Artificial marble slab embedded with metal patterns and manufacturing process thereof

A marble slab, inlaid metal technology, applied in the field of decorative building materials, can solve the problems of lack of in-depth development and research, natural marble damage, etc., and achieve the effect of bright three-dimensional aesthetic effect, color and thickness, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

