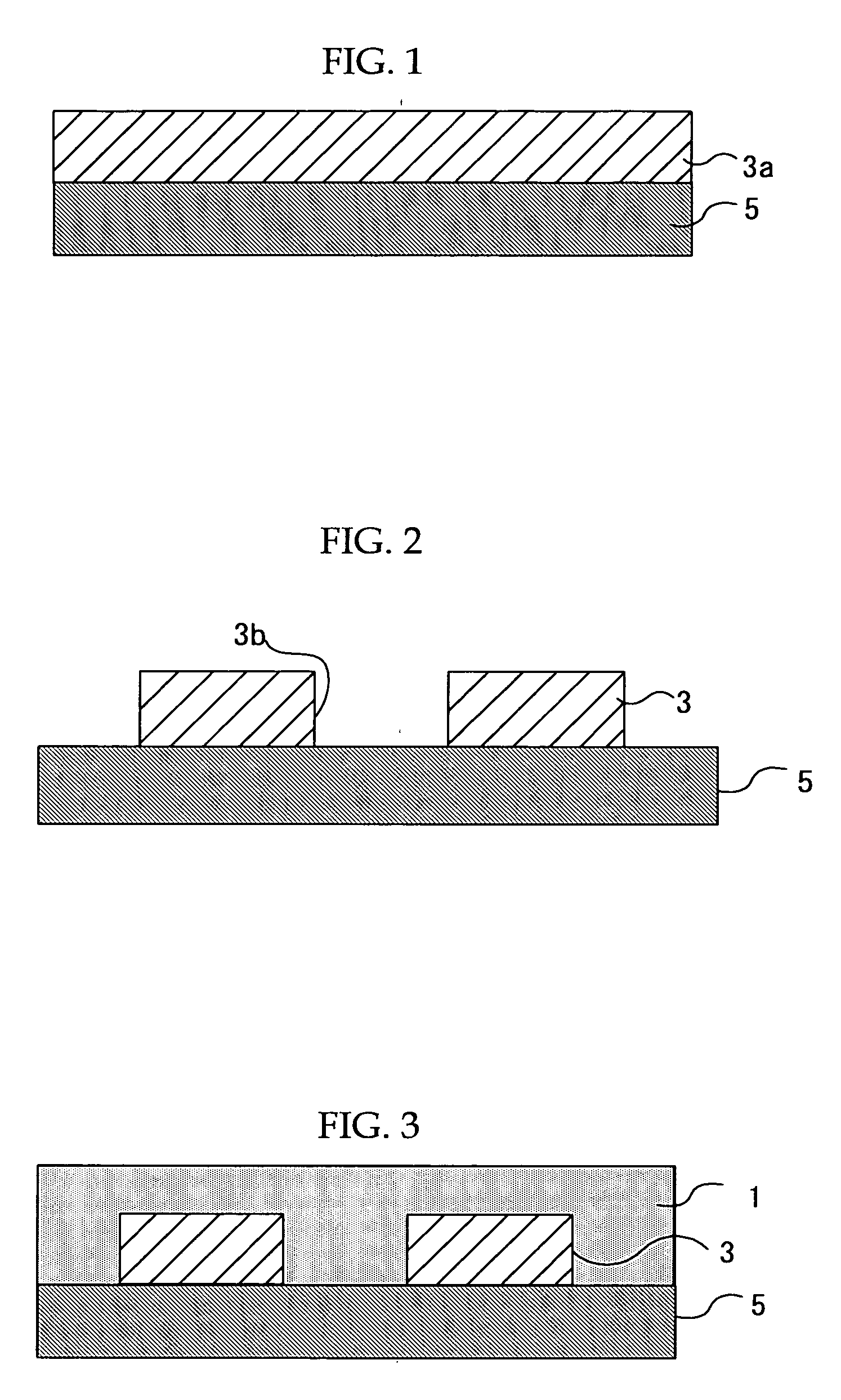

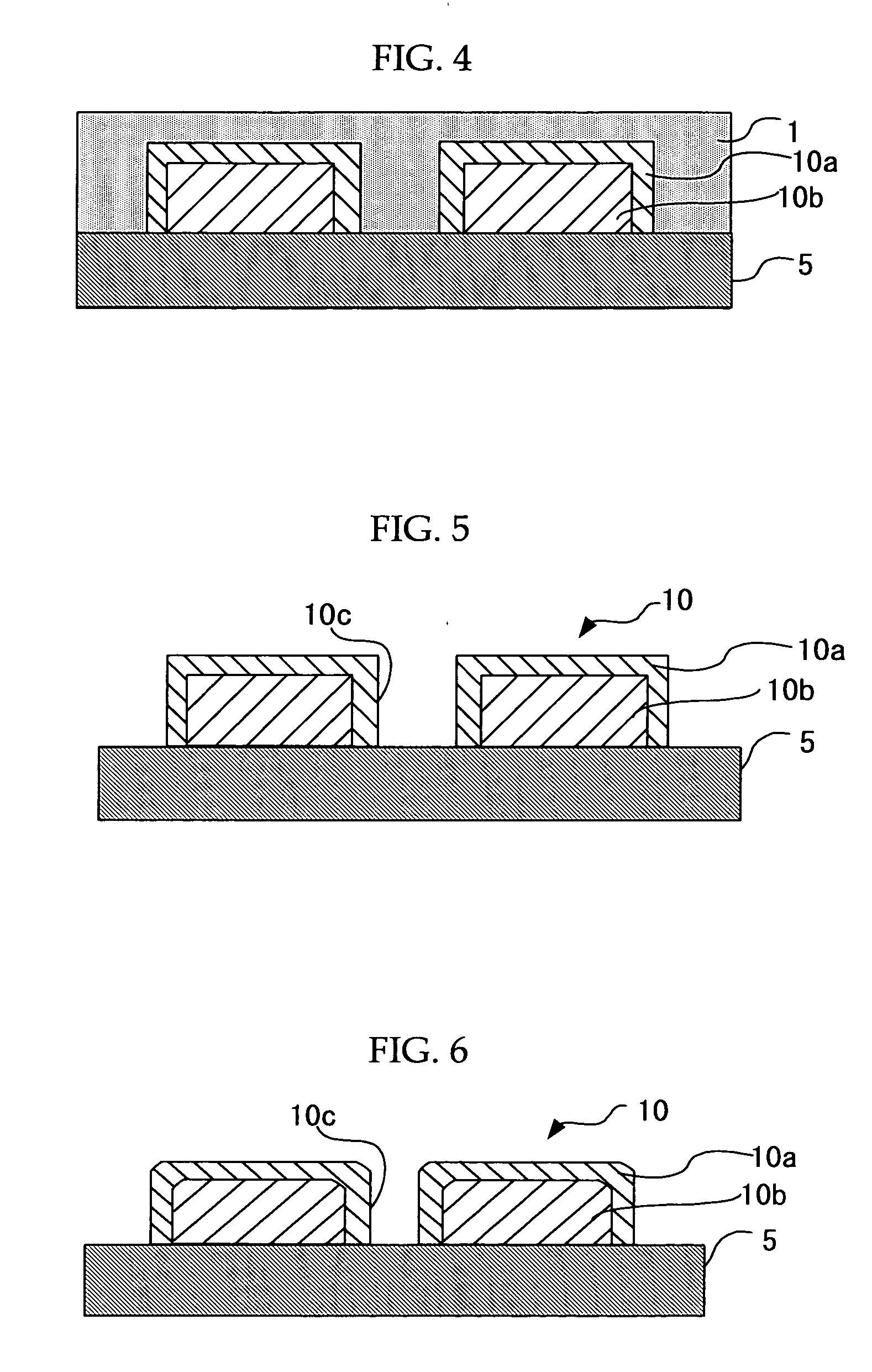

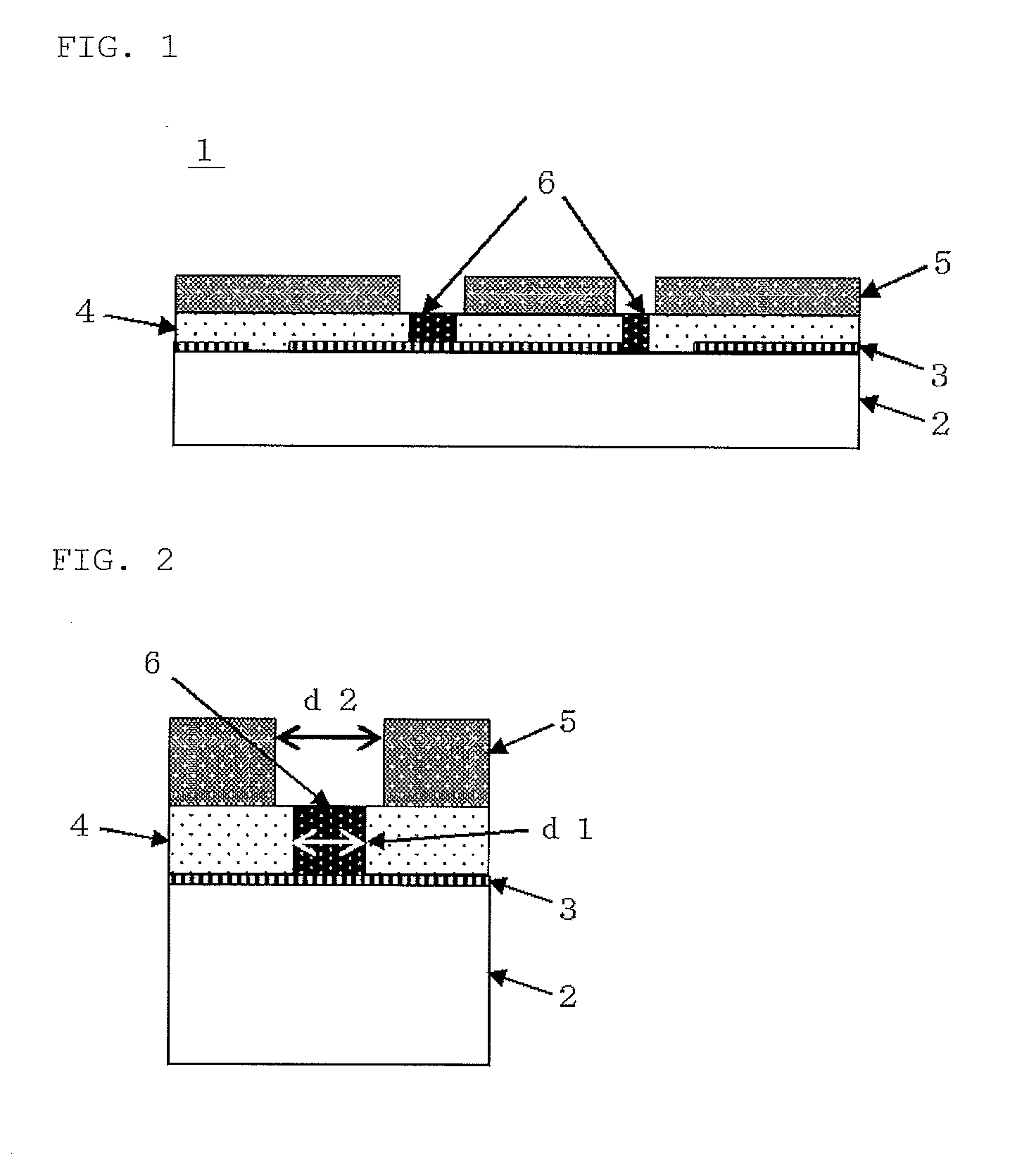

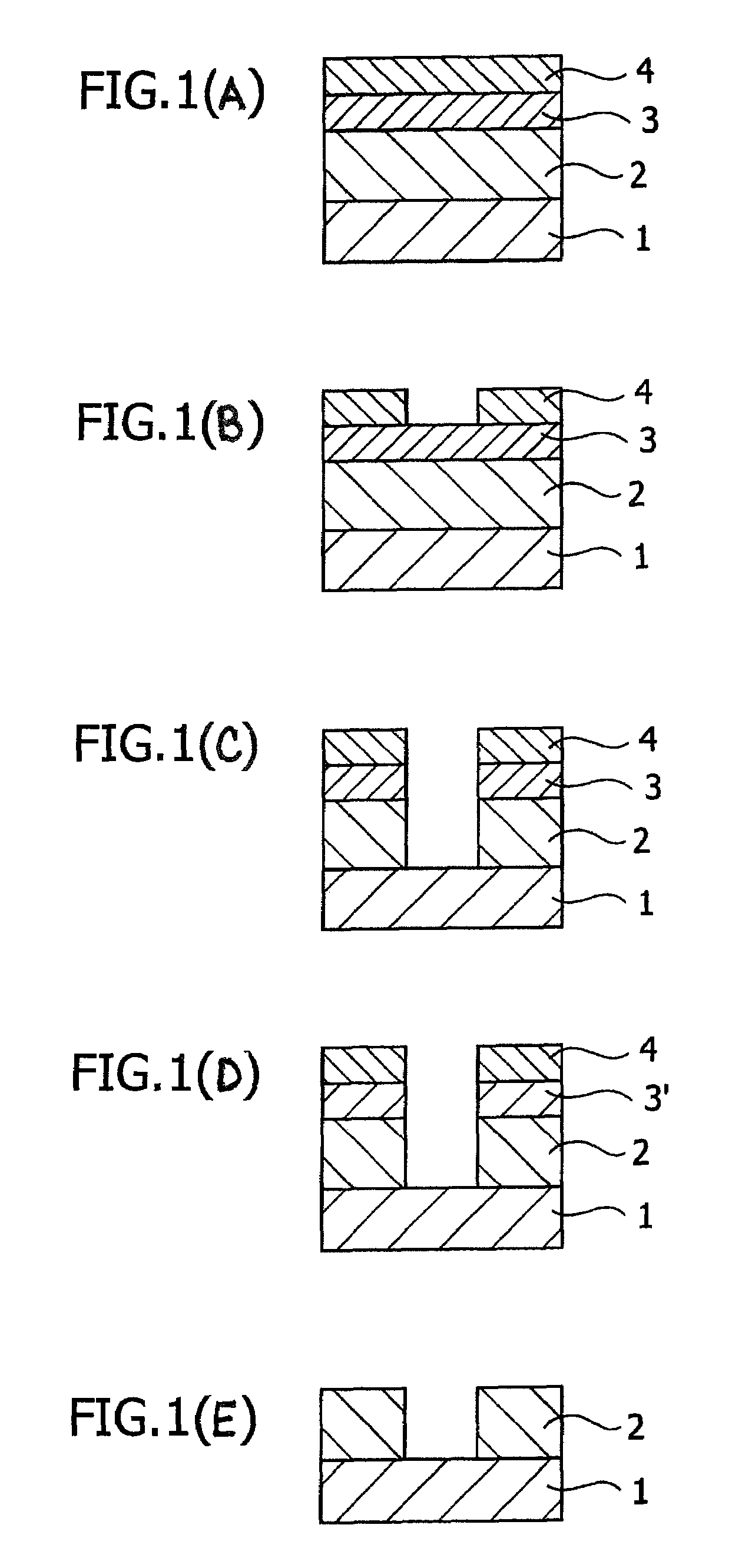

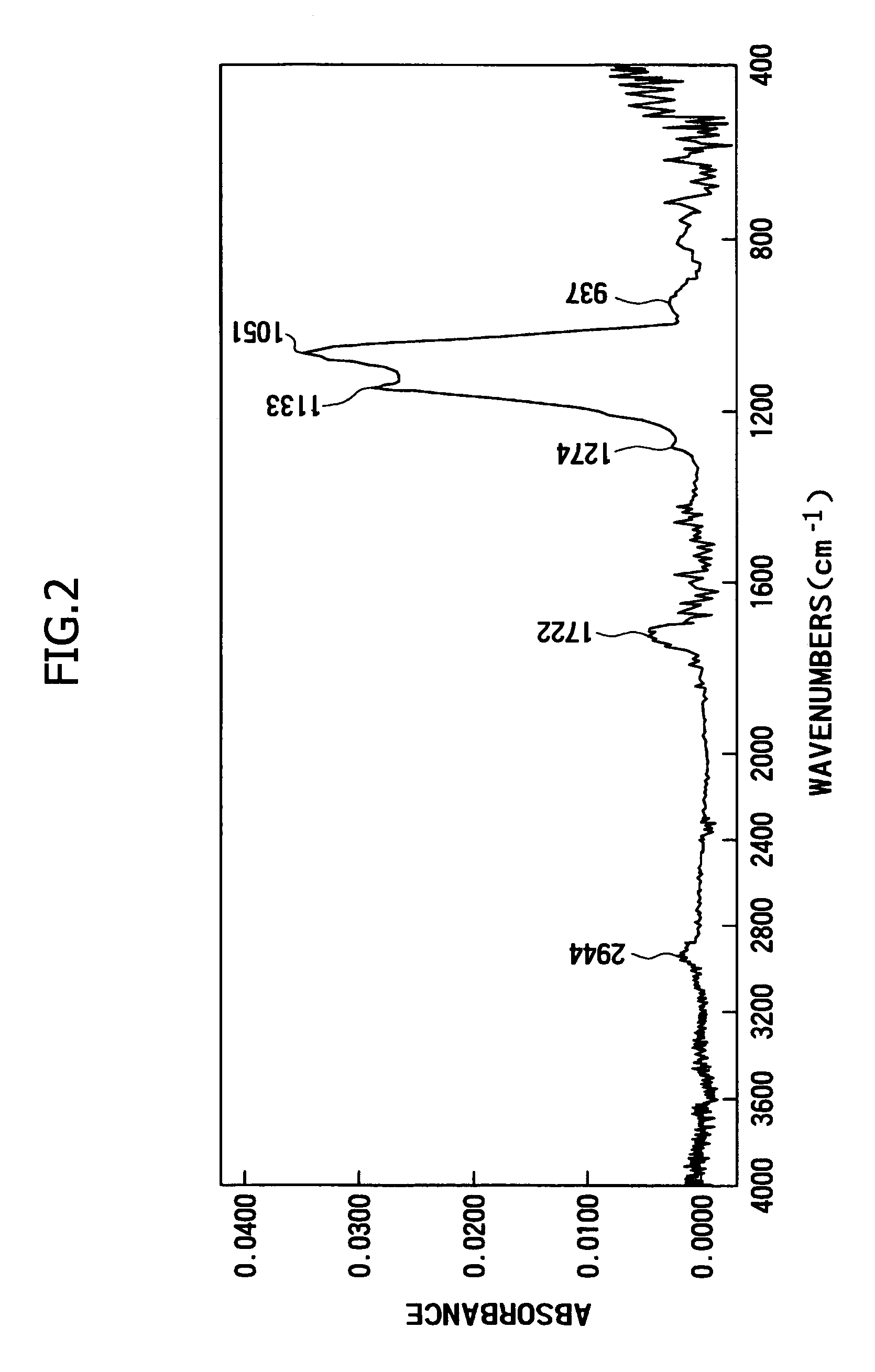

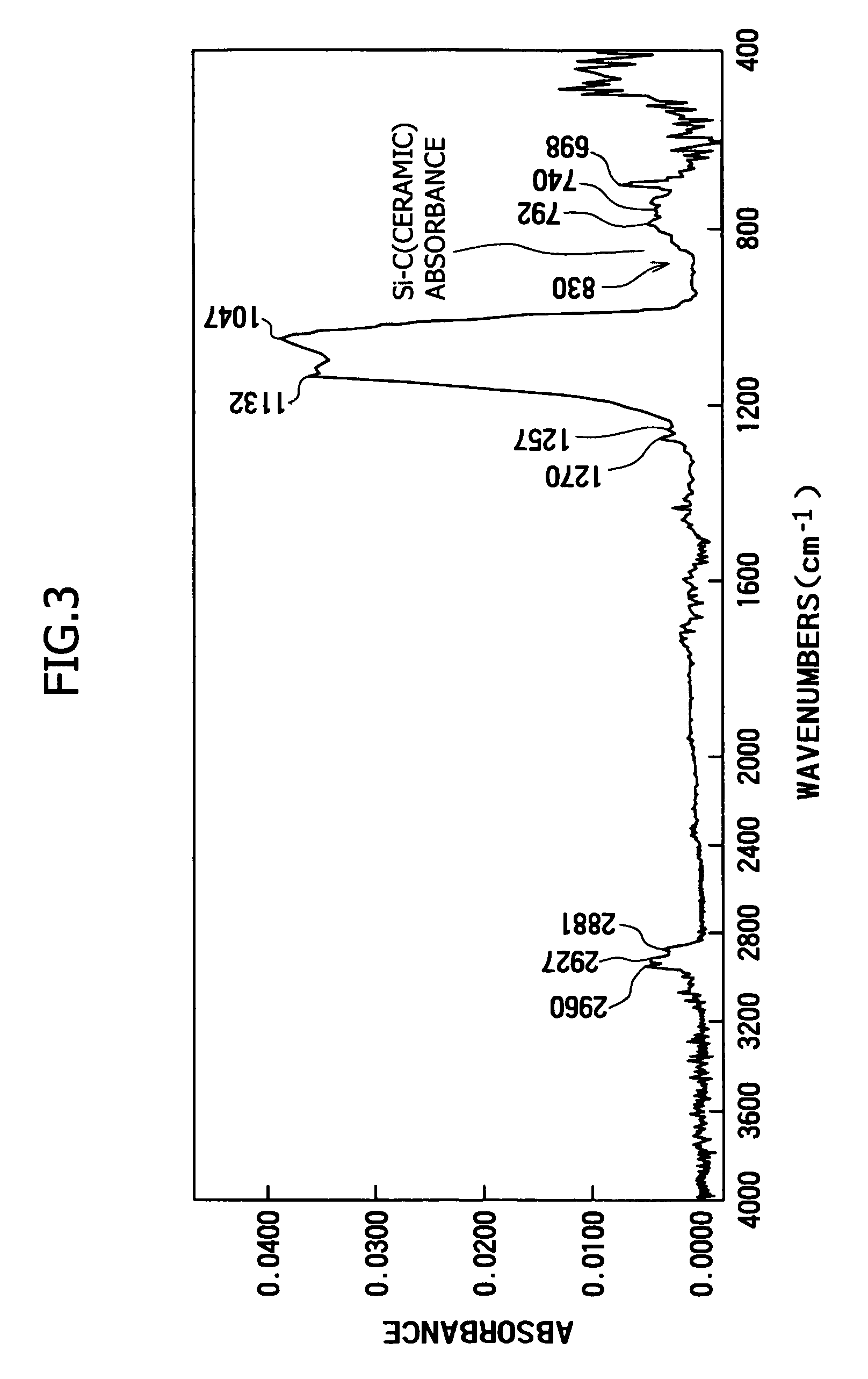

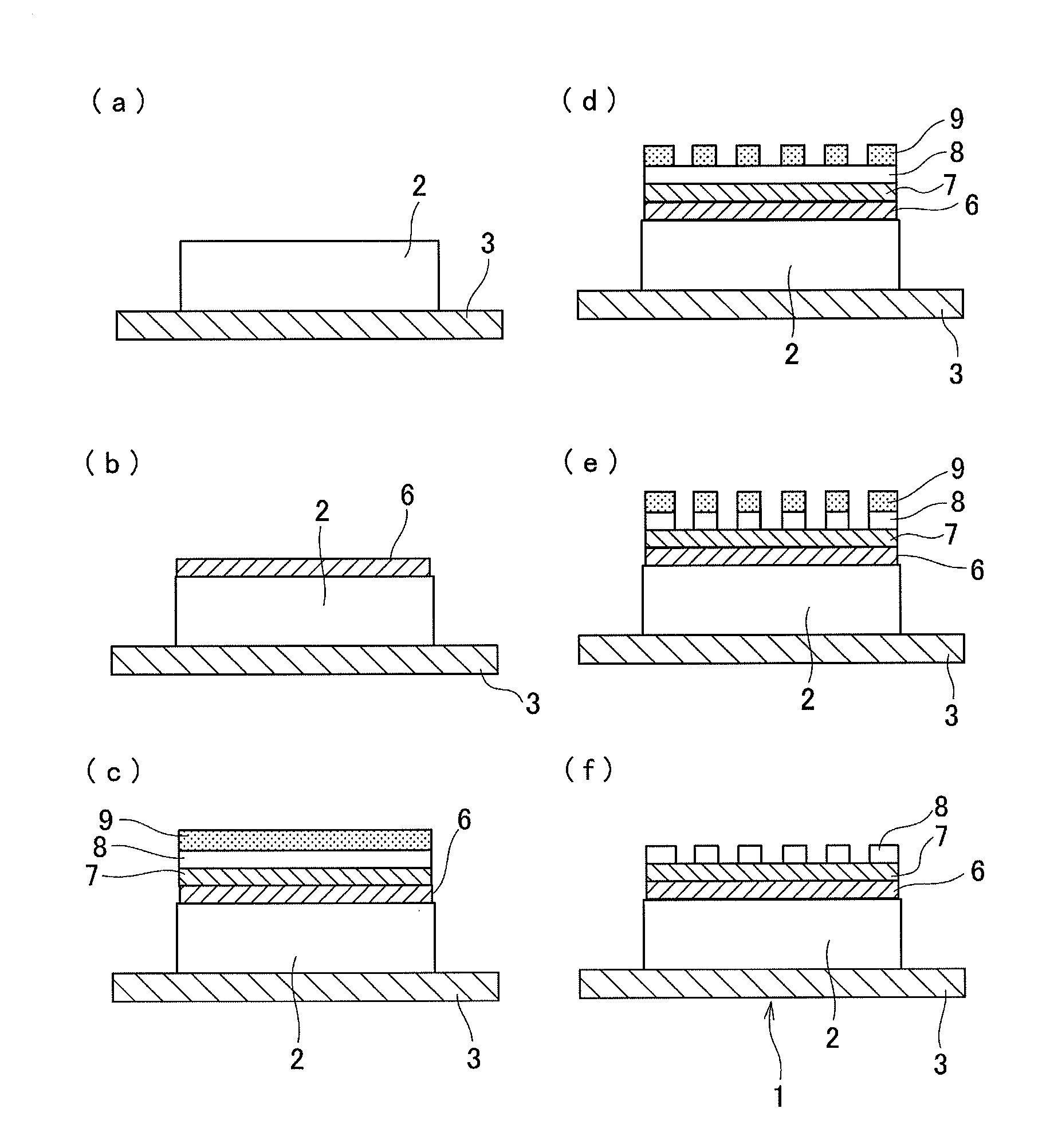

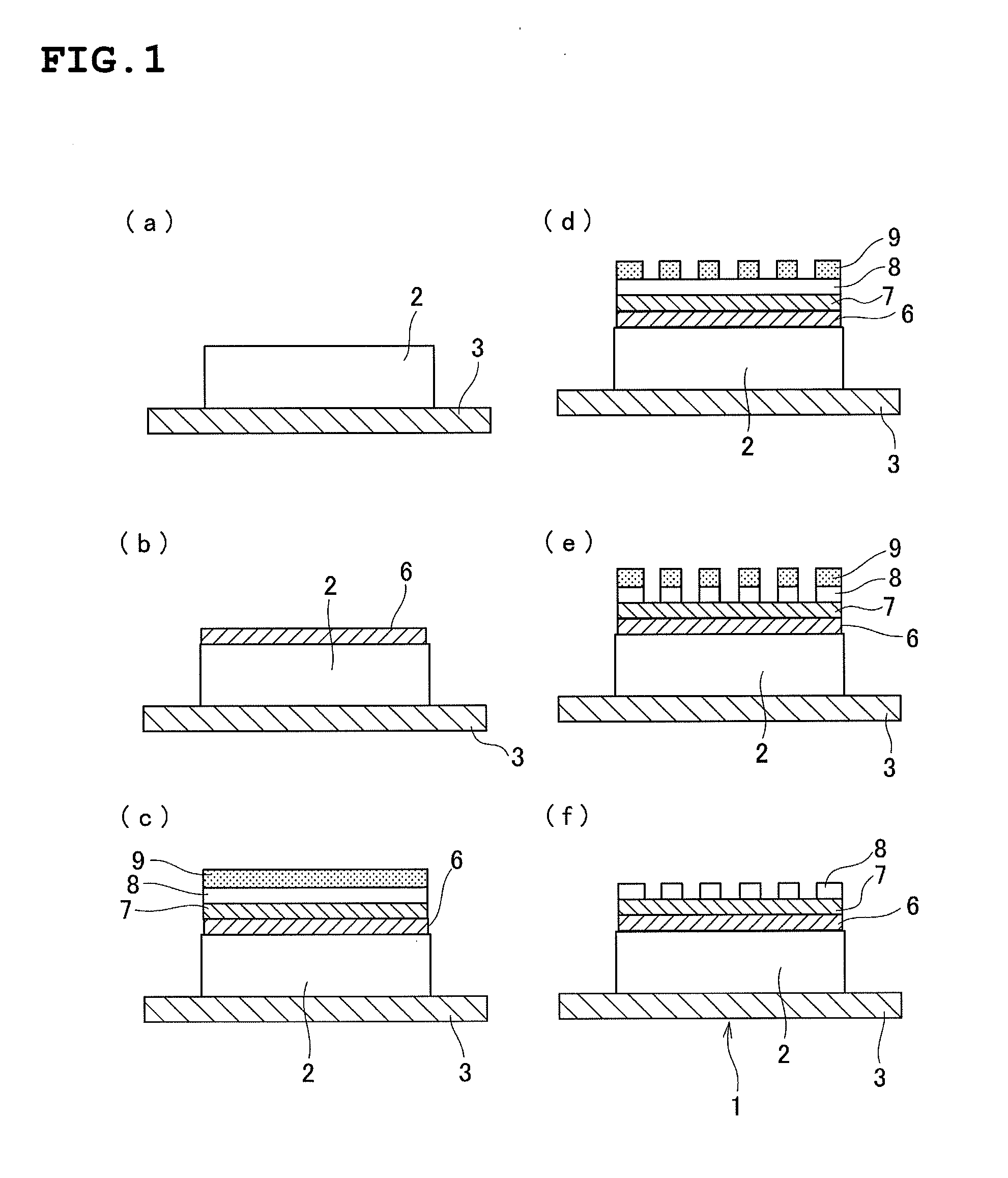

Antireflective film-forming composition, method for manufacturing the same, and antireflective film and pattern formation method using the same

ActiveUS20050277058A1Improve etch selectivityEtching speed is fastSemiconductor/solid-state device manufacturingSilver halide emulsionsCross-linkResist

The present invention provides a material for an antireflective film characterized by high etching selectivity with respect to a resist, that is, which has a fast etching speed when compared to the resist, and in addition, can be removed without damage to a film which is to be processed. The present invention also provides a pattern formation method for forming an antireflective film layer on a substrate using this antireflective film-forming composition, and a pattern formation method that uses this antireflective film as a hard mask, and a pattern formation method that uses this antireflective film as a hard mask for processing the substrate. The present invention provides an antireflective film-forming composition comprising an organic solvent, a cross linking agent, and a polymer comprising a light absorbing group obtained by hydrolyzing and condensing more than one type of silicon compound, a crosslinking group and a non-crosslinking group.

