Patents

Literature

116results about How to "Non-deformable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material of imitated glass reinforced plastic, its manufacture method and its application

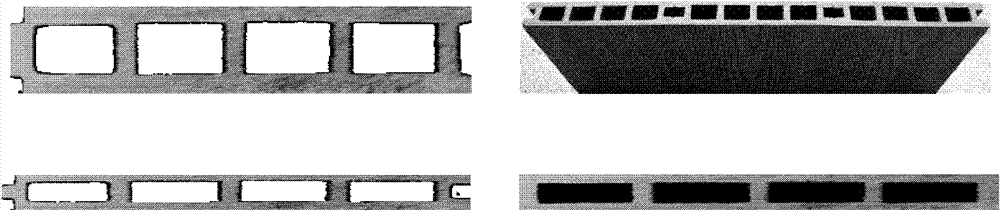

The invention discloses a composite material of an imitated glass reinforced plastic, which comprises a basic layer, the basic layer comprises the following ingredients by weight: 120-160 parts of active light calcium carbonate powder, 60-130 parts of recovered plastic, 30-60 parts of glass fiber and / or basalt fiber, 10-30 parts of coupling agent, 1-30 parts of foaming agent, 30-60 parts of processing auxiliary agent and 1-5 parts of stabilizing agent. The composite material also comprises a superficial layer and a filling layer. The composite material can replace a plurality of glass reinforced plastic products, steel products, stone products, ceramic products, wood products and plastic products. The composite material possesses the characteristics of wood, such as nailing, sawing, pasting and shaving, and enables secondary processing; and has the characteristics of B-1 grade fire protection, insect protection, no fumigation, water resistance, corrosion resistance, rust resistance, sound insulation, heat insulation, light weight, high intensity, impact resistance, strong plasticity, good physical properties, long service life, no formaldehyde containing, no radiation, acid and alkali resistance, hot and cold resistance, ultraviolet resistance, no paint requirement, easy construction, recoverable property, regeneration and utilization and the like.

Owner:黄云清

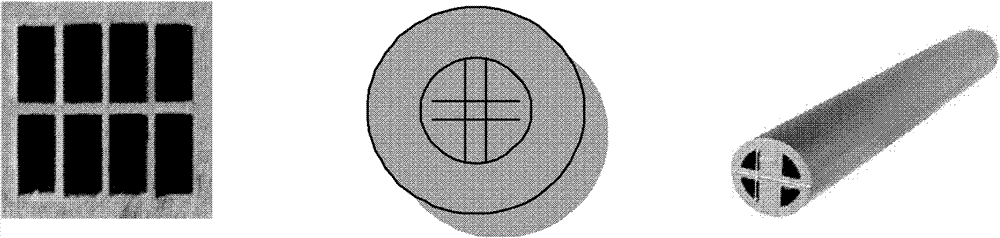

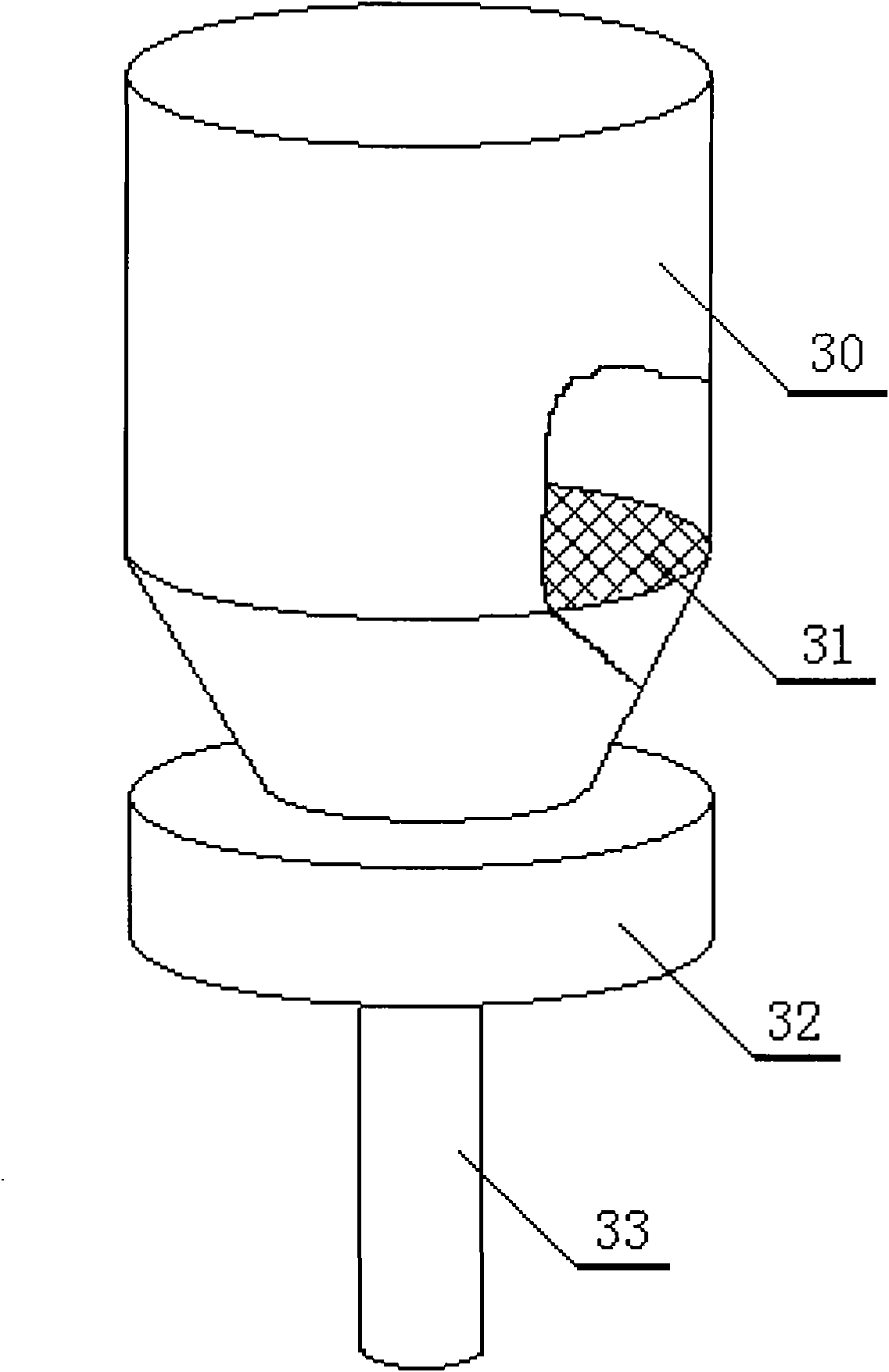

Forming method of wall-flow type honeycomb ceramic carrier

ActiveCN101117289AHigh temperature resistantNon-deformableCatalyst carriersExhaust apparatusMicrowave ovenMethylcellulose Powder

The invention relates to a forming method of a wall flow type honeycomb ceramics carrier billet for collection of diesel engine tail gas particles. A mixture power of pure silicon carbide and methylcellulose is stirred evenly and is poured into a stirring mill and then is stirred to make the silicon carbide power and the methylcellulose mix ed evenly; a flour water solution of water and flour is stirred evenly and poured into the stirring mill with stirring and makes the pug stirred evenly enough; tung oil is added into the stirred pug, and is stirred for a plurality of minutes, when the pug can be felted together, the pug is put into a container and is sealed to guarantee that the water in the pug can not be vaporized, and is kept musty for one day; after milled and extruded to be formed, the pug is dried by a microwave oven, finally holes are filled, after the pug is parched, dried and fired, then the billet is obtained.

Owner:GUIZHOU HUANGDI DIESEL ENGINE CLEANER

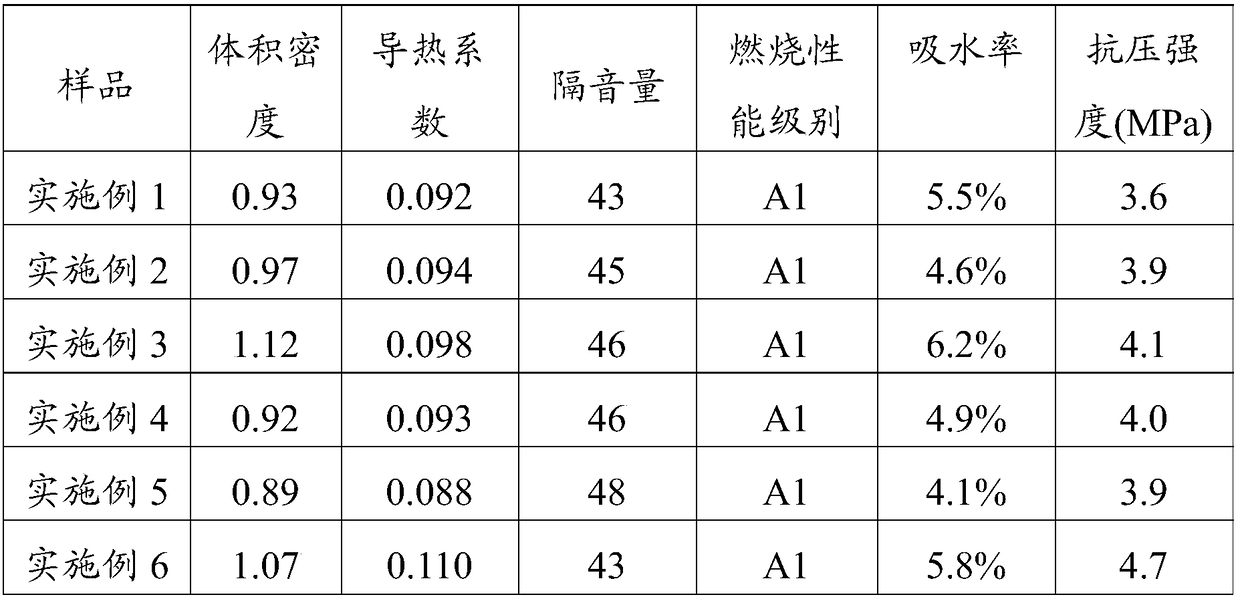

Fiber-reinforced fireproof insulation board and preparation process thereof

InactiveCN103979918AOvercome defectsAvoid defectsSolid waste managementClimate change adaptationCalcium formateFire retardant

The invention discloses a fiber-reinforced fireproof insulation board. The fiber-reinforced fireproof insulation board is prepared from the raw materials in parts by weight: 80-100 parts of fly ash, 30-50 parts of expanded perlite, 10-20 parts of ceramsite, 10-20 parts of plant fiber, 5-10 parts of floating bead, 5-8 parts of meerschaum, 3-5 parts of sodium fluosilicate, 3-5 parts of calcium formate, 3-5 parts of flame retardant, 0.1-0.5 part of oleic triisopropanolamine and 0.1-0.3 part of glycol dimethyl ether. According to the fiber-reinforced fireproof insulation board, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; through the organic combination and generated synergism of the fly ash, lightweight aggregate and additives, the defects in the existing building insulation boards can be effectively overcome.

Owner:秦菊霞

Plant fiber reinforced inorganic light composite and preparation method thereof

InactiveCN106747031APrevent shrinkageFast condensationSolid waste managementCeramicwareMagnesium chloride hexahydrateFlexural strength

The invention discloses a plant fiber reinforced inorganic light composite which is mainly prepared from magnesium chloride hexahydrate, magnesium sulfate heptahydrate, light calcined magnesia, water, a water reducer, a reinforcing agent, reinforcing fibers, a foaming agent, an exciting agent, a stabilizer and adjusting admixture. The preparation method comprises steps as follows: magnesium chloride hexahydrate, magnesium sulfate heptahydrate and water are mixed to be made into a saline solution; light calcined magnesia, the water reducer and the reinforcing agent are added to the saline solution, the mixture is stirred at a constant speed, and an inorganic sizing material is obtained; the reinforcing fibers are added to the inorganic sizing material and stirred at a constant speed, the adjusting admixture, the stabilizer and the exciting agent are dropwise added slowly, finally, the foaming agent is added quickly, the mixture is stirred at a high speed, and a foamed inorganic sizing material is obtained; the foamed inorganic sizing material is poured into a die, left to stand for foaming, removed from the die and maintained, and the plant fiber reinforced inorganic light composite is obtained. The composite has the advantages of high pressure resistance, high bending resistance, low density, no formaldehyde, aging resistance, mildew resistance, termite resistance, moisture-proof performance, no deformation, sound and heat insulation, good heat preservation and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Anti-drop diamond brad and manufacturing process thereof

The invention discloses an anti-drop diamond brad, which comprises a cutter bit, a matrix and a base, and is characterized in that: the cutter bit is prepared from uniform powder prepared by mixing a soft matrix material and a superfine diamond in an irregular shape through hot-pressing sinter molding, wherein the soft matrix material consists of the following components in percentage by weight: 15 to 25 percent of copper, cobalt and iron alloy, 45 to 85 percent of bronze powder, 2 to 5 percent of tin powder, 5 to 10 percent of nickel powder, 2 to 5 percent of titanium powder, 2 to 6 percent of zinc powder and a proper amount of filler; the superfine diamond has the concentration of 12 to 25 percent; and a dovetail groove connecting mechanism is arranged on opposite surfaces of the cutterbit and the matrix. The diamond cutter bit is reasonable in components and proportion, the cutter bit has high bending strength and good self-sharpening property, and a holding force of diamond particles is improved; moreover, the dovetail groove connecting mechanism is arranged between the cutter bit and the matrix, so that the diamond cutter bit is firmly connected with the matrix, the phenomenon that the diamond cutter bit drops is avoided, potential safety hazards are eliminated, and the service life of the diamond brad is prolonged.

