Making technology of pottery ware

A production process and pottery technology, applied in the field of tea set production, can solve the problems of easy wear and scratches after long-term use, unable to reflect the natural state, poor practical application effect, etc., achieving high practical value, facilitating promotion, and eliminating the need for ingredients the troublesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

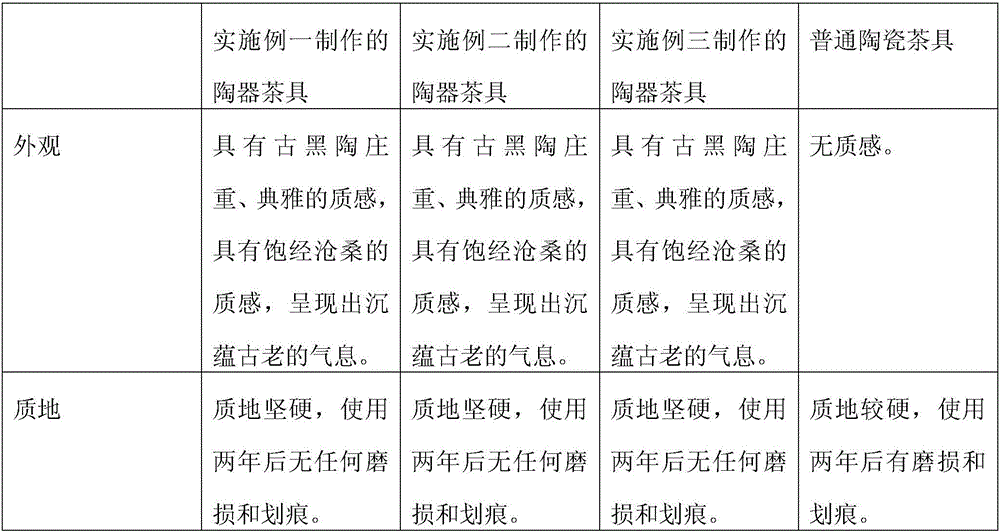

Examples

Embodiment 1

[0015] The manufacturing process of this kind of pottery includes the following steps:

[0016] The first step is the selection of raw materials. Gold silk red mud is selected as the main material for pottery, and then the selected gold silk red mud is first washed to remove impurities. After washing, it is precipitated. The precipitation time is 8 hours. After the precipitation is completed, take the sediment and place it in a cool and ventilated place for natural air drying. The natural air drying time is 16 hours. After natural air drying, a layered sediment is obtained. The upper layer of the sediment is a soft layer, and the lower layer is a hard layer. The soft layer and the hard layer of the sediment are lowered, and finally the soft layer and the hard layer are selected and mixed according to a ratio of 1:1 to obtain pottery raw materials;

[0017] The second step is the production of the porcelain body. The obtained pottery raw materials are mixed with water to form m...

Embodiment 2

[0023] The manufacturing process of this kind of pottery includes the following steps:

[0024] The first step is the selection of raw materials. Gold silk red mud is selected as the main material for pottery production, and then the selected gold silk red mud is first washed to remove impurities. After washing, it is precipitated. The precipitation time is 9 hours. , after the precipitation is completed, take the sediment and place it in a cool and ventilated place for natural air drying. The natural air drying time is 20 hours. Remove the soft layer and hard layer of the sediment, and finally select and mix the soft layer and hard layer according to the ratio of 1:1 to obtain pottery raw materials;

[0025] The second step is the production of the porcelain body. The obtained pottery raw materials are mixed with water to form mud. The ratio of water to pottery raw materials is 0.6:1. Prepare the ceramic body by hand drawing the mud material, and then place the prepared porc...

Embodiment 3

[0031] The manufacturing process of this kind of pottery includes the following steps:

[0032] The first step is the selection of raw materials. Gold silk red mud is selected as the main material for pottery production, and then the selected gold silk red mud is first washed to remove impurities. After washing, it is precipitated. The precipitation time is 10 hours. After the precipitation is completed, take the sediment and place it in a cool and ventilated place for natural air-drying. The natural air-drying time is 24 hours. Remove the soft layer and hard layer of the sediment, and finally select and mix the soft layer and hard layer according to the ratio of 1:1 to obtain pottery raw materials;

[0033] The second step is the production of the porcelain body. The obtained pottery raw materials are mixed with water to form mud. The ratio of water to pottery raw materials is 0.6:1. Prepare the ceramic body by hand drawing the mud material, and then place the prepared porce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com