Owner:SHIN ETSU CHEM IND CO LTD +1

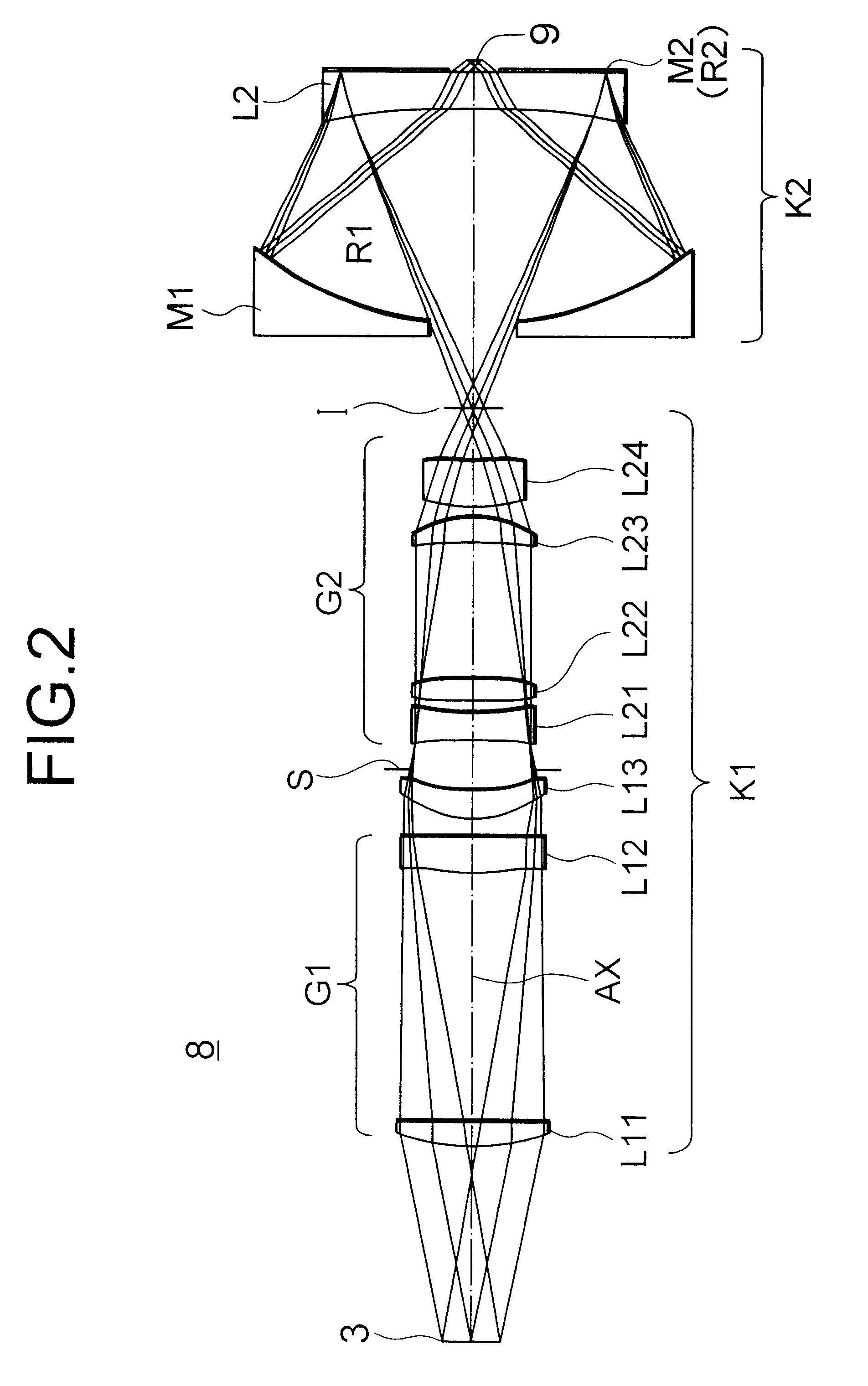

Catadioptric imaging system and a projection exposure apparatus provided with said imaging system

InactiveUS6473243B1Avoiding deterioration of image forming performanceInhibit deteriorationMicroscopesPhotomechanical exposure apparatusRadiationImage-forming optical system

Owner:NIKON CORP

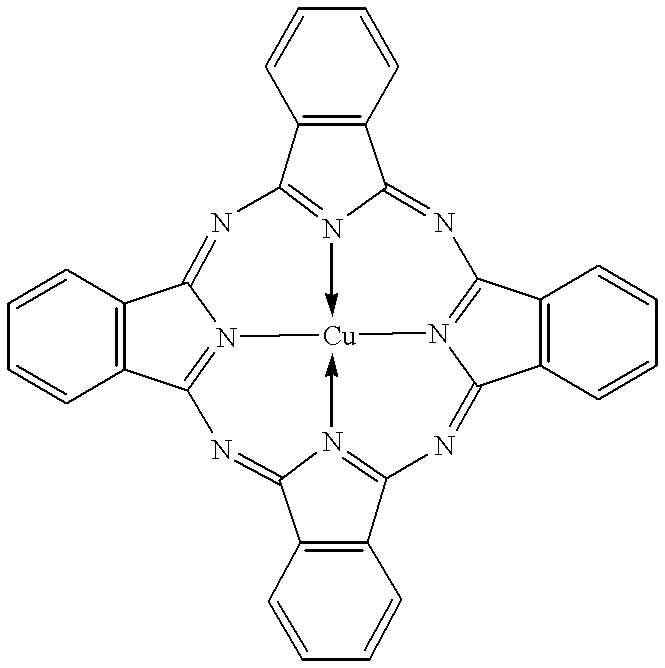

Fluorescent conversion filter and color display device using the same

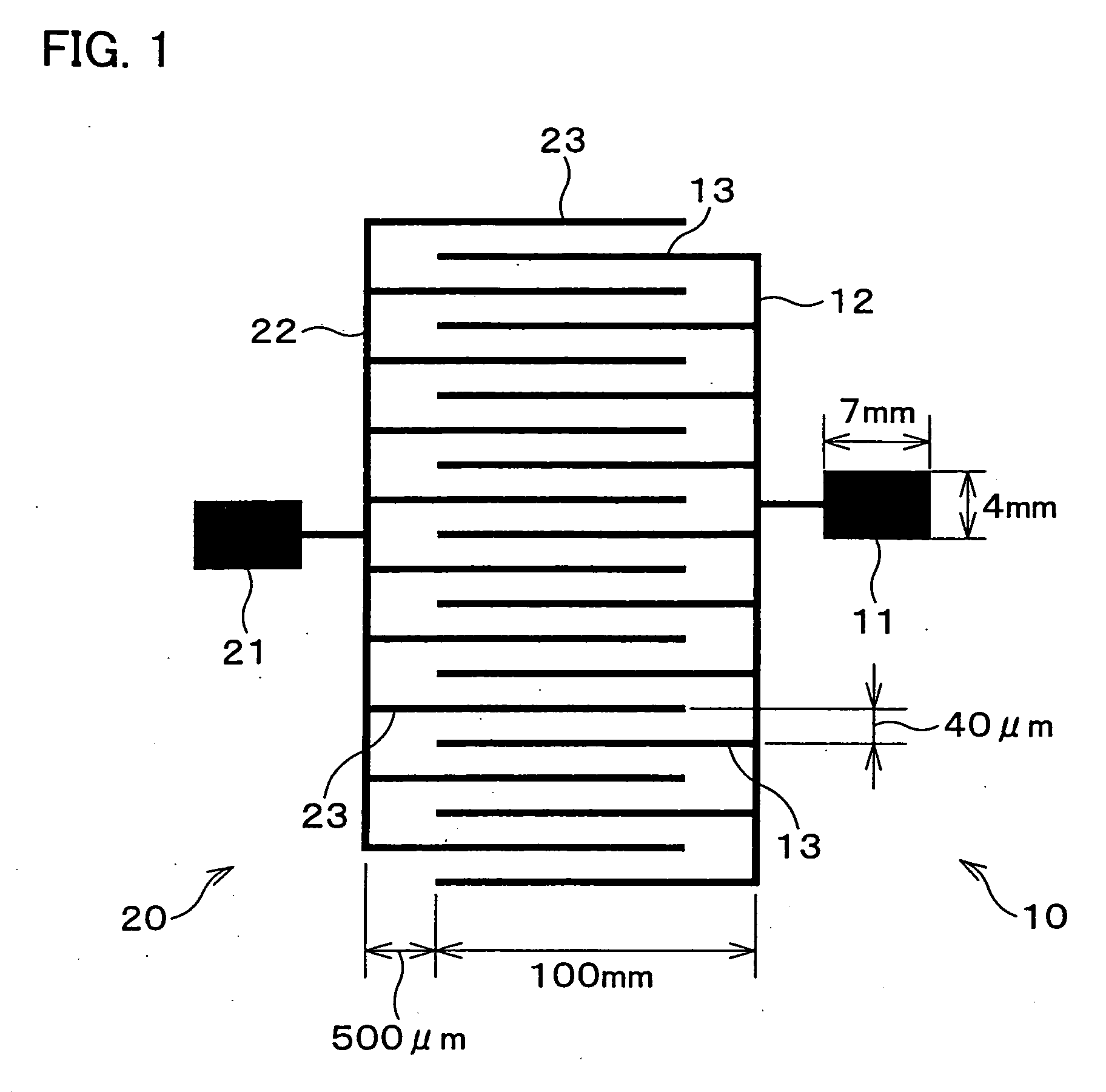

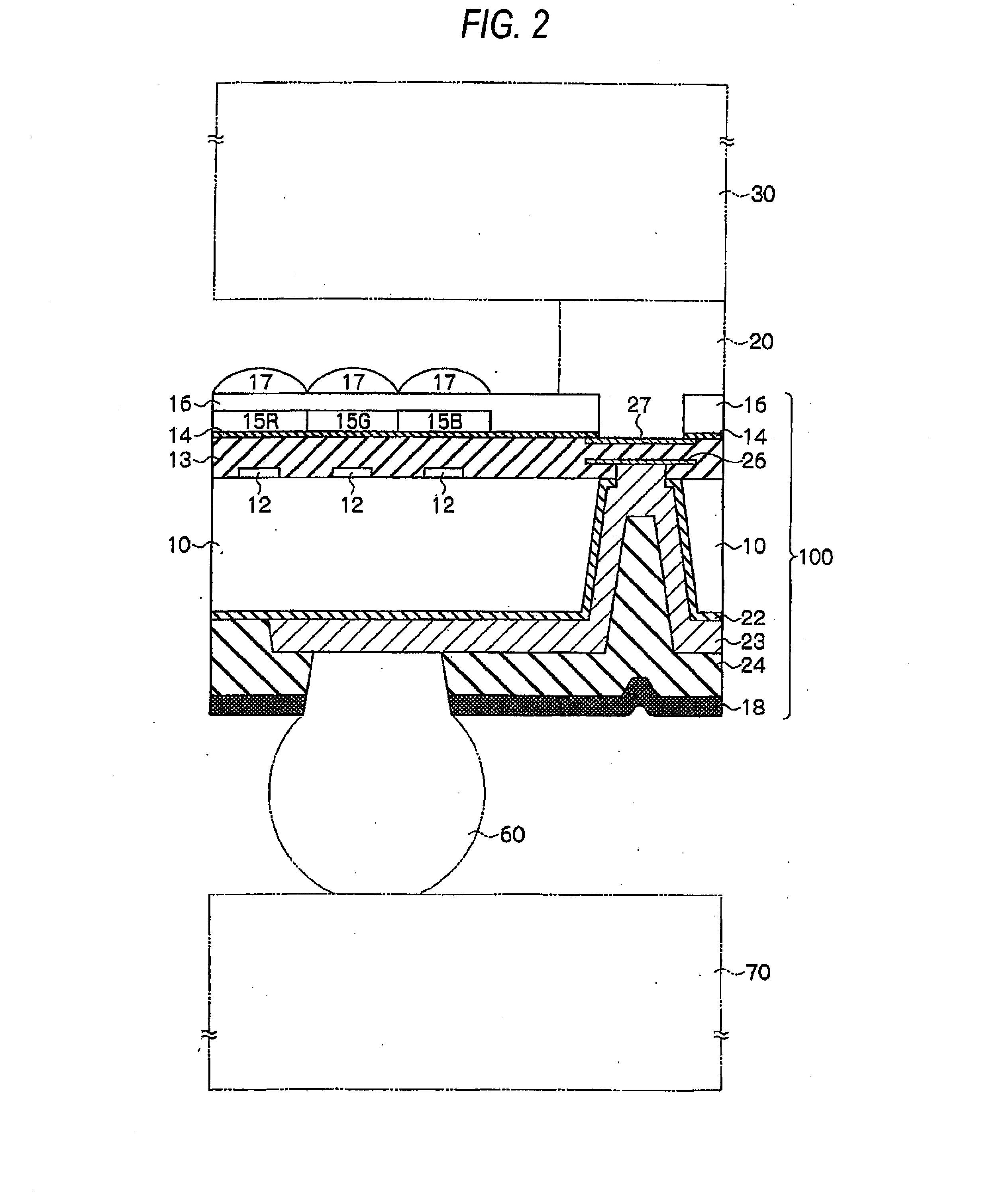

InactiveUS6249372B1Facilitates its fine patteringImprove the display effectOptical filtersSolid-state devicesDisplay deviceWavelength

A fluorescent conversion filter includes a fluorescent conversion film which facilitates converting light from a wavelength region between near ultraviolet and green to light in the red region which can be finely patterned. A color display device can be produced which includes the fluorescent conversion filter. The fluorescent conversion filter includes a fluorescent conversion film and a light absorption film on the display side surface of the flourescent conversion film. The flourescent conversion film has an absorbance of 1 or less in the wavelength region between 450 nm and 520 nm. The light absorption film has an absorbance of greater than I in the wavelength region between 450 nm and 520 nm. The fluorescent conversion film contains a photo-curing resin or a photo- and thermo-setting resin, that contains an acrylate polymer, a methacrylate polymer or an acrylate-methacrylate copolymer as its main component.

Owner:SHARP KK

Photosensitive resin composition capable of being developed with aqueous developer and photosensitive dry film resist, and use thereof

InactiveUS20060199920A1Simple manufacturing processAvoid property damagePhotosensitive materialsPhotomechanical apparatusImidePolymer science

A photosensitive resin composition according to the present invention includes at least a base resin component (A) and a (meth)acryls compound (B), wherein the base resin component (A) is any one of: a polyimide resin (A-1) having at least either a hydroxyl group or a carboxyl group in its structure; a polyamide resin (A-2) having at least either a hydroxyl group or a carboxyl group in its structure; and photosensitive imide(meth)acrylsiloxaneoligomer (A-3). On this account, it is possible to realize characteristics such as (1) realization and improvement of water system developing property, (2) improvement of utility as an imidized film, (3) improvement of post-curing property, and (4) simplification of manufacture of a print wiring substrate. Thus, the photosensitive resin composition can be favorably used particularly in a photosensitive dry film resin, a laminate using the same, a print wiring substrate using the same, and the like.

Owner:KANEKA CORP

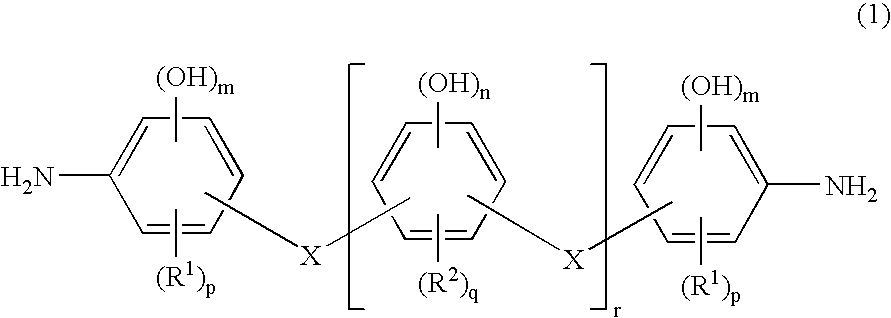

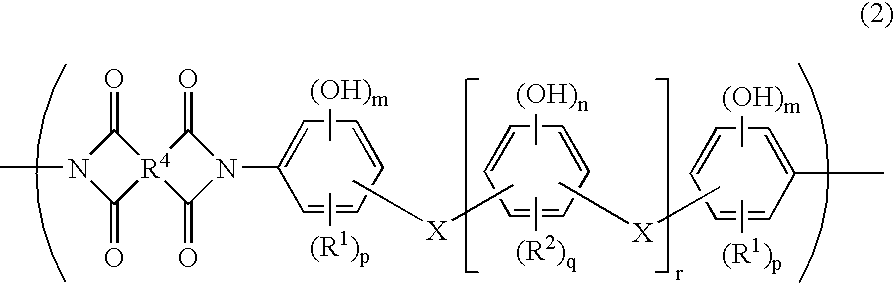

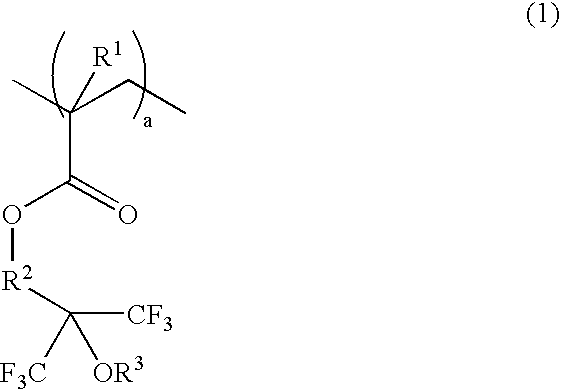

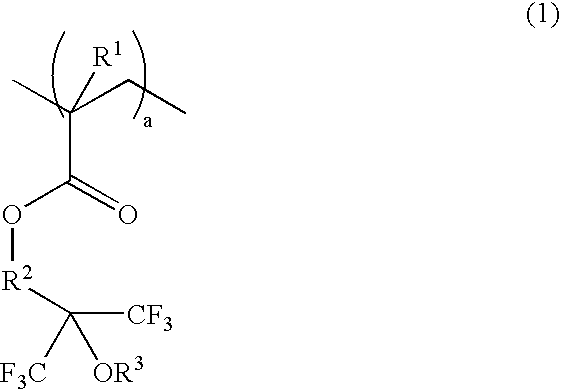

Antireflection film composition, patterning process and substrate using the same

InactiveUS20070134916A1Improve accuracyFunction increasePhotomechanical apparatusSemiconductor/solid-state device manufacturingChemistryPhotoresist

There is disclosed an antireflection film composition for forming an intermediate resist film of a multilayer resist film used in lithography comprising: at least a polymer obtained by reacting a chelating agent with a polymer having a repeating unit represented by the following general formula (1); an organic solvent; and an acid generator. There can be provided a novel antireflection film composition that exhibits high etch selection ratio to a photoresist film, that forms a dense inorganic film, whereby an excellent pattern can be formed on the overlying photoresist film, that can be removed with wet stripping, that exhibits high preservation stability and high dry etching resistance when an underlying layer is etched, and that is suitable for forming an intermediate resist film of a multilayer resist film; a patterning process in which an antireflection film is formed over a substrate by using the antireflection film composition; and a substrate having the antireflection film as an intermediate resist film.

Owner:SHIN ETSU CHEM IND CO LTD

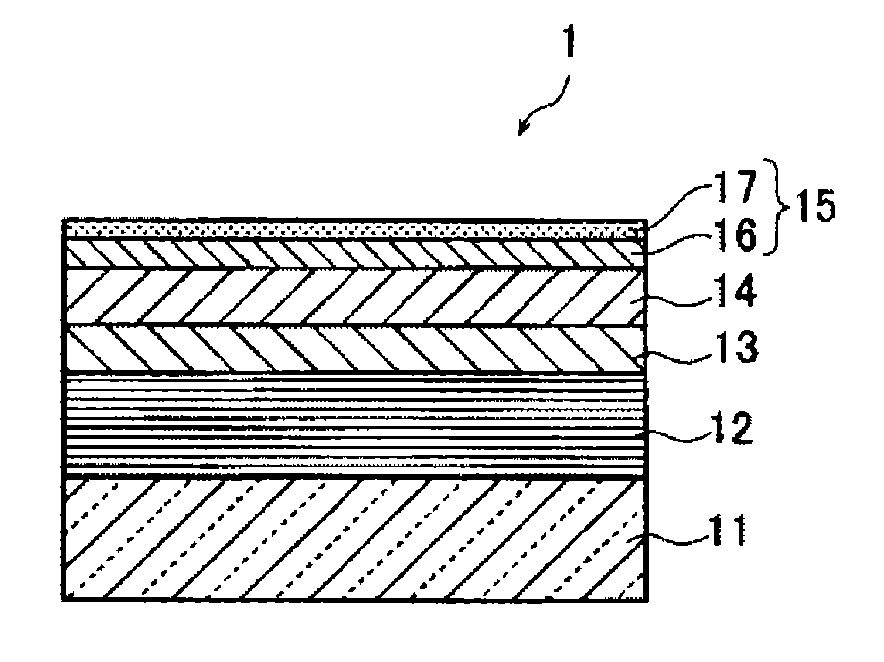

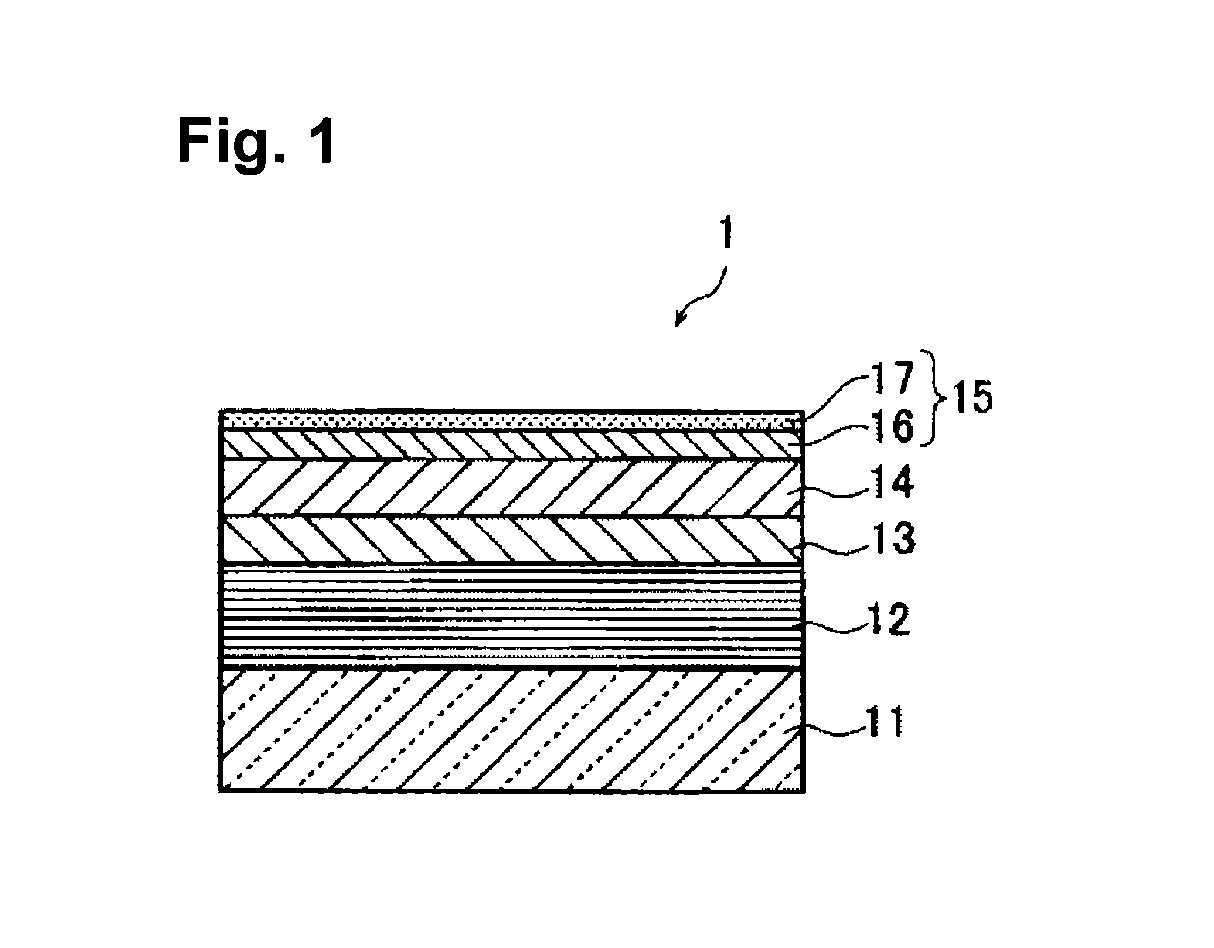

Reflective mask blank for EUV lithography and process for producing the same

ActiveUS20120322000A1Sufficient etching rateSimple processVacuum evaporation coatingSemiconductor/solid-state device manufacturingLithographic artistNitrogen

To provide an EUV mask blank provided with a low reflective layer, which has excellent properties as an EUV mask blank. A reflective mask blank for EUV lithography comprising a substrate, and a reflective layer for reflecting EUV light, an absorber layer for absorbing EUV light and a low reflective layer to an inspection light (wavelength: 190 to 260 nm) for a mask pattern, formed in this order on the substrate, wherein the low reflective layer has a stacked structure having a first layer containing at least 95 at % in total of silicon (Si) and nitrogen (N), and a second layer containing at least 95 at % in total of tantalum (Ta), oxygen (O) and nitrogen (N) or a second layer containing at least 95 at % in total of tantalum (Ta) and nitrogen (N), stacked in this order from the absorber layer side.

Owner:ASAHI GLASS CO LTD

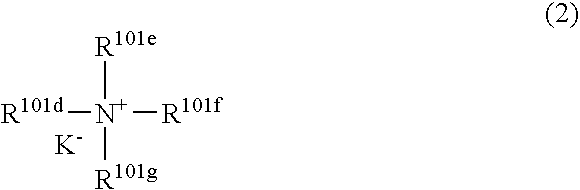

Rinse liquid for lithography and method for forming resist pattern using same

InactiveUS20060124586A1Low priceImprove securitySurface-active detergent compositionsDecorative surface effectsResistPhotochemistry

The present invention provide with a rinse solution for lithography and a resist pattern forming method using the same, which can prevent an inclination and peeling-off of a resist pattern and form a resist pattern having a high aspect ratio with high reproducibility. The rinse solution for lithography of the present invention comprises water and a nonionic surfactant having an ethyleneoxy group but not having a fluorine atom. The resist forming method of the present invention comprises the step of rinsing the pattern after development treatment with the rinse solution for lithography.