Owner:福建省泉州万龙石业有限公司

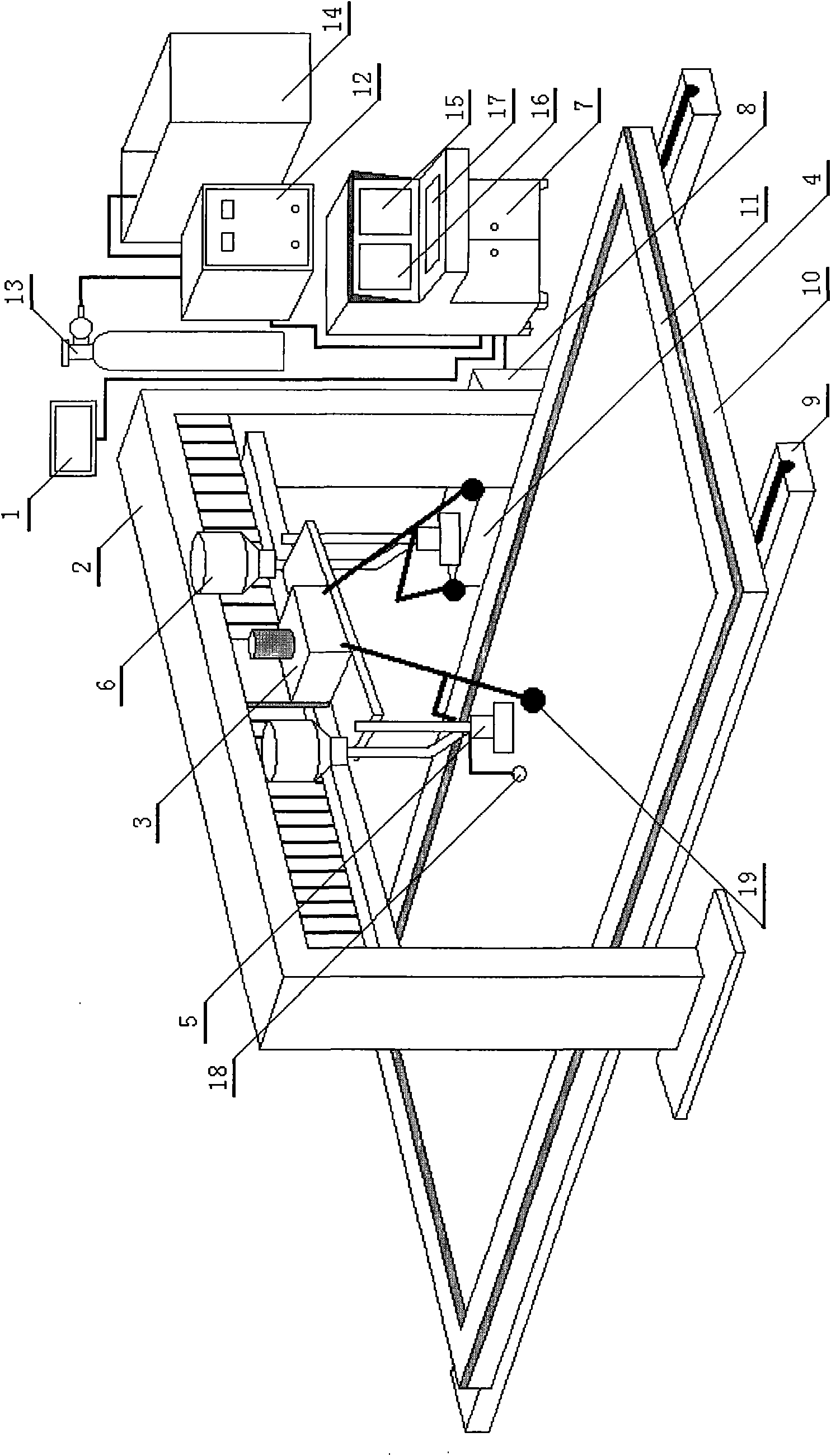

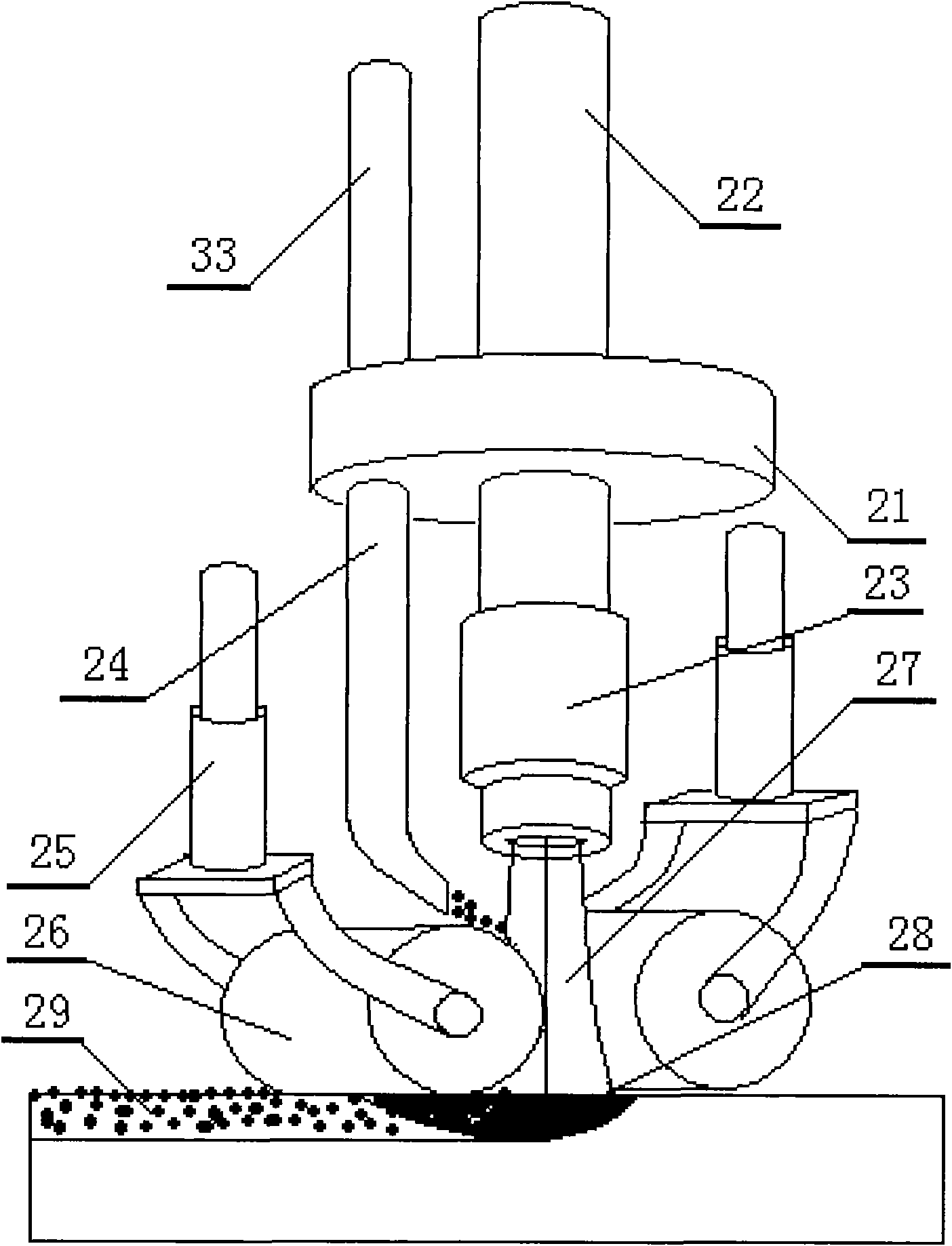

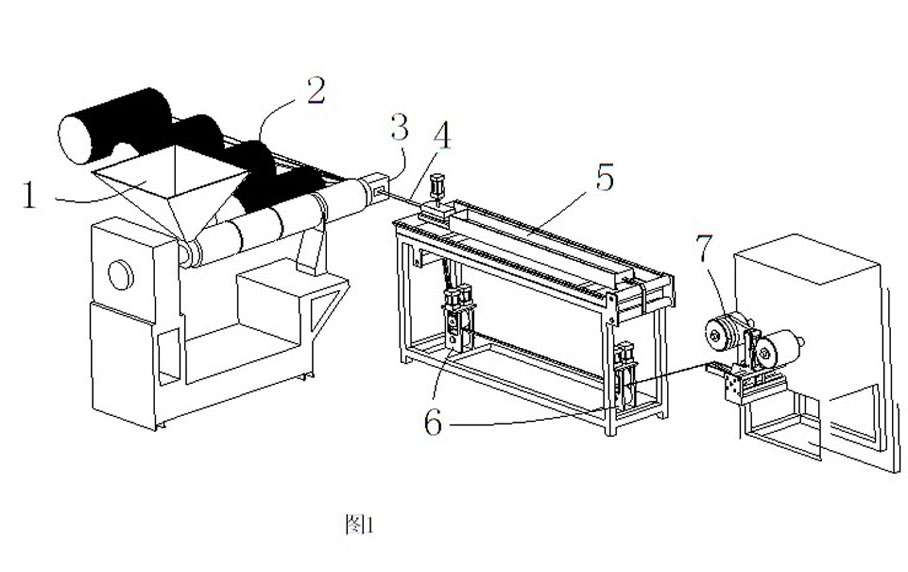

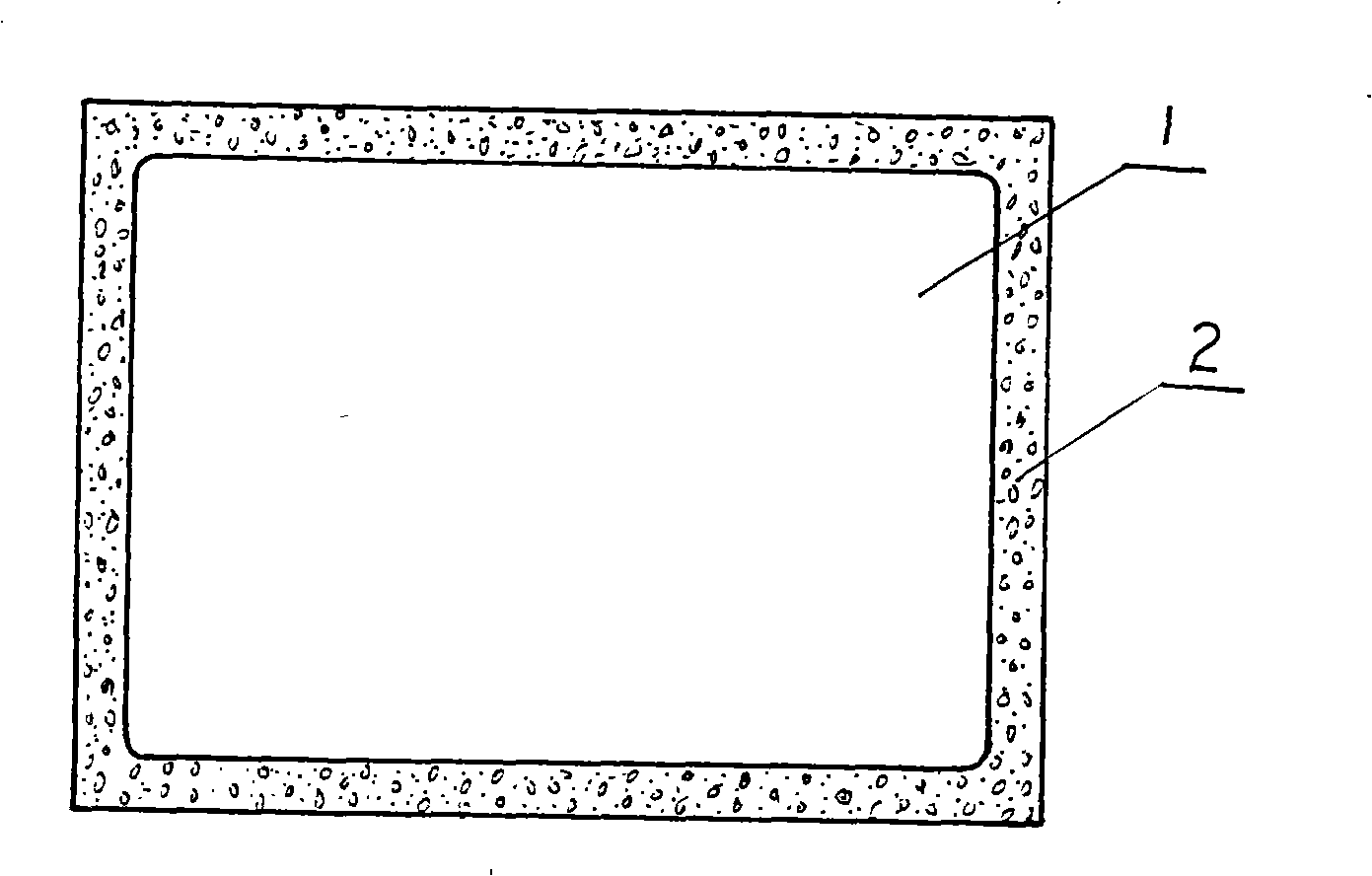

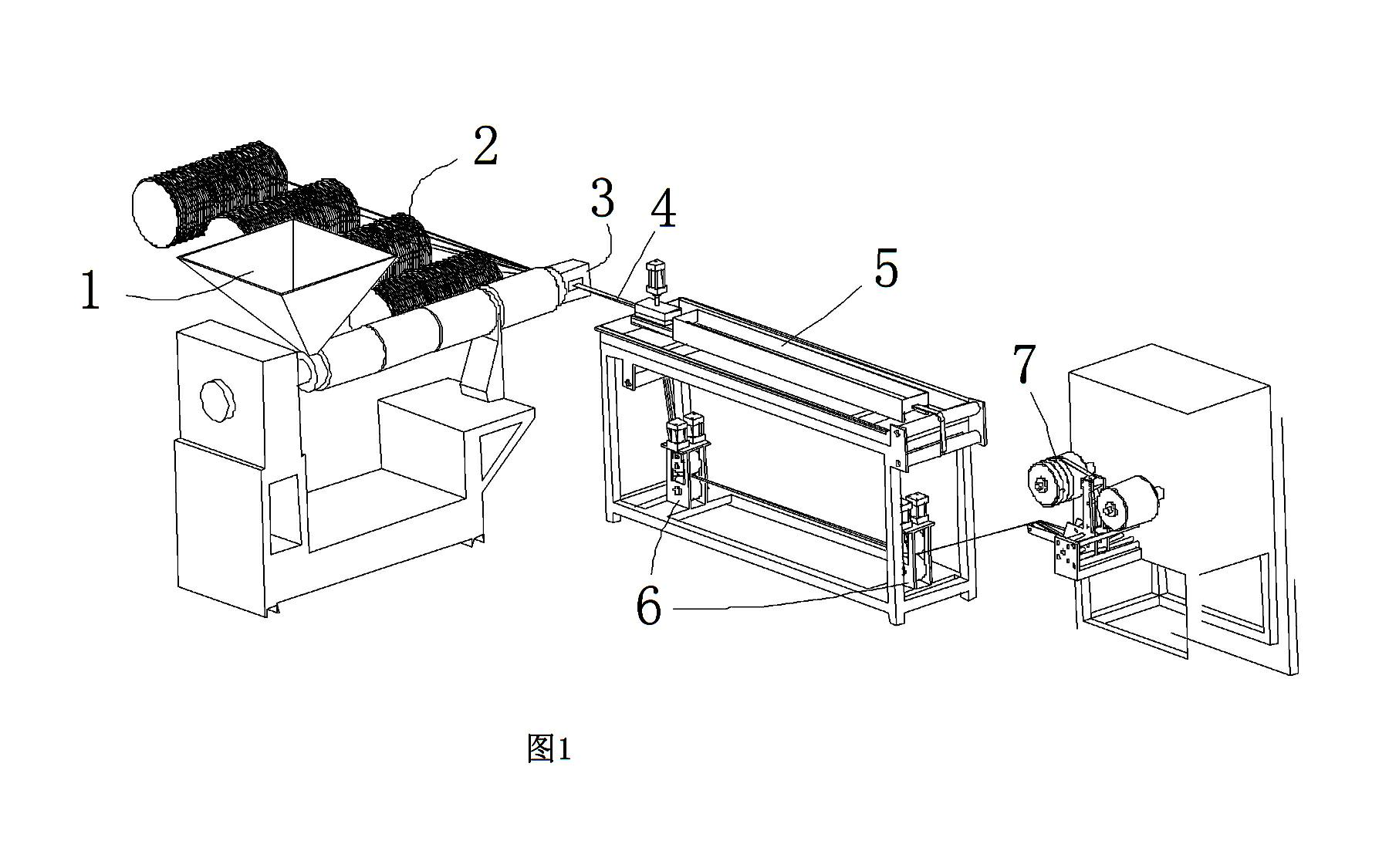

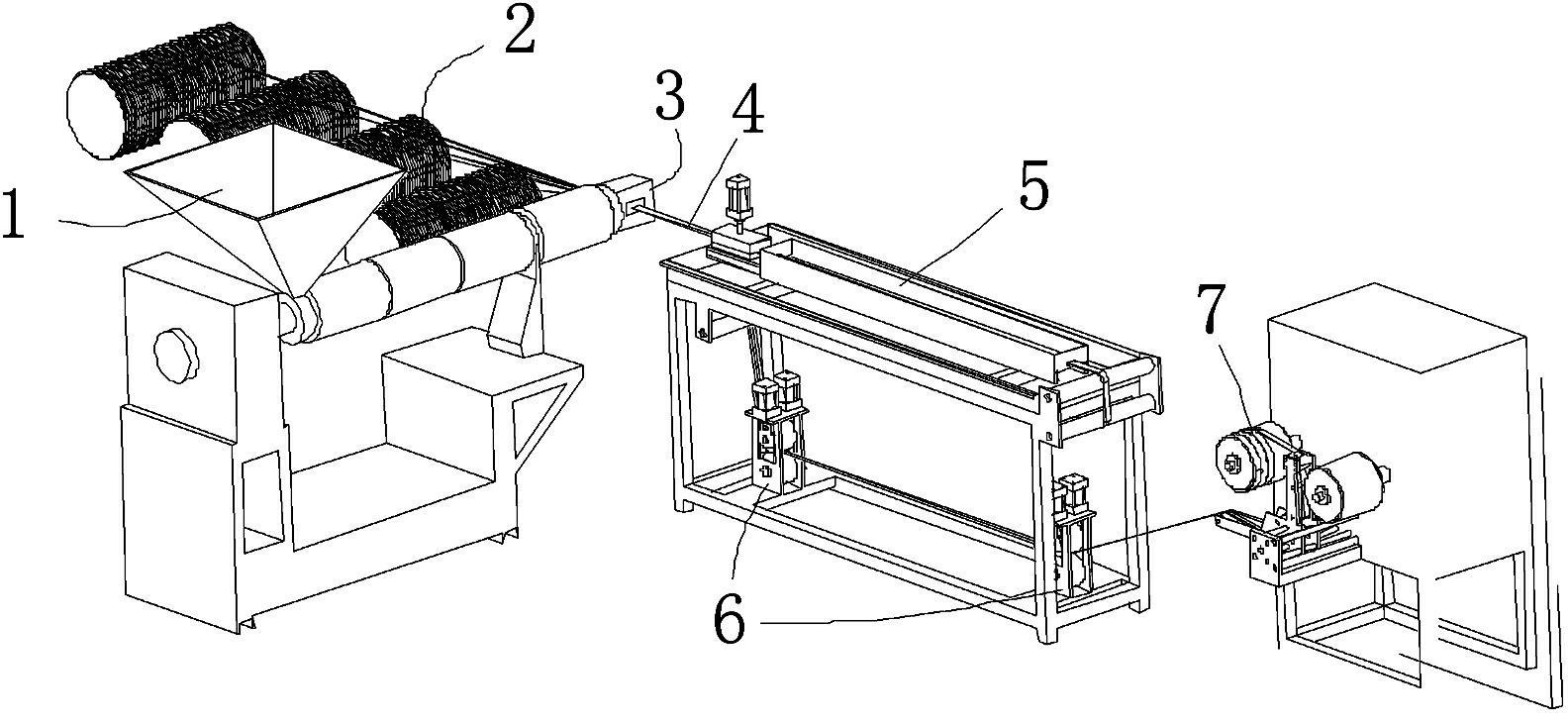

Method and apparatus for producing hard particle abrasion resistant composite steel board

InactiveCN101602162ASpread evenlyAchieve preparationOther manufacturing equipments/toolsMelting tankDecomposition

