Device for detecting and signaling a physical value when connected to a rim, and rim comprising such a device

a technology for detecting and signaling a physical value, which is applied in the direction of vehicle tyre testing, instruments, roads, etc., can solve the problems of not being able to visually check if the sensor is still fastened correctly, screwing a wheel sensor to the tire valve, and being more expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

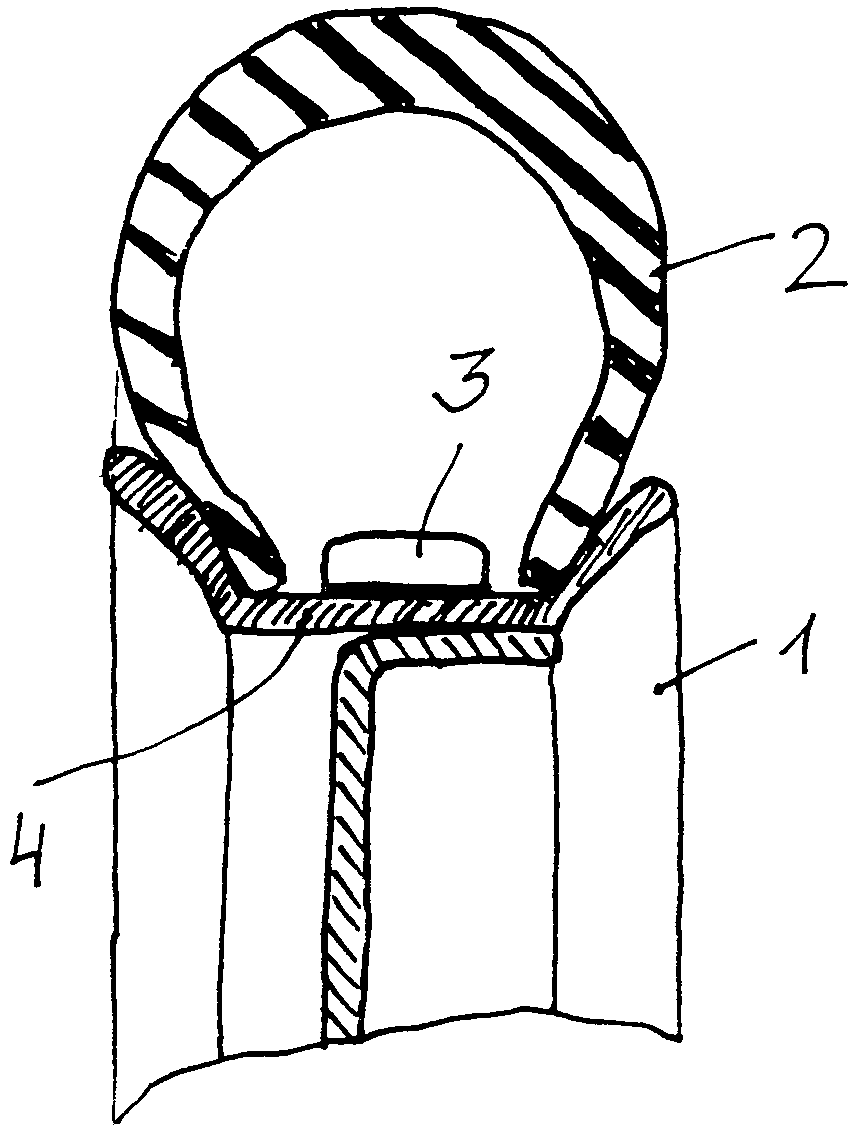

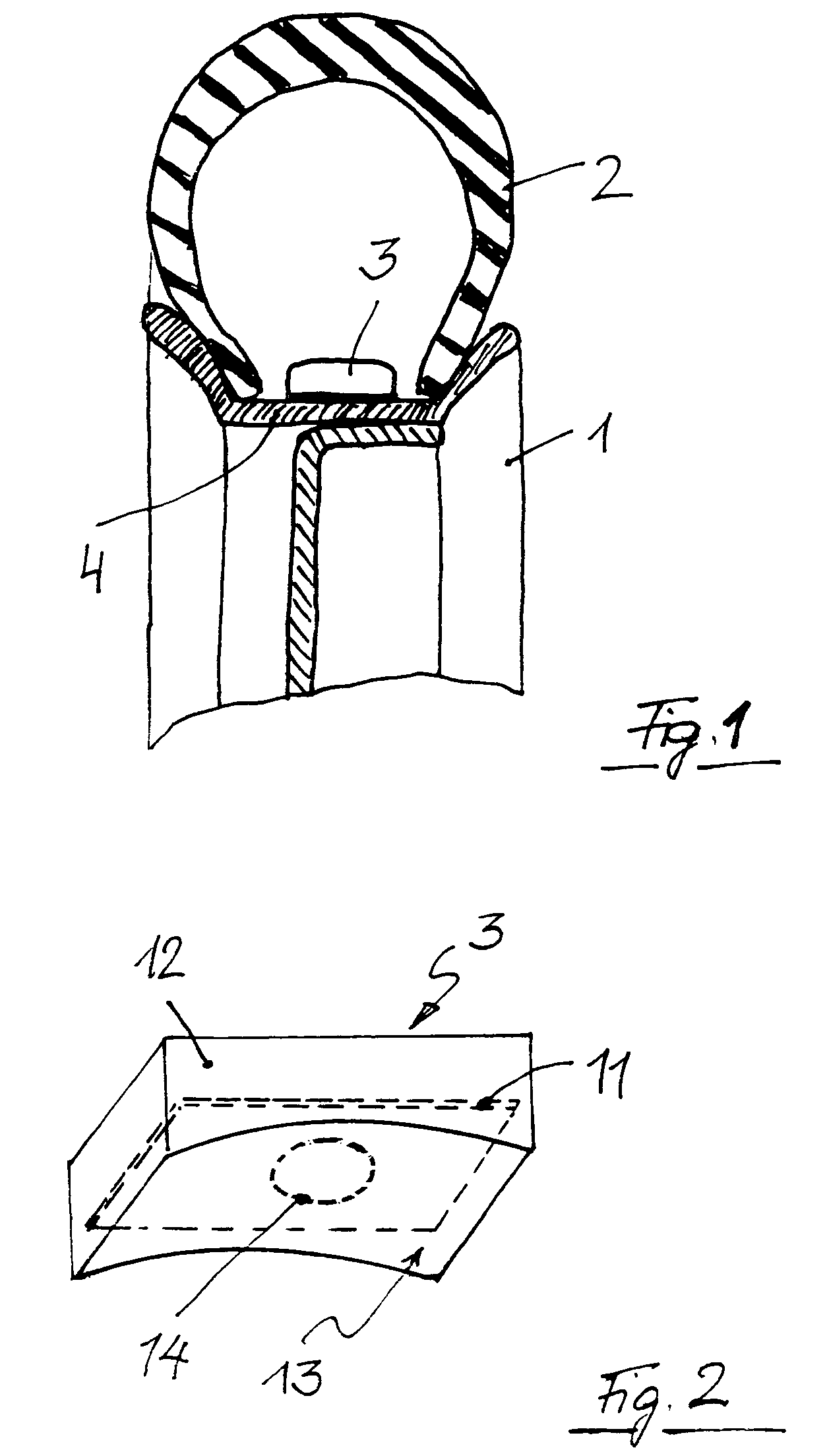