Owner:KOBAYASHI MASAKAZU +3

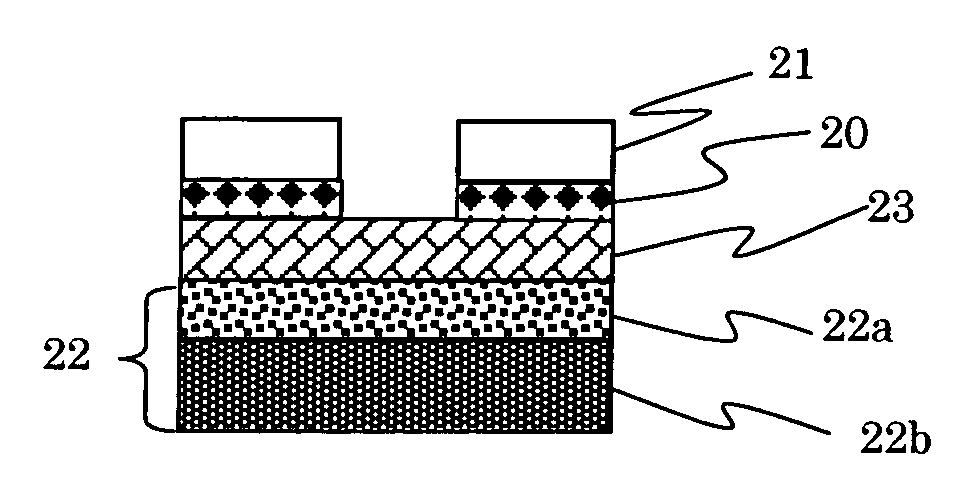

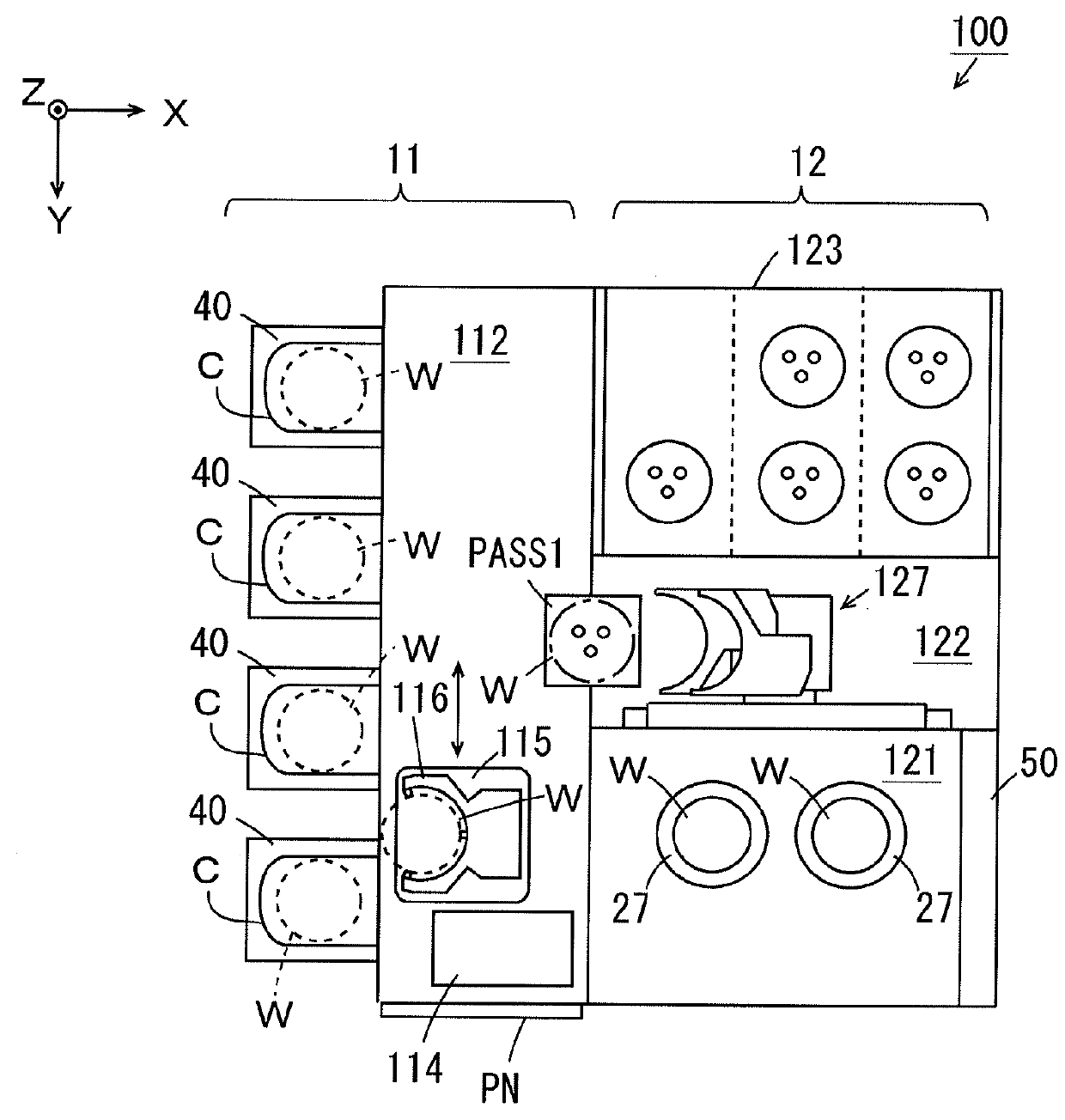

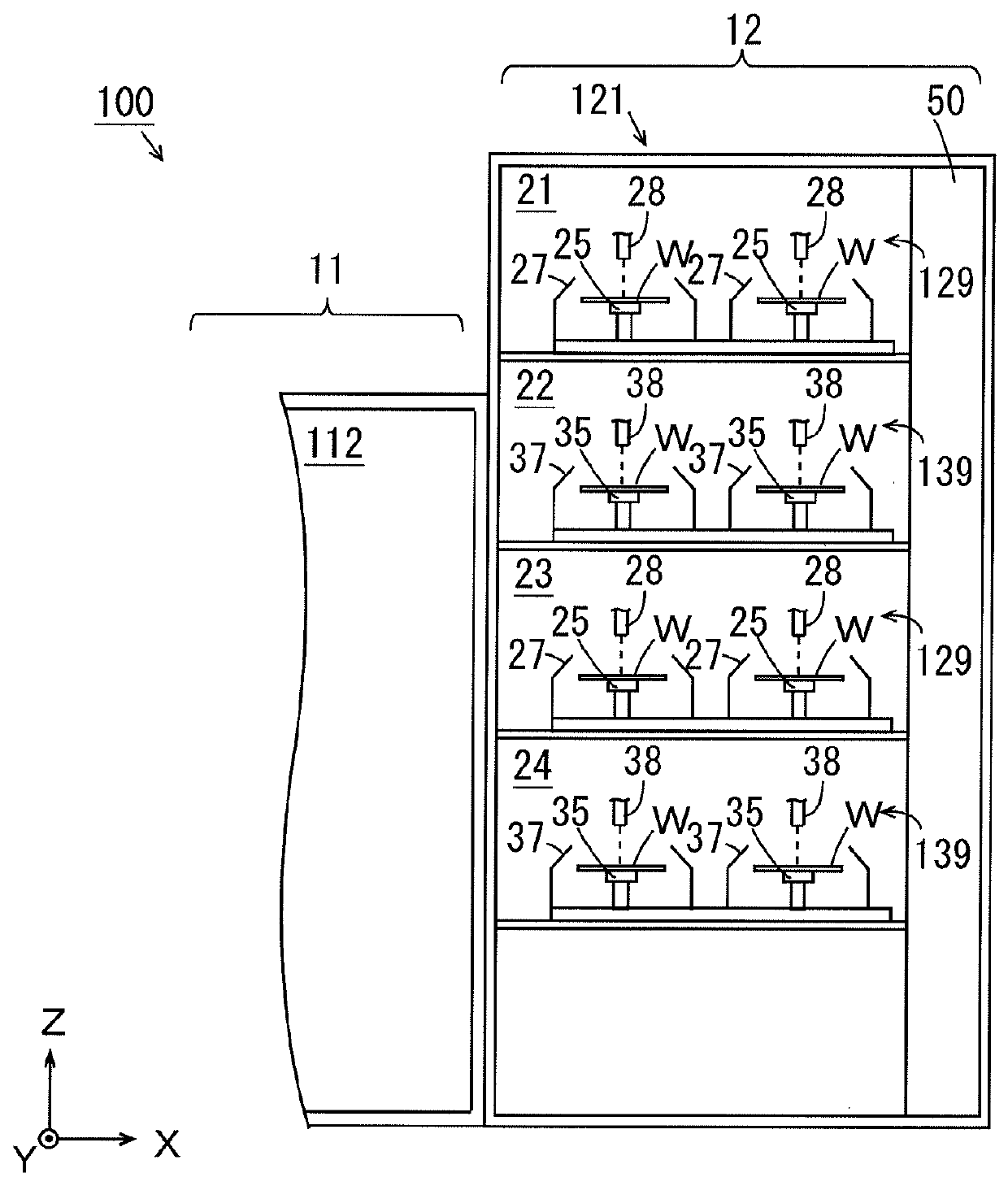

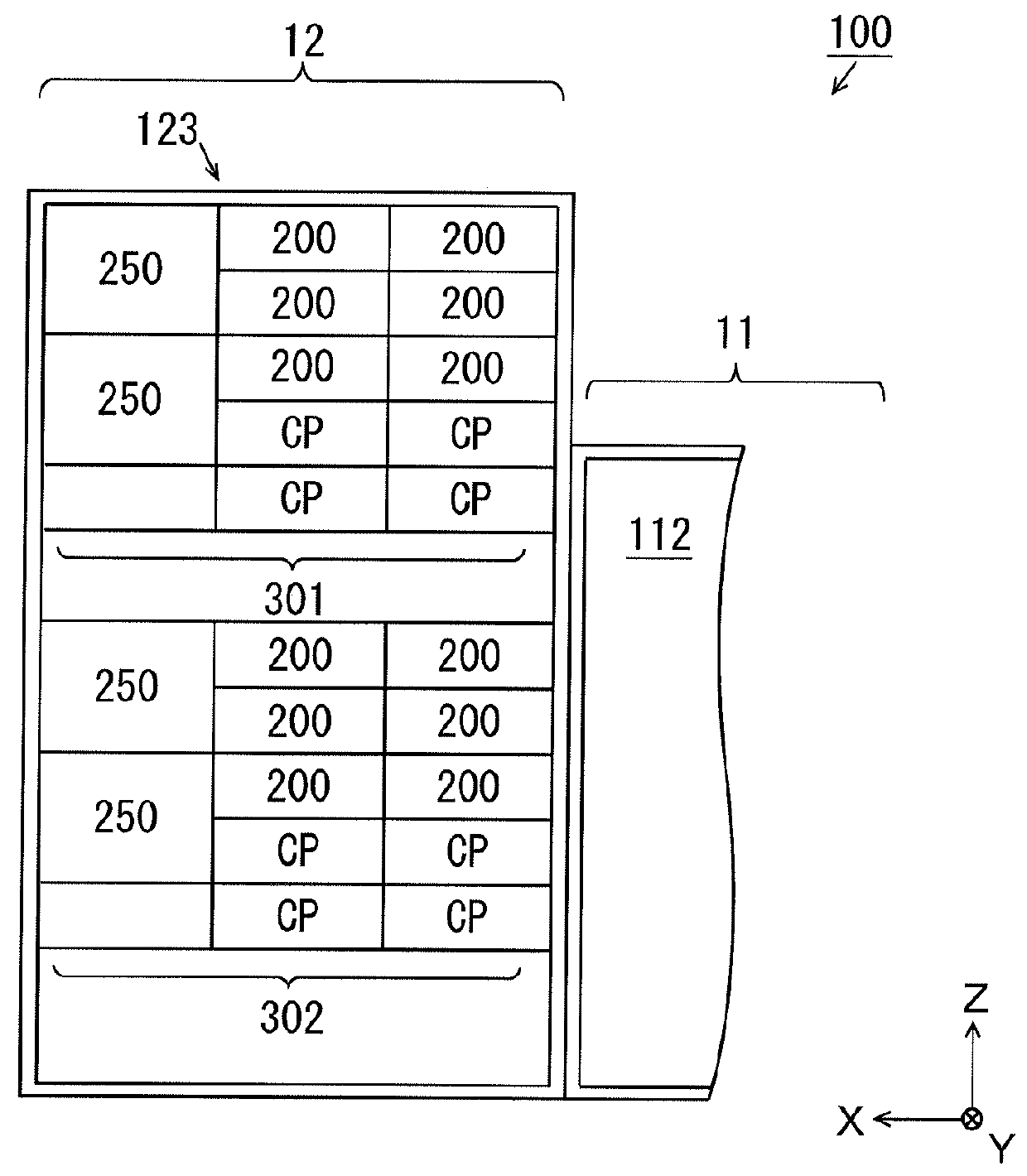

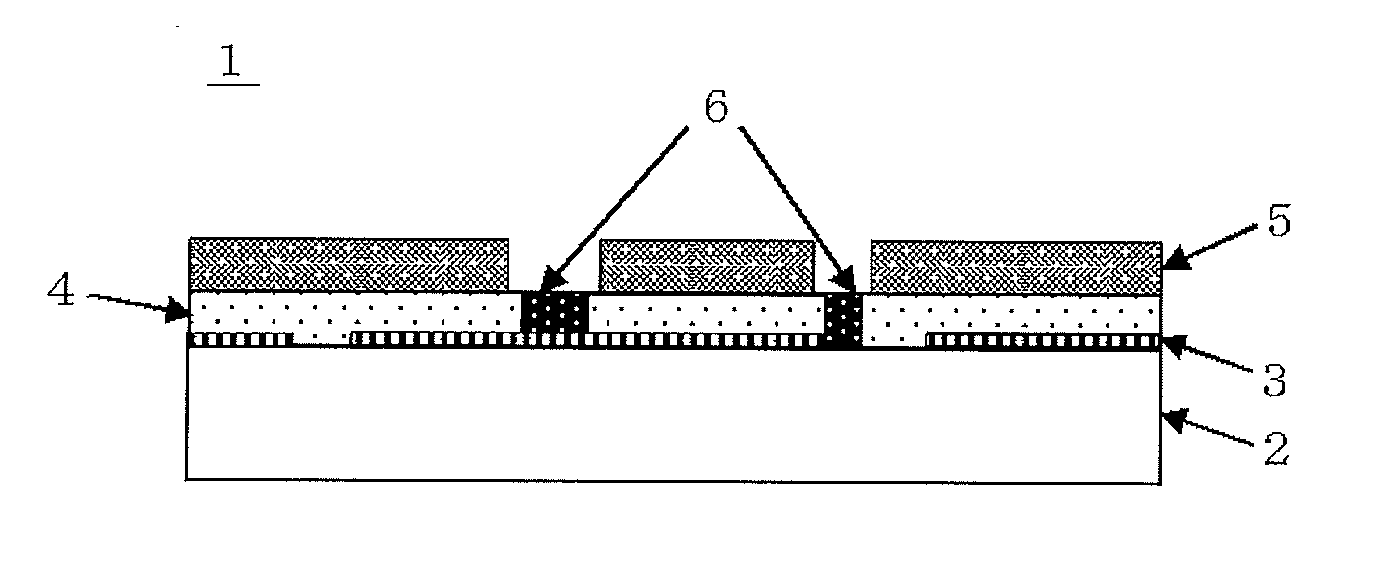

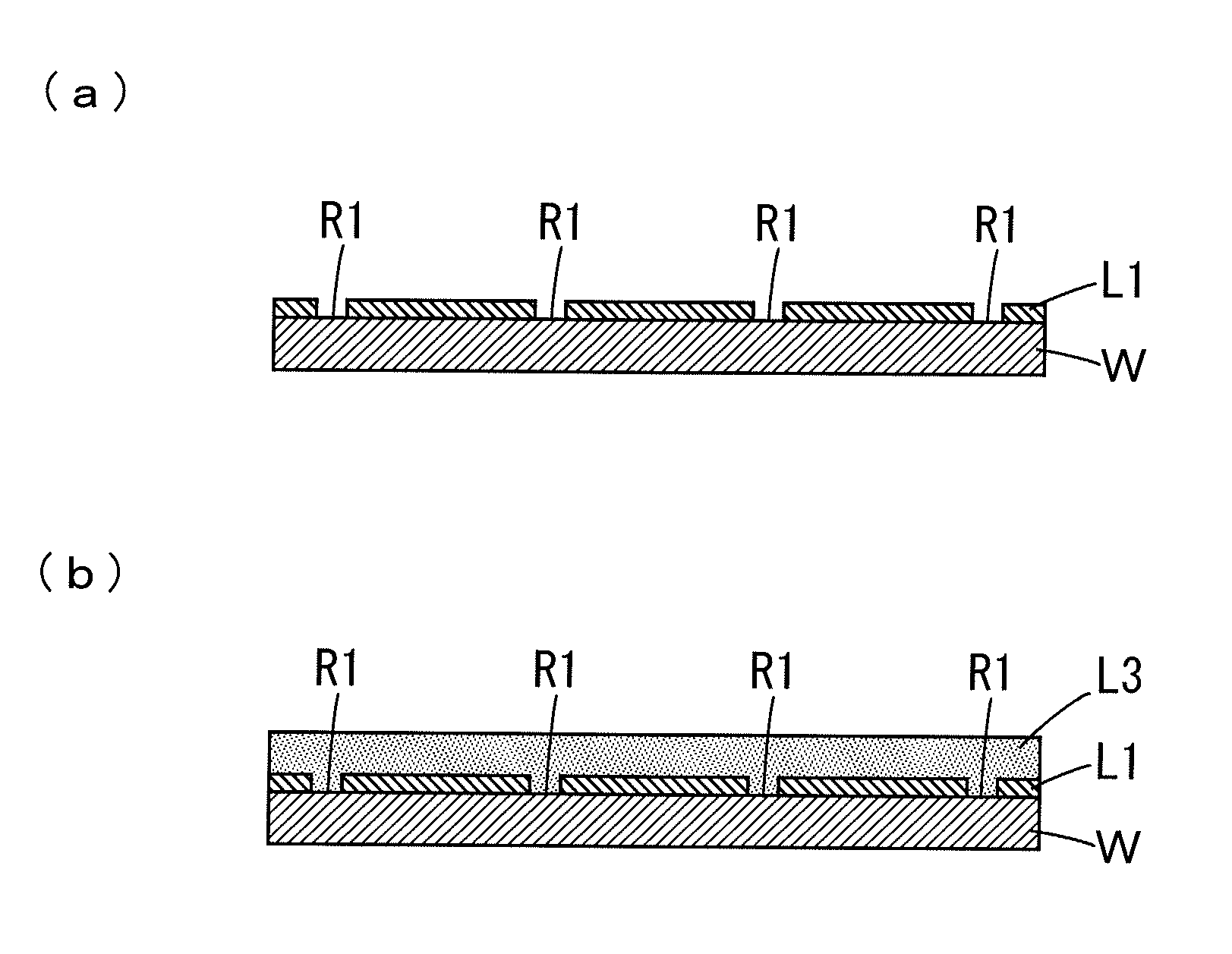

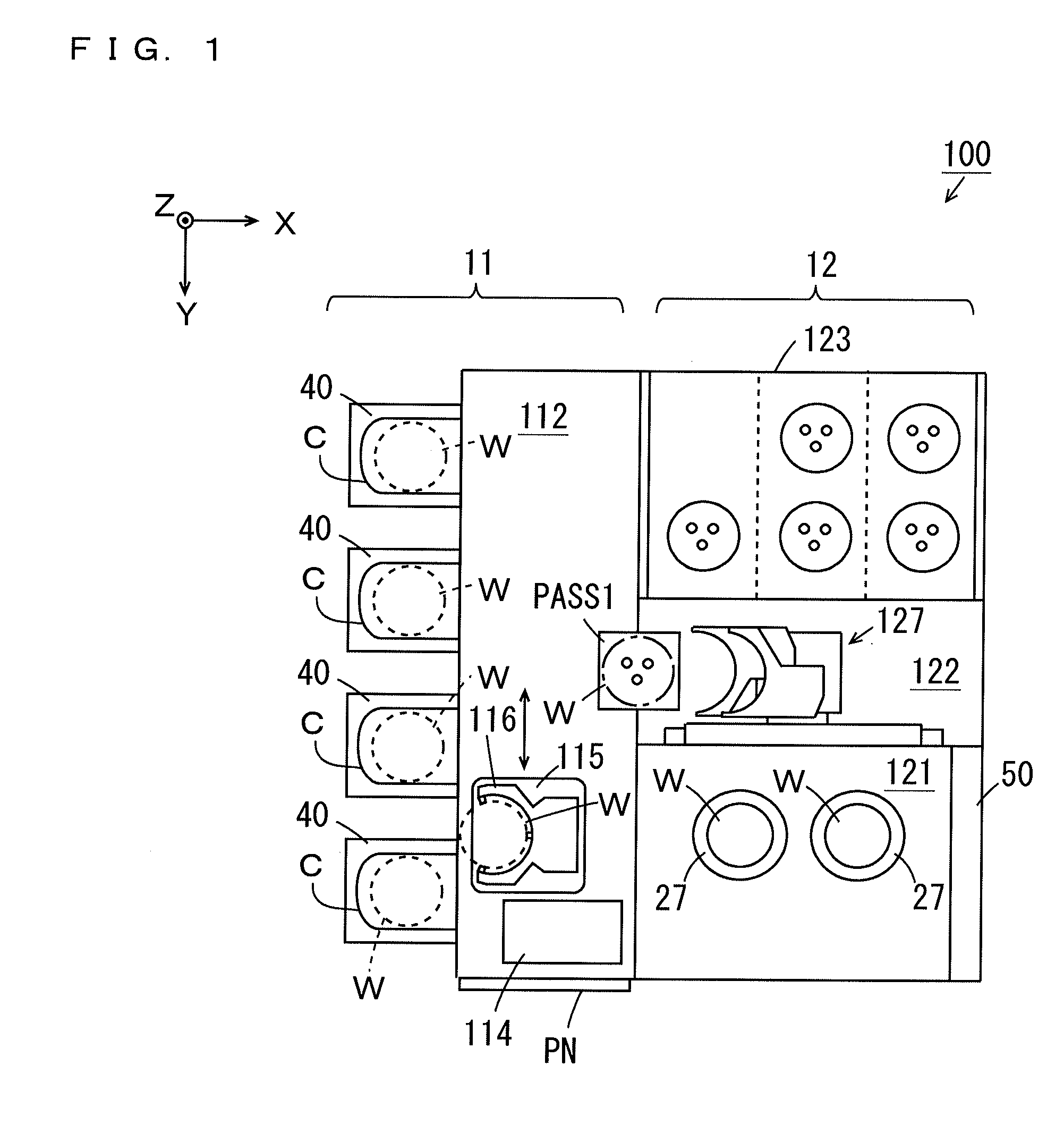

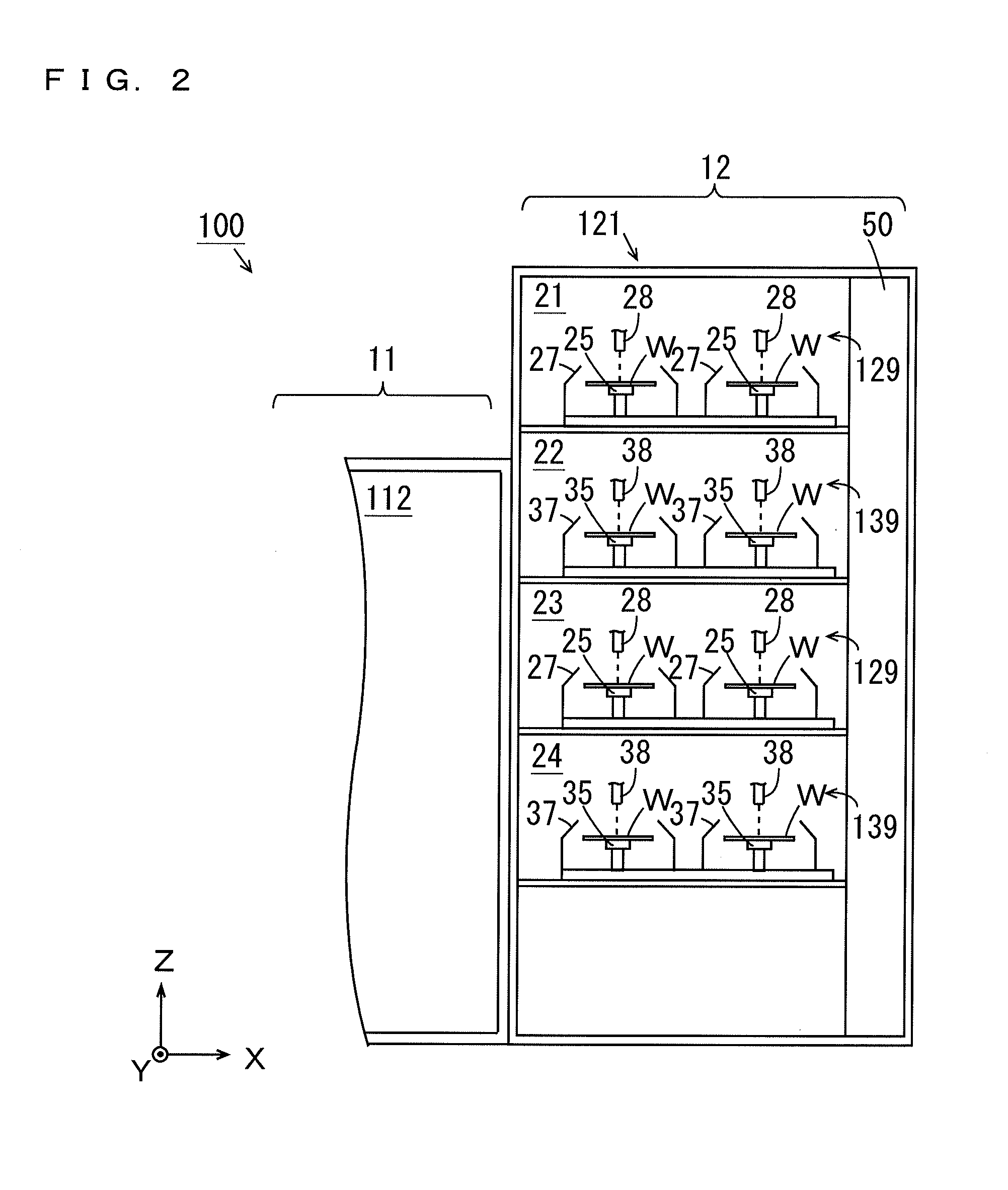

Substrate processing apparatus and substrate processing method

ActiveUS9375748B2Forming accuratelyPromotes microphase separationLiquid surface applicatorsLiquid processingEngineeringSolvent

An underlayer is formed to cover the upper surface of a substrate and a guide pattern is formed on the underlayer. A DSA film constituted by two types of polymers is formed in a region on the underlayer where the guide pattern is not formed. Thermal processing is performed while a solvent is supplied to the DSA film on the substrate. Thus, a microphase separation of the DSA film occurs. As a result, patterns made of the one polymer and patterns made of another polymer are formed. Exposure processing and development processing are performed in this order on the DSA film after the microphase separation such that the patterns made of another polymer are removed.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