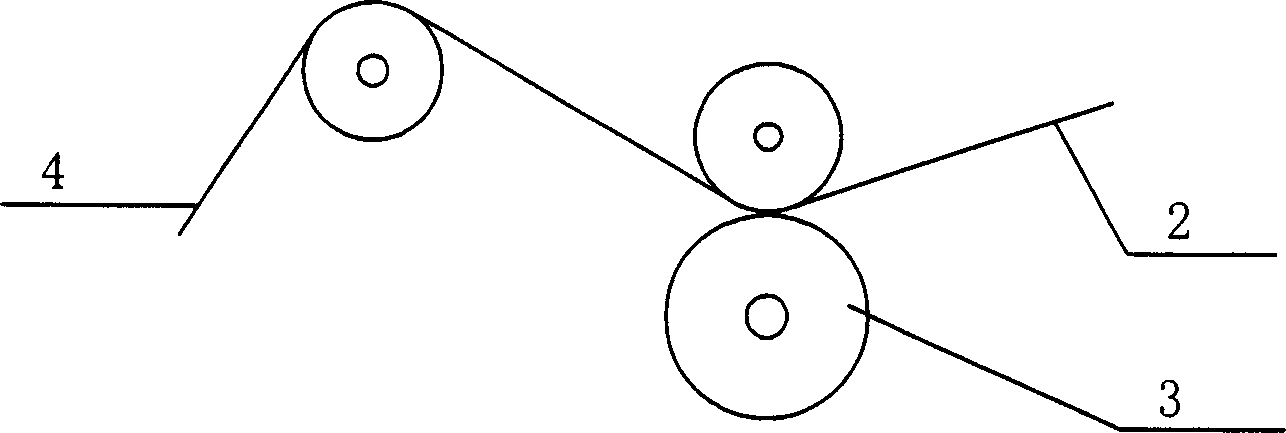

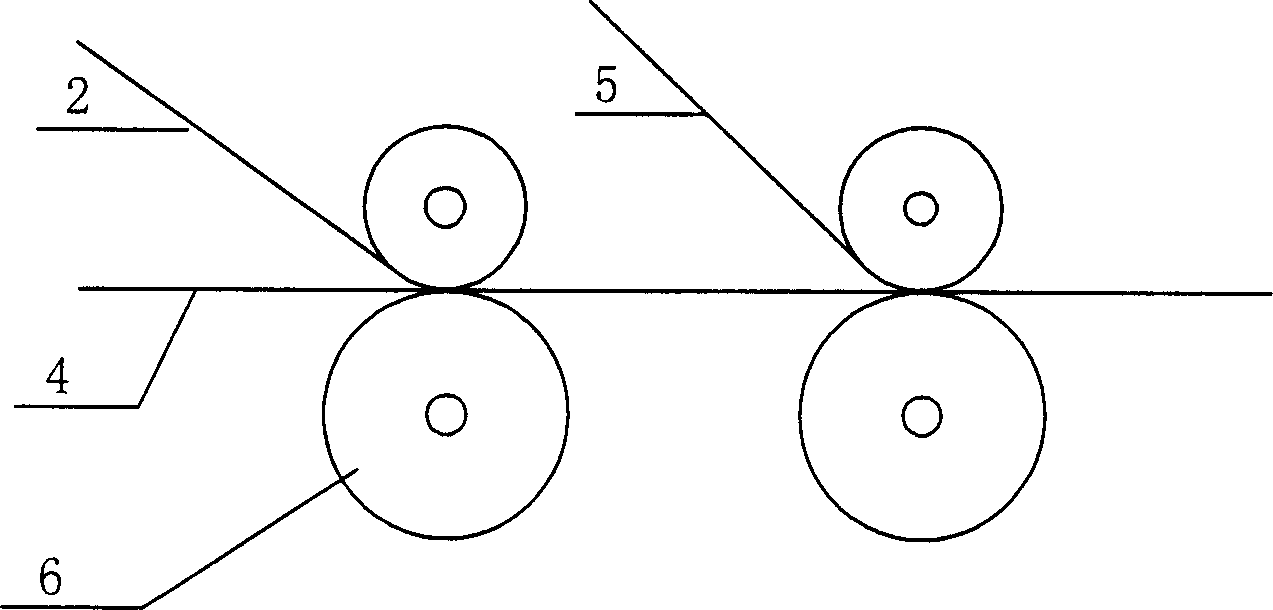

The invention relates to a method and an apparatus for producing hard particle abrasion resistant composite steel board. The method includes puddle welding on the surface of the steel board base to form a welding puddle, where no slag is allowed to exist; uniformly sprinkling the hard particle material onto the welding puddle; rolling on the puddle with a roller thereafter, so as to roll the hard particle material into the welding puddle or surface layer of the welding puddle to form a hard particle composite layer which is flat in the surface. Therefore, the hard particle abrasion resistant composite steel board comprising the hard particle composite layer and the steel board base is formed. The invention has advantages that abrasion resistance performance can be evidently enhanced by deploying any materials in high hardness as the hard particle material of the composite layer, such as hard alloy, cermet, diamond or the like; the steel board has strong bonding strength, flat surface, uniform thickness, and the performance of the hard particle material is unlikely to change due to high temperature decomposition or burning loss. The apparatus is not only specialized in production of hard particle abrasion resistant composite steel board, but also suitable for production of composite steel board of other types, and an automatic production can be further implemented thereby.

Owner:HARBIN INST OF TECH

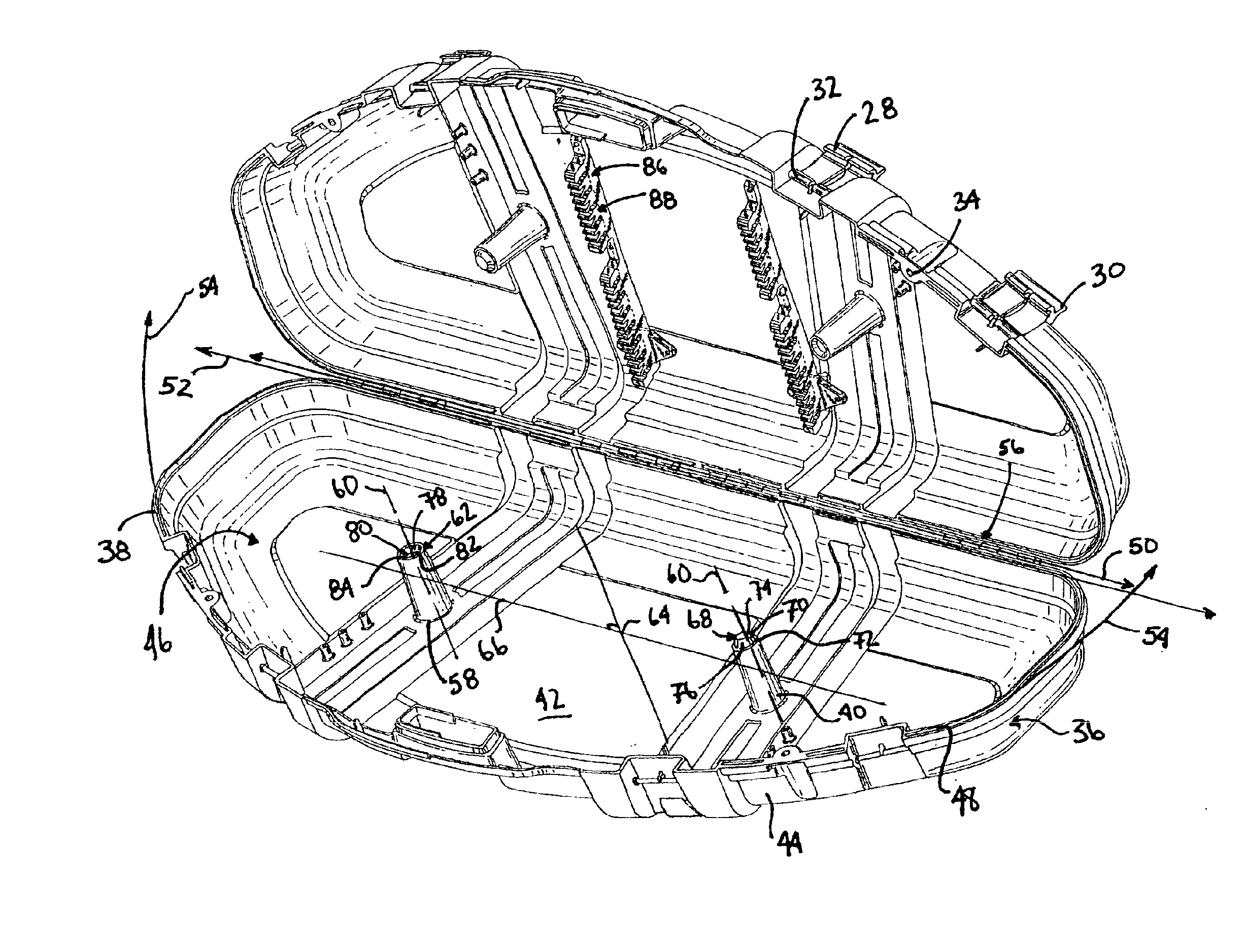

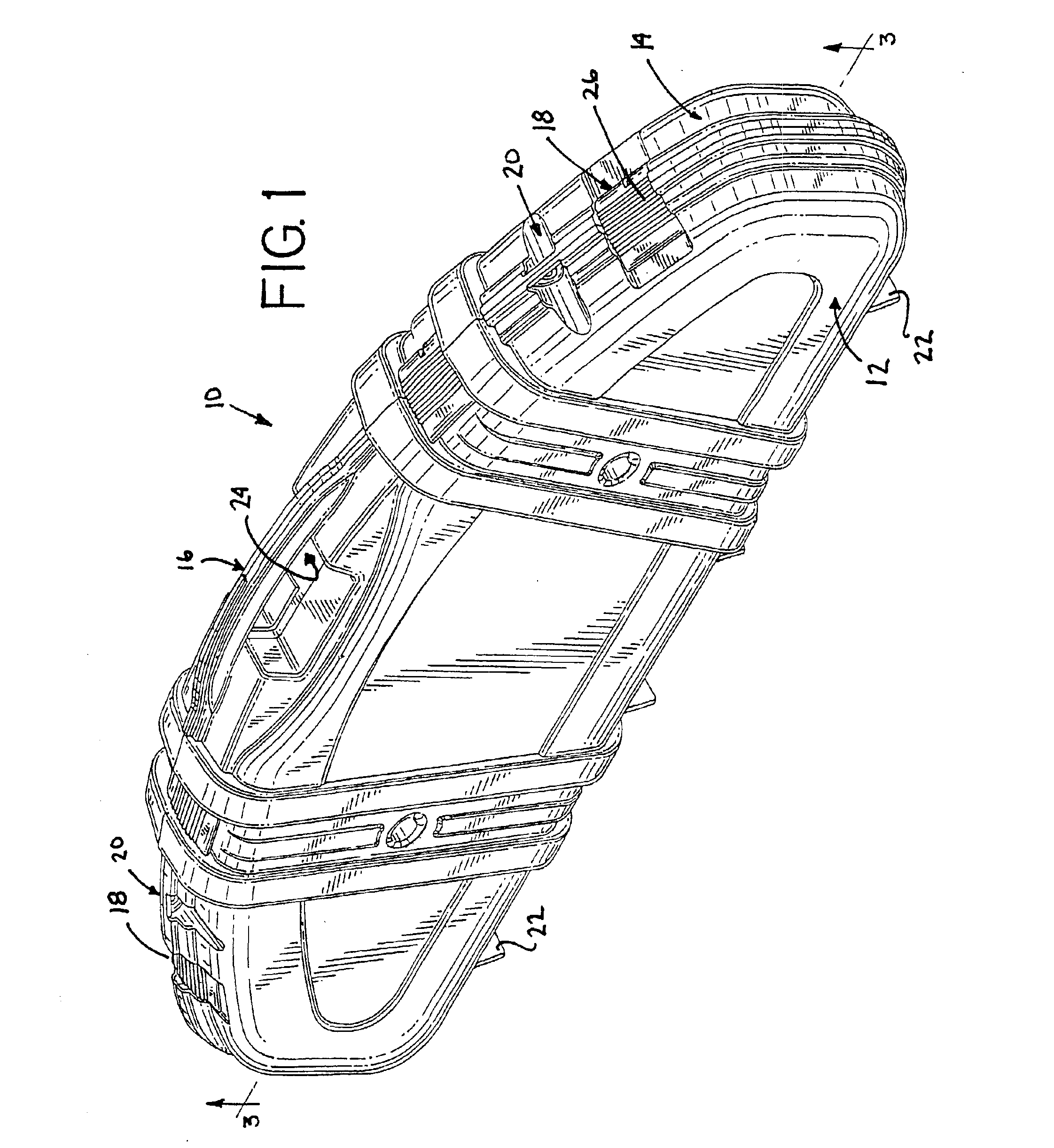

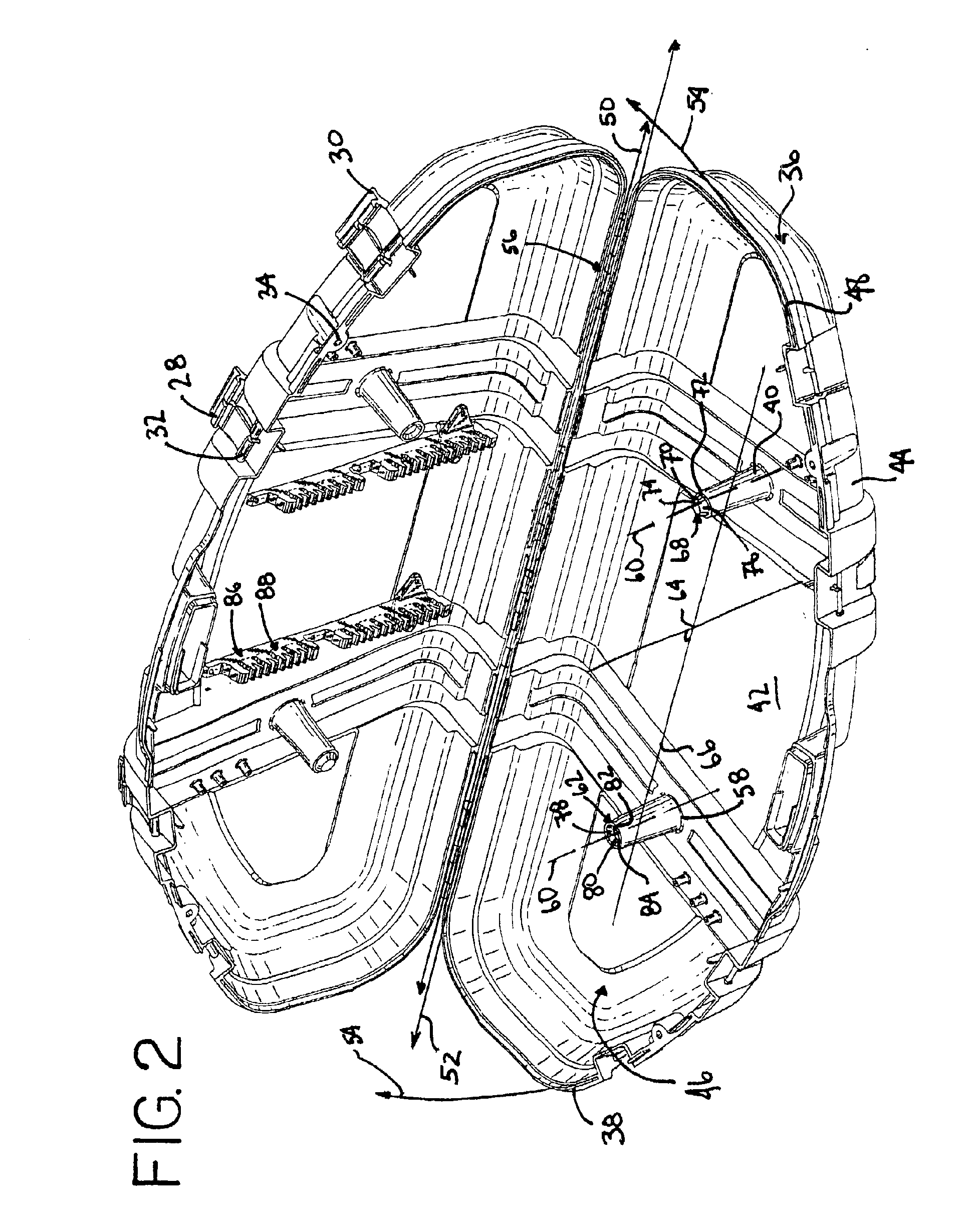

Arrow case

InactiveUS6880698B2Non-deformableAvoid deformationBows/crossbowsWing fastenersEngineeringMechanical engineering

Owner:PLANO MOLDING CO LLC

Compound packing strap and production technology

The invention relates to a compound packing strap, comprising fiber yarns and a mixed material covering the fiber yarns, wherein the mixed material contains polypropylene accounting for 99% to 100% by weight percent, antioxidant accounting for 0 to 10per mill by weight percent and anti-ultraviolet agent accounting for 0 to 10per mill by weight percent. The compound packing strap has the characteristics of high strength, non-deformability and long service life, is strong after packing, and prevents goods from being damaged by pack collapse since a packing box is deformed and becomes loose under the external force, thereby solving the problems the usage of the current packing straps brings to goods transportation and carrying.

