Jian tea bowl firing process

A process and green body technology, which is applied in the field of sintering process, can solve the problems of unclear formula selection and temperature control, high energy consumption, rare rabbit hair, etc., and achieves high artistic value and appreciation value, and the process flow is clear. , the effect of beautiful stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Jianzhan firing process is characterized in that it comprises the following steps:

[0044] (1) prepare body raw materials and glaze slurry;

[0045] The green body raw material is prepared by the following method: mixing 4 parts by weight of red mud, 3 parts by weight of white mud and 20 parts by weight of field mud, pulverizing, elutriating, passing through a 100-mesh sieve, pressing filtration, and then adding 0.2 parts by weight 1 part of leaf powder, smelting and stale for 15 days to obtain the green body raw material;

[0046] Described leaf powder is that dry maple leaf is ground into 100 orders;

[0047] The glaze slurry is prepared by the following method: 80 parts by weight of glaze stone, 30 parts by weight of potassium feldspar, 10 parts by weight of talc, 20 parts by weight of limestone, 5 parts by weight of calcite, 1 part by weight of iron red, Mix 10 parts by weight of Taihu mud and 5 parts by weight of yellow mud, add 1.2 times by weight of water and ...

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is:

[0063] Step (5) is replaced by: putting the qualified green body into the kiln again for roasting, and the roasting passes through the following stages:

[0064] The first stage: the temperature of the kiln is raised from normal temperature to 300°C at a constant speed after 40 minutes; the temperature of the kiln is raised from 300°C to 900°C at a constant speed after another 90 minutes;

[0065] The second stage: the temperature of the kiln is raised from 900°C to 1200°C at a constant speed after another 150 minutes;

[0066] The third stage: heat preservation at 1200°C for 3 hours, and when the heat preservation reaches 2 hours, put in 250g of oil firewood per cubic meter of kiln space, once every 10 minutes, and throw in 3 times in total;

[0067] The fourth stage: stop the furnace, cool naturally, and leave the kiln.

[0068] refer to figure 2 , the Rabbit Hair Jianzhan obtained in this example is a ...

Embodiment 3

[0071] The difference between this embodiment and embodiment 1 is:

[0072] Replace the fourth stage of step (5) with: stop the furnace, open the kiln door, close the kiln door when the temperature of the kiln drops to 1180°C, and put in 80g of fuel oil per cubic meter of kiln space, every 3 minutes Throw once, 7 times in total, starting from the second time, the amount of diesel fuel is reduced by 5g per cubic meter of kiln space each time; 2 minutes after the last throw, open the firewood inlet for 3 minutes to reduce the reducing atmosphere, and then close the throw Chaikou.

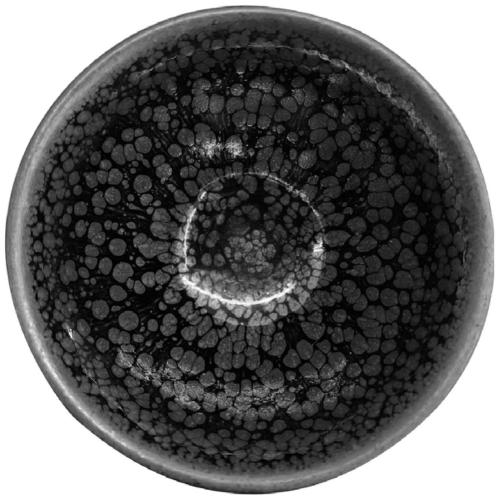

[0073] The Jianzhan obtained in this example is a partridge-spotted Jianzhan, the color of the glaze is silver blue, slightly tinged, and the spots are round or oval, with different sizes, roughly lustrous yellow-brown, distributed or Dense or sparse, the shape is like boiling oil droplets, and it shines like oil droplets on the water surface.

[0074] According to this embodiment, the yield is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com