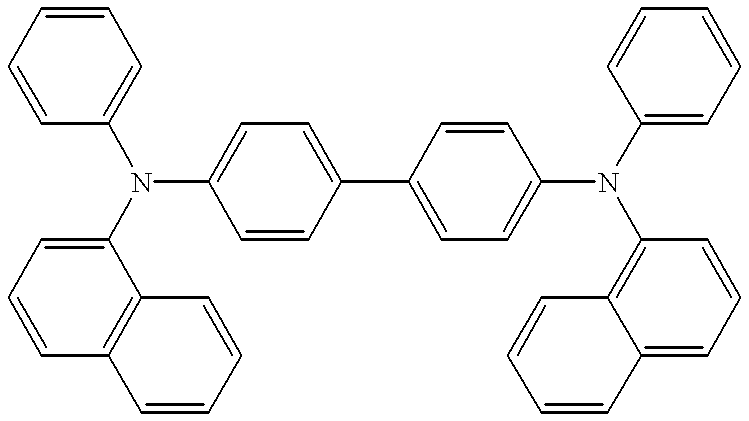

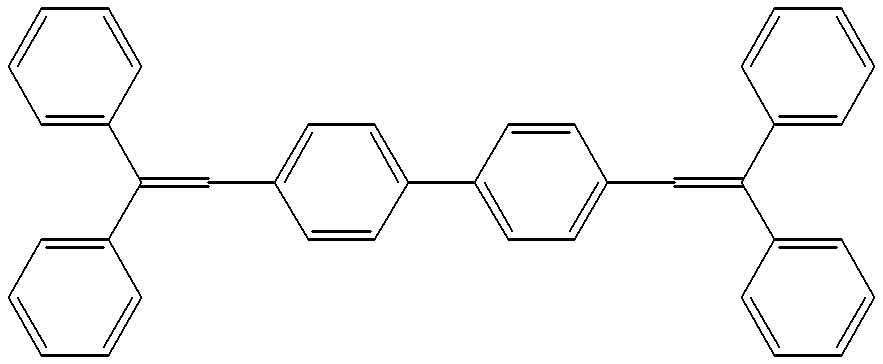

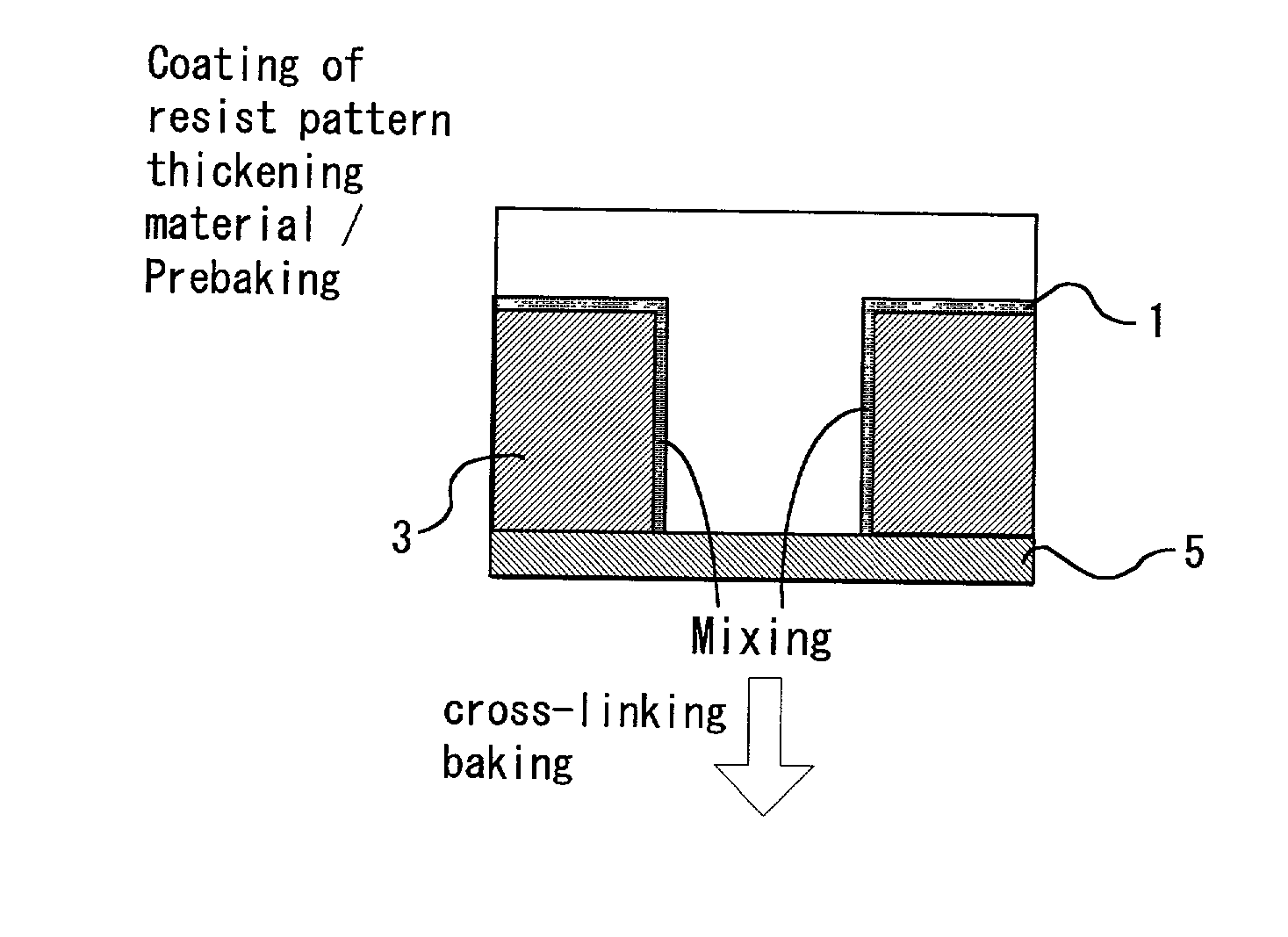

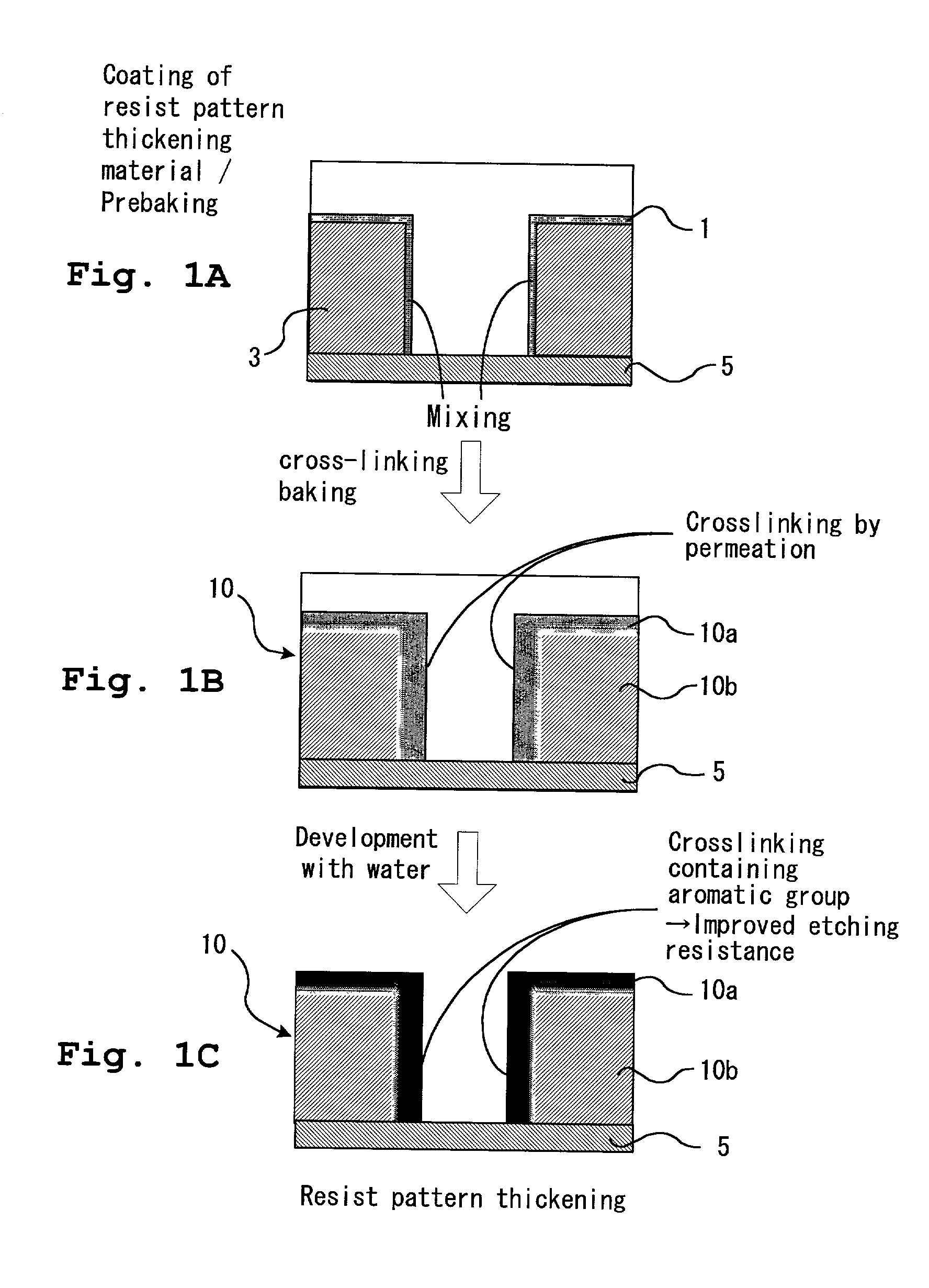

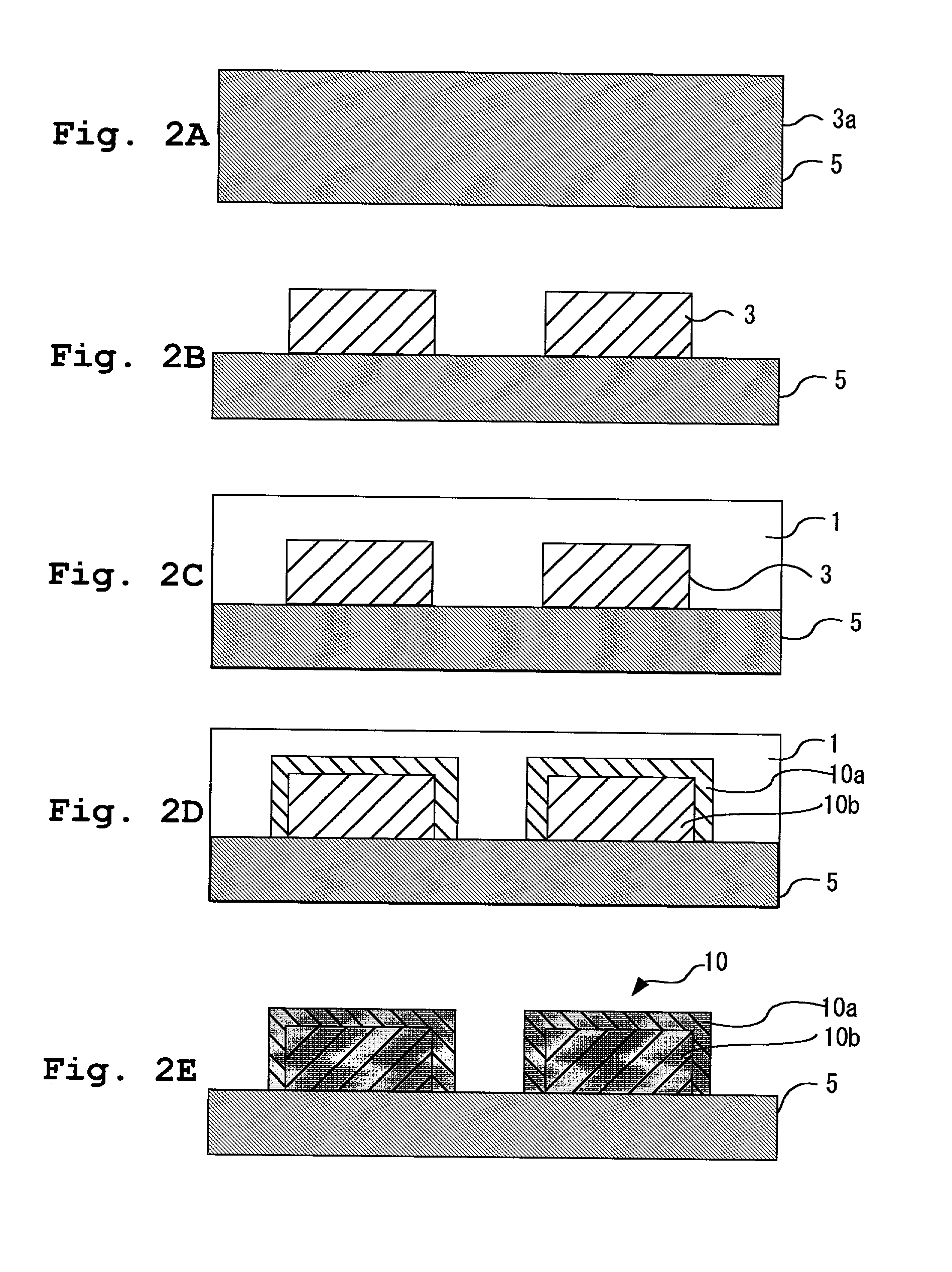

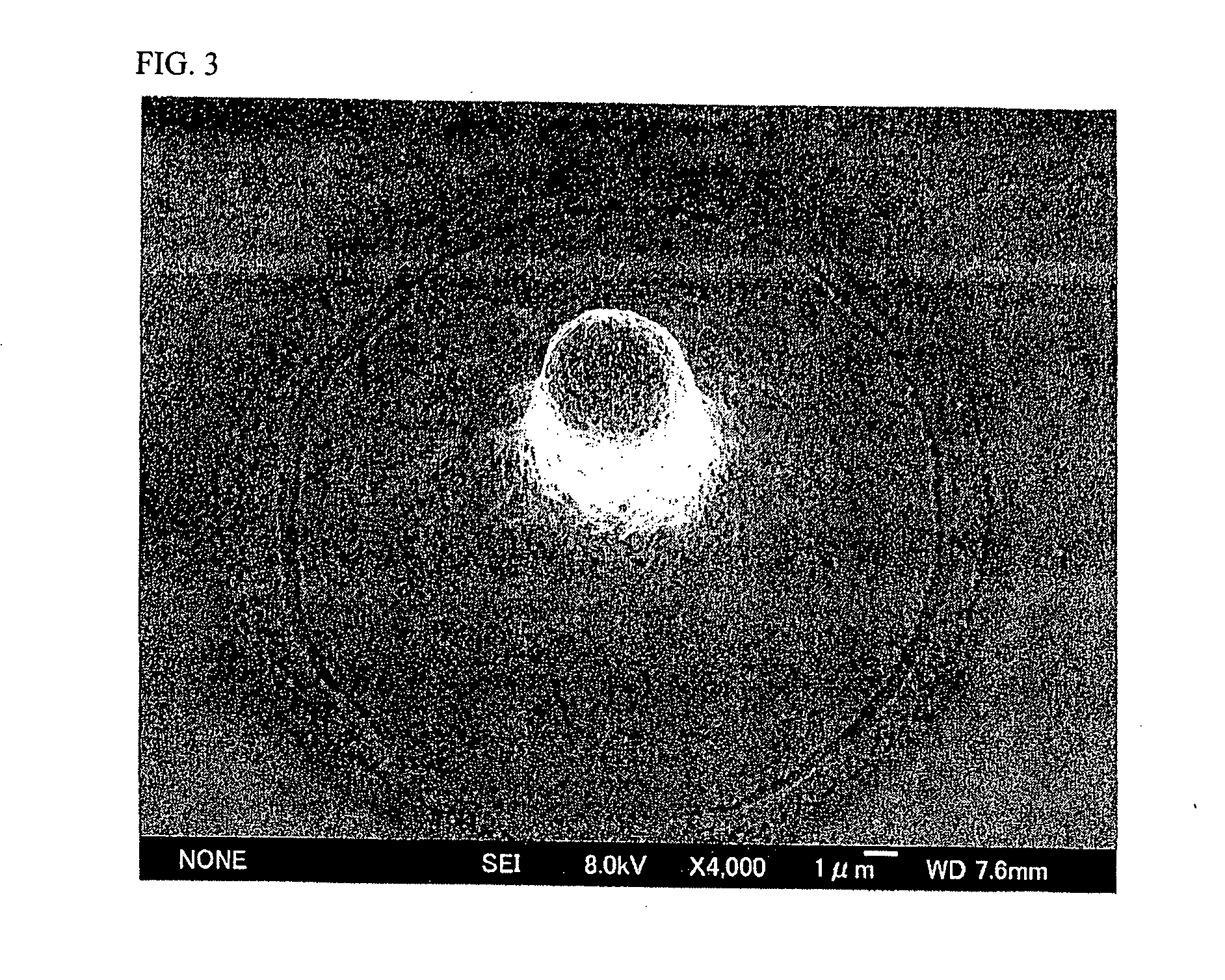

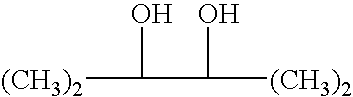

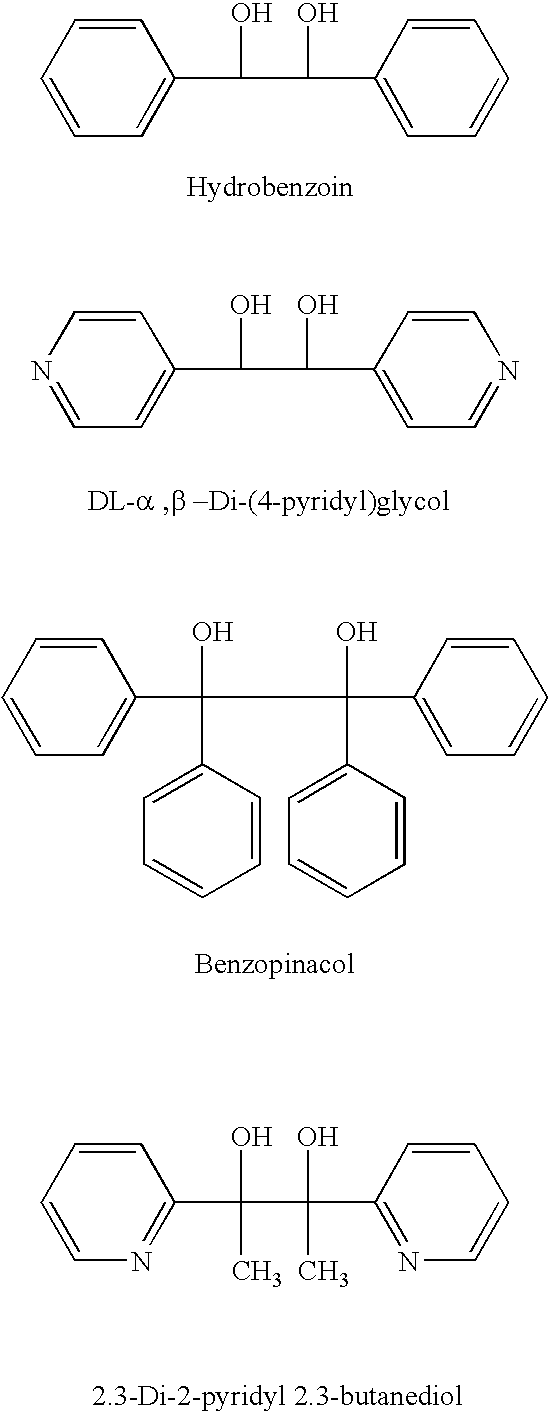

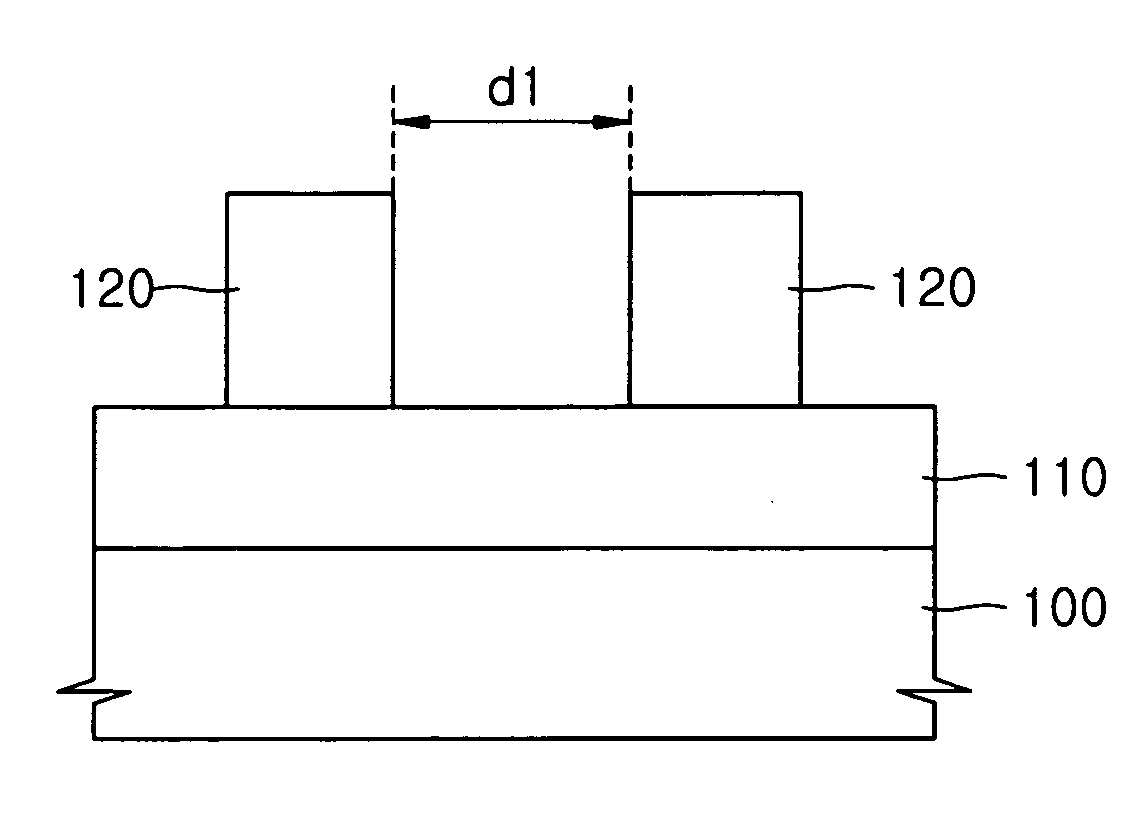

Resist pattern thickening material, resist pattern and forming method thereof, and semiconductor device and manufacturing method thereof

InactiveUS20030102285A1Excellent etch resistanceExquisite patternConstruction of head windingsDecorative surface effectsResistWater soluble

A resist pattern thickening material comprises a resin, a crosslinking agent and a water-soluble aromatic compound. A resist pattern comprises an upperlayer on an underlayer resist pattern with an etching rate (Å / s) ratio of the underlayer resist pattern to the upper layer under the same condition of 1.1 or more, or comprises an upperlayer containing an aromatic compound on an underlayer resist pattern. A method for forming a resist pattern comprises applying a resist pattern thickening material after forming an underlayer resist pattern, on the surface of the pattern. A semiconductor device comprises a pattern formed by the resist pattern. A method for manufacturing the semiconductor device comprises applying after forming an underlayer resist pattern on an underlying layer, the thickening material to the surface of the pattern to thicken the pattern, and patterning the underlying layer by etching using the pattern as a mask.

Owner:FUJITSU LTD

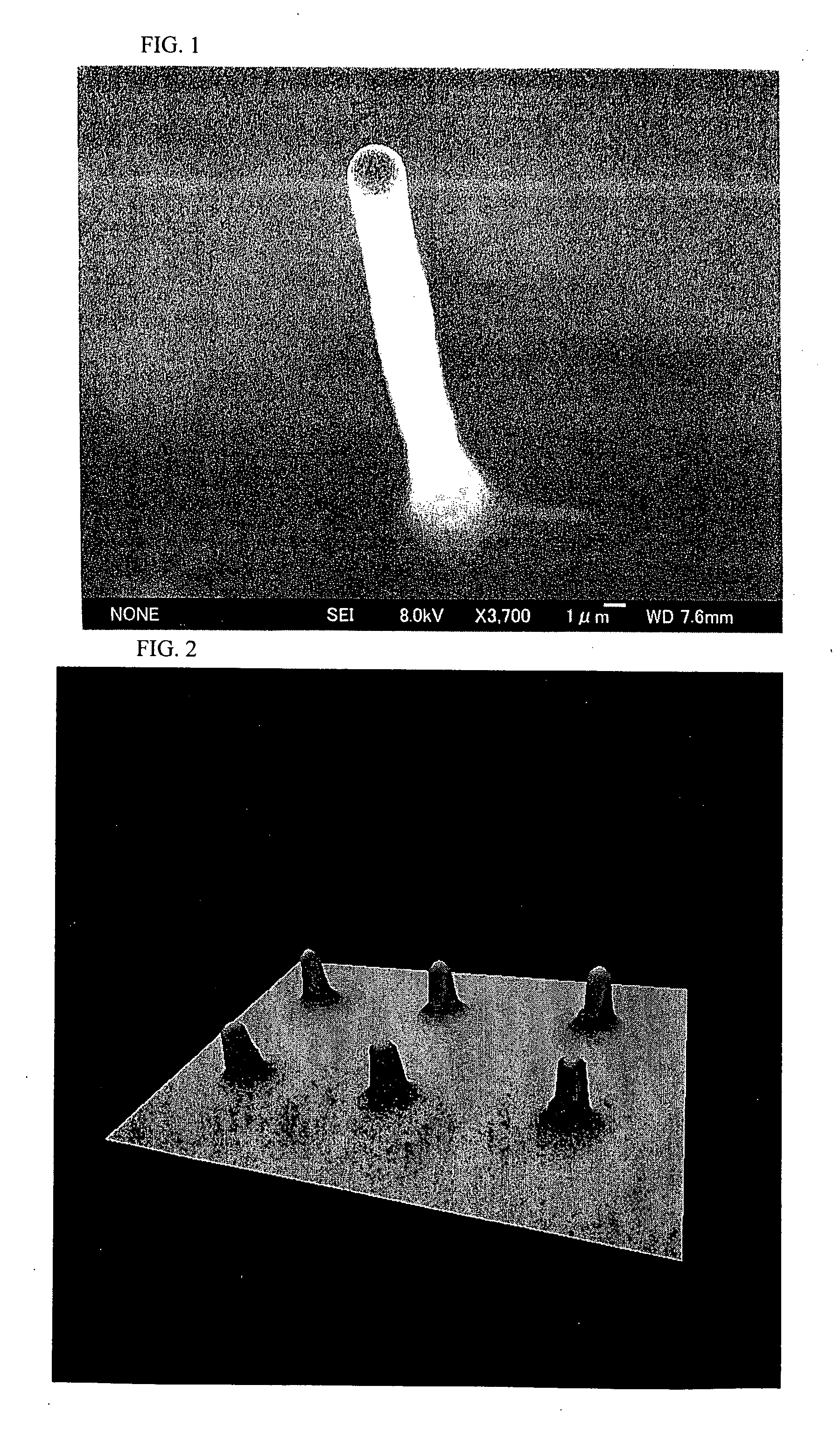

Metal nanoparticle dispersion usable for ejection in the form of fine droplets to be applied in the layered shape

ActiveUS20070098883A1Wide applicabilityGood reproducibilityOther chemical processesMixing methodsBoiling pointFluid viscosity

The present invention provides a dispersion usable for forming an electroconductive layer having an extremely fine pattern and a high thickness / minimum width ratio in the cross-section, and which has a high fluidity enabling application of inkjet to draw a fine pattern at high accuracy and contains only metal nanoparticles as a conductive medium. According to the present invention, a metal nanoparticle dispersion suitable to multiple layered coating by jetting in the form of fine droplets is prepared by dispersing metal nanoparticles having an average particle size of 1 to 100 nm in a dispersion solvent having a boiling point of 80° C. or higher in such a manner that the volume percentage of the dispersion solvent is selected in the range of 55 to 80% by volume and the fluid viscosity (20° C.) of the dispersion is chosen in the range of 2 mPa·s to 30 mPa·s, and then when the dispersion is discharged in the form of fine droplets by inkjet method or the like, the dispersion is concentrated by evaporation of the dispersion solvent in the droplets in the course of flight, coming to be a viscous dispersion which can be applicable to multi-layered coating.

Owner:HARIMA CHEM INC +1

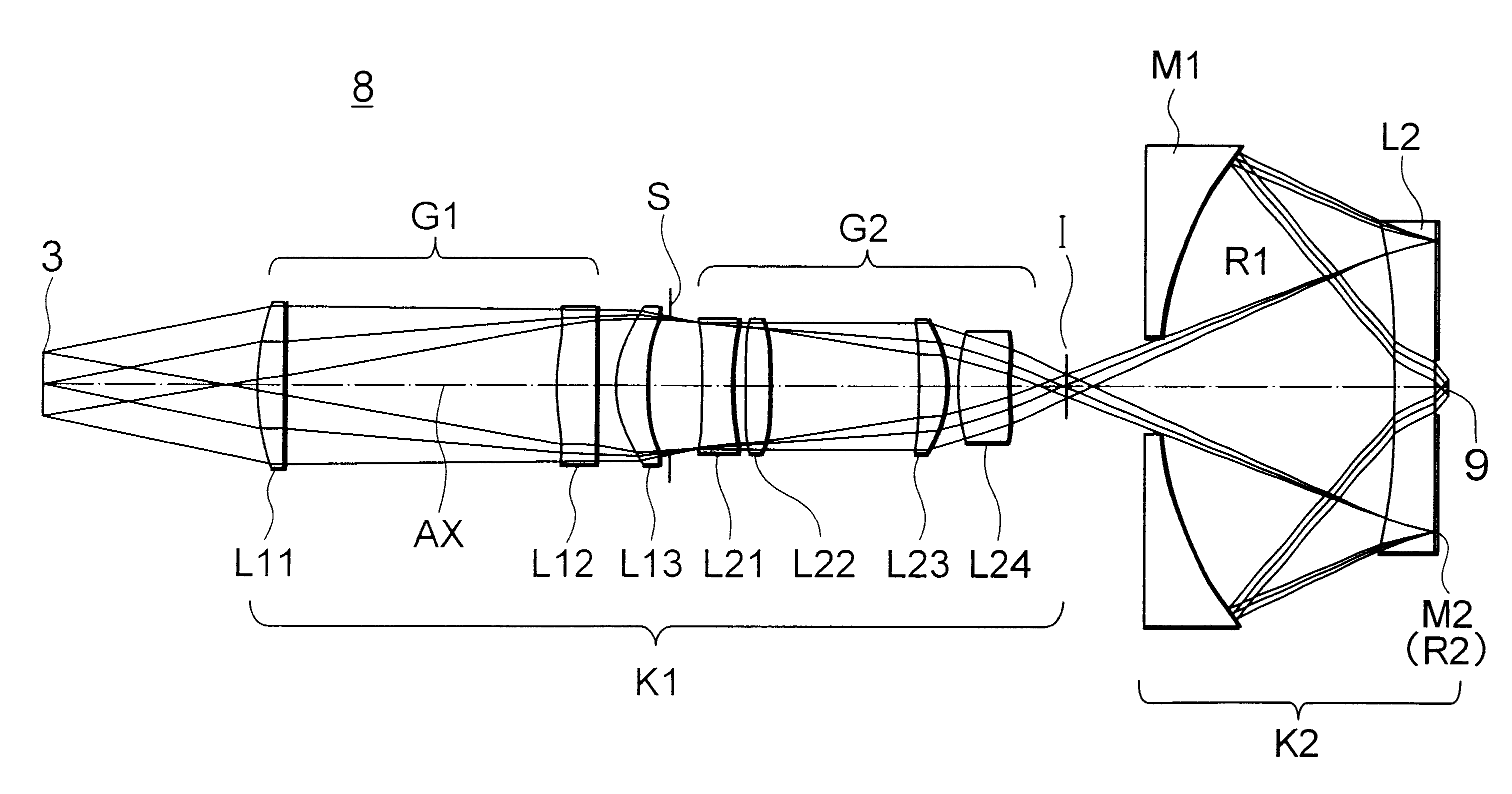

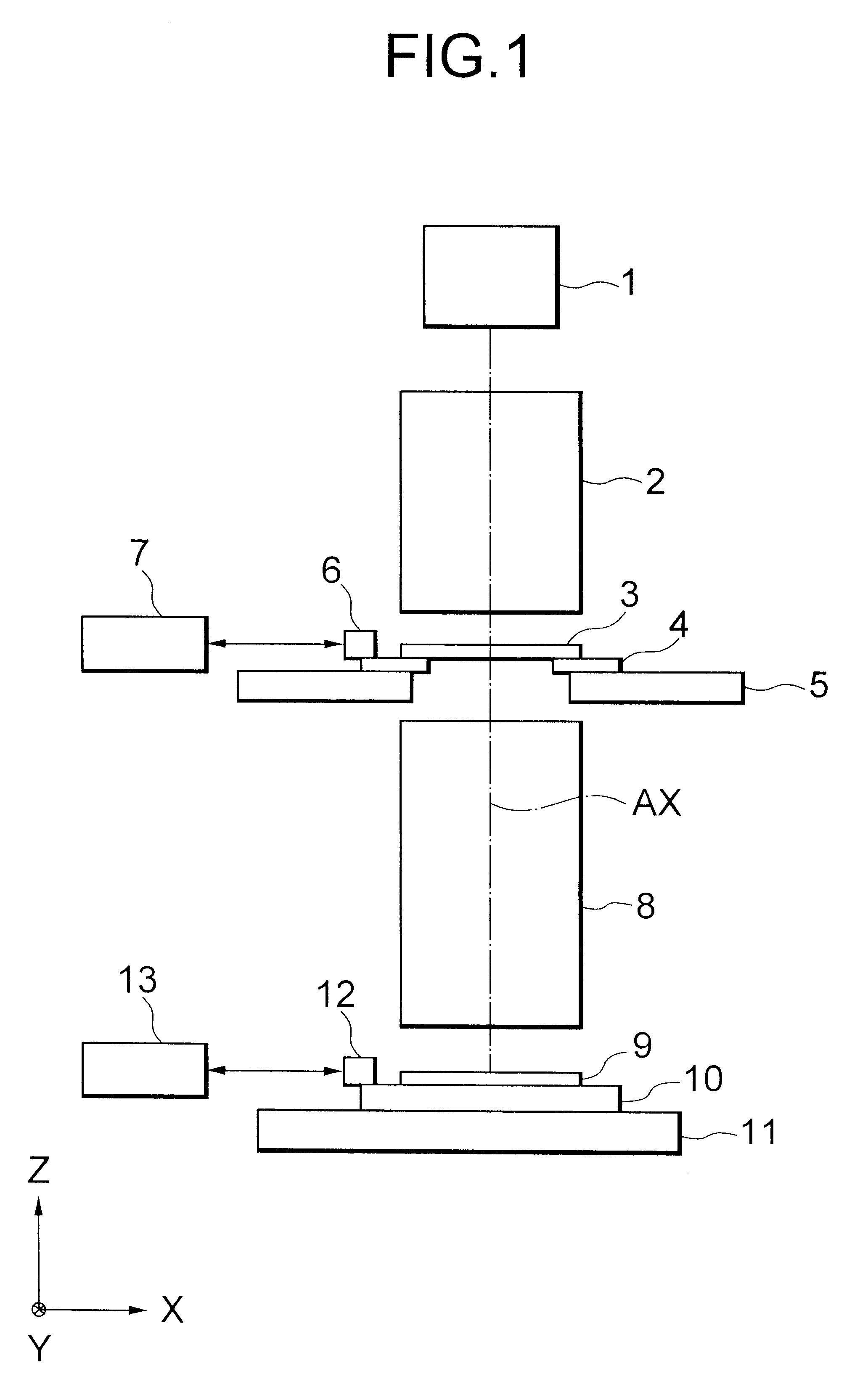

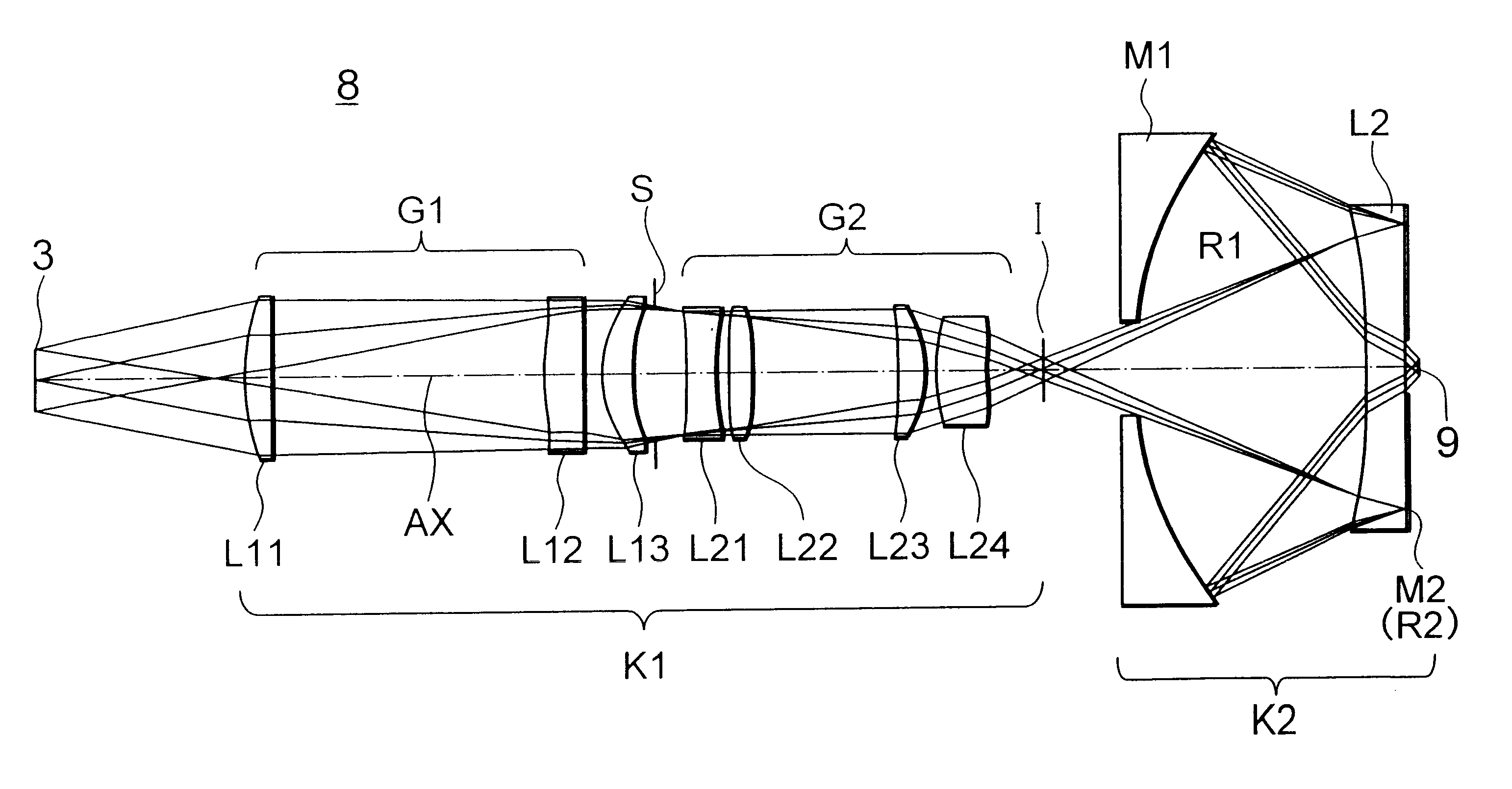

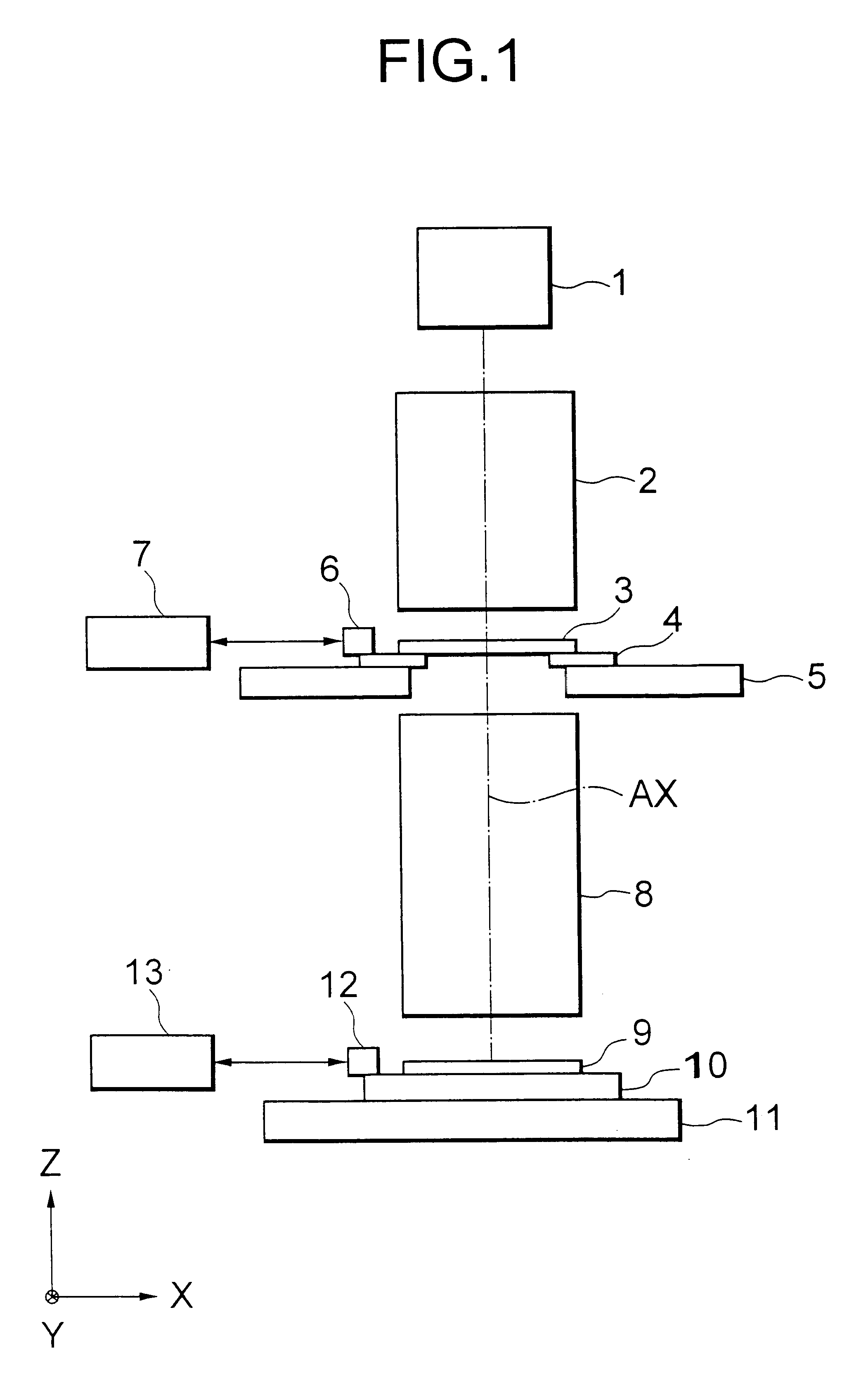

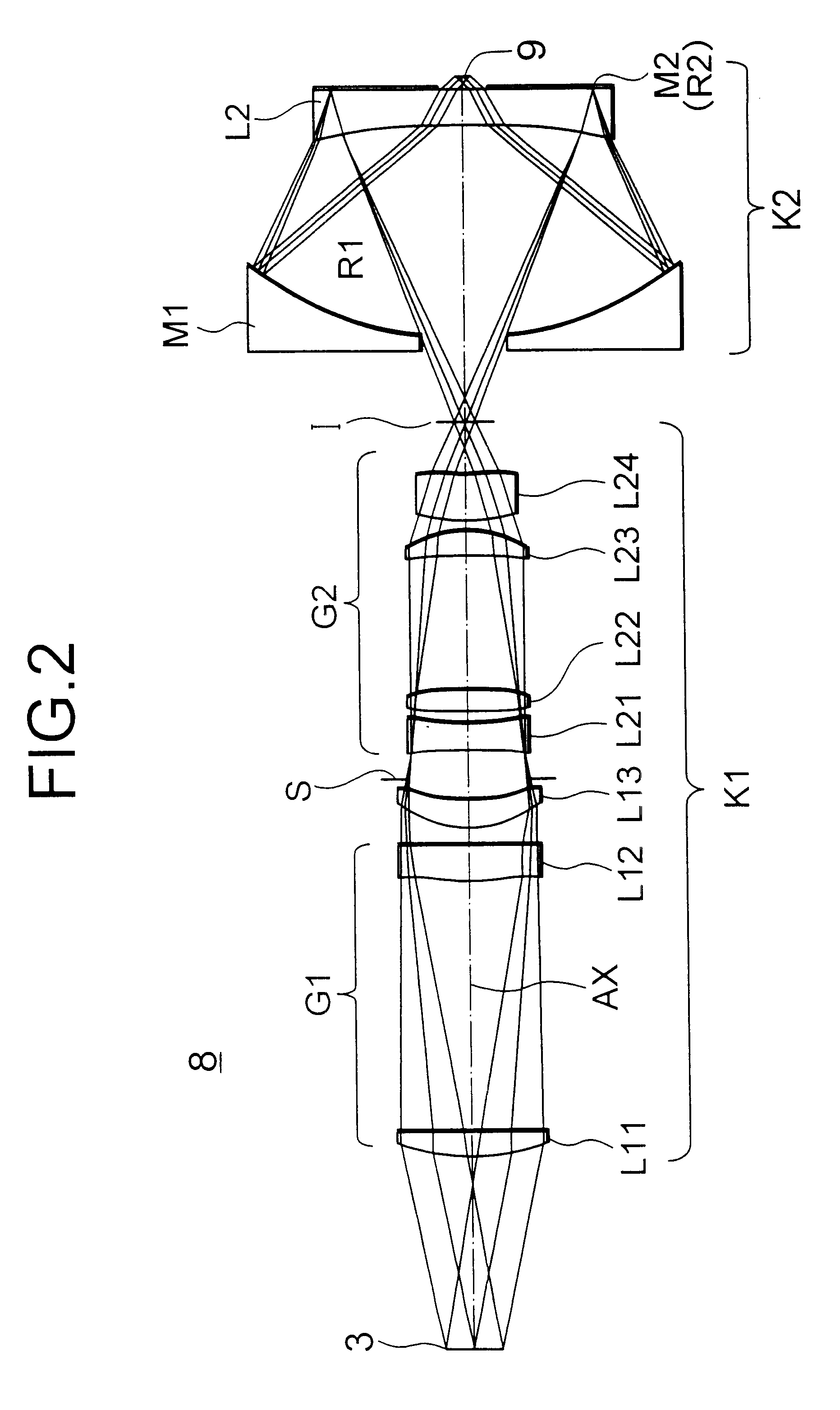

Catadioptric imaging system and a projection exposure apparatus provided with said imaging system

InactiveUS6639734B2Avoiding deterioration of image forming performanceInhibit deteriorationPhotomechanical exposure apparatusMicrolithography exposure apparatusOptic systemRadiation

The object of the present invention is to provide a catadioptric imaging system, or the like, which is capable of obtaining a desired image-side NA and an image circle without increasing the size of a reflecting mirror with a smaller number of lenses. This catadioptric imaging system comprises a first imaging optical system and a second imaging optical system, wherein the first imaging optical system is provided with a positive first lens group, an aperture stop, and a positive second lens group in the order from the object side, and the second imaging optical system is provided with a primary mirror comprising a concave first reflecting surface having a first radiation transmitting portion at the center thereof, and a secondary mirror comprising a second reflecting surface having a second radiation transmitting portion at the center thereof. In this case, all of the refracting members for constituting the optical system is formed of the same optical material, or at least one of the refracting surfaces and the reflecting surfaces is formed to be aspherical, or a refracting member is disposed to be separated from the first reflecting surface or the second reflecting surface.