Owner:史丽君

Integrated nano inorganic wall light heat insulation facing section bar and preparation thereof

InactiveCN101348355AWith thermal insulationEnvironmentally friendlyCovering/liningsSolid waste managementFiberSilicon oxide

The invention relates to an integrated type nano inorganic wall light weight heat preservation veneer and a method for preparing the same. The veneer consists of a heat preservation substrate which is formed by the one-piece pressure moulding of a plurality of inorganic mineral materials and a veneering layer, wherein the heat preservation substrate is prepared by husk type expanded perlite light-weight aggregate, cement, silicon oxide micropowder, wood fiber micropowder, organosilicon emulsion and cement reinforcing agent according to the blending ratio; the veneering layer is prepared by quartz sand, calcium carbonate, cement, silicon oxide micropowder and wood fiber micropowder according to the blending ratio and is in one-piece pressure moulding. Compaed with prior art, the veneer has the advantages of light weight, high strength, good heat insulation and heat preservation effects, tight bonding, energy conservation and environmental protection, resource conservation, easy construction, short construction period, low cost and long service life, etc.

Owner:信阳天意节能技术股份有限公司

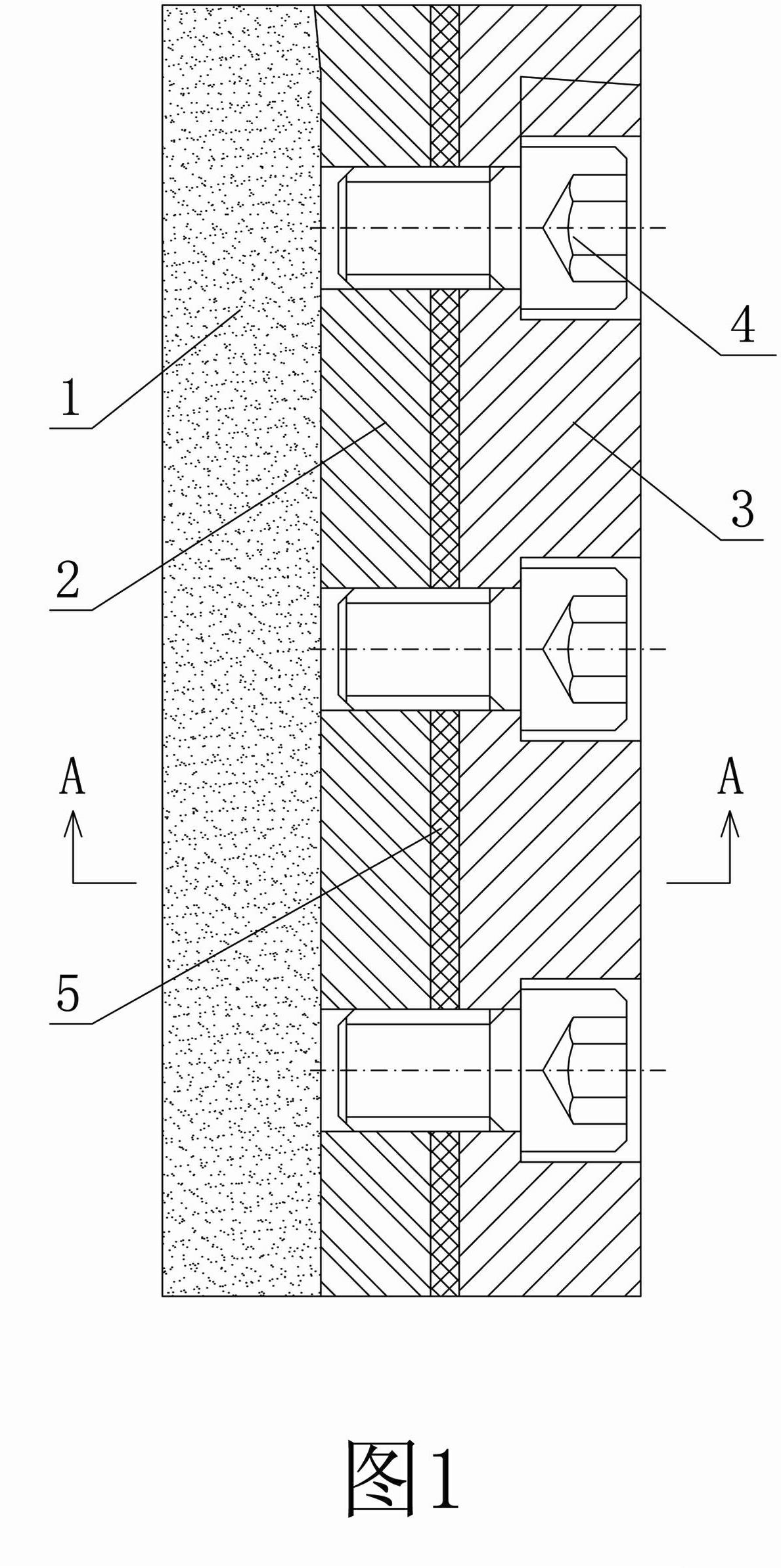

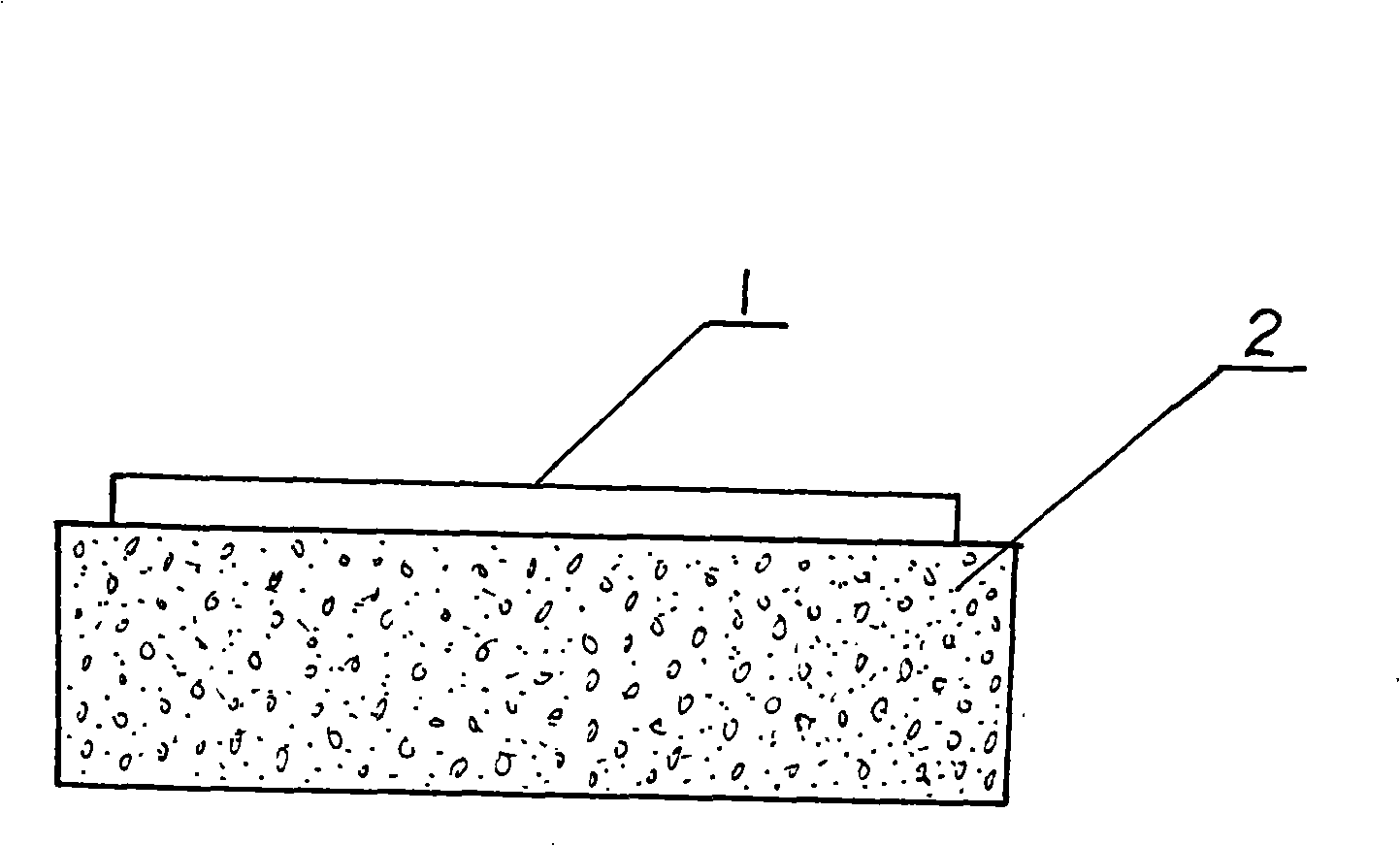

Coal ash heat-preservation heat-insulation fire-proof slab and producion method thereof

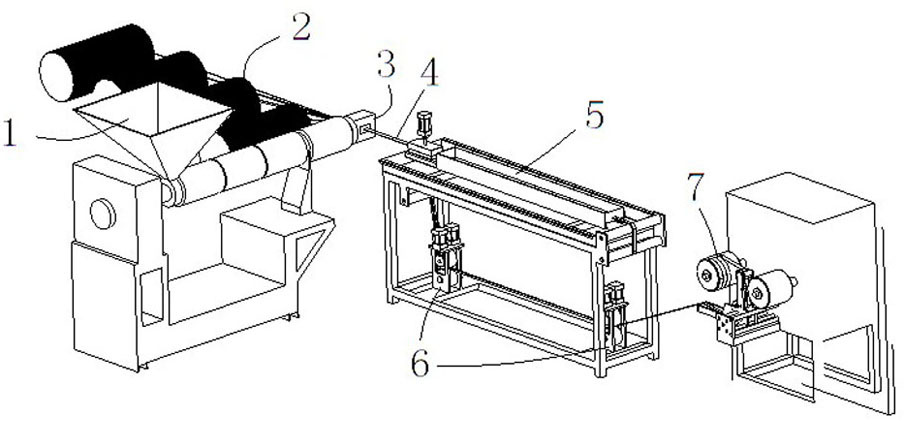

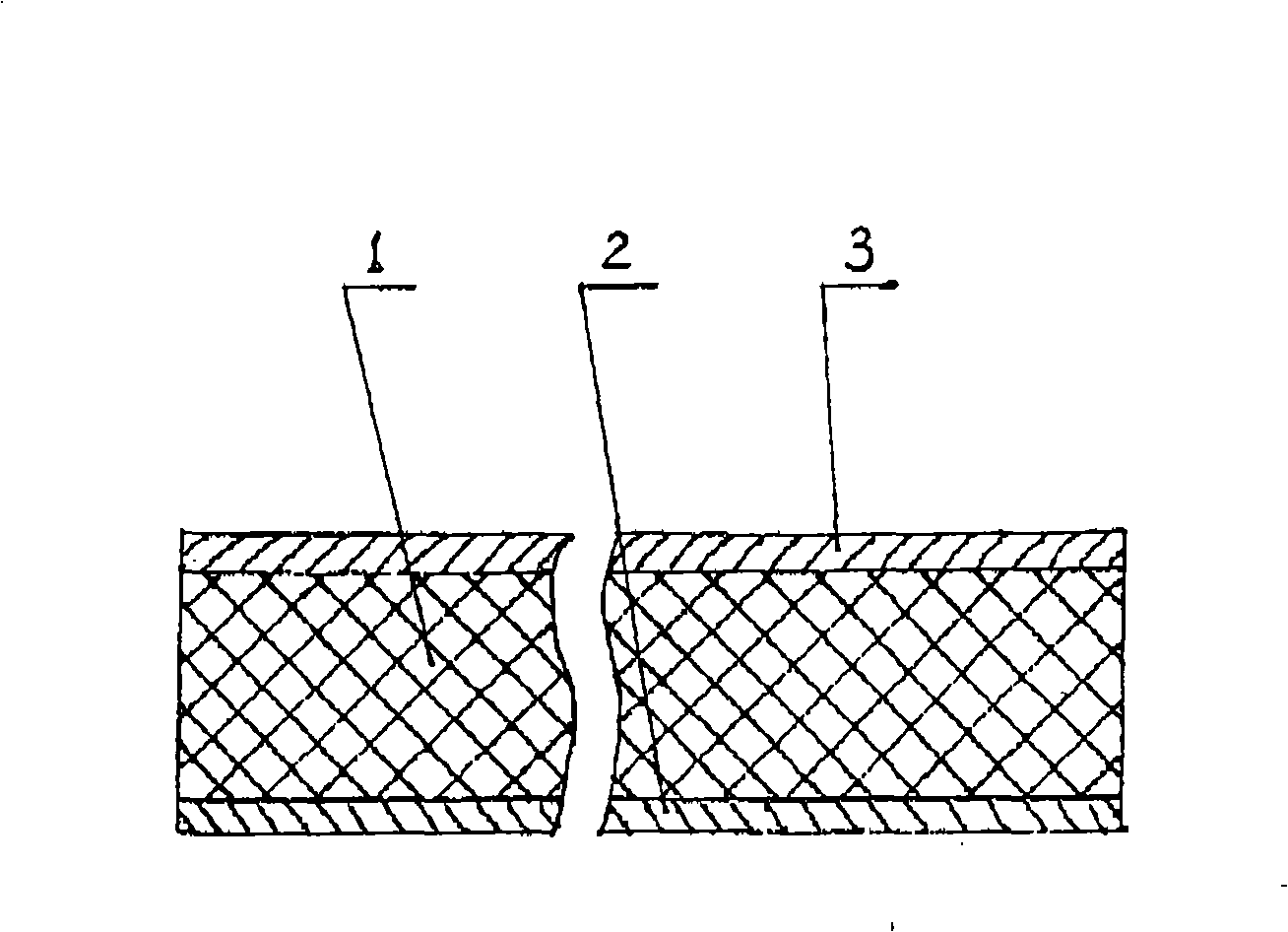

InactiveCN101343897AHigh temperature resistantNon-deformableCovering/liningsLaminationDistortionMelamine resin