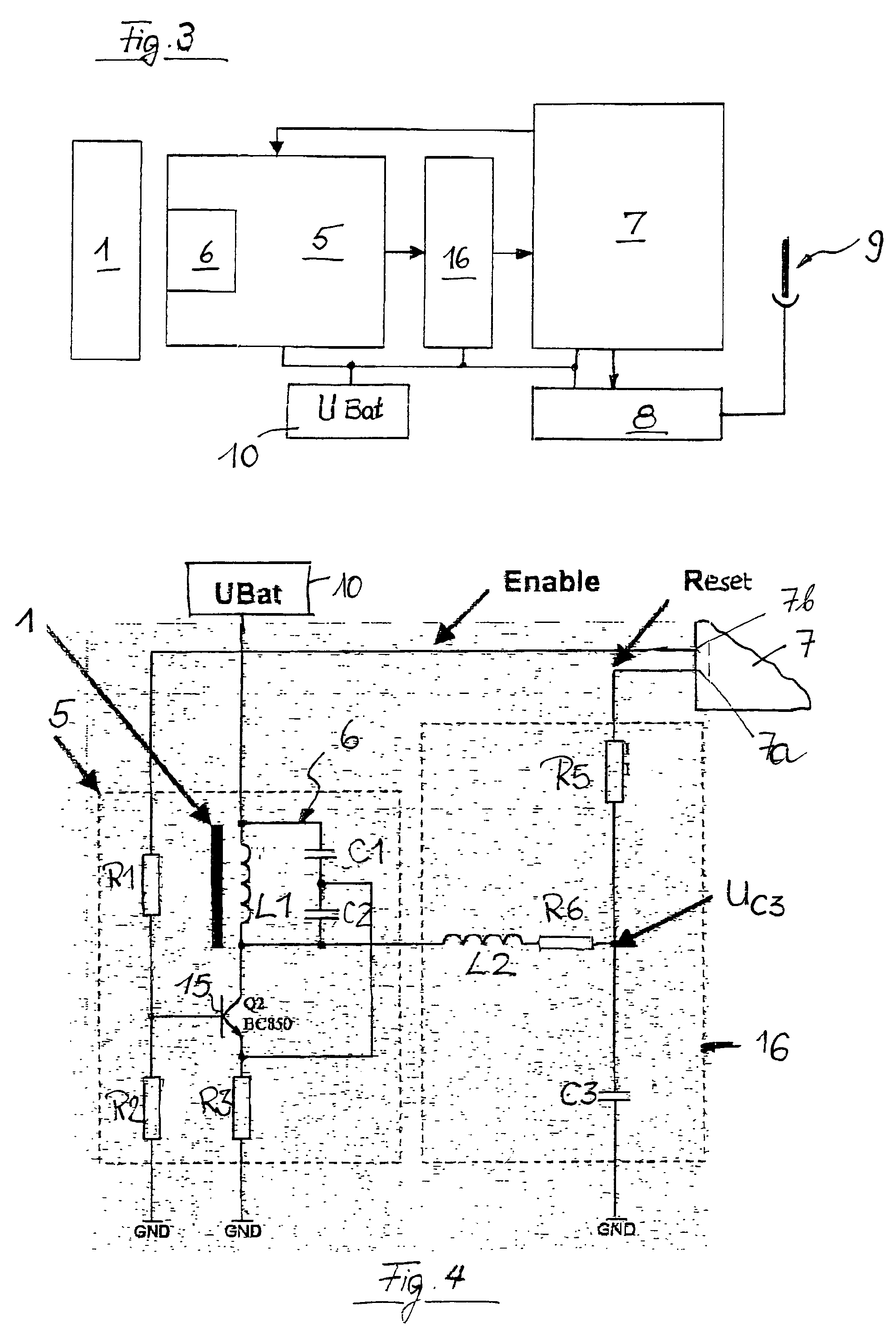

[0028]FIG. 1 shows a wheel having a rim 1 made from metal, especially from steel or aluminium. A pneumatic tire 2 is mounted on the rim 1. A wheel sensor 3, arranged below the pneumatic tire 2, is mounted on the rim base 4, for example by bonding. The wheel sensor 3 mainly serves for monitoring air pressure in the tire 2 and comprises for this purpose a pressure sensor, preferably also a temperature sensor and an acceleration sensor, further a control circuit equipped with a microprocessor or an ASIC, and means for signaling the values so measured by means of a radio transmitter and an antenna. The measured values obtained are digitally encoded, supplemented by an identification code defining the particular wheel sensor 3, and are transmitted by radio via a data bus to a receiver and evaluation unit arranged in the vehicle. The energy for the wheel sensor 3 is conveniently supplied by a battery 10—see FIGS. 3 and 4—but could be injected as well from the outside, by a sampling transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com