Owner:NIKON CORP

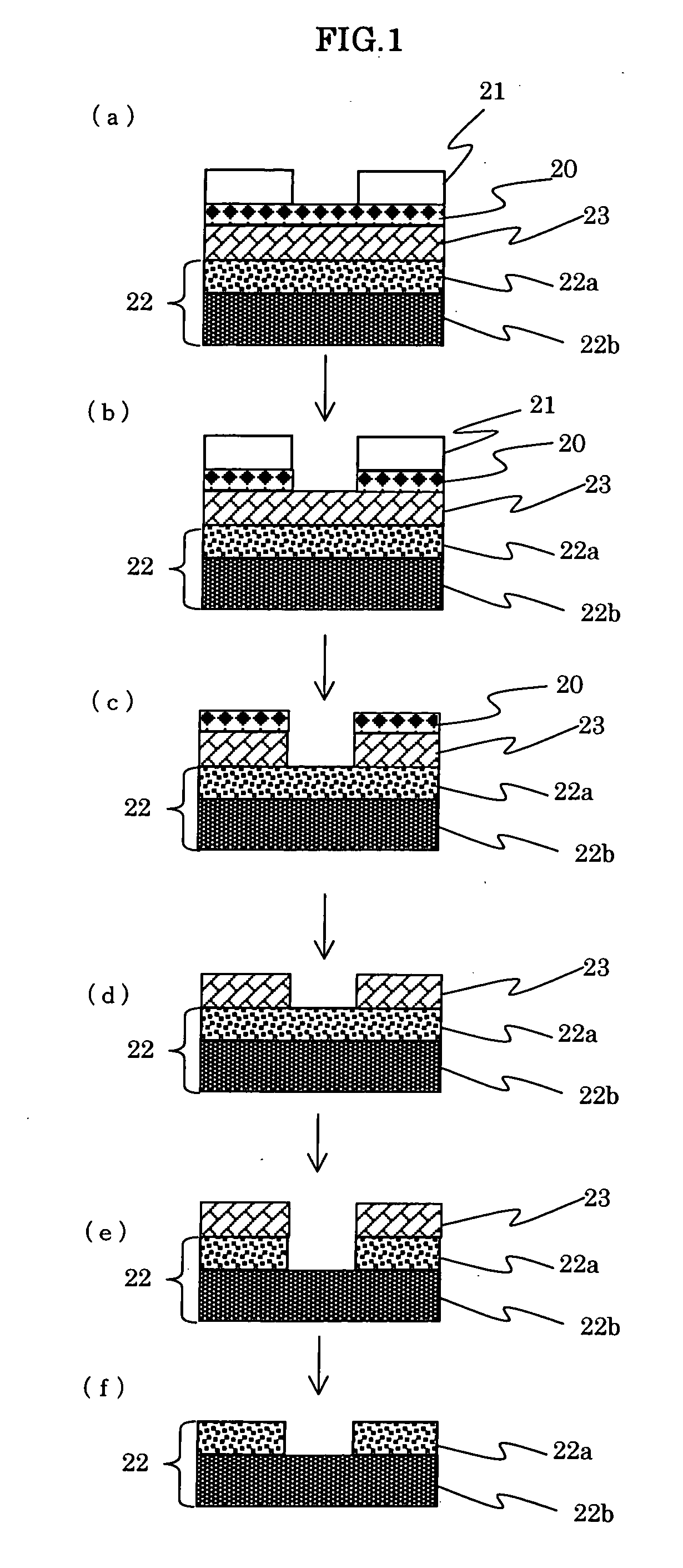

Process for forming resist pattern, semiconductor device and manufacturing method for the same

InactiveUS20080044770A1High precisionEfficiently manufactureSemiconductor/solid-state device manufacturingPhotosensitive material processingResistLight source

To provide a process for forming a resist pattern, which the process can adopt even ArF excimer laser light as exposure light in a patterning step, can thicken a resist pattern (e.g., a hole pattern) regardless of its size, and can reduce the size of a resist space pattern with high precision while preventing changes in the resist pattern shape, to thereby make this process easy, inexpensive and efficient while exceeding the exposure (resolution) limits of light sources of exposure devices. The process of the present invention for forming a resist pattern includes: forming a resist pattern; applying over a surface of the resist pattern a resist pattern thickening material; heating the resist pattern thickening material to thicken the resist pattern followed by development; and heating the resist pattern which has been thickened.

Owner:FUJITSU LTD

Printed wiring board, method for producing printed wiring board and semiconductor device

InactiveUS20160322293A1Efficient productionHigh hardnessSecond resist patternSemiconductor/solid-state device detailsResistElectrical conductor

The present invention provides a printed wiring board comprising: a conductor circuit on an insulating substrate, a white solder resist layer which is composed of a photosensitive resin composition on the insulating substrate having the conductor circuit, and a protective layer which is composed of a silicone resin composition on the white solder resist layer. The inventive printed wiring board shows superior thermo-discoloration resistivity and excellent patterning resolution.

Owner:SHIN ETSU CHEM IND CO LTD

Micropattern forming material, micropattern forming method and method for manufacturing semiconductor device

InactiveUS20040029047A1Improve the immunityImprove accuracyElectric discharge tubesSemiconductor/solid-state device manufacturingResistOrganic solvent

A micropattern forming material comprises a polar change material formed on a resist pattern capable of generating an acid, the polar change material being soluble in water or an alkali, a portion of the polar change material in contact with the resist pattern undergoing a polar change caused by the acid from the resist pattern to form an insolubilized film insoluble in water and the alkali; and water or a mixed solvent of water and a water-soluble organic solvent.

Owner:RENESAS TECH CORP

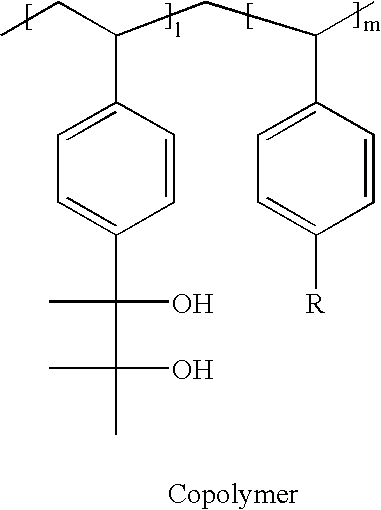

Resist lower layer film composition and patterning process using the same

ActiveUS20080227037A1Etching speed is fastShorten the time periodPhotosensitive materialsPhotoprinting processesResistPolymer

Owner:SHIN ETSU CHEM IND CO LTD

Antireflective film-forming composition, method for manufacturing the same, and antireflective film and pattern formation method using the same

ActiveUS7541134B2Improve etch selectivityEtching speed is fastSemiconductor/solid-state device manufacturingSilver halide emulsionsResistCross-link

The present invention provides a material for an antireflective film characterized by high etching selectivity with respect to a resist, that is, which has a fast etching speed when compared to the resist, and in addition, can be removed without damage to a film which is to be processed. The present invention also provides a pattern formation method for forming an antireflective film layer on a substrate using this antireflective film-forming composition, and a pattern formation method that uses this antireflective film as a hard mask, and a pattern formation method that uses this antireflective film as a hard mask for processing the substrate. The present invention also provides an antireflective film-forming composition comprising an organic solvent, a cross linking agent, and a polymer comprising a light absorbing group obtained by hydrolyzing and condensing more than one type of silicon compound, a crosslinking group and a non-crosslinking group.

Owner:SHIN ETSU CHEM CO LTD +1

Polymerizable composition

ActiveUS20130072615A1Increased durabilityHigh light transmittanceNanoinformaticsPhotomechanical apparatusOrganic chemistryPolymerization

A polymerizable composition includes: a polymerization initiator; a polymerizable compound; a tungsten compound; and an alkali-soluble binder.

Owner:FUJIFILM CORP

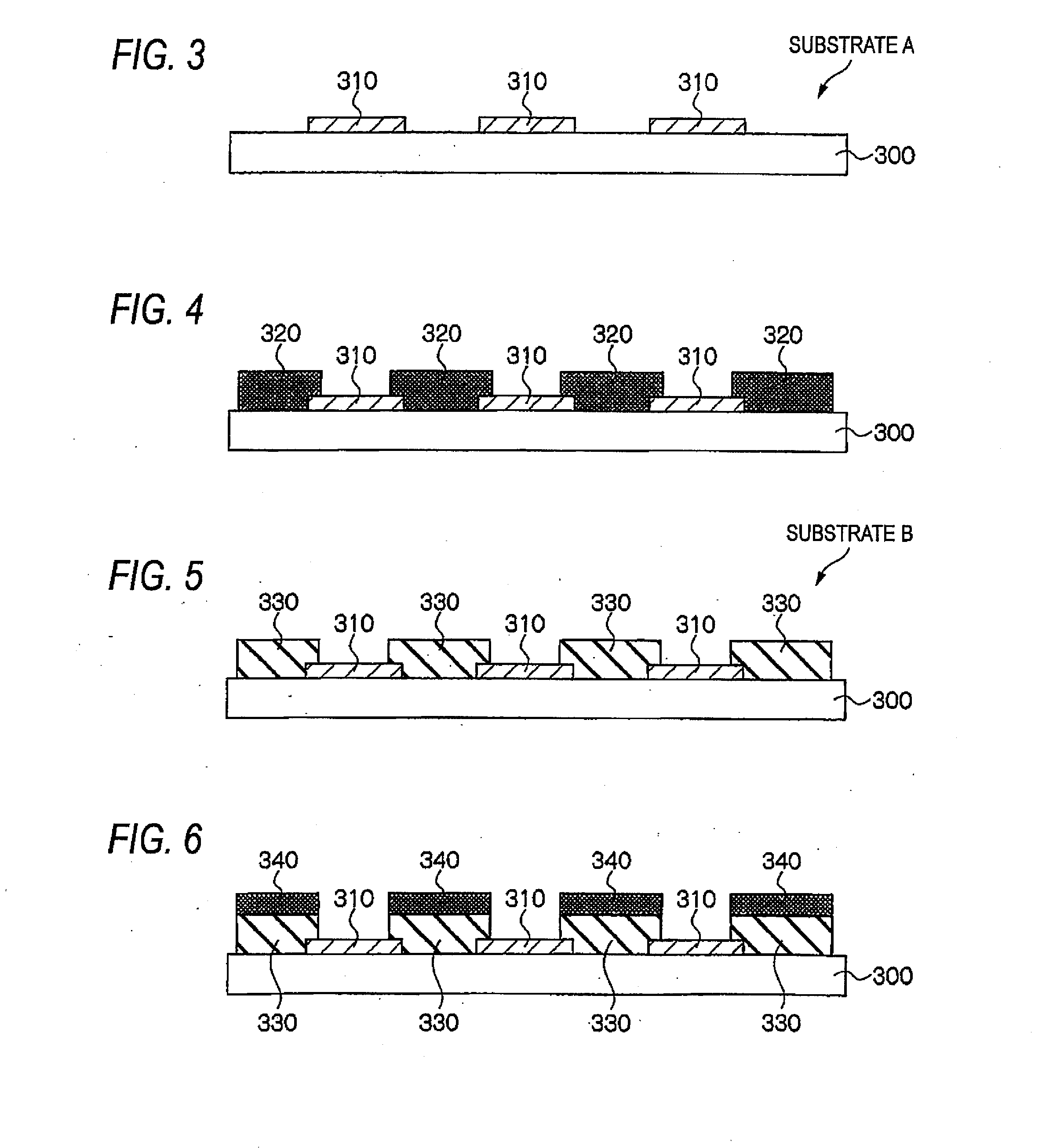

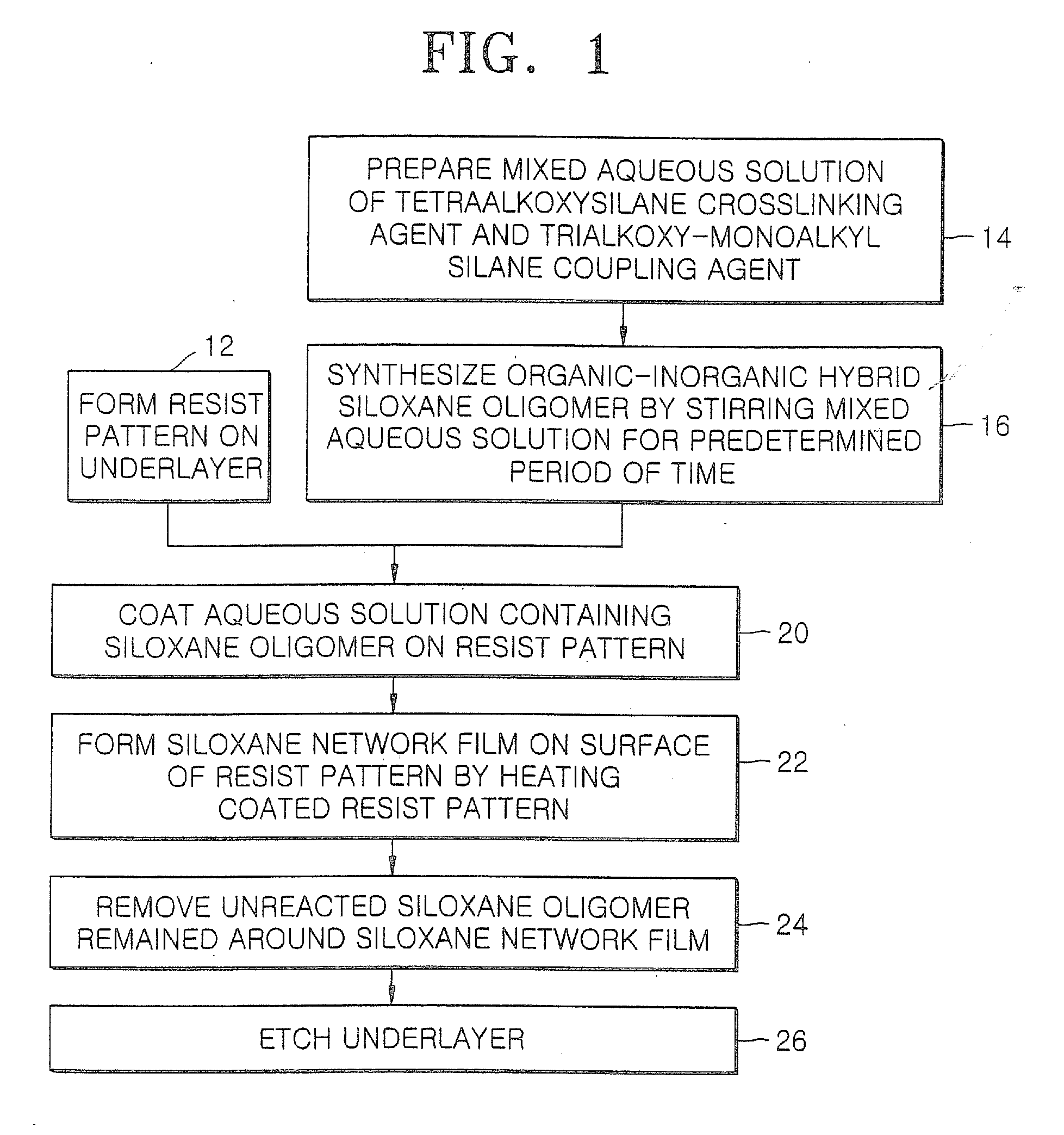

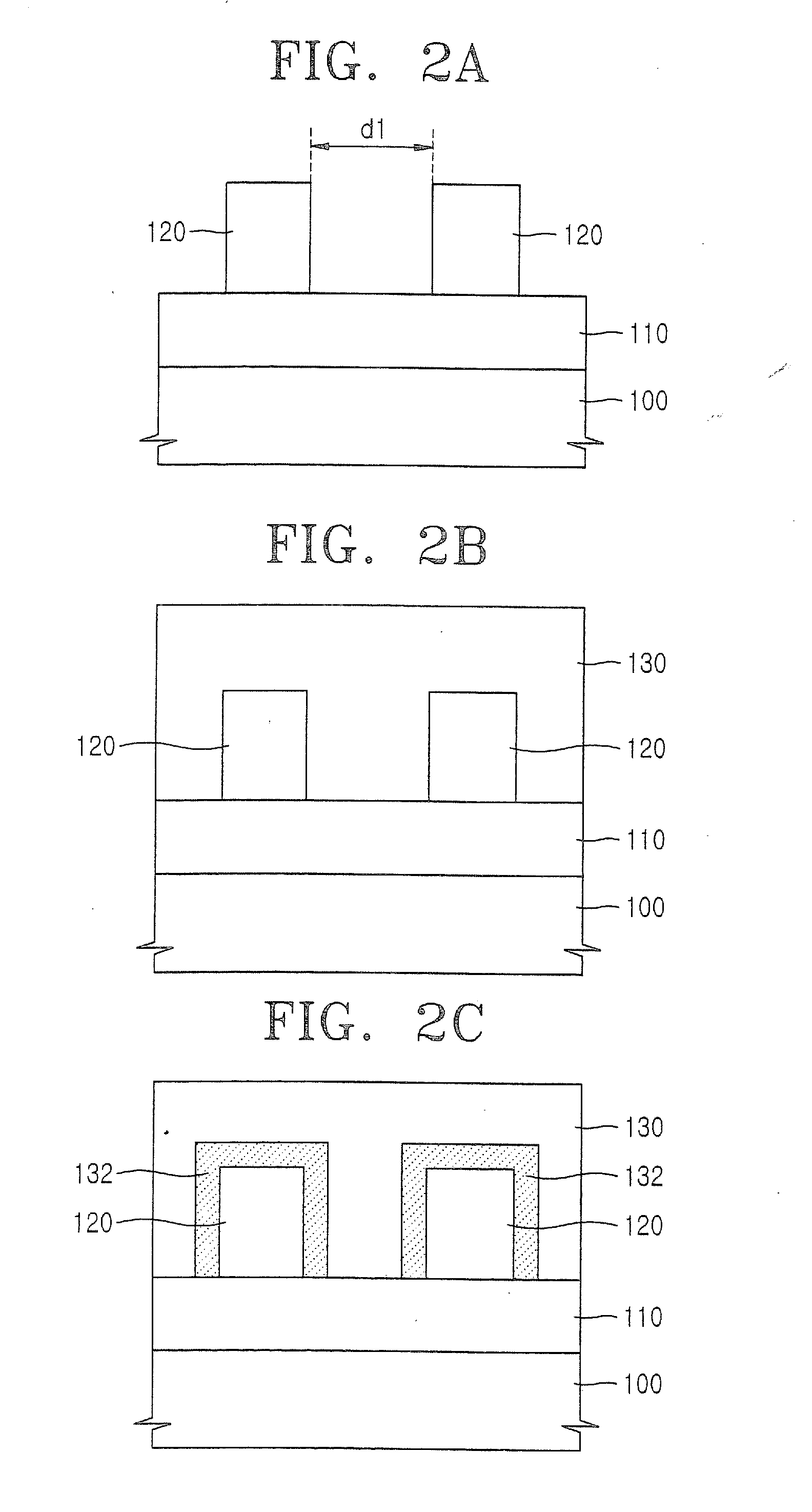

Mask Patterns for Semiconductor Device Fabrication and Related Methods and Structures

InactiveUS20080176152A1Simple and inexpensive processSolve the lack of resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingResistEngineering

Methods of forming an integrated circuit device may include forming a resist pattern on a layer of an integrated circuit device with portions of the layer being exposed through openings of the resist pattern. An organic-inorganic hybrid siloxane network film may be formed on the resist pattern. Portions of the layer exposed through the resist pattern and the organic-inorganic hybrid siloxane network film may then be removed. Related structures are also discussed.

Owner:SAMSUNG ELECTRONICS CO LTD

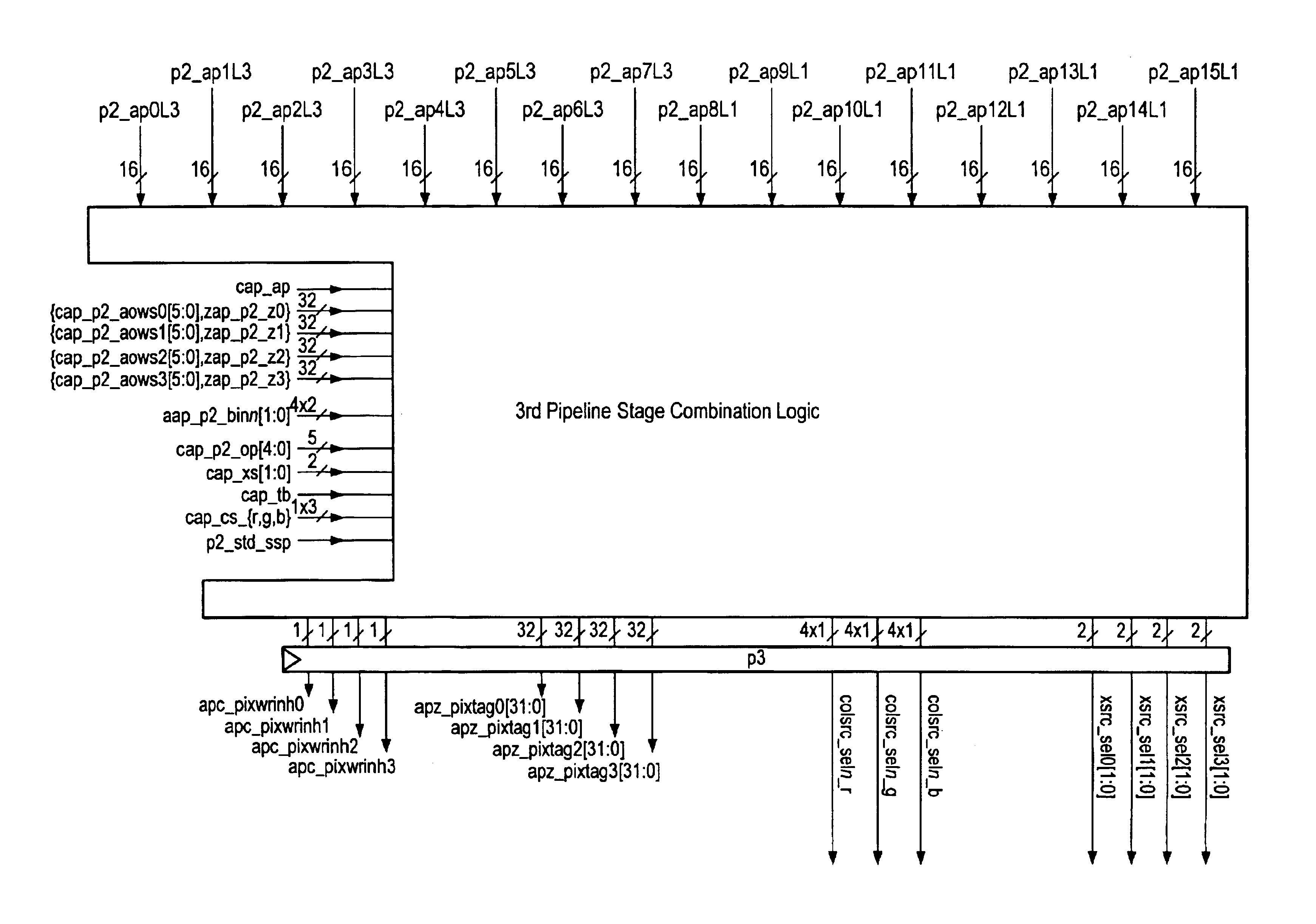

Area pattern processing of pixels

InactiveUS6924808B2Exquisite patternMemory adressing/allocation/relocationCathode-ray tube indicatorsScan lineComputer science

Owner:ORACLE INT CORP

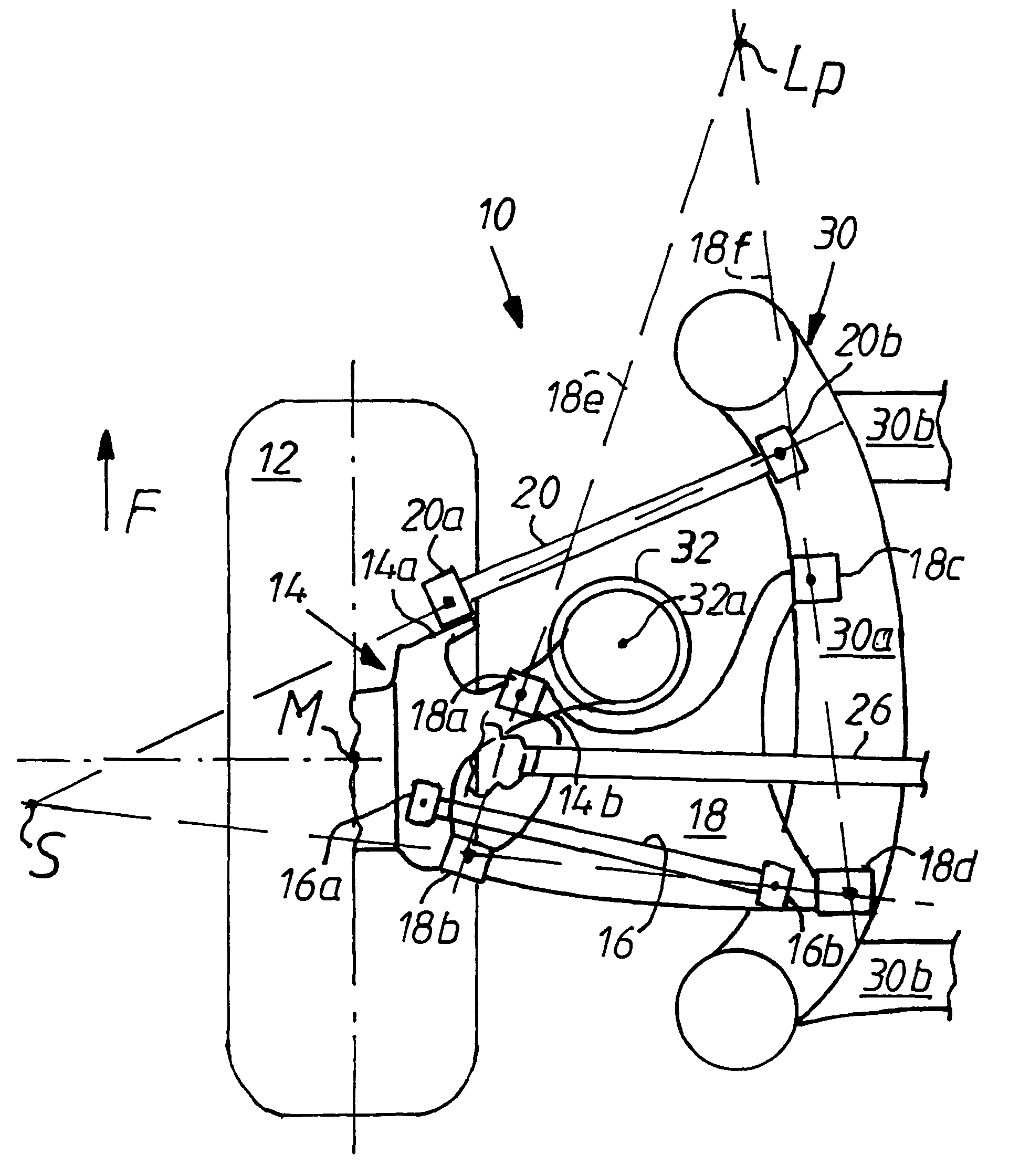

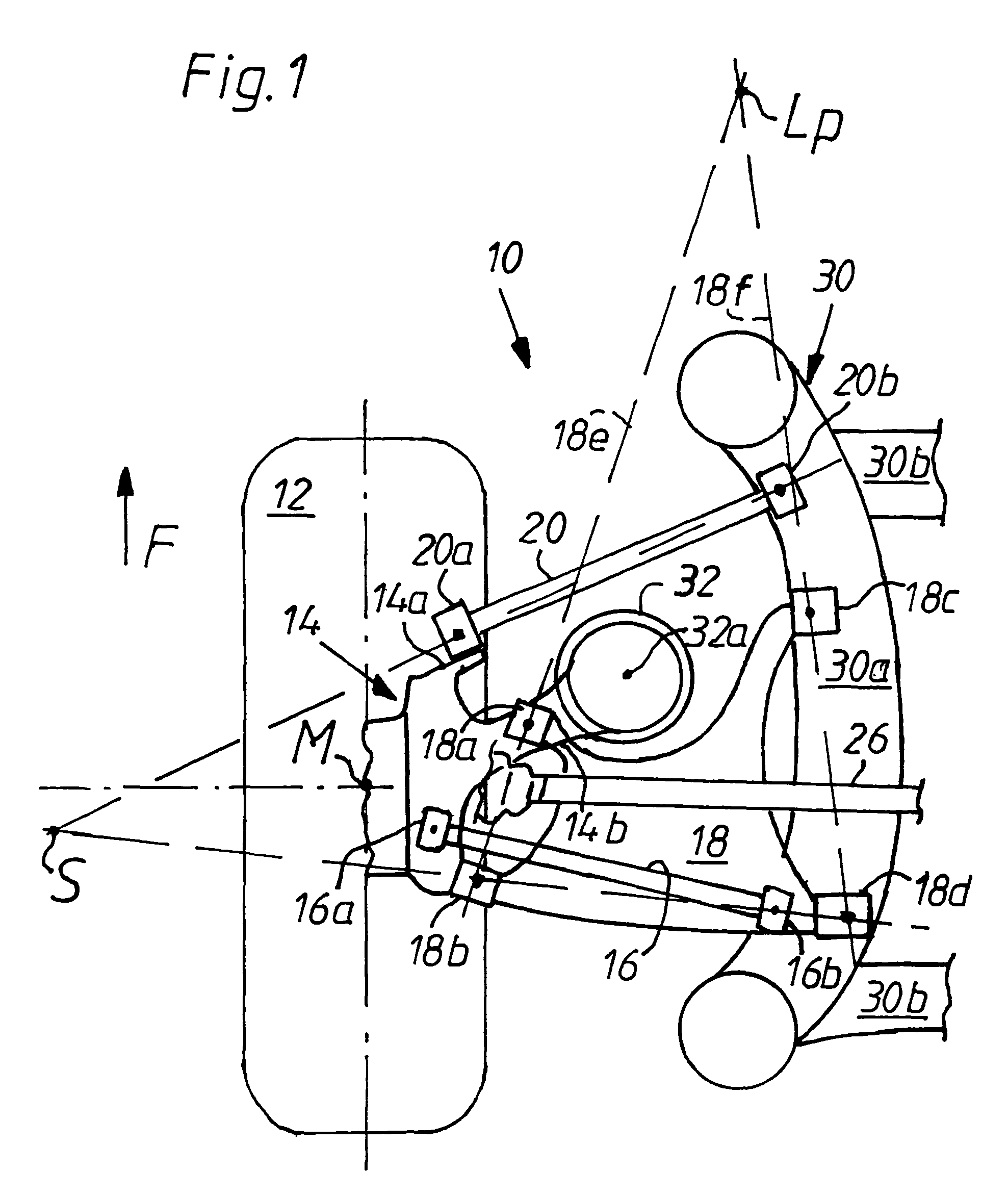

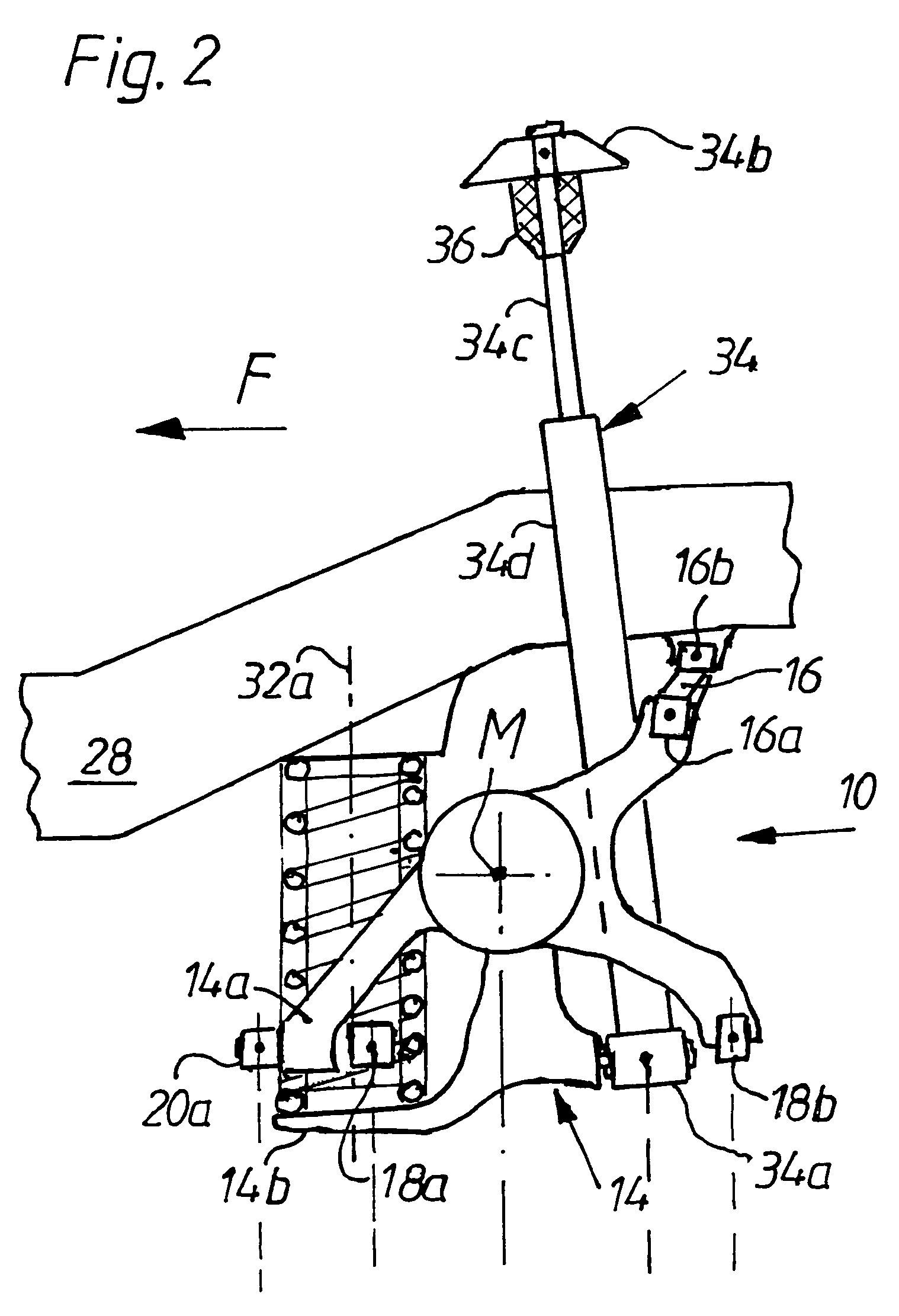

Independent wheel suspension for the rear wheels of motor vehicles

ActiveUS7784806B2Prevents undesirable joint steeringFavorableResilient suspensionsPivoted suspension armsControl armEngineering