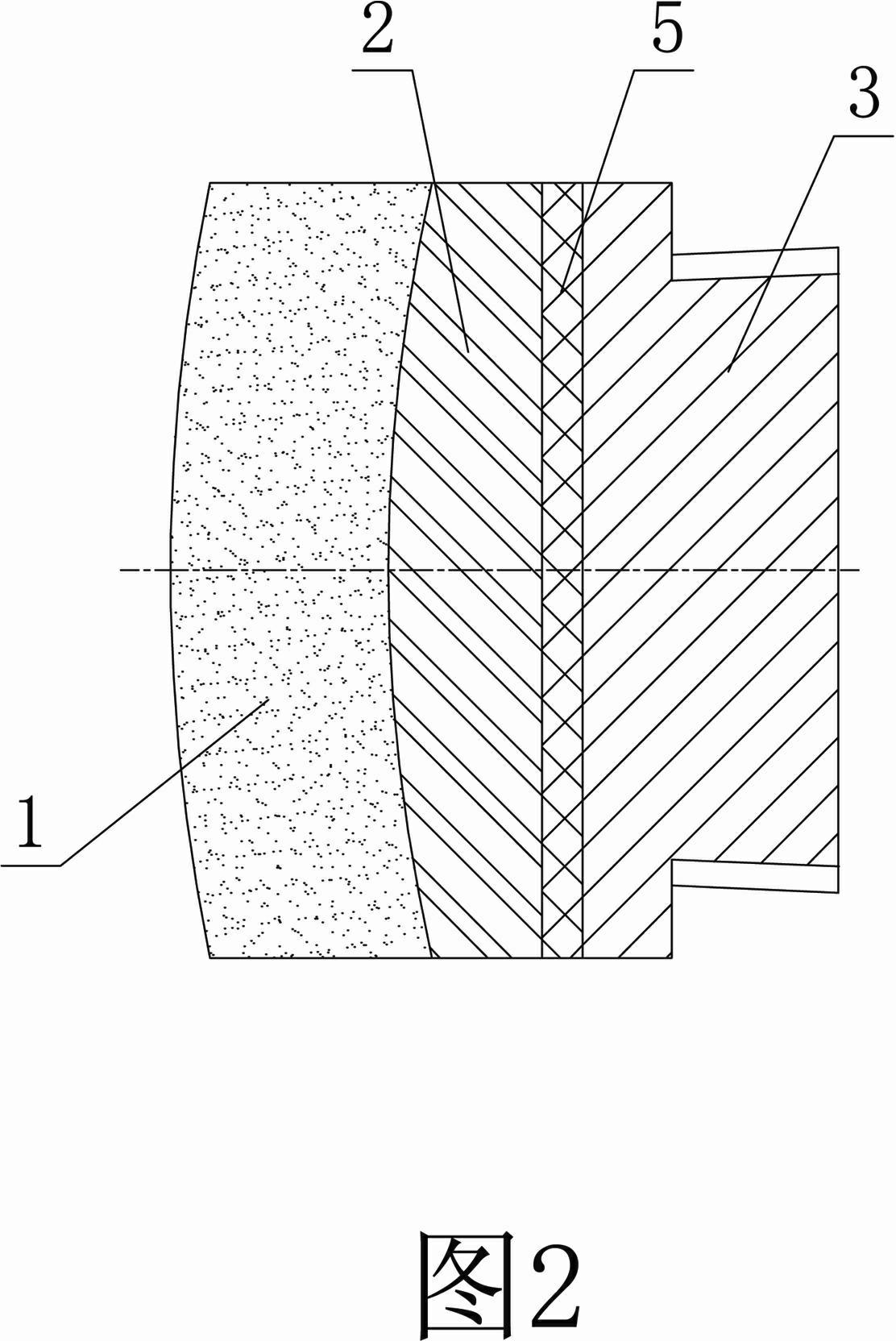

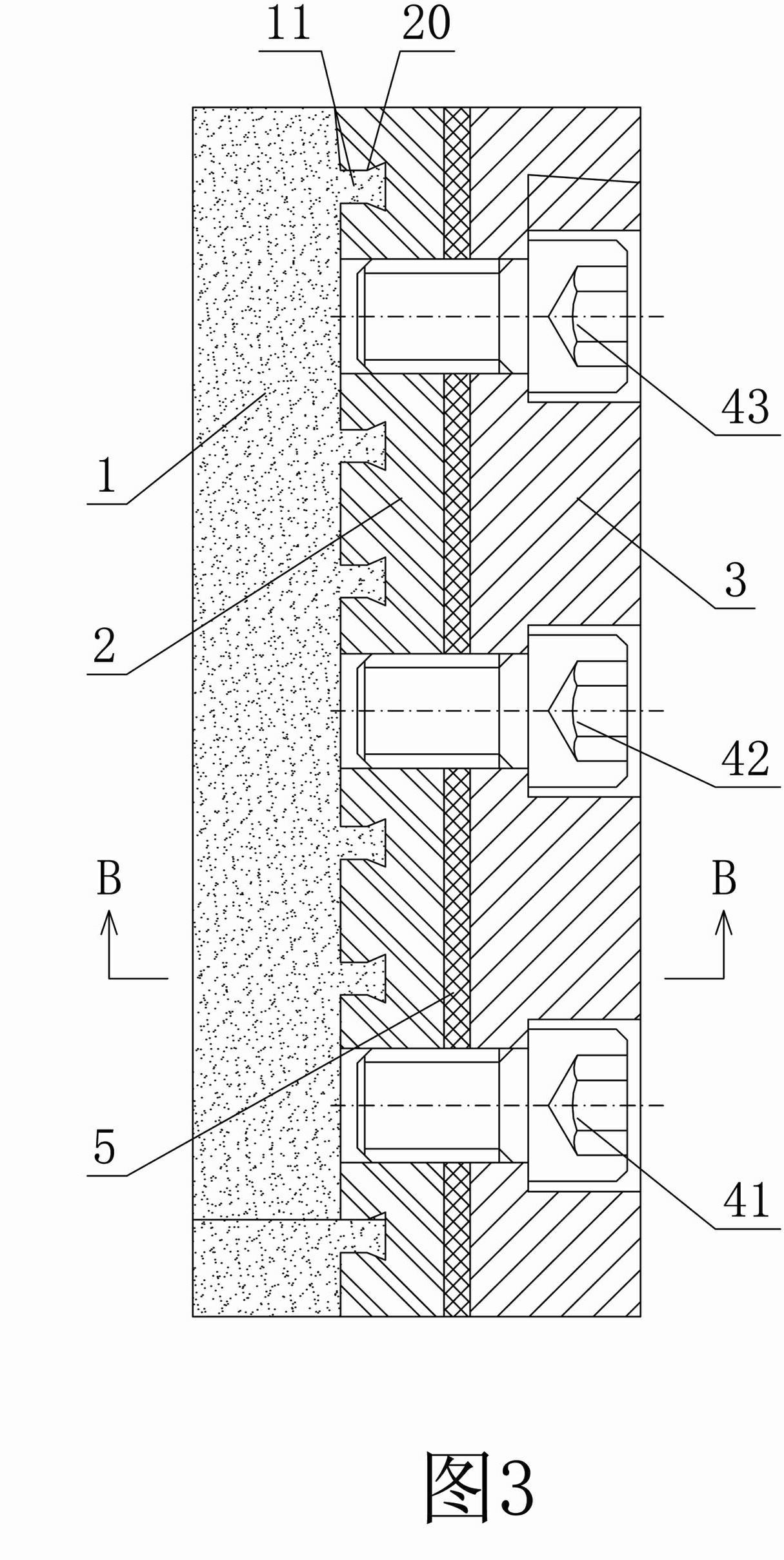

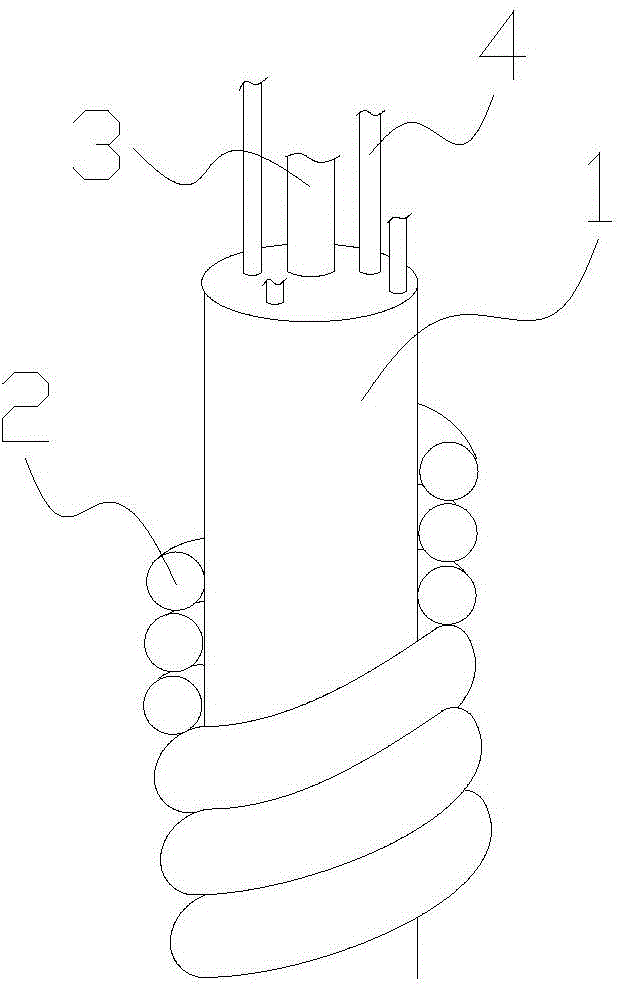

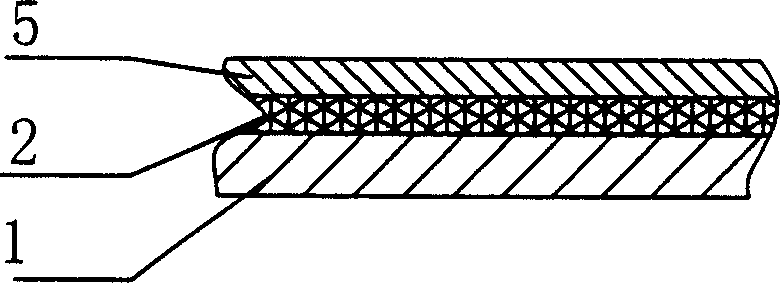

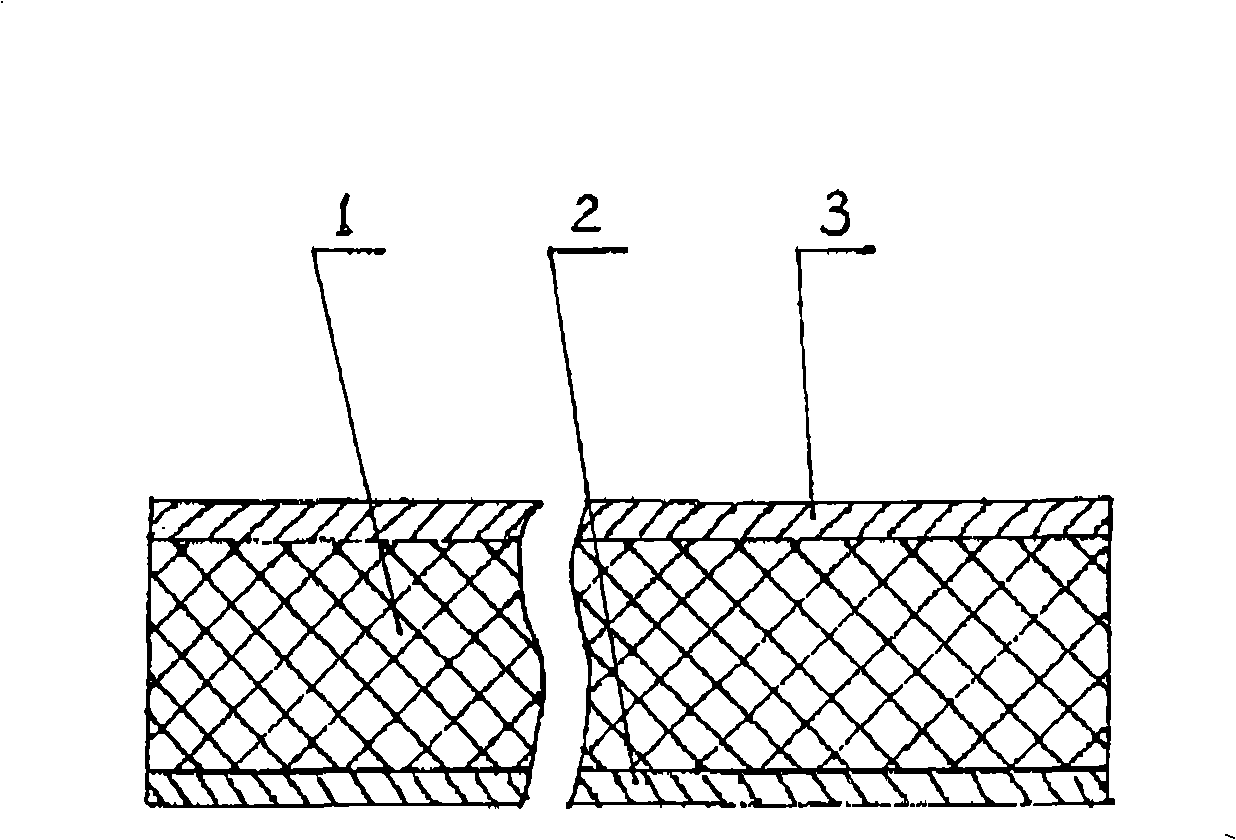

The invention discloses a coal ash thermal retardation and heat insulation fireproof plate as well as a production method thereof. The coal ash thermal retardation and heat insulation fireproof plate consists of a phenol formaldehyde foam plate layer (1) and a coal ash layer (2). The coal ash thermal retardation and heat insulation fireproof plate is characterized in that the coal ash layer blended with fireproof resin is hot-pressed on one surface of the phenol formaldehyde foam plate. The production method comprises the following steps: firstly, materials are prepared in parts by weight: 1000 parts of coal ashes, not less than 100 parts of formaldehyde phenol resin or melamine resin, and 10 to 30 parts of solidifying agent hexamethylene tetramine; secondly, the components are evenly blended, and poured into a mould, and flattened; thirdly, the phenol formaldehyde foam plate is put into the mould; and fourthly, temperature and pressure are increased on a hot pressing machine. Coal ashes are selected as the raw material in the invention, and are formed after being burnt at a high temperature, and can bear the high temperature of hundreds of Celsius degrees, the coal ashes are heated, pressed and shaped after a bonding agent and a solidifying agent are added, and the coal ash thermal retardation and heat insulation fireproof plate has the advantages of high temperature resistance, non distortion, light mass, high intensity and fire prevention, and the purpose of the invention is completely achieved.

Owner:四川威尔达节能科技有限公司

Cement foaming insulation board, preparation method and application thereof

The invention relates to a cement foaming insulation board, a preparation method and application thereof; the cement foaming insulation board is prepared by adopting the steps of: uniformly mixing 4-6 parts by weight of acidic cement, 0.15-1.6 parts by weight of hydrogen peroxide by adding proper dosage of water, adding 1-3 parts by weight of curing agent in a mould, and uniformly stirring and curing, wherein the total forming duration is less than 25 min. According to the cement foaming insulation board provided by the invention, a fireproof and environmental-friendly material is used as a raw material of a building insulation board, so that the material has the advantages of small mass, sound insulation, environmental protection, high toughness, non-deformation, non-slag dropping and long service life; the curing agent is adopted in the preparation process to reinforce the adhesion effect and improve the integral strength and hardness of the board, and the board is firmer; and the cement foaming insulation board can be applied on outer walls, interior walls and partition walls of buildings.

Owner:天津得全集成房屋有限公司

Composite fiber band and production process

InactiveCN102152895AHigh strengthExtended service lifeSynthetic resin layered productsFlexible elementsPolypropyleneAntioxidant

The invention relates to a composite fiber band which comprises fibers and a mixed material which is wrapped outside the fibers, wherein the mixed material comprises the following components in percentage by weight: 80-85 percent of polypropylene, 0.5-10 percent of short fibers, 12-70 percent of long fibers, 0-1 percent of antioxidant and 0-1 percent of ultraviolet screener. The composite fiber band has the characteristics of high strength, no deformation and long service life; and after packing, the composite fiber band is firm, and the phenomenon that a packing box is loosened to damage commodities due to deformation caused by external force is avoided, and the problems brought to transporting and handling by packing used at present are solved.

Owner:史丽君

Heat preserving facing integrated inorganic section bar and preparation thereof

InactiveCN101498165AEnvironmentally friendlyAgingCovering/liningsSolid waste managementInorganic saltsFiber

The invention relates to an insulated facing integrated inorganic section and a preparation method thereof. The section consists of an insulated basal body and a facing layer which are made of various inorganic mineral materials, wherein the insulated basal body is prepared from inorganic slat composite slurry-like kernel materials and expanded perlite grain materials; and the facing layer is prepared form quartz sand, calcium carbonate, calcium oxide, cement, silicon oxide ultrafine micro powder and wood finer ultrafine micro powder. The section is formed by integrally pressing and compounding the insulated basal body and the facing layer, ensures that two layers of materials are organically combined together, can completely avoid the phenomena of the cracking and the shedding between the insulated basal body and the facing layer, can reliably improve the manufacturing precision and the standard grade, can greatly reduce the workload of the wall body decorated construction, improve the construction efficiency, reliably ensure the engineering quality, and can greatly shorten the engineering period and save the material cost and engineering cost under the same conditions.

Owner:信阳天意节能技术股份有限公司

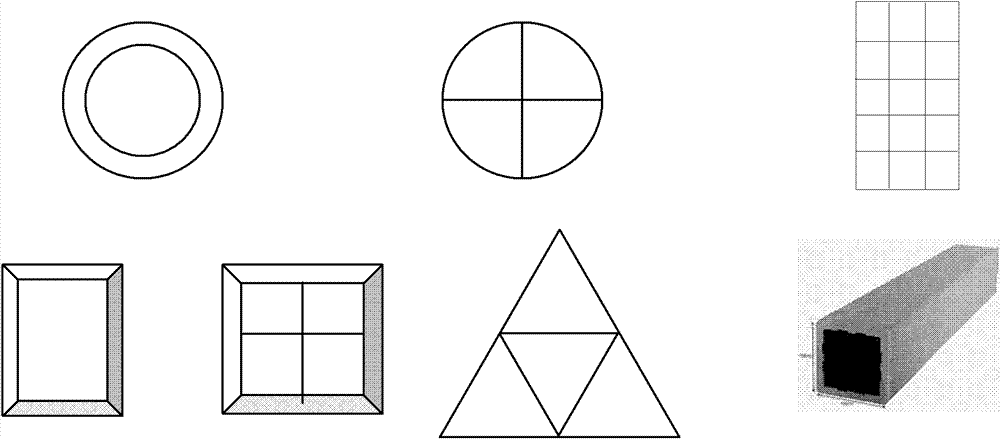

Plate and its production method

The invention discloses a sheet material and relative producing method. Said sheet material is formed by two enforcement layers and one intermediate structural layer. Wherein, the structural layer comprises mineral powder, light material powder, adhesive agent and plasticizer, while the plasticizer is formed by glass fiber mesh cloth and adhesive agent. And the inventive method comprises: preparing material, mixing material, laying, pressurizing, solidification, and demouding and incising, maintaining, drying, and detecting. The main raw material of sheet material is mineral powder which can be resistant to fire and water, without formaldehyde and radioactivity, which is environment-friendly. The basic material of said sheet material is light plant powder; therefore, the invention has better processing property and lower breakage rate, while it can be used in furniture, decoration and separation.

