Manufacturing technology of iron covering silver kettle

A manufacturing process, silver pot technology, applied in the field of iron-clad silver integrated pot manufacturing process, can solve the problems of poor artistry, high difficulty, increased processing difficulty, etc., to achieve the effect of improving fit, eliminating gaps, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

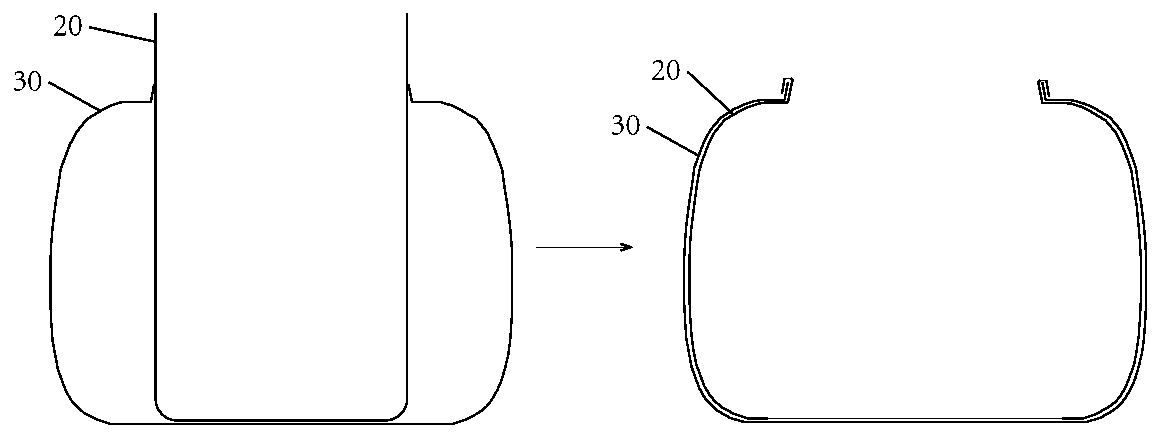

[0043] like Figure 2 to Figure 5 As shown, a kind of iron-clad silver pot manufacturing process that the present invention proposes comprises the following steps:

[0044] S1, blanking, cutting to obtain a circular silver plate 2, and cutting to obtain a circular or ring-shaped iron plate 3;

[0045] S2, forming the silver pot, forming the silver plate 2 into an arc-shaped silver pot core 20, and completing the molding by hand;

[0046] S3. Forming and covering the iron pot, forming the iron plate 3 into an arc-shaped or cylindrical iron pot shell 30, and then putting the iron pot shell 30 outside the silver pot core 20, or directly placing the iron plate 3 on the silver pot core Molding is carried out on 20, and the molding is completed by hand, and the temperature of the iron plate is kept at 580-630°C by spray gun or gas welding for annealing and molding.

[0047] S4, pot body shaping, shaping the upper part of the pot body into a pot shape, ensuring that the inner wall ...