The invention relates to an independent wheel suspension for the rear wheels of motor vehicles, having a wheel support which is hinge-connected to at least one upper and one lower control arm, the lower control arm being connected by way of two more or less horizontal arm bearings forming pivot axes on the body of the motor vehicle and on the wheel support and a guide arm of the wheel support to another bearing, and also having a bearing spring resting on the wheel support and a more or less vertically oriented telescopic shock absorber. For the creation of a structurally and elastokinematically favorable wheel suspension it is proposed, as viewed from above, that the other guide rod is mounted more or less in the lower guide rod plane and diagonally forward from the exterior toward the interior, in such a way that the intersection of imaginary extensions of the other guide rod and the rear bearing points of the lower guide rod is positioned beyond the extended wheel center axis.

Owner:AUDI AG

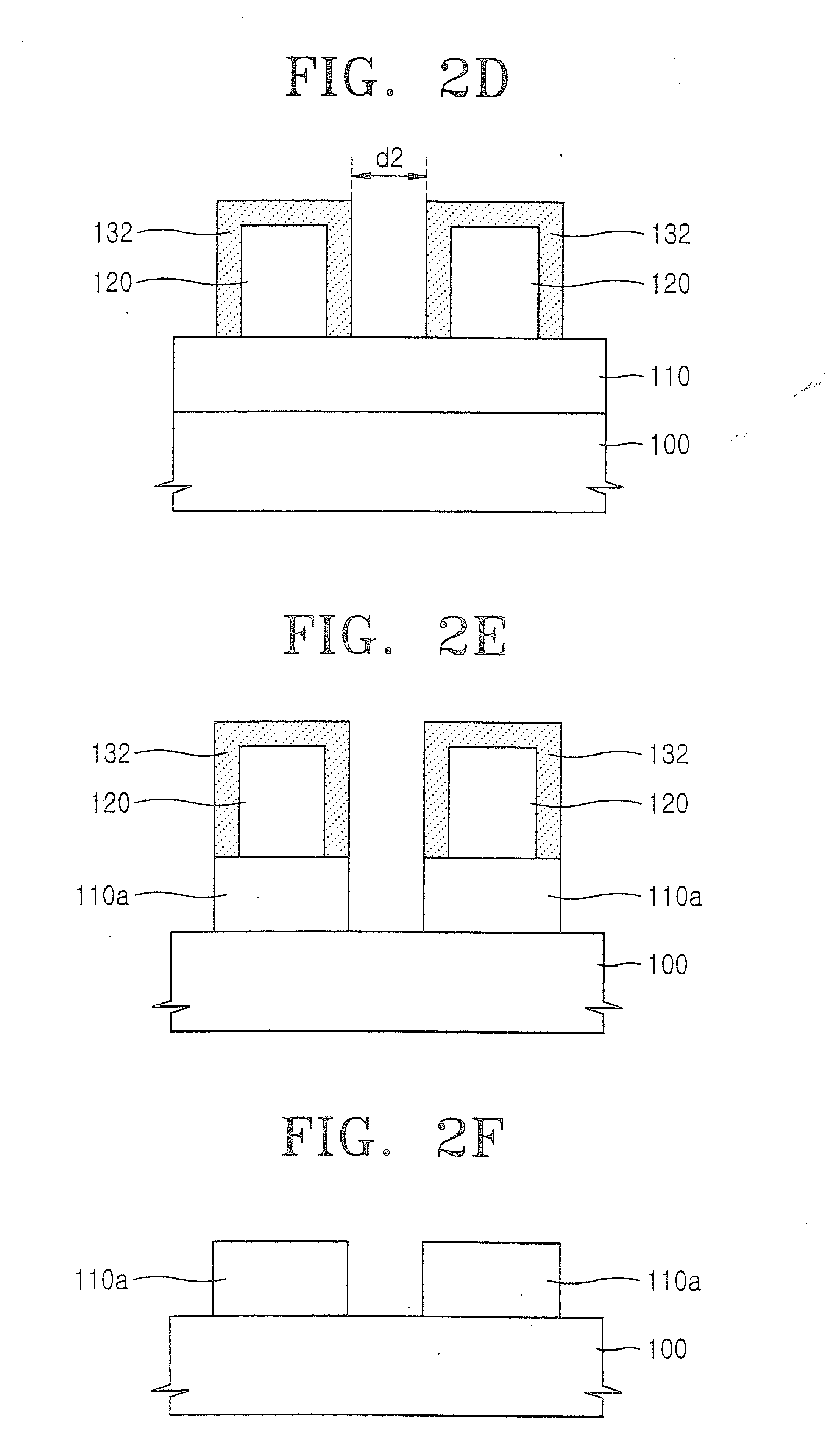

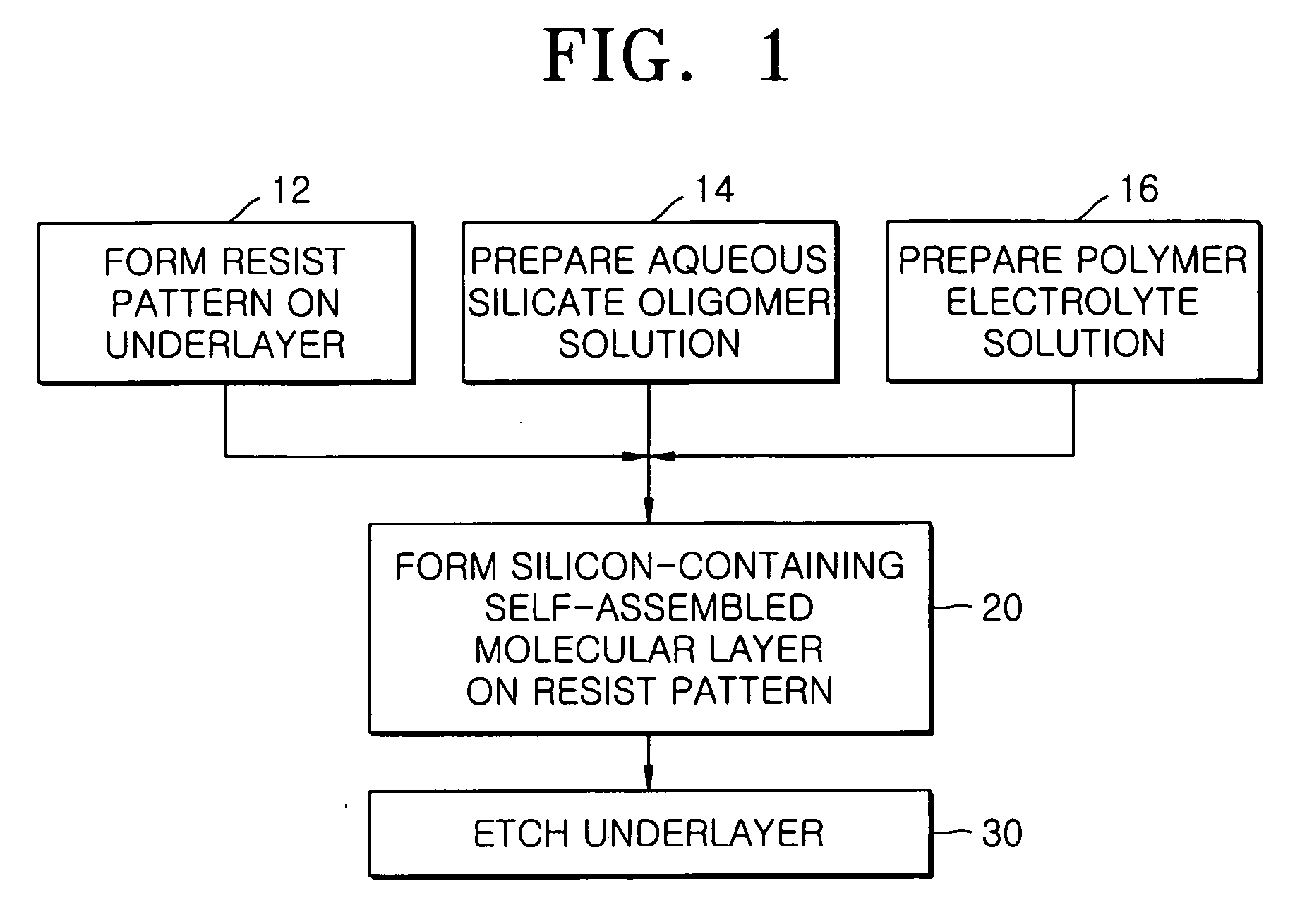

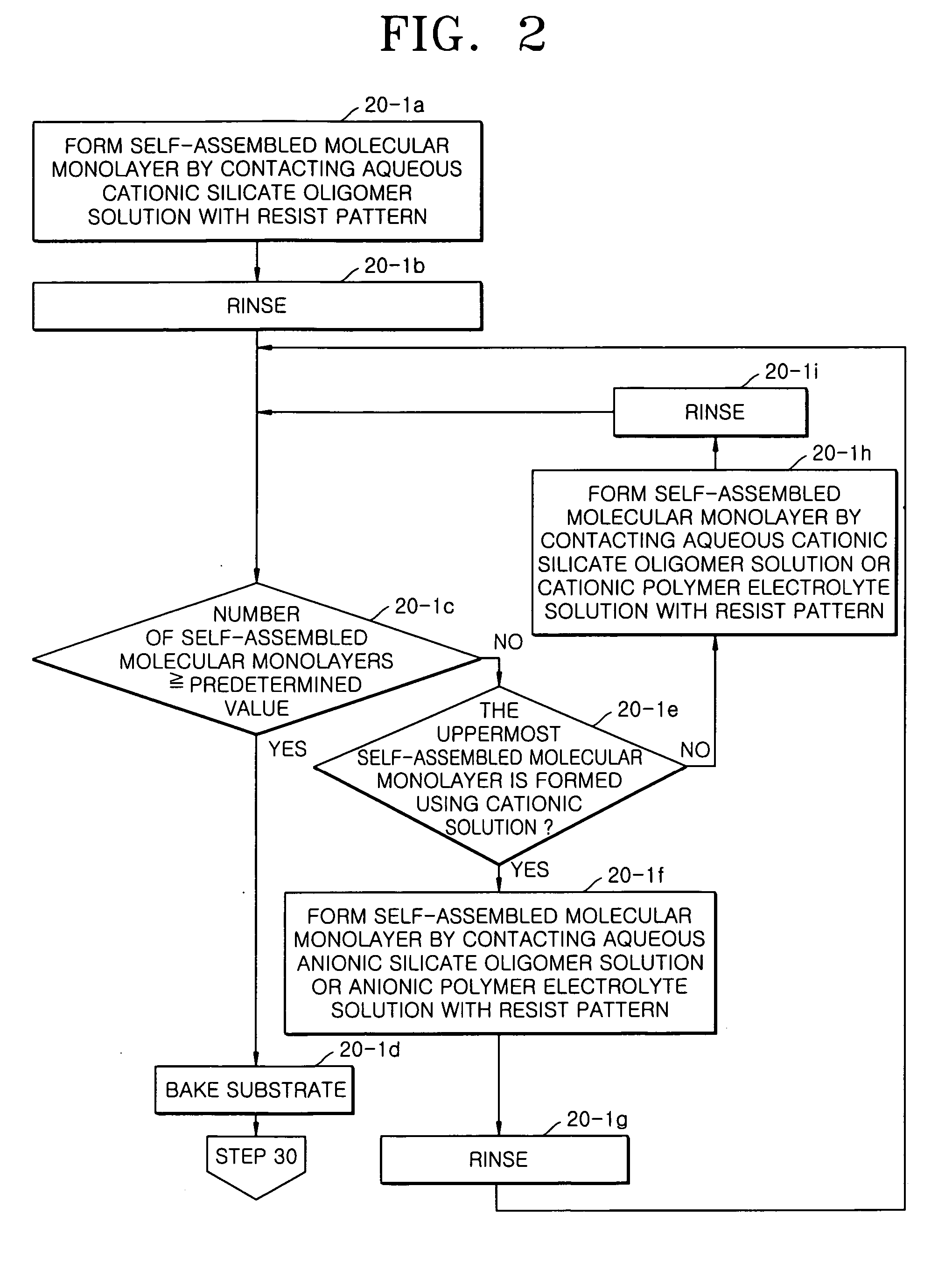

Mask pattern for semiconductor device fabrication, method of forming the same, and method of fabricating finely patterned semiconductor device

InactiveUS20060046205A1Simple and inexpensive processSimple methodMaterial nanotechnologyPhotosensitive materialsResistSilicon dioxide

Provided are a mask pattern including a silicon-containing self-assembled molecular layer, a method of forming the same, and a method of fabricating a semiconductor device. The mask pattern includes a resist pattern formed on a semiconductor substrate and the self-assembled molecular layer formed on the resist pattern. The self-assembled molecular layer has a silica network formed by a sol-gel reaction. To form the mask pattern, first, the resist pattern is formed with openings on an underlayer covering the substrate to expose the underlayer to a first width. Then, the self-assembled molecular layer is selectively formed only on a surface of the resist pattern to expose the underlayer to a second width smaller than the first width. The underlayer is etched by using the resist pattern and the self-assembled molecular layer as an etching mask to obtain a fine pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

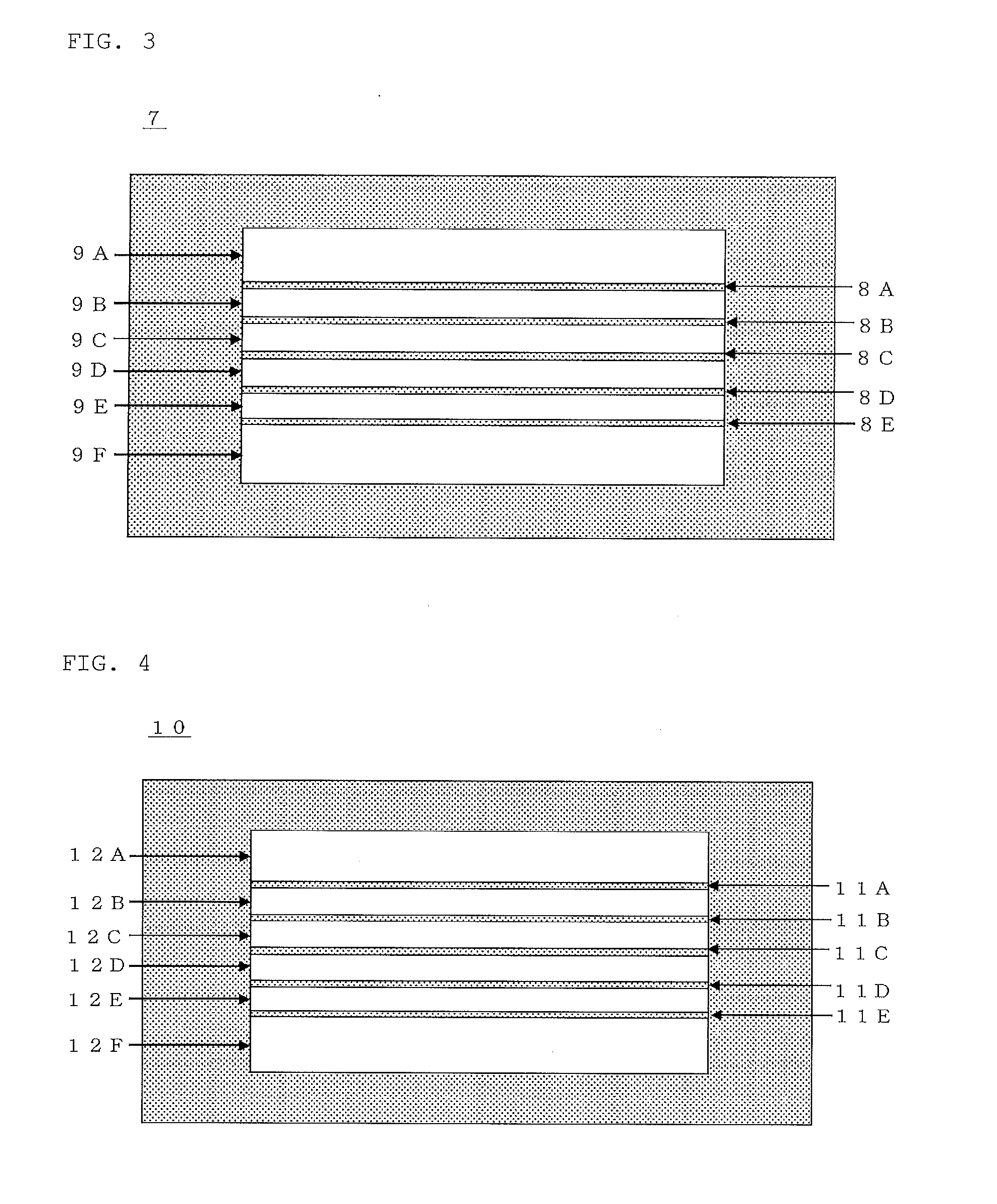

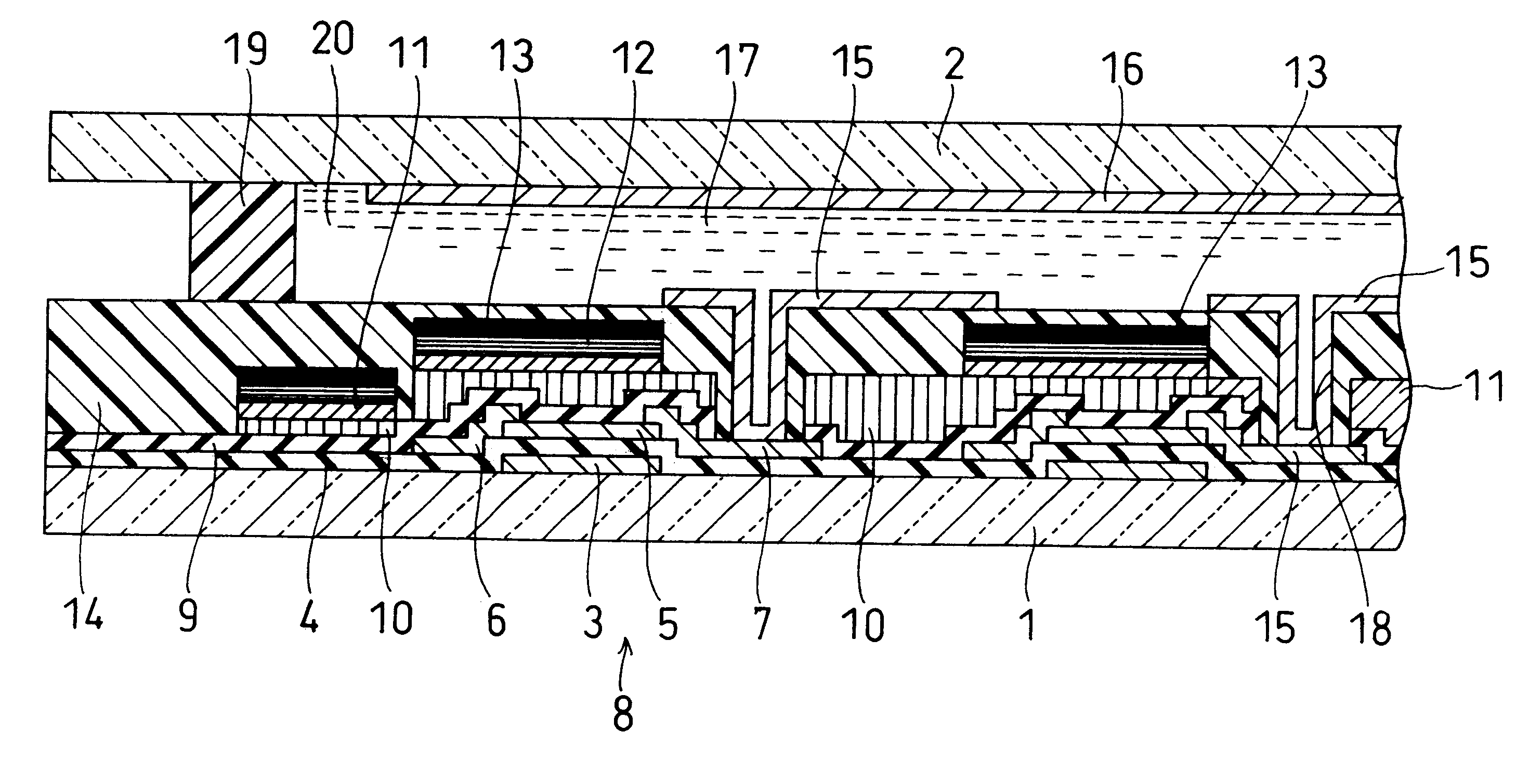

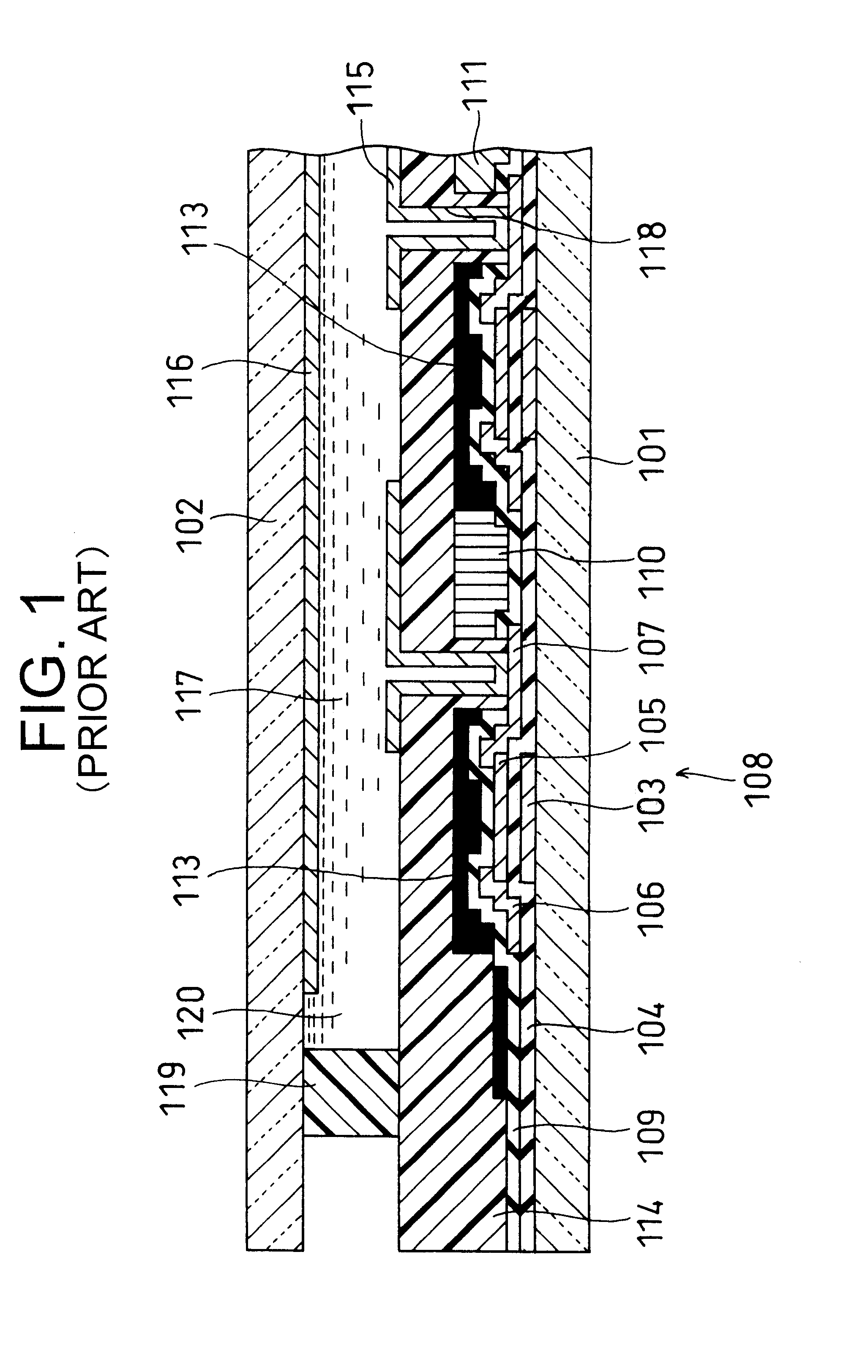

Color liquid crystal display panel

InactiveUS6445432B2Inhibit flakingHigh optical densityTelevision system detailsStatic indicating devicesInsulation layerLiquid-crystal display

First and second transparent substrates which are arranged to face each other are provided to a color liquid crystal display panel. A liquid crystal layer is provided between the first and the second transparent substrates. A plurality of thin film transistors are provided on the first transparent substrate. An insulation film provided on the first transparent substrate so as to cover the thin film transistors. A color filter which includes first to third color layers stacked on the insulation layer is provided. A contacting color layer is provided on the insulation film in a region above the thin film transistors. The contacting color layer has at least one color layer selected from a group of composed of the first to third color layers. A black matrix is provided on the contacting color layer. The black matrix has opening portions for transmitting light from the color filter.