Owner:曾友余

Method for manufacturing thermal insulation fire-proof board with foaming ceramic fine bead and product thereof

InactiveCN101342725AHigh temperature resistantNon-deformableCeramic shaping apparatusSold ingredients supply apparatusMicrosphereThermal insulation

The invention discloses a method for manufacturing heat-insulating fire-resisting board with hollow ceramic microspheres; the method is implemented according to the following steps that A. prepare the materials according to the following weight proportions: 1000 proportion of powder hollow ceramic microspheres, not less than 100 proportion of phenolic resin or melamine resin and 10 to 30 portion of curing agents; B. evenly mix the materials and pour into a mold for smoothing; C. heat and pressurize the mixture on a hot press. The raw material used for the method is powder hollow ceramic microsphere, which belongs to the ceramic foaming product and could bear high temperature up to hundreds of degrees; the adhesive and curing agents are added and the mixture is molded after being heated and pressurized to obtain the board which has the advantages of being high temperature resistant and hard to deform, light weight and high strength. In this way, the object of the invention is fully realized.

Owner:四川威尔达节能科技有限公司

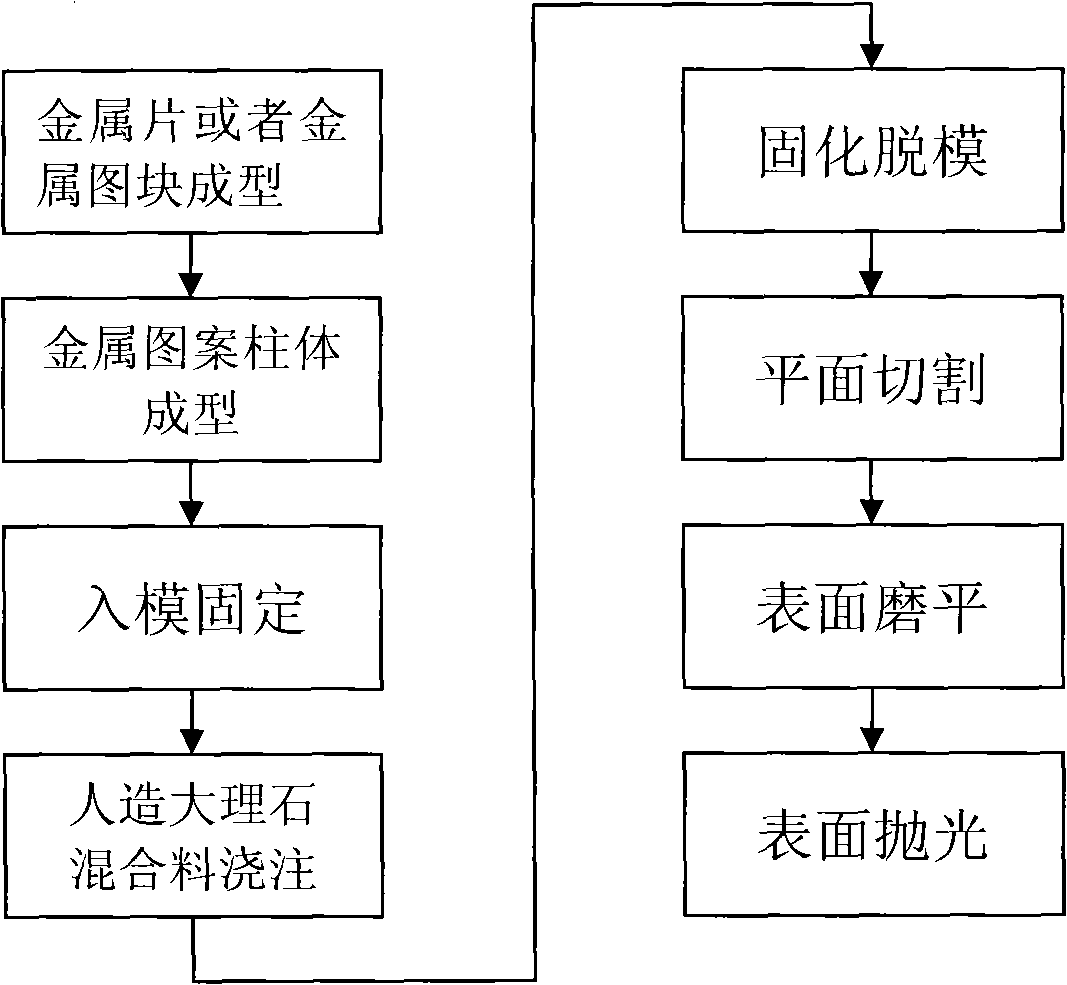

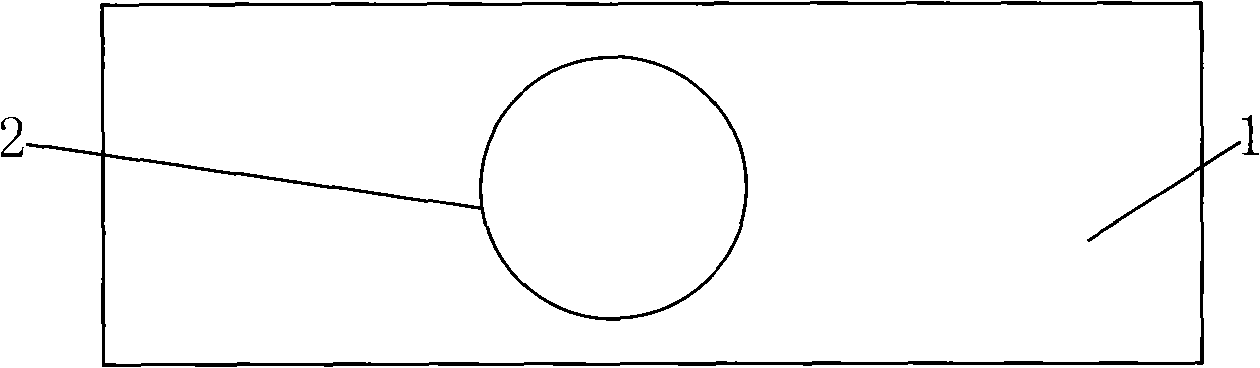

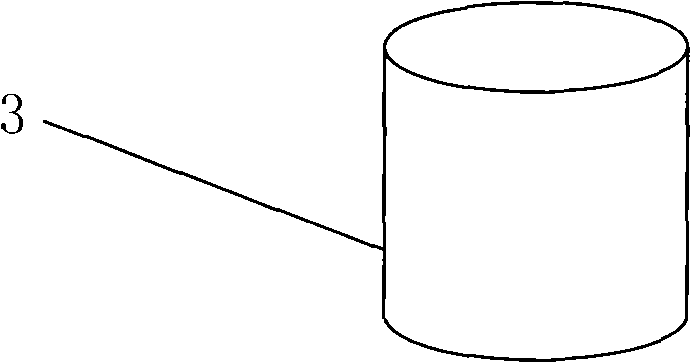

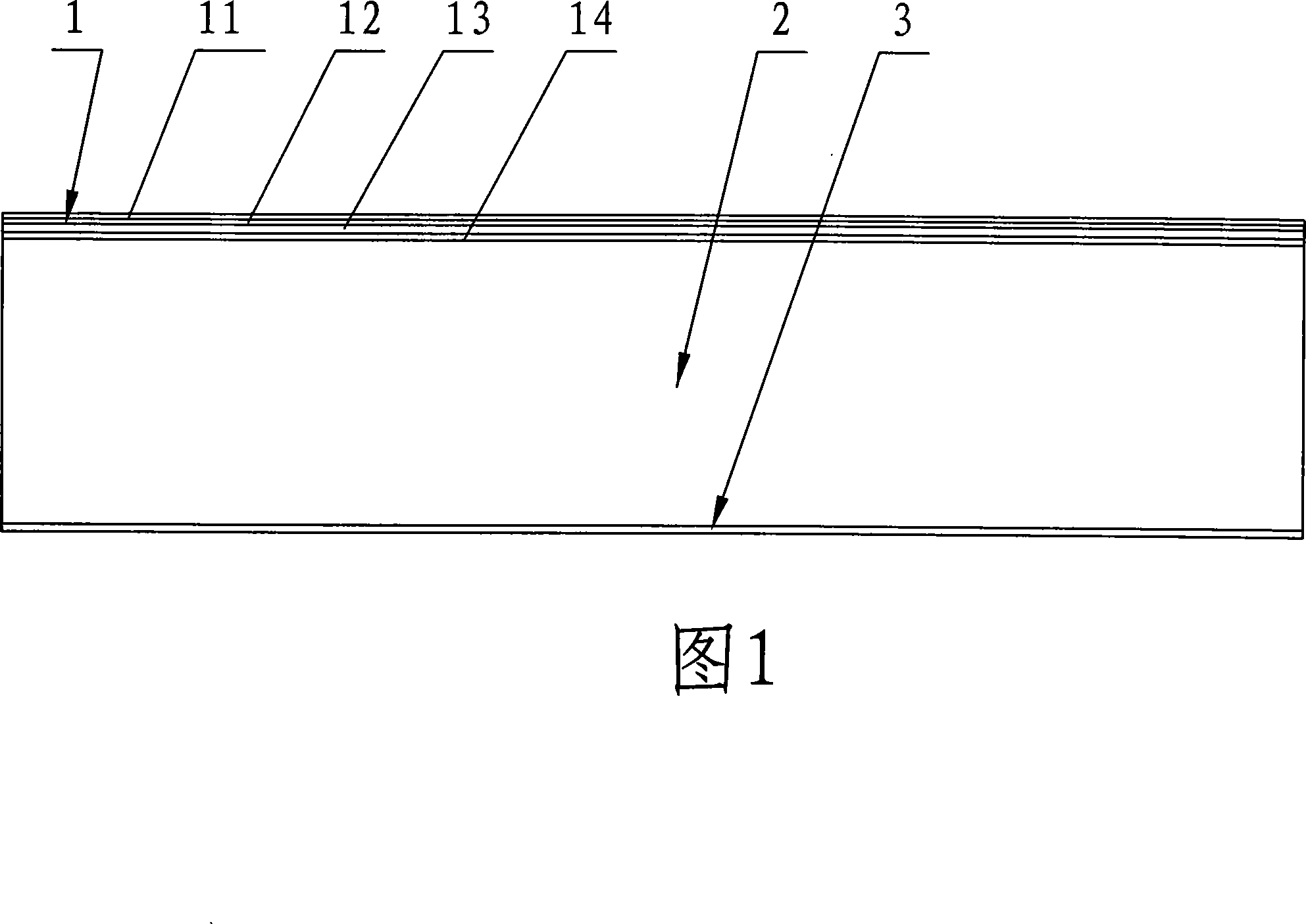

Artificial marble slab embedded with metal patterns and manufacturing process thereof

InactiveCN101564965ASimple processPracticalDecorative surface effectsSpecial ornamental structuresBuilding materialFlame resistance

The invention belongs to a decorative building material, and discloses an artificial marble slab embedded with metal patterns. A manufacturing process for the artificial marble slab is characterized by comprising the following steps: making a selected metal sheet or a metal graph block into a metal pattern column; and placing the metal pattern column into a fixed die, casting the metal pattern column by marble mixed slurry, cutting a marble material after compounding, curing and demoulding, and polishing the surface of the marble material to obtain the artificial marble slab embedded with the metal patterns. The manufacturing process not only solves the synthesis of the metal patterns and the artificial marble, but also has the advantages of simple process, strong practicability, wide application and vivid aesthetic three-dimensional effect. The artificial marble slab added with metal has the property of the artificial marble, has richer and thicker colors than a common artificial marble slab because the metal patterns is in the artificial marble slab, and generates new tactile sensation. Simultaneously, the product has the characteristics of good physiochemical performance, flame resistance, no deformation, and the like. Through a mode of plane cutting, the product can be made into ultrathin slabs of different specifications of 5 to 20 millimeters and the like.

Owner:SHANGHAI HUDA INVESTMENT & DEV

Termpered layer composite solid wooden board and its processing method

InactiveCN101148050AWith impact resistanceHigh strengthWood veneer joiningWood layered productsSolid woodHigh wear resistance

The present invention relates to one kind of composite solid timber board with one toughened layer and its production process, and belongs to the field of timber processing technology. The composite solid timber board includes one facing layer, one base layer and one bottom layer. The facing layer includes one antiwear layer, one decorating layer, one quartz fiber layer and one dacron fiber layer adhered successively from top to bottom; the base layer is made of timber; and the bottom layer is one balance paper layer, single sheet or fiber board. The composite solid timber board has high strength, high impact toughness, stable size, high wear resistance and low production cost. It ma be applied widely as indoor building material.

Owner:孙和根

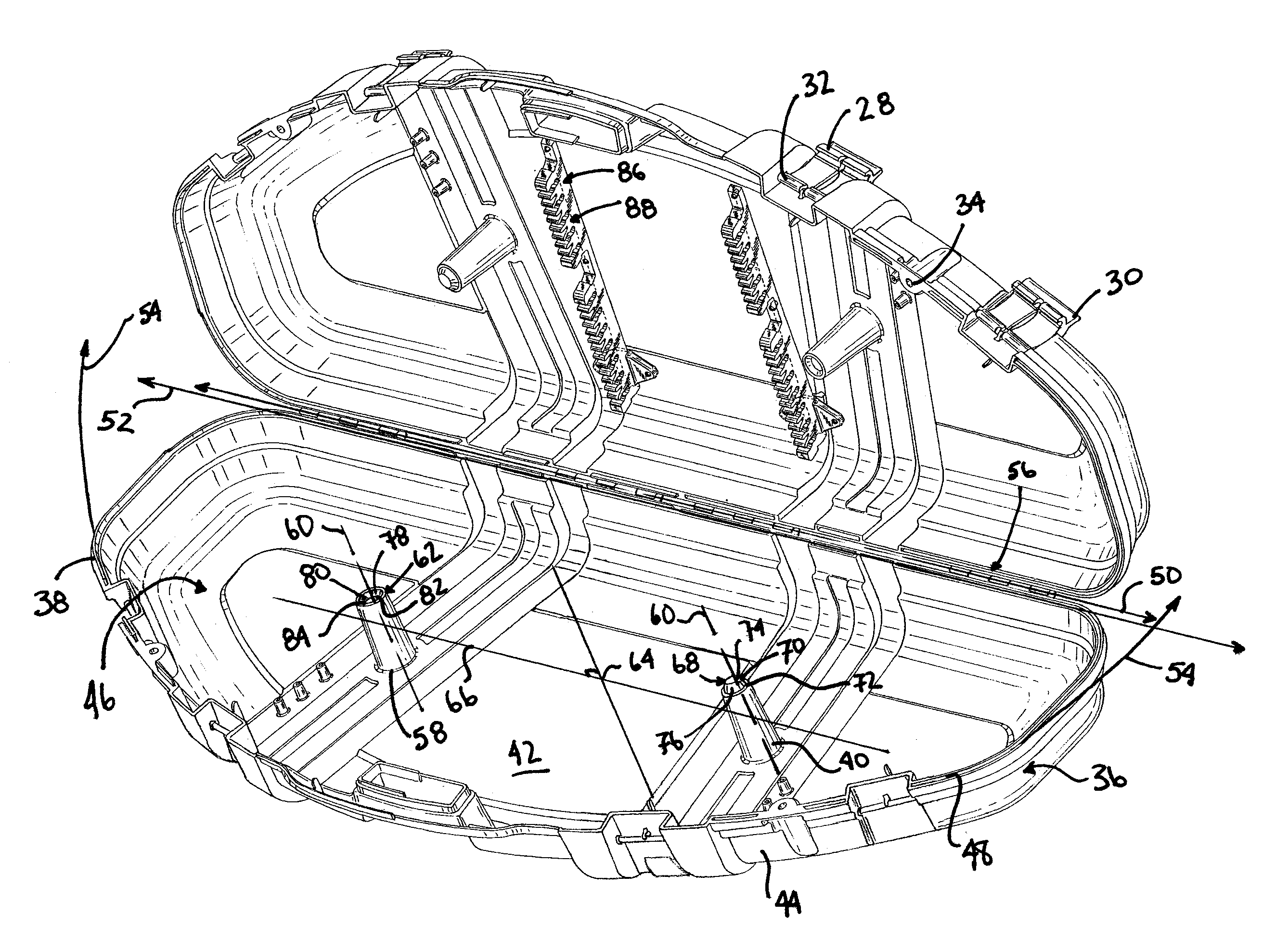

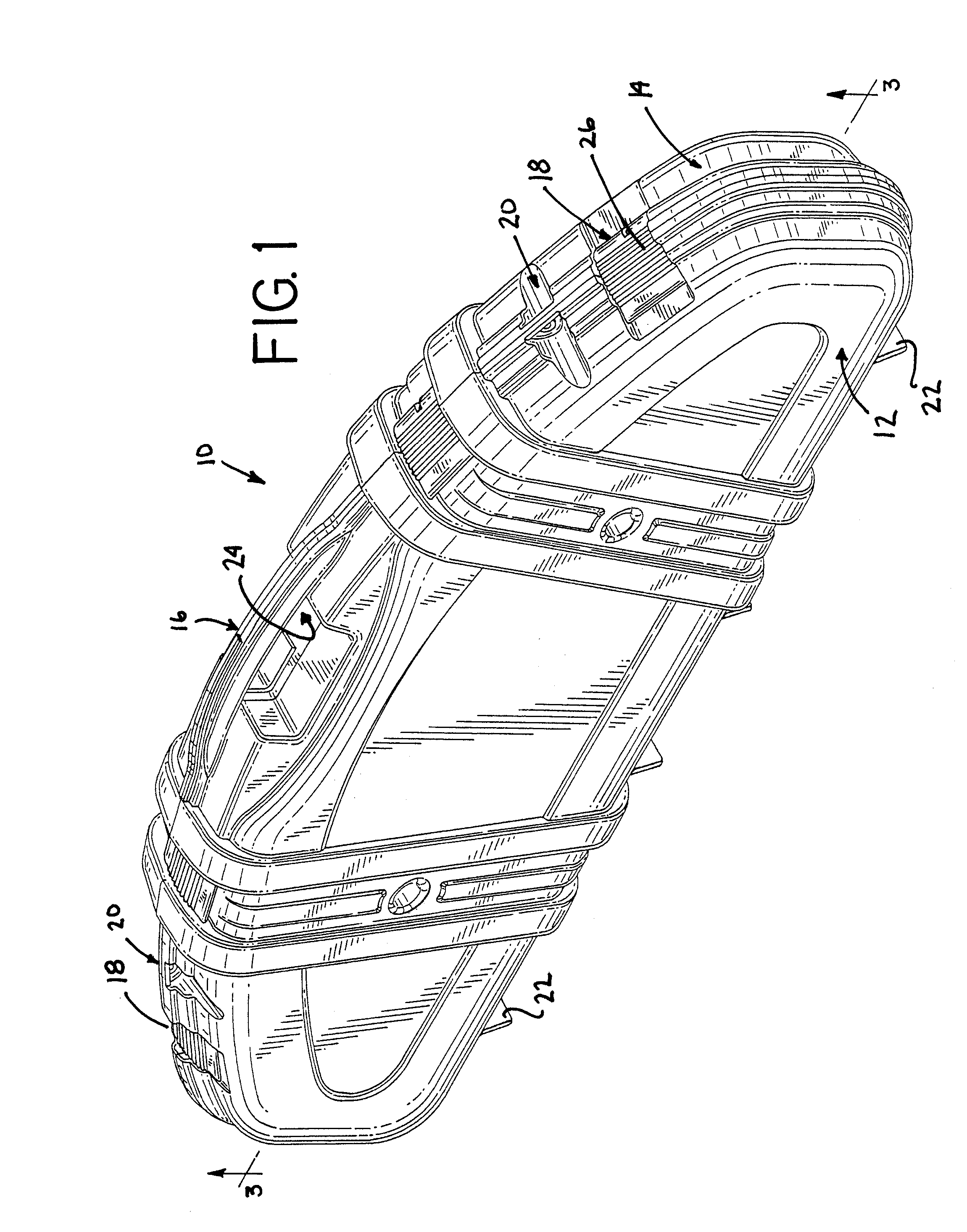

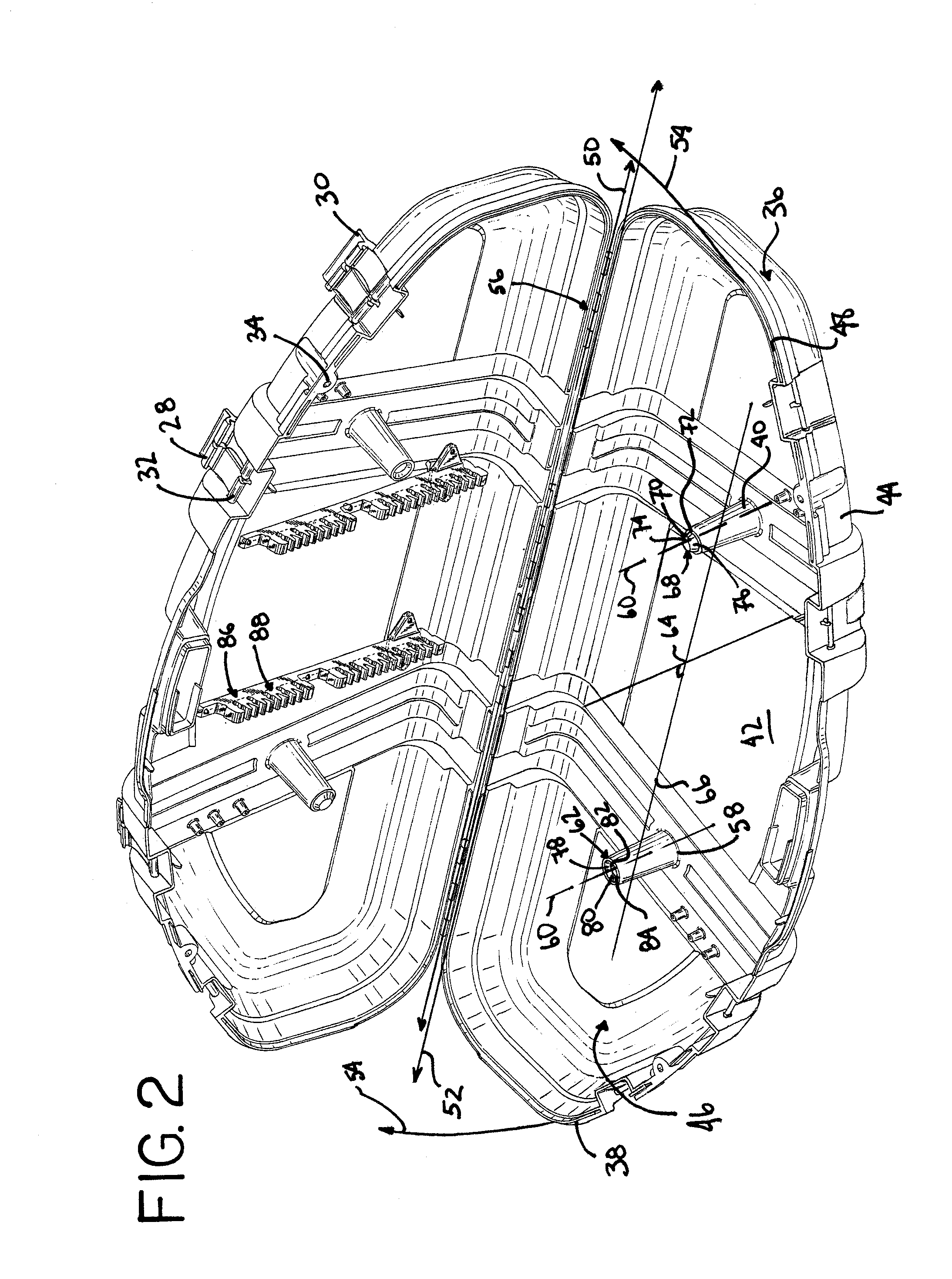

Case for Archery Equipment

InactiveUS20020040858A1Non-deformableBows/crossbowsOther accessoriesEngineeringMechanical engineering

<heading lvl="0">Abstract of Disclosure< / heading> A case for archery equipment includes, interengaging first and second half portions connected for movement between open and closed positions. The first half portion includes a first wall defining a first interior recess and having a first mating rim. The first half portion further includes a plurality of first supports formed in the first wall, and located within the first interior recess. The second half portion includes a second wall defining a second interior recess and having a second mating rim. The second half portion further includes a plurality of second supports formed in the second wall and located within the second interior recess. Each first support has a first longitudinal axis and is aligned along a common first axis which intersects each first longitudinal axis normally within and defining a first common plane. Each second support has a second longitudinal axis and is aligned along a common second axis which intersects each second longitudinal axis normally within defining a second and common plane. The first and second planes are parallel and offset in the open position and aligned in opposition in the closed position such that each first support engages each said second support in mating contact. A load applied to the case in a closed position is distributed among the first and second supports and the first and second mating rims, resulting in a protective zone defined by the first and second interior recesses.

Owner:PLANO MOLDING CO LLC

Fiber-reinforced aerated insulation board and preparation process thereof

ActiveCN103980000AOvercome defectsAvoid defectsWood working apparatusFlat articlesCalcium formateWaste material

The invention discloses a fiber-reinforced aerated insulation board. The fiber-reinforced aerated insulation board is prepared from the following raw materials in parts by weight: 80-100 parts of fly ash, 30-50 parts of expanded perlite, 10-20 parts of ceramsite, 10-20 parts of plant fiber, 5-10 parts of floating bead, 5-8 parts of meerschaum, 3-5 parts of sodium fluosilicate, 3-5 parts of calcium formate, 2-4 parts of foamer, 0.1-0.5 part of oleic triisopropanolamine and 0.1-0.3 part of glycol dimethyl ether. According to the fiber-reinforced aerated insulation board, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; through the organic combination and generated synergism of the fly ash, lightweight aggregate and additives, the defects in the existing building insulation boards can be effectively overcome.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

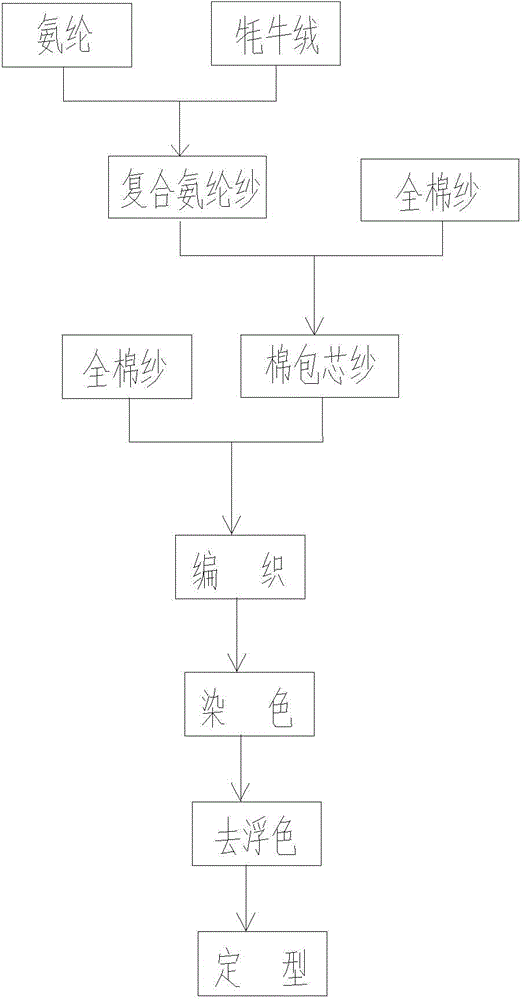

Knitting technology for high-elastic silk stocking

ActiveCN105586701AHigh cotton contentComfortable to wearWeft knittingShaping/stretching tubular fabricsPlain weaveDyeing

The invention discloses a knitting technology for high-elastic silk stockings, and relates to the field of silk stocking knitting. The knitting technology comprises the following six steps: manufacturing composite spandex yarns, manufacturing cotton covering yarns, knitting, dyeing, removing flooding, and shaping. In the step of manufacturing composite spandex yarns, spandex is used as inner yarns, and through a nozzle on an air jet spinning machine, yakwook is wrapped on the surface of the spandex to form high-elastic composite spandex yarns. In the step of manufacturing cotton covering yarns, the composite spandex yarns produced in the previous step are used as inner yarns, and full-cotton yarns are used as covering yarns and are wrapped on the composite spandex yarns according to a same spiral direction, to manufacture the cotton covering yarns. In the knitting step, two strands or more than two strands of the cotton covering yarns and the full-cotton yarns are fed in a knitting machine for plain weave. After early finished products are completed, dyeing, removing flooding, and shaping are performed. The silk stocking produced by the knitting technology is characterized by high elasticity and no deformation, and the silk stocking is comfortable to wear and good in shaping effect.

Owner:浙江宝娜斯袜业有限公司

Printing veneering sheet material and its manufacturing method and use

InactiveCN1557642AProtect from high temperature damageHigh temperature resistantNatural patternsDecorative surface effectsMetal sheetEngineering

The printed facing sheet includes metal sheet and decorating sheet contacting closely on to the metal sheet. The decorating sheet may have various patterns, including patterns of stone, timber, metal, ceramic, animal, plant, etc. The making process and use of the printed facing sheet is also disclosed. The present invention has bright decorating layer, various patterns, simple making process, wide application range, low cost and other features.

Owner:FOSHAN SHUNDE JINGSEN COMPOUND MATERIAL

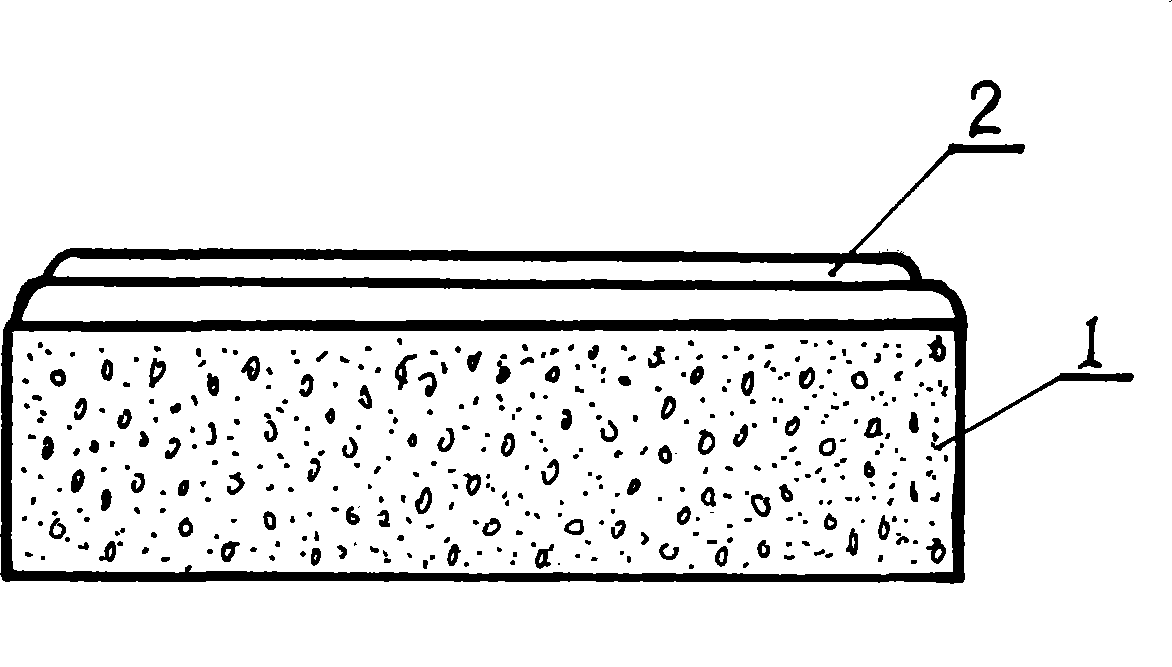

Foaming ceramic micro-ball heat preservation heat insulation fire-proof slab and producing method thereof

InactiveCN101343915AHigh temperature resistantNon-deformableCovering/liningsCelsius DegreeTemperature resistance

The invention discloses a foam ceramic micro bead heat-retaining and heat-insulating fireproof plate and a production method thereof. The foam ceramic micro bead heat-retaining and heat-insulating fireproof plate is composed of a phenol formaldehyde foam plate layer (1) and a foam ceramic micro bead layer (2). The foam ceramic micro bead heat-retaining and heat-insulating fireproof plate is characterized in that the foam ceramic micro bead layer blended with fireproof resin is hot-pressed on one surface of the phenol formaldehyde foam plate. The production method comprises the following steps: firstly, components are prepared according to parts by weight: 1000 parts of powder ceramic hollow micro beads, not less than 100 parts of phenol formaldehyde resin or trimeric cyanamide resin, and 10 to 30 parts of solidifying agent hexamethylene tetramine; secondly, the components are evenly blended, poured into a mould and flattened; thirdly, the phenol formaldehyde foam plate is put into the mould; and fourthly, temperature and pressure are increased on a hot pressing machine, the raw material selected in the invention comprises powder ceramic hollow micro beads which can bear the high temperature of hundreds of Celsius degrees and has the advantages of high temperature resistance, non distortion, light mass, high intensity and fire prevention after being heated, pressurized and shaped through adding a bonding agent and a solidifying agent, and the purpose of the invention is completely achieved.

Owner:四川威尔达节能科技有限公司

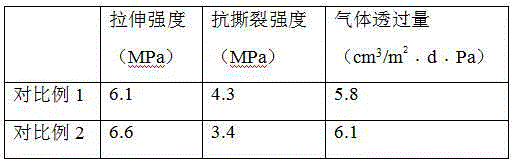

Film material for greenhouse and preparation method of film material

The invention belongs to the field of plastic film materials, and relates to a film material for a greenhouse and a preparation method of the film material. The film material comprises PE (polyethylene), PVC (polyvinyl chloride), polyethylene glycol diacrylate, methyltriacetoxysilane, trimethylsiloxysilicate, polyethylene adipate-1,4-glycol, polyglycerol polyricinoleate and triethyl citrate. The preparation method comprises the following steps that (1) a high-speed mixer is started and the materials are added for high-speed uniform mixing; (2) extruding granulation is performed by a twin-screw extruder; (3) the materials are plasticized and then extruded; (4) the materials are pulled; and (5) the materials are flattened to form the film material for the greenhouse. The prepared film material for the greenhouse has good tensile strength, tearing strength and air tightness.

Owner:SUZHOU DINGLI PACKAGING

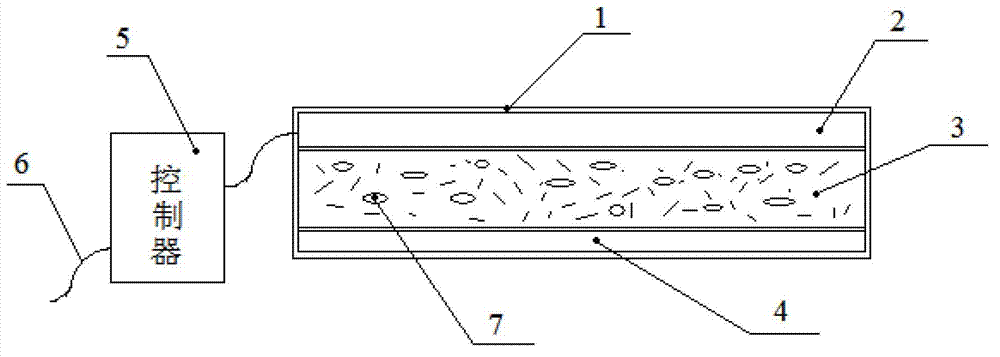

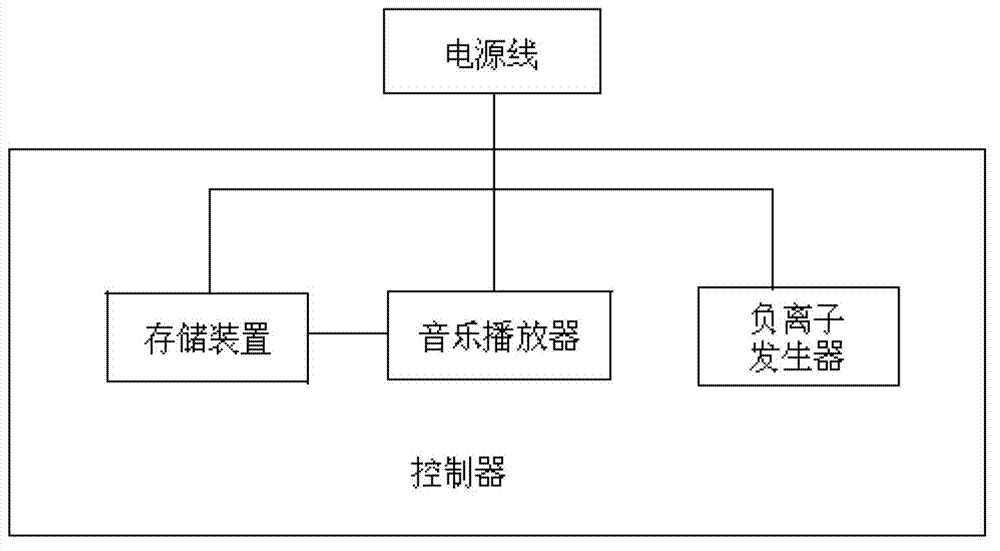

Intelligent water heating health preserving mattress

InactiveCN102763996AHigh temperature resistantNon-deformableStuffed mattressesSpring mattressesElectricityEngineering

The invention discloses an intelligent water heating health preserving mattress, which comprises a mattress body and a controller, wherein the mattress body comprises a mattress outer cover, an ice pad, an inner pad layer and a water heating layer, the ice pad, the inner pad layer and the water heating layer are sequentially arranged inside the mattress outer cover and are in sequential overlapped arrangement from bottom to top, tourmaline sheets in uniform distribution are arranged inside the inner pad layer, the water heating layer is electrically connected with the controller, and the controller is connected with a power supply through a power supply wire. The mattress provided by the invention has the heating function, and also has the temperature reduction and dry heat relieving functions, the tourmaline sheets arranged in the inner pad layer can promote the human body mineral substance absorption, and various promoting effects are realized on the human body health. The intelligent water heating health preserving mattress belongs to a comfortable high-technology product with complete functions and high use safety.

Owner:王占海

Baking-free plant straw building wall material and production method thereof

ActiveCN102225861ASimple production processReduce energy consumptionSolid waste managementRoom temperatureAcoustic board

The invention discloses a baking-free plant straw building wall material and a production method thereof. The wall material is mainly obtained by the following steps: mixing the following components in parts by weight: 5-20 parts of light calcium carbonate, 10-30 parts of bentonite, 5-15 parts of silicon ash, 2-5 parts of triethanolamine, 1-3 parts of organic silicon and 15-25 parts of cotton straw powder; adding 40-55 parts of modified sodium carbonate for abundantly and evenly stirring; and placing the mixture in an extrusion forming machine for extrusion formation under the pressure of 10-15 Mpa so as to obtain the building wall material. Compared with the prior art, the wall material disclosed by the invention is naturally solidified at room temperature after raw material smashing, stirring and extrusion forming, thus production process is extremely simple, and the produced product has the characteristics of light weight, low energy consumption, no pollution, corrosion resistance, dampproof property, mothproof property and the like and can be widely applied to walls, wallboards and sound insulation plates in the field of buildings.

Owner:新疆西营海华新型建材有限公司

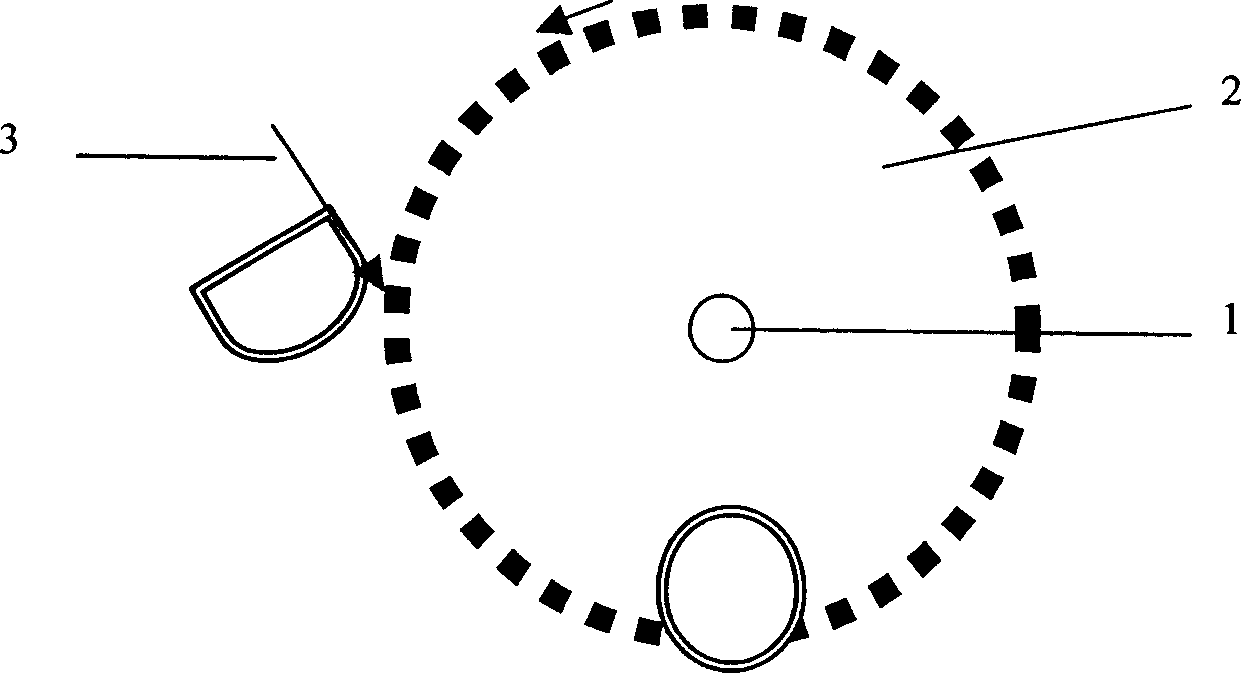

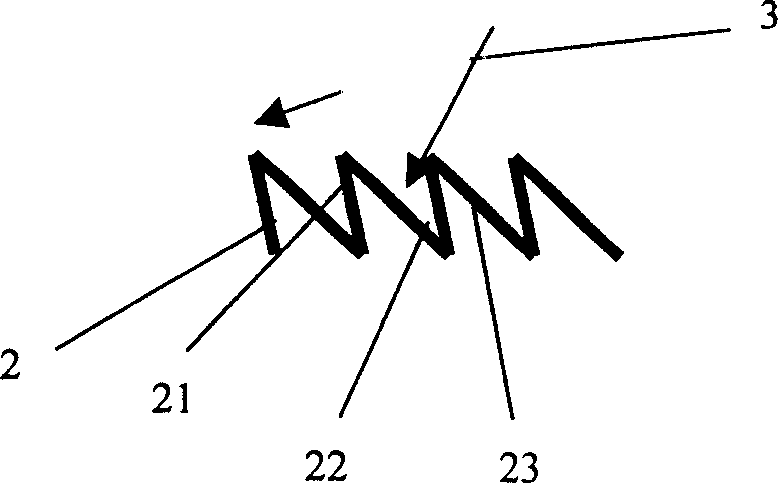

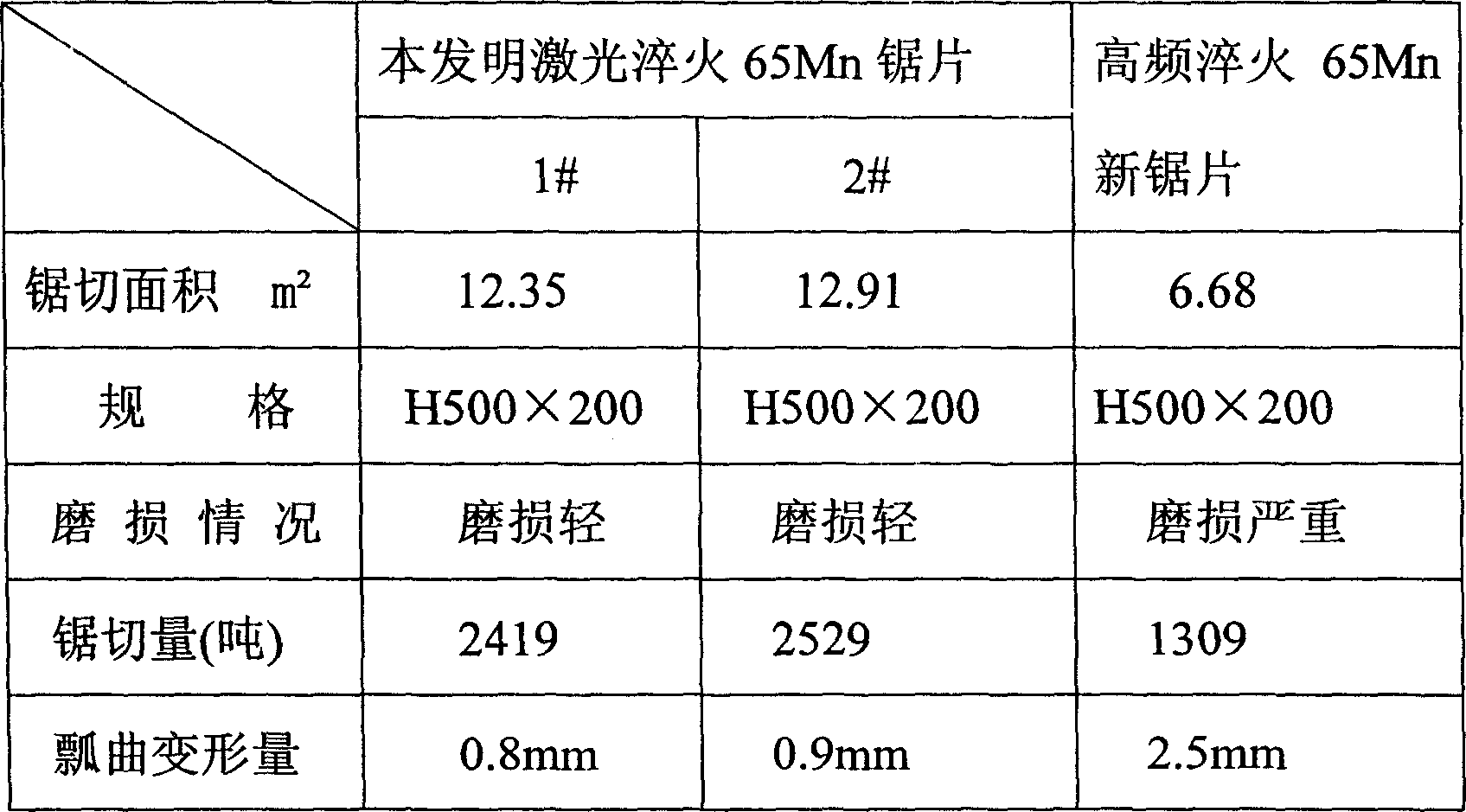

Laser reinforcing technological method for circular saw bit

InactiveCN1851006ANon-deformableExtended service lifeFurnace typesHeat treatment furnacesCircular discCircular saw

The invention discloses the laser intensifying method using for the disc saw piece, it includes the steps: (1) the disc saw piece is fixed on the tool principal axis; (2) the tooth part is executed the spreading pretreatment using the absorbing light; (3) the tooth part is executed the laser intensifying process, the tool principal axis and the irradiating direction of the light beam is vertical, the light beam irradiates the disc saw piece radial. The invention can quench the all working part of the tooth, so the root of the tooth is protected, the laser intensifying has the inhere advantage of intensifying, so the saw piece has many merits such as the long using life, the better ability of standing up the tear, the fixedness and the without the crack.

Owner:GUANGTONG TECH GUANGZHOU CITY +1

Island ultra-thin fiber needling PU basecloth nonsulphur sulfuration impregnation liquid and method for manufacturing the basecloth

A needle-punched nonwoven raw PU fabric is prepared from the islands-type superfine polyester / polyamide fibres through non-sulfur sulfurizing, thermosensitive setting to uniformly disperse the copolymer emulsion in the gaps of needle-punched non-woven fabric, decreasing alkali content to dissolving out polyester component, and softening finishing. Its advantages are high air and moisture permeability, soft handle, high strength and elasticity, and less environmental pollution.

Owner:杭州福华人造革基布有限公司

Multifunctional breathable fabric

InactiveCN103462270AGood moisture absorption and air permeabilityWear cool and comfortableProtective garmentSpecial outerwear garmentsPolyesterMoisture

The invention discloses multifunctional breathable fabric which is formed by blending and weaving polyester fibers, natural silk fibers, natural wool fibers and ramie fibers. The multifunctional breathable fabric is composed of, by weight, 10-15% of the polyester fibers, 24-29% of the natural silk fibers, 20-35% of the natural wool fibers and 31-36% of the ramie fibers. The fabric is formed by blending and weaving the polyester fibers, the natural silk fibers, the natural wool fibers and the ramie fibers, thereby being good in moisture-absorbing and breathing performance and cool and comfortable to wear, the polyester fibers, the natural wool fibers and the ramie fibers have a function of resisting and absorbing ultraviolet rays and can protect human skin, and the polyester fibers also have effect of enabling the fabric not to deform.

Owner:WUJIANG HAIFENG WEAVING

Vermiculite plate with sound insulation and fire protection functions and preparation method of vermiculite plate

ActiveCN109133837ASimple production processNo need for heat and pressureFire protectionWeather resistance

The invention belongs to the field of building material plates, and discloses a vermiculite plate with sound insulation and fire protection functions. The vermiculite plate comprises, by weight, 20-60parts of expanded vermiculite, 5-20 parts of sound insulation materials, 10-50 parts of modified water glass, 3-25 parts of curing agents and 5-30 parts of water by pouring. The invention further discloses a preparation method of the vermiculite plate. The vermiculite plate has excellent sound insulation, heat insulation, fire protection and water resistance performances, and has the advantages of light weight, long-laid non-deformation, simple processing technology, high strength, good weather resistance, green and environmental protection.

Owner:梁海潮

Composite sound insulation plate and production process thereof

The invention discloses a composite sound insulation board and a production process thereof. The composite sound insulation board is prepared from the following raw materials in parts by weight: 35-40parts of bentonite, 6-15 parts of wood fibers, 5-10 parts of perlite particles, 4-8 parts of activated carbon, 6-11 parts of plant straw powder, 2-5 parts of light calcined magnesia, 3-7 parts of xanthan gum powder, 5-10 parts of expanded vermiculite, 5-7 parts of silica fume, 10-20 parts of polyacrylamide and 5-9 parts of a binder. According to the composite sound insulation board, the characteristics of the bentonite are utilized, common pollutants in air can be adsorbed, and the prepared sound insulation board is good in sound insulation effect, has heat preservation and waterproof performance, is free of radioactive elements and does not generate toxic gas; the composite sound insulation board is simple in preparation process and suitable for industrial mass production; the raw materials are easily available and environment-friendly and accord with the green development trend of China; the composite sound insulation board also has the characteristics of corrosion resistance, moisture resistance, worm damage resistance, no deformation and the like, and can be widely applied to walls, wallboards and sound insulation boards in buildings.

Owner:佛山市易于嘉农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com