Embodiment 2

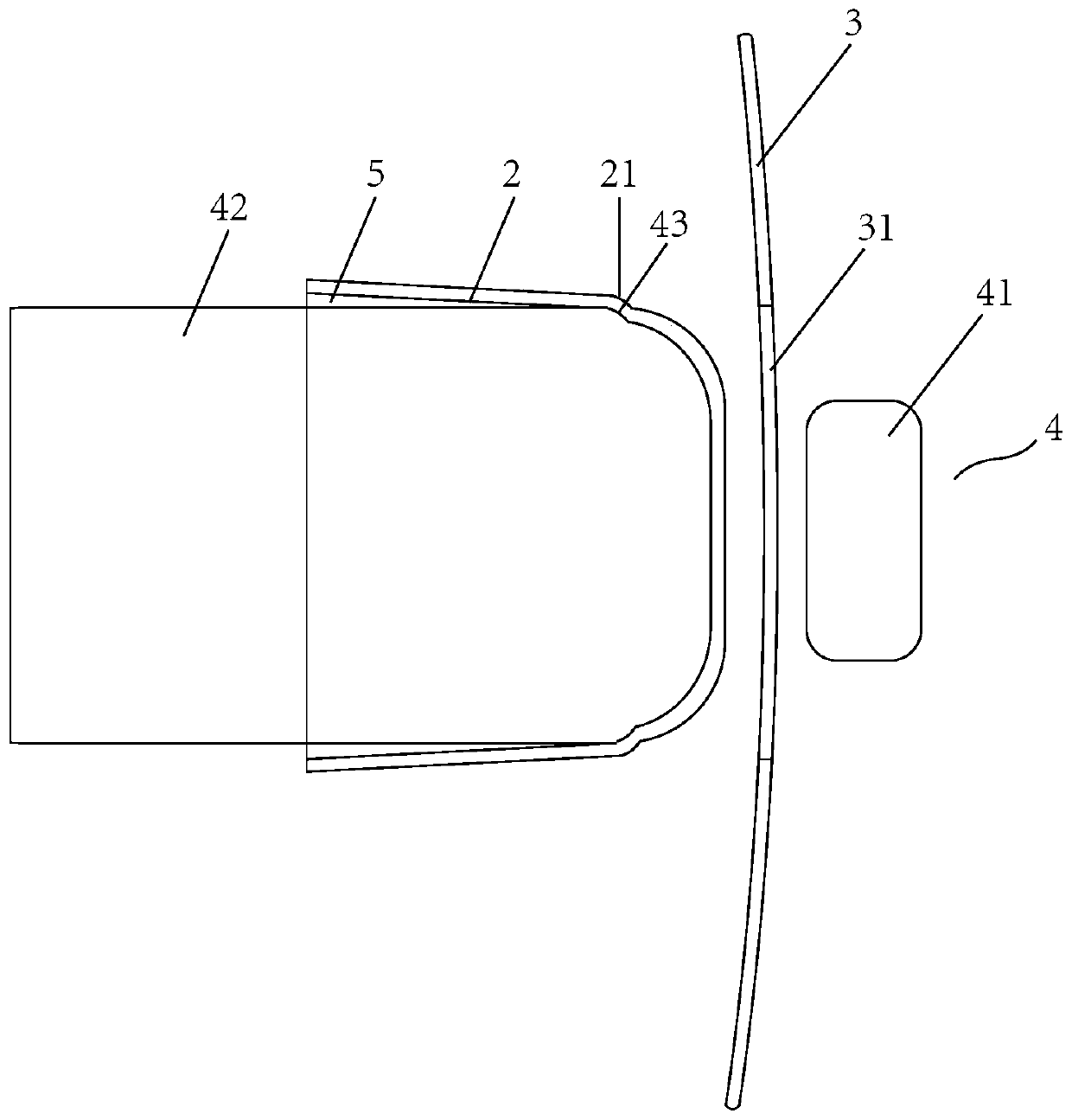

[0052] like figure 1 As shown, a kind of iron-clad silver pot manufacturing process that the present invention proposes comprises the following steps:

[0053] S1, blanking, cutting to obtain a circular silver plate 2, and cutting to obtain a circular iron plate 3;

[0054] S2, forming the silver pot, spinning the silver plate 2 into a silver pot core 20 through a spinning forming device;

[0055] S3. Forming and coating the iron pot, forming the iron plate 3 into an arc-shaped iron pot shell 30, and then putting the iron pot shell 30 on the outside of the silver pot core 20, and spinning the formed iron pot shell 30 by the silver pot core The bottom of the 20 is placed outside the silver pot core 20, and when the iron plate 3 is formed into an iron pot shell 30, the iron plate 3 is spun and formed into an iron pot shell 30 by a spinning forming device;

[0056] S4, pot body shaping, shaping the upper part of the pot body into a pot shape, ensuring that the inner wall of the...

Embodiment 3

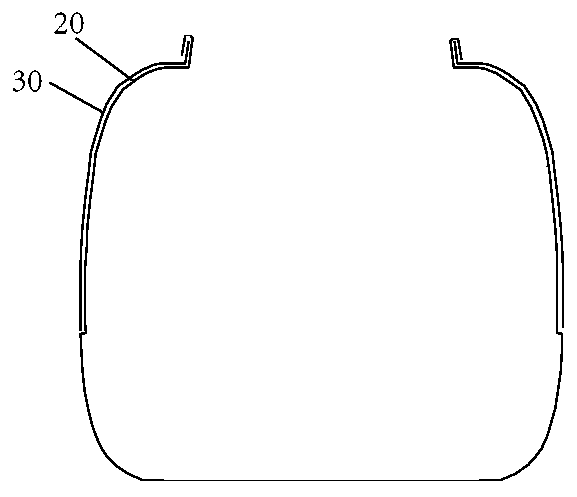

[0060] A kind of iron clad silver pot manufacturing process that the present invention proposes, comprises the following steps:

[0061] S1, blanking, cutting to obtain a circular silver plate 2, and cutting to obtain a circular iron plate 3;

[0062] S2, forming the silver pot, spinning the silver plate 2 into a silver pot core 20 through a spinning forming device;

[0063] S3, forming and cladding of the iron pot, when the iron plate 3 is formed into an arc-shaped iron pot shell 30, the iron plate 3 is directly molded on the silver pot core 20, and when the iron plate 3 is formed into the iron pot shell 30, The iron plate 3 is formed into an iron kettle shell 30 by spinning with a spinning forming device;

[0064] S4, pot body shaping, shaping the upper part of the pot body into a pot shape, ensuring that the inner wall of the iron pot shell 30 and the outer wall of the silver pot core 20 are closely attached during shaping;

[0065] S5. Finished pot processing, matching l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com