Owner:NEC LCD TECH CORP

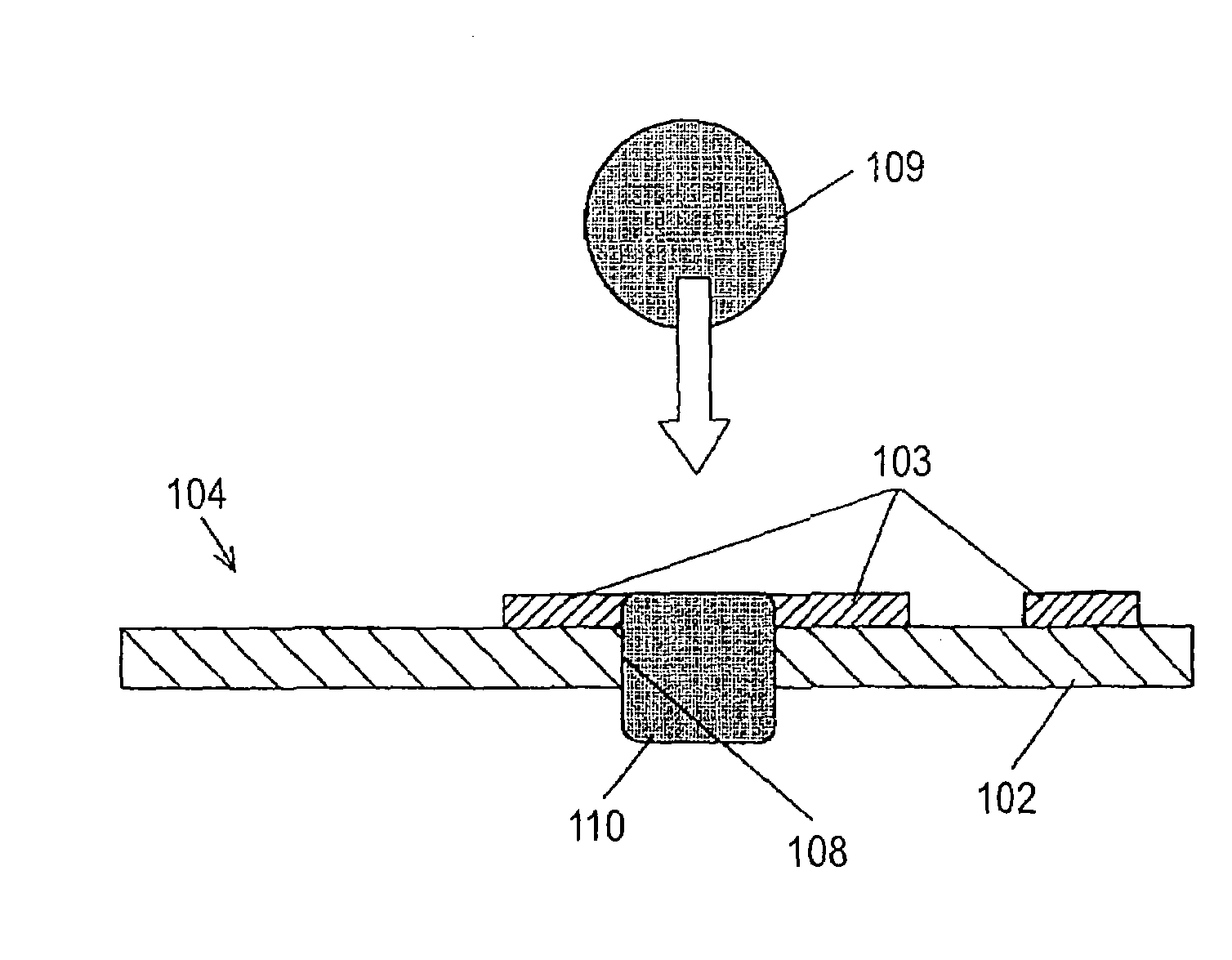

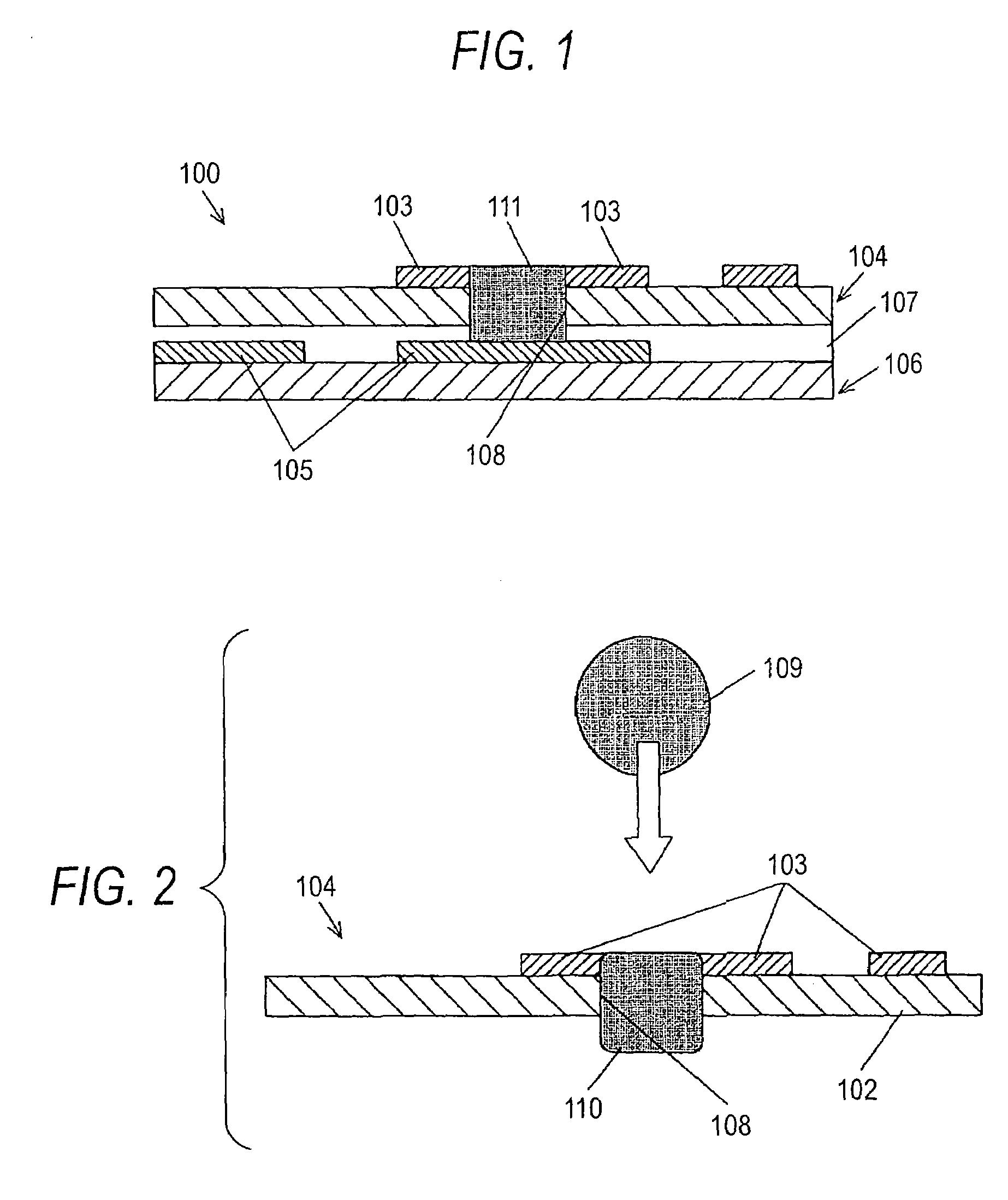

Mold for imprinting and production method thereof

InactiveUS20120328728A1Exquisite patternHigh pattern accuracyNanoinformaticsConfectioneryComposite material

Owner:HOYA CORP

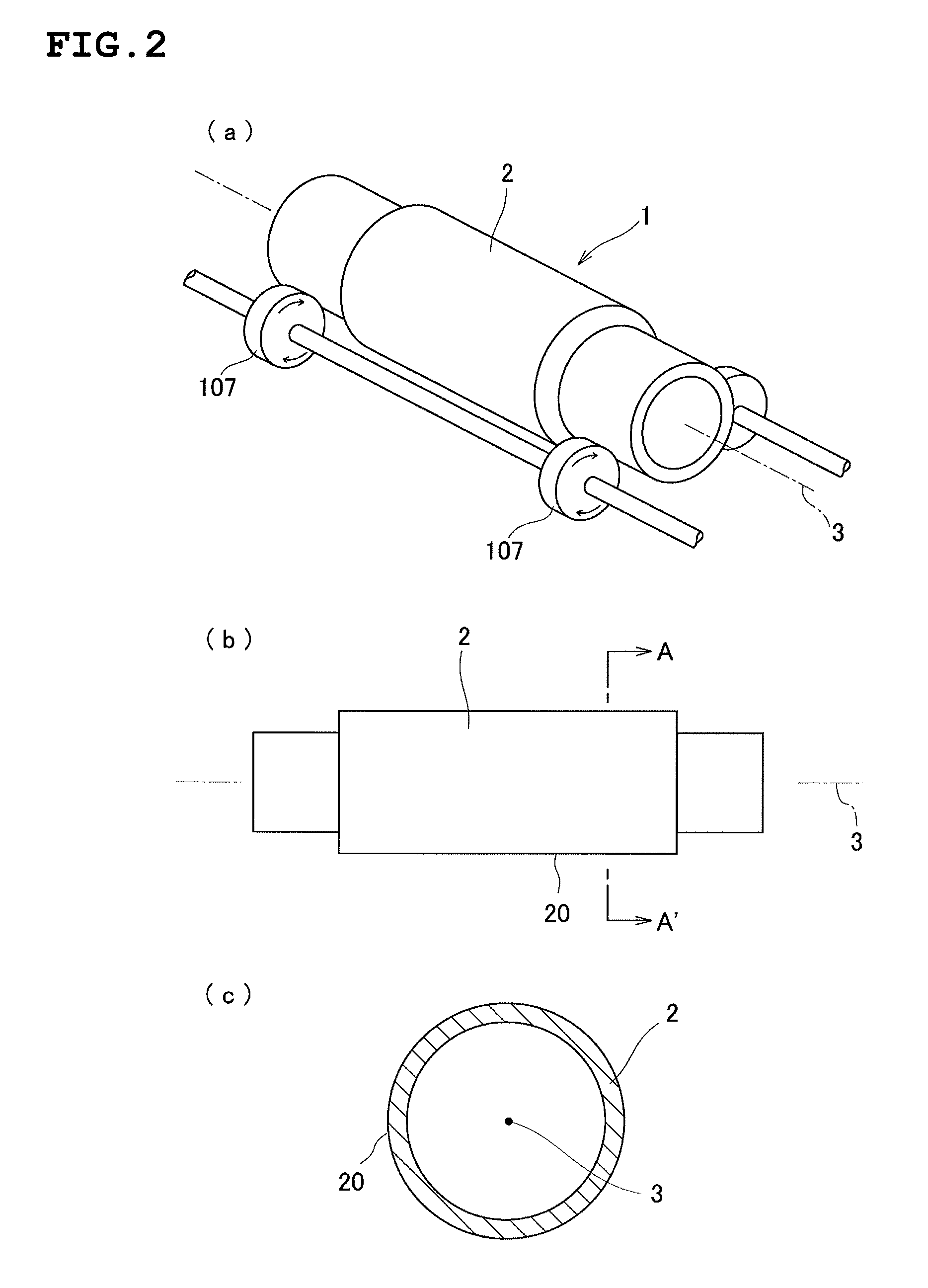

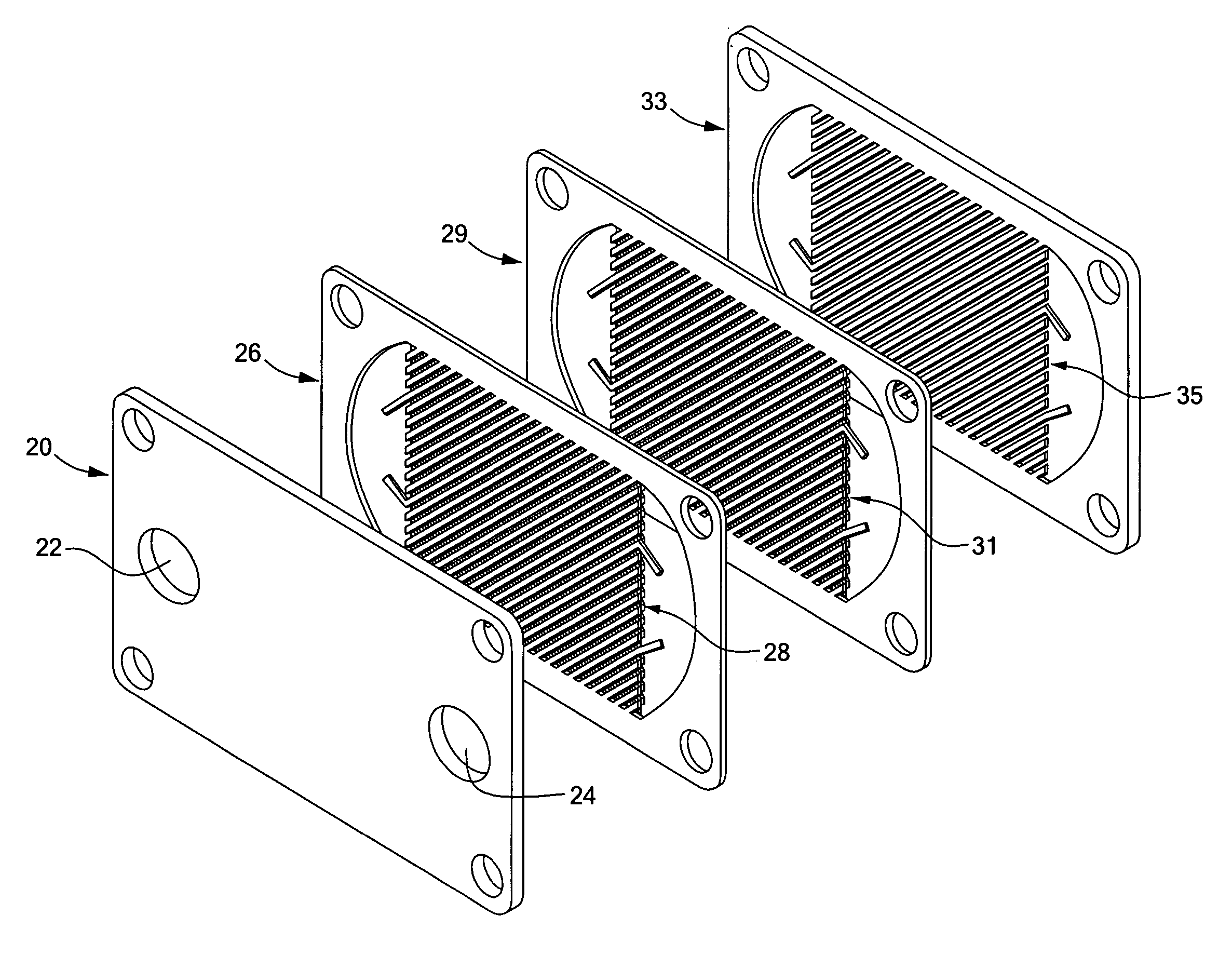

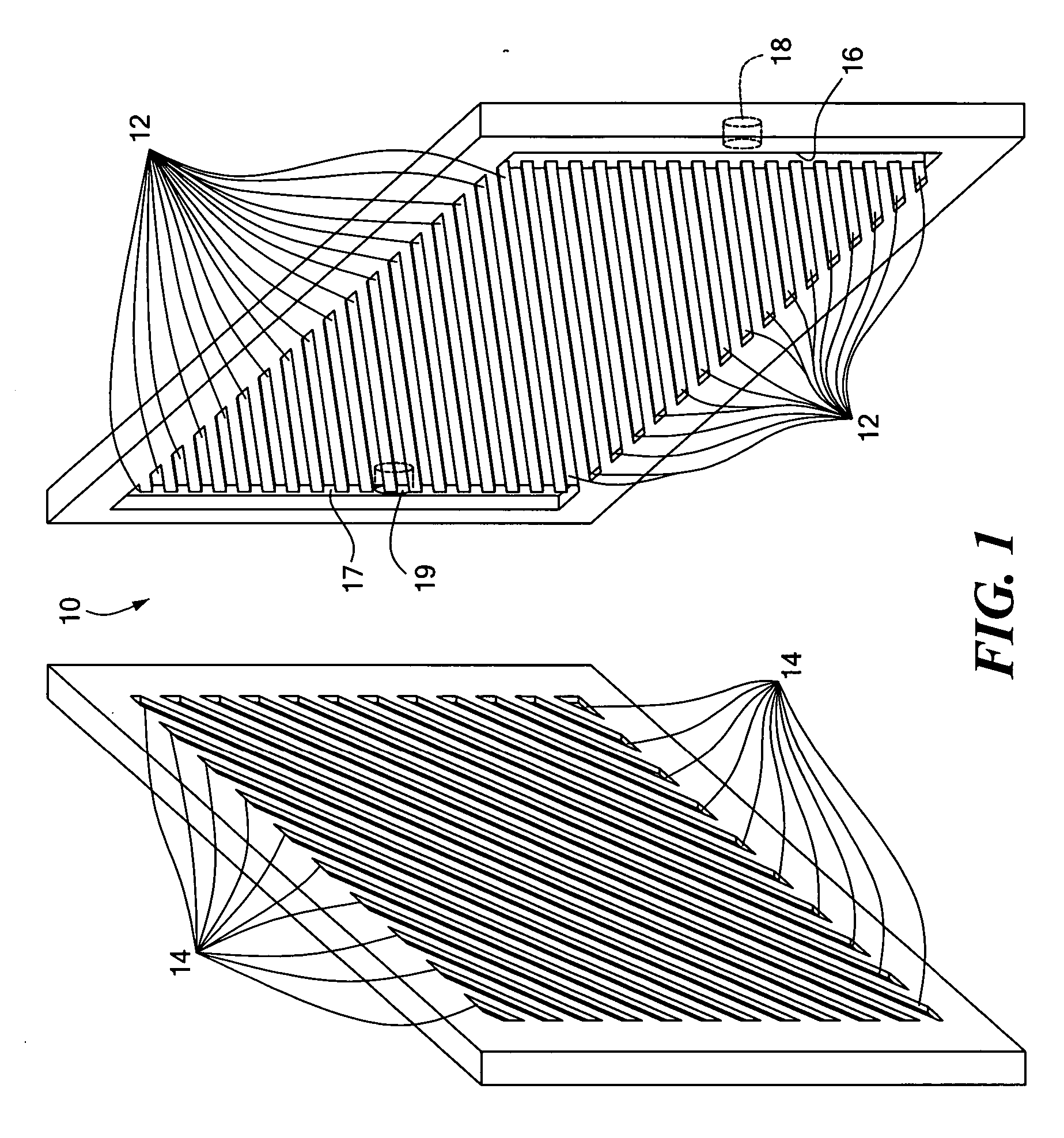

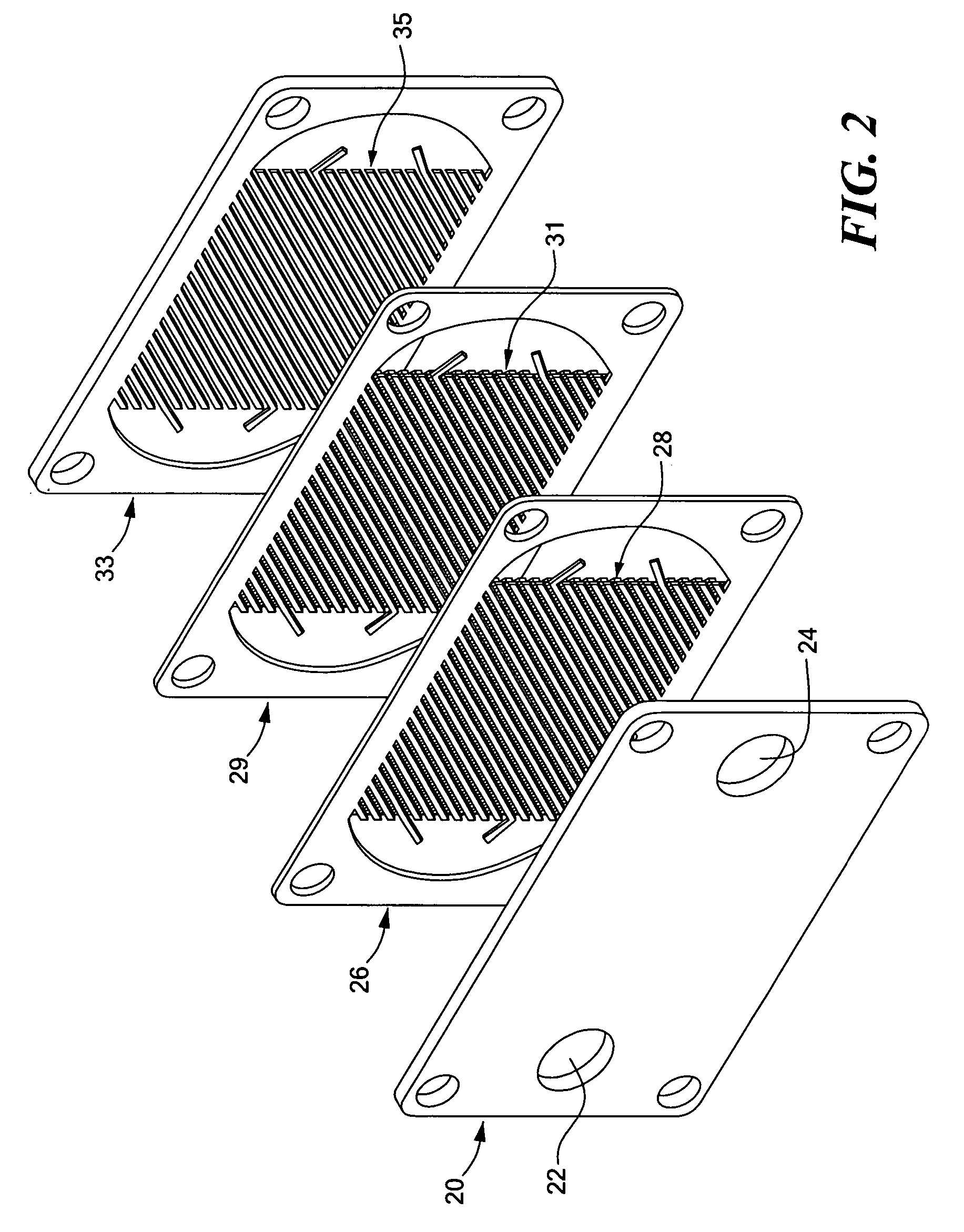

Contact cooling device

InactiveUS20060108100A1Expensive to operateMaintaining contact pressureHeat transfer modificationCooling/ventilation/heating modificationsEngineeringCold plate

A high performance cold plate cooling device including multiple, relatively thin plates, each having patterns formed thereon that, as arranged within the device, cause turbulence in a fluid passing within the cooling device. Adjacent plates within the cooling device are arranged such that fluid channels within their patterns are arranged crosswise. One or more barriers extending at least a portion of the length of the device separate the crosswise channels into two or more flow sections and increase uniformity of thermal performance over the active plate area. Manufacturing of the device includes stacking the plates in an alternating fashion such that the channels within the pattern of each plate are crosswise with respect to the channels in the pattern of an adjacent plate and adjacent barrier walls abut.

Owner:LYTRON

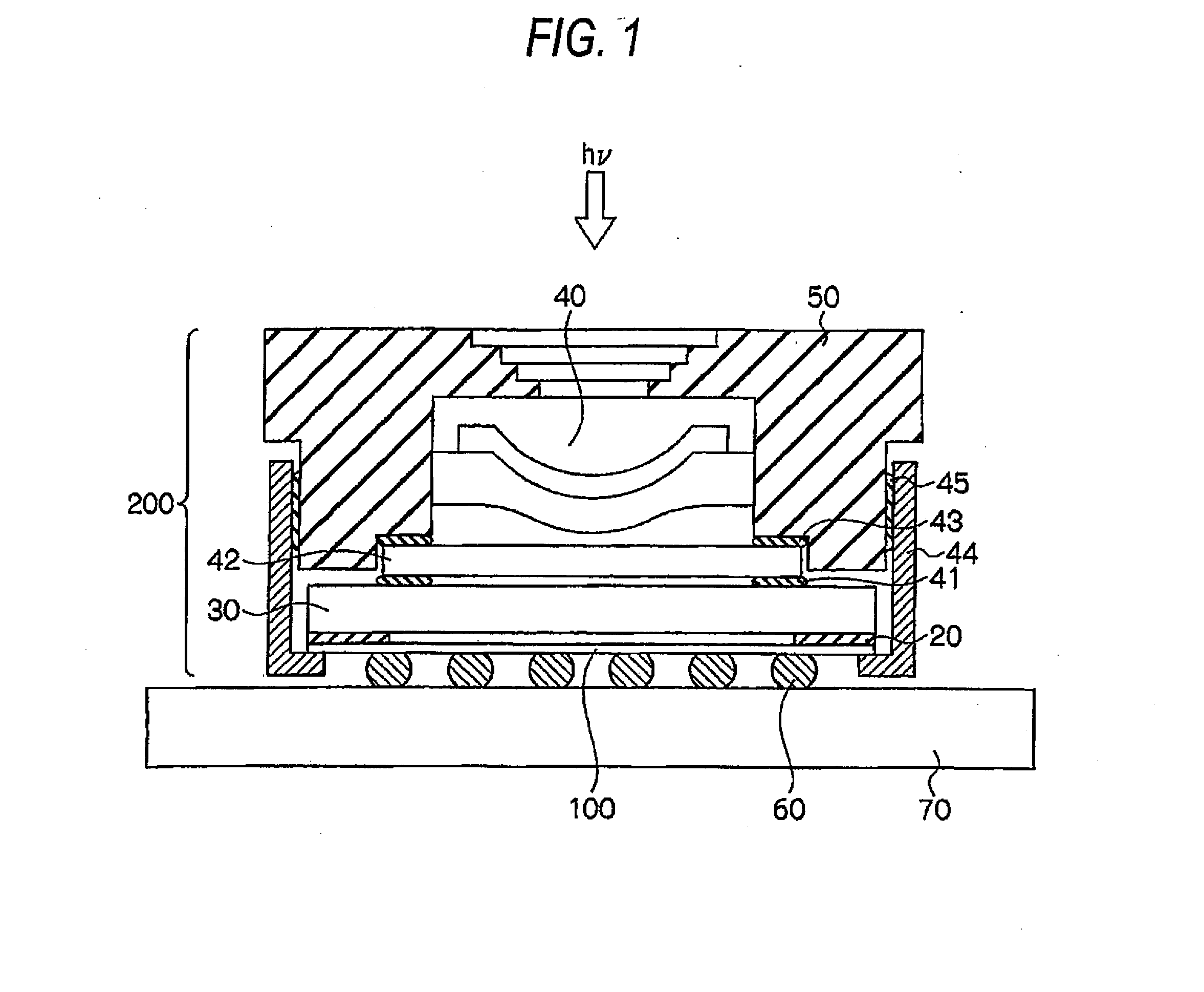

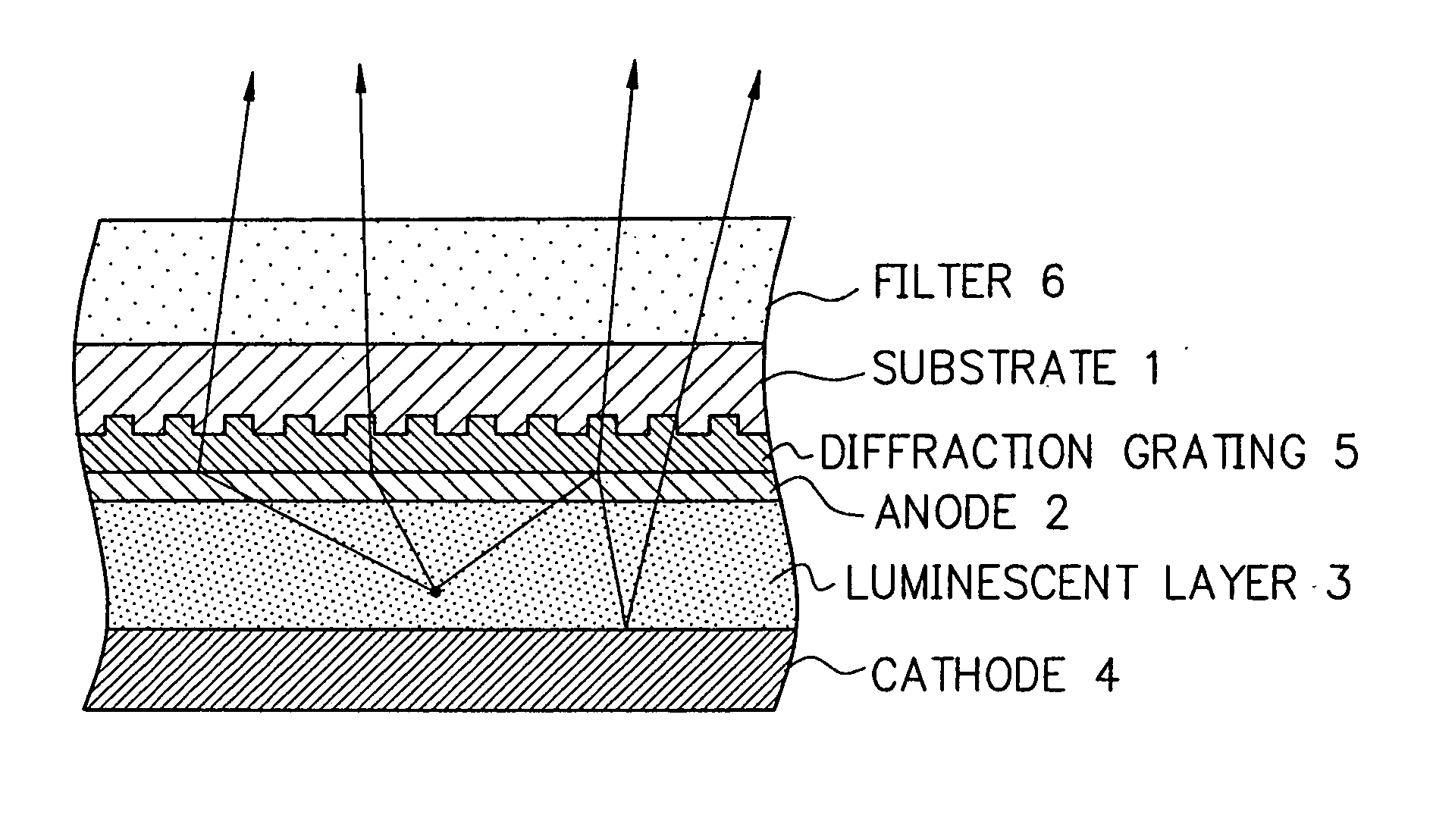

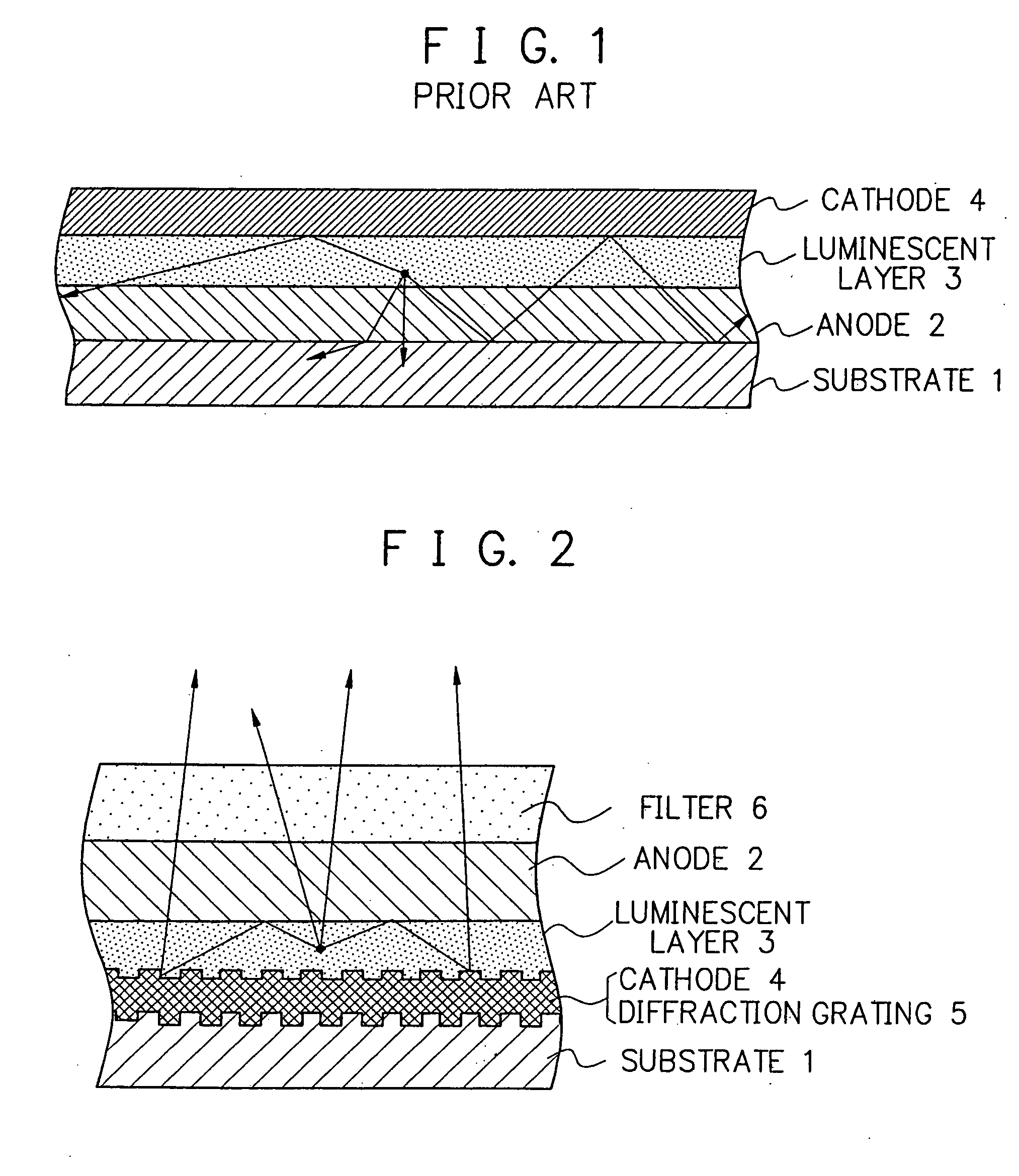

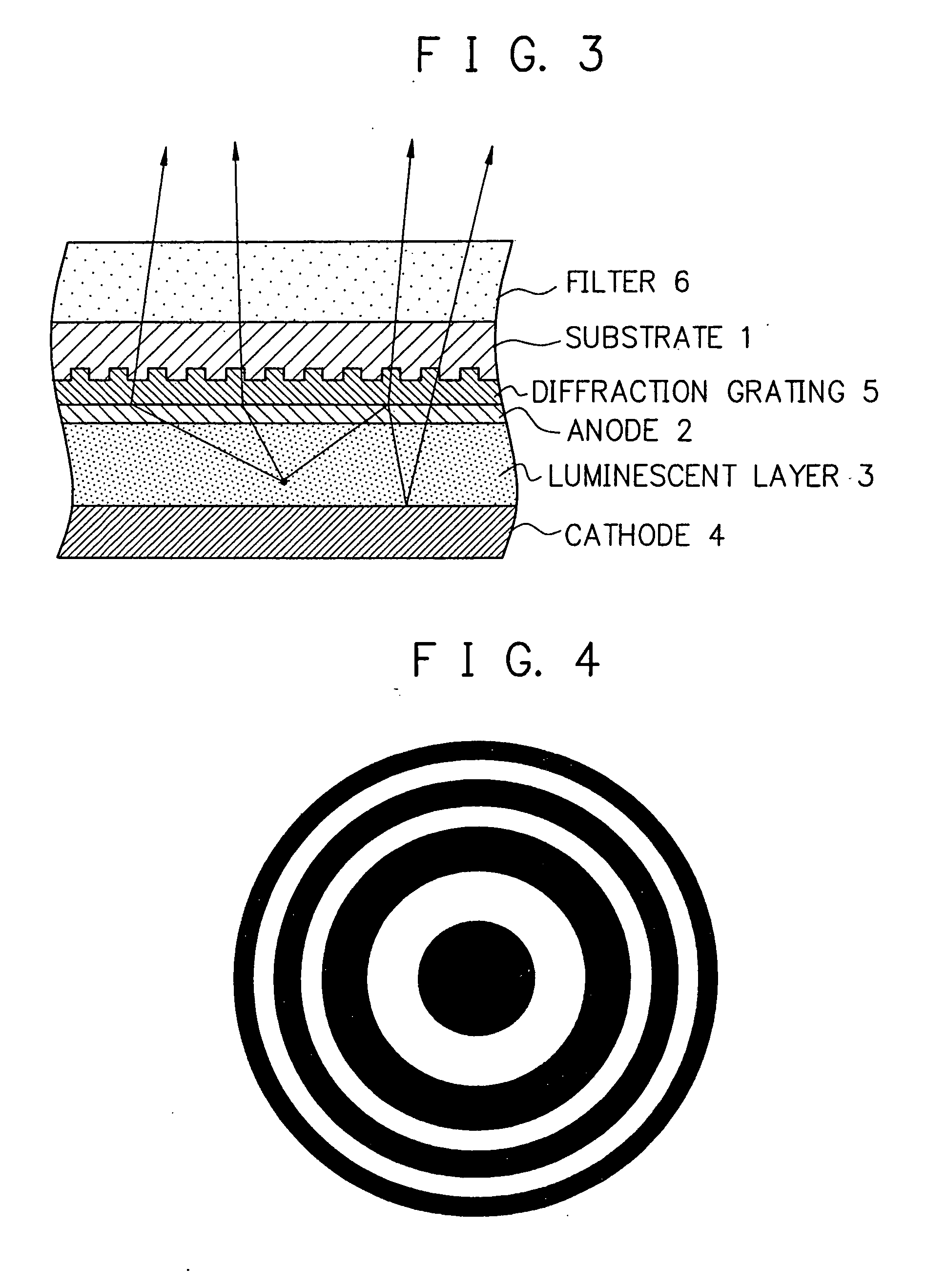

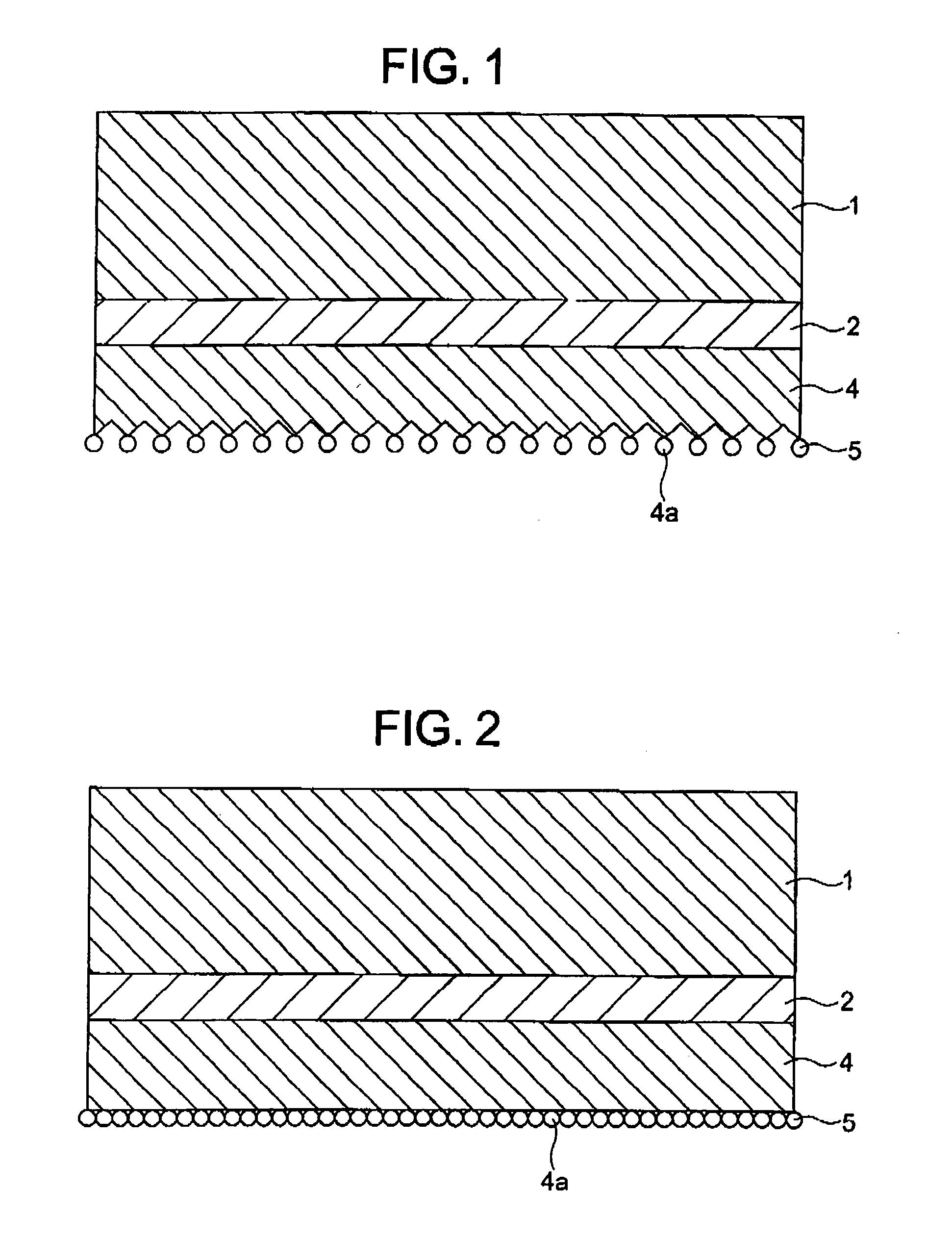

Light emitting device and manufacturing method thereof and display used this light emitting device

InactiveUS20050026530A1Exquisite patternSimple processDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceHue

A light emitting device and a manufacturing method thereof and a display used the light emitting device, in which fine patterning for the light emitting device is realized by a simple process and the light leakage is prevented and the efficiency at extracting light is increased, are provided. The light emitting device provides an organic electroluminescent (EL) device in which electrodes and a luminescent layer are formed, a diffraction grating or a zone plate, and a filter. Light emitted from the luminescent layer transmits through the diffraction grating or the zone plate, which is formed with a designated grating pitch, or is reflected at the diffraction grating or the zone plate. With this, the transmitting or reflecting light is controlled to be in a designated angle region. And when the light is transmitted through the filter, light having different color tone and chromaticity from those of the light emitted from the luminescent layer is extracted.

Owner:SAMSUNG DISPLAY CO LTD

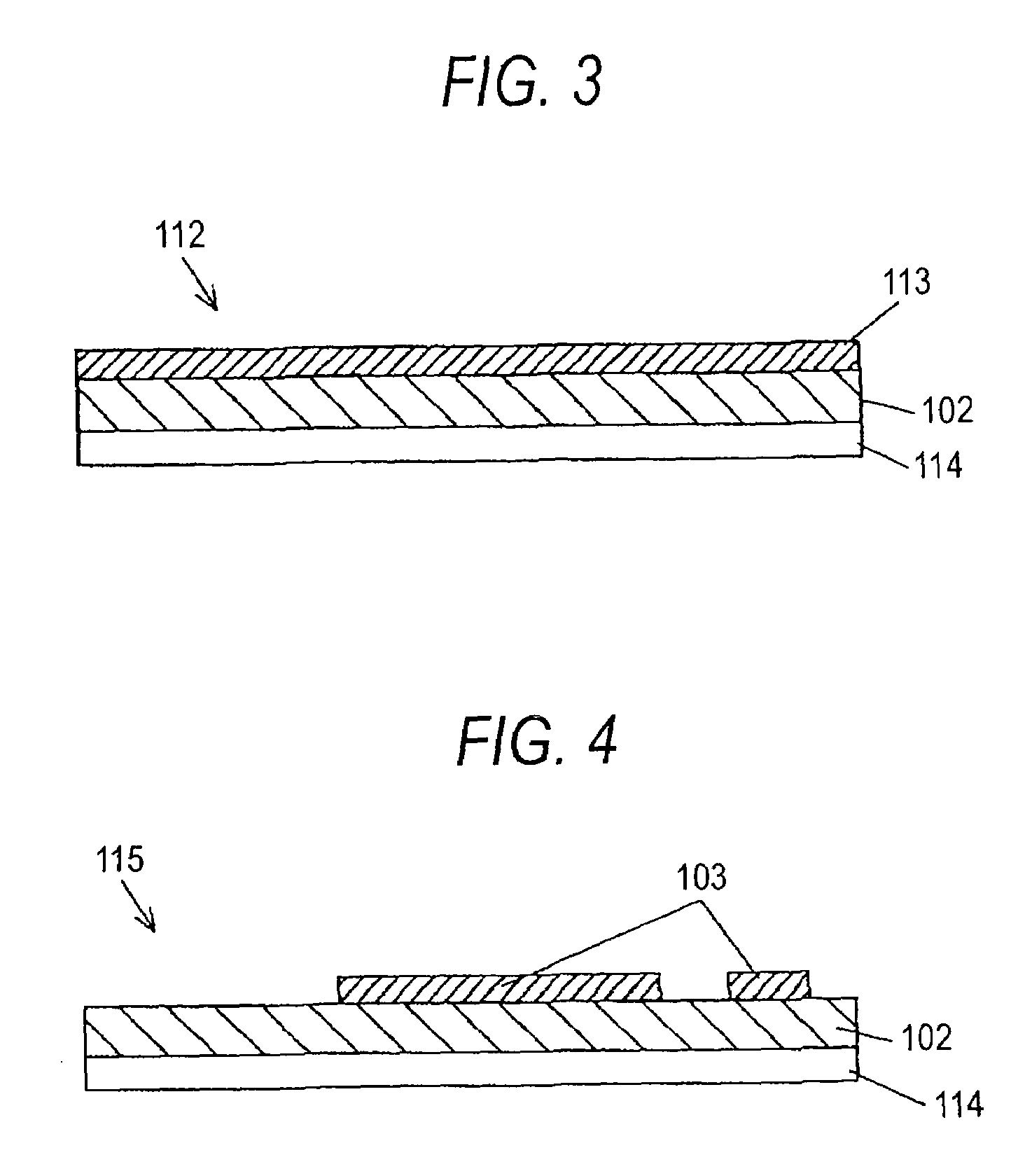

Multi-layered flexible print circuit board and manufacturing method thereof

InactiveUS7263769B2Improve connection reliabilityIncrease production capacityPrinted circuit assemblingElectrically conductive connectionsEngineeringFlexible electronics

A multi-layered flexible print circuit board comprising an insulating layer, a circuit layer formed on the front and back surfaces of the insulating layer and a hole connecting between the circuit layers via the insulating layer, wherein there is provided an electrically-conductive member having a metal layer formed thereon at least on the surface thereof which is press-fitted into the hole to electrically conduct the circuit layer.

Owner:PANASONIC CORP

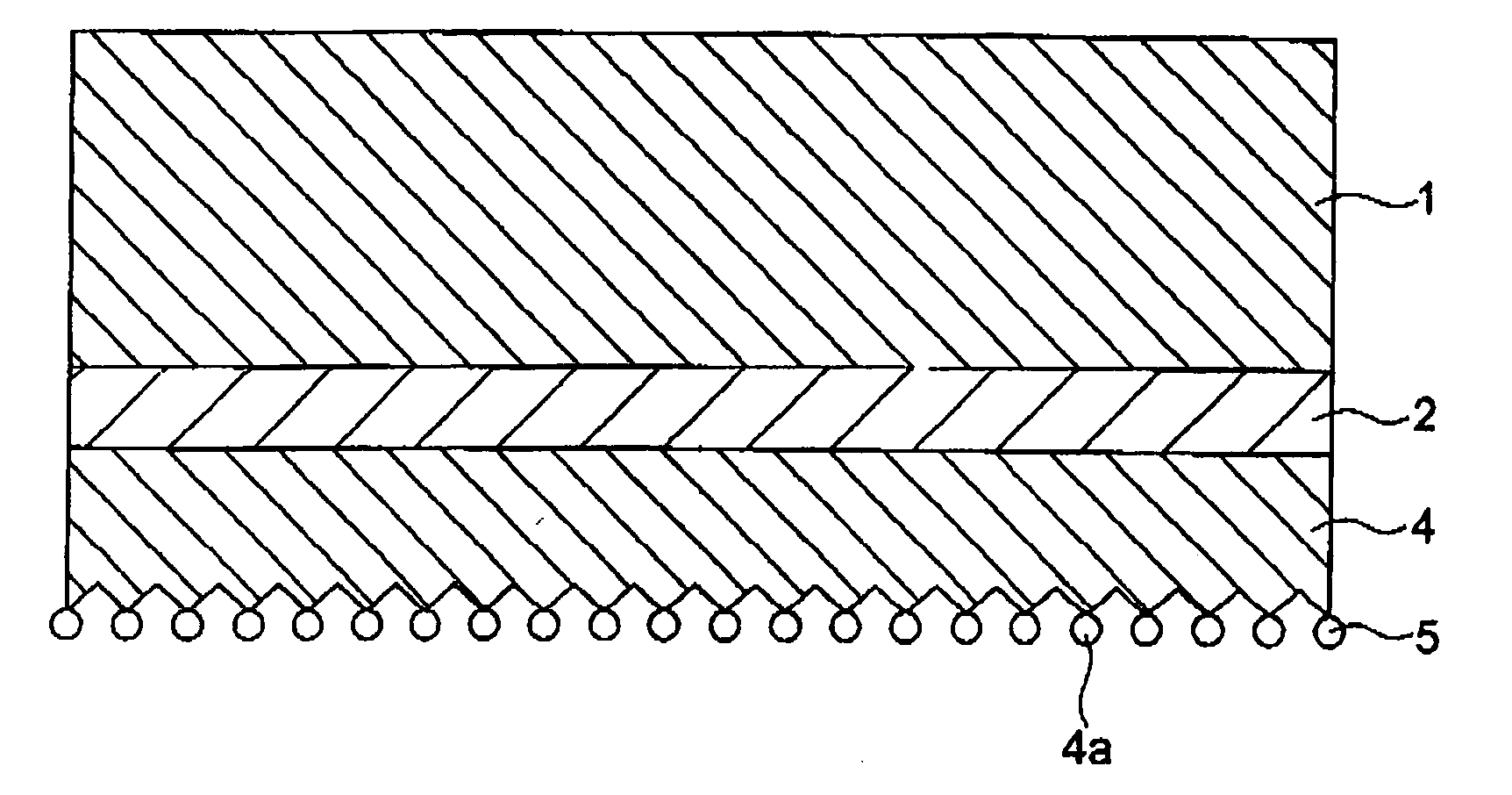

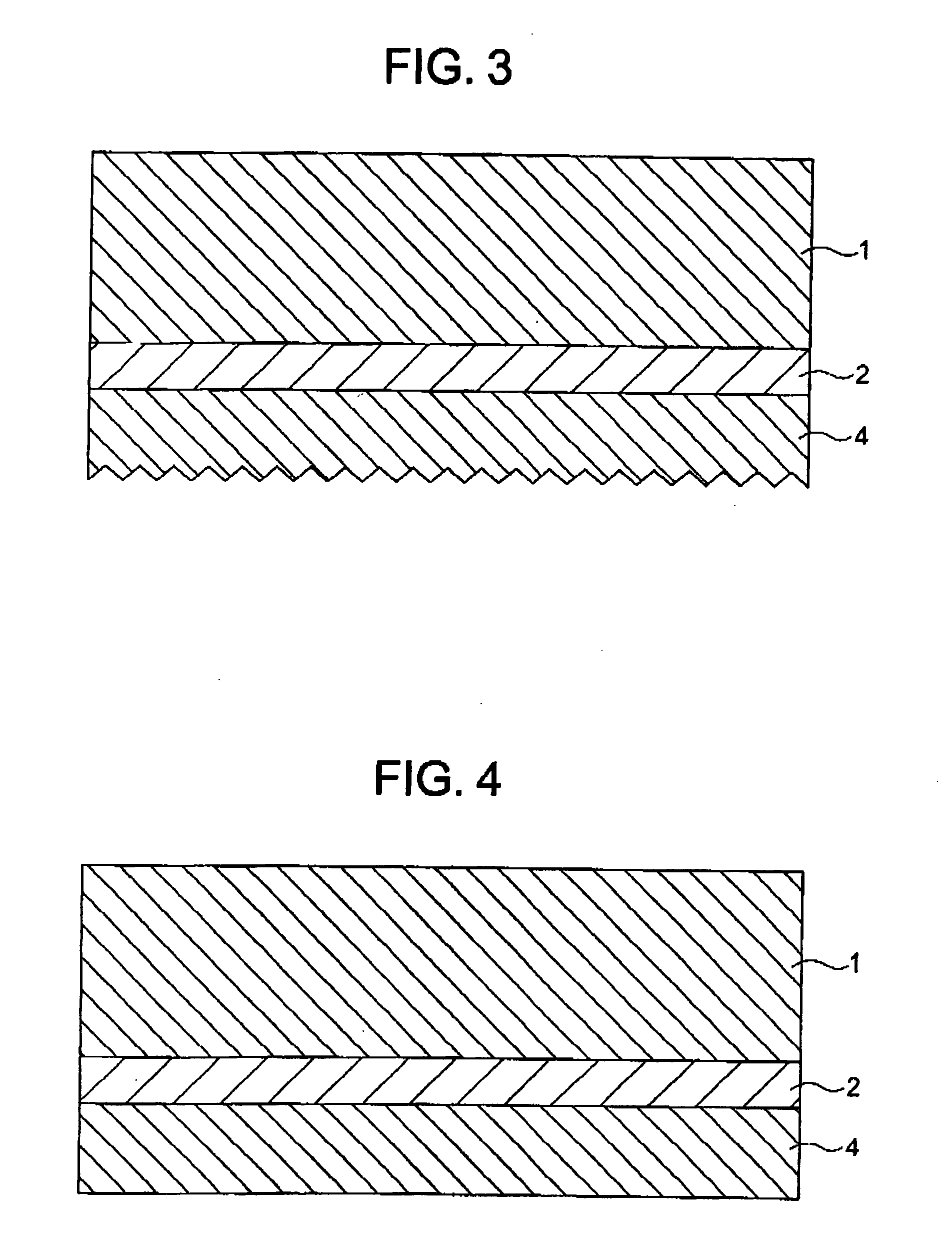

Ultra-thin copper foil with carrier and printed wiring board using ultra-thin copper foil with carrier

InactiveUS20050158574A1High peel strengthEasy wiringInsulating substrate metal adhesion improvementThermometers using material expansion/contactionSurface roughnessCopper foil

To produce an ultra-thin copper foil with a carrier foil that microscopic crystal grains can be deposited without being affected by the surface roughness of a carrier foil, etching can be performed until an ultra-fine width such that line / space is 15 μm or less, and the microscopic line and a wiring board have large peel strength even after line of 15 μm is etched. An ultra-thin copper foil wherein a carrier foil, a peeling layer, an ultra-thin copper foil are laminated in this order, the ultra-thin copper foil (before roughening treatment is performed) is an electrolytic copper foil that surface roughness of 2.5 μm as ten point height of roughness profile, and the minimum distance between peaks of salients of a based material is 5 μm or more. Moreover, the surface of the ultra-thin copper foil is performed roughening treatment.

Owner:FURUKAWA ELECTRIC CO LTD

Substrate processing apparatus and substrate processing method

ActiveUS20140022521A1Forming accuratelyPromotes microphase separationElectric discharge tubesPretreated surfacesPolymer sciencePolymer chemistry

An underlayer is formed to cover the upper surface of a substrate and a guide pattern is formed on the underlayer. A DSA film constituted by two types of polymers is formed in a region on the underlayer where the guide pattern is not formed. Thermal processing is performed while a solvent is supplied to the DSA film on the substrate. Thus, a microphase separation of the DSA film occurs. As a result, patterns made of the one polymer and patterns made of another polymer are formed. Exposure processing and development processing are performed in this order on the DSA film after the microphase separation such that the patterns made of another polymer are removed.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

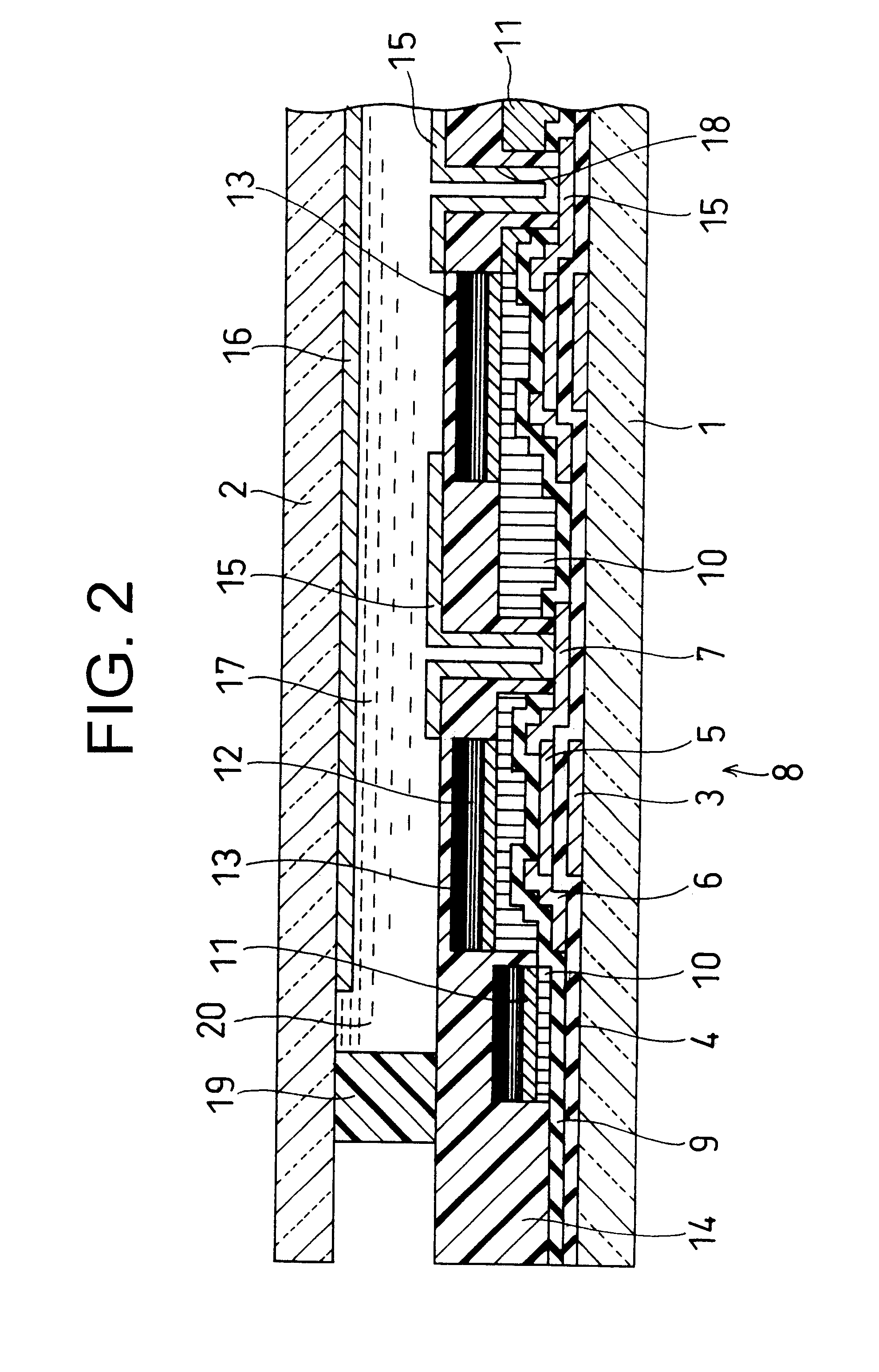

Piezoelectric substance, piezoelectric element, liquid discharge head using piezoelectric element, liquid discharge apparatus, and production method of piezoelectric element

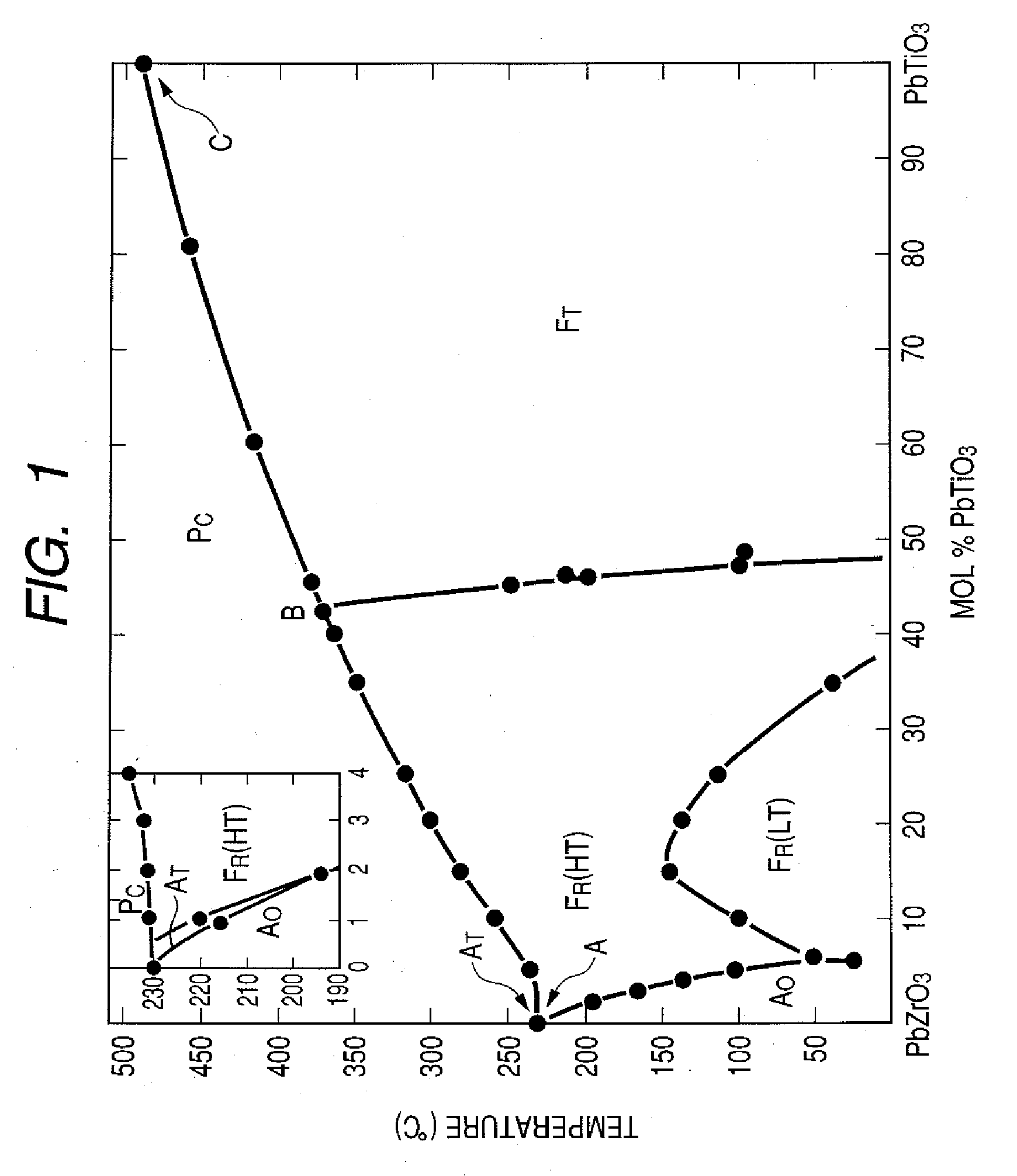

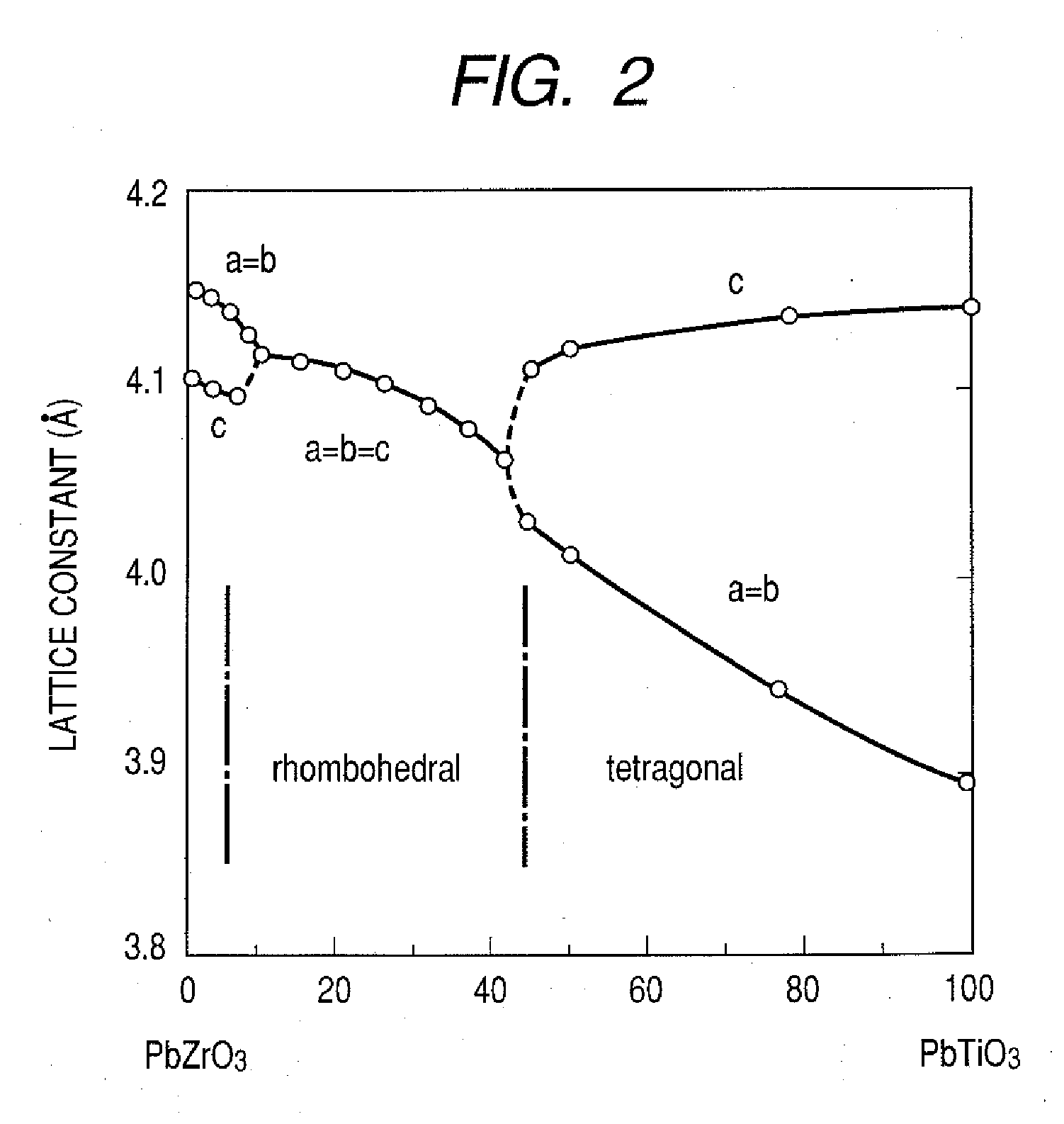

ActiveUS20070048190A1Large piezoelectricitySuppress leakage currentAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionCurie temperatureTitanium

A piezoelectric material, characterized in that a main component of the piezoelectric substance is PZT which has perovskite type structure expressed in Pb(ZrxTi1-x)O3 (1) (x expresses an element ratio Zr / (Zr+Ti) of Zr and Ti in the formula), an element ratio Pb / (Zr+Ti) of Pb, Zr and Ti of the piezoelectric substance is 1.05 or more, and an element ratio Zr / (Zr+Ti) of Zr and Ti is 0.2 to 0.8 inclusive, and a Curie temperature Tc of the piezoelectric substance and a Curie temperature Tc0 in a bulk at an element ratio of Zr and Ti of the piezoelectric substance satisfy relation of Tc>Tc0+50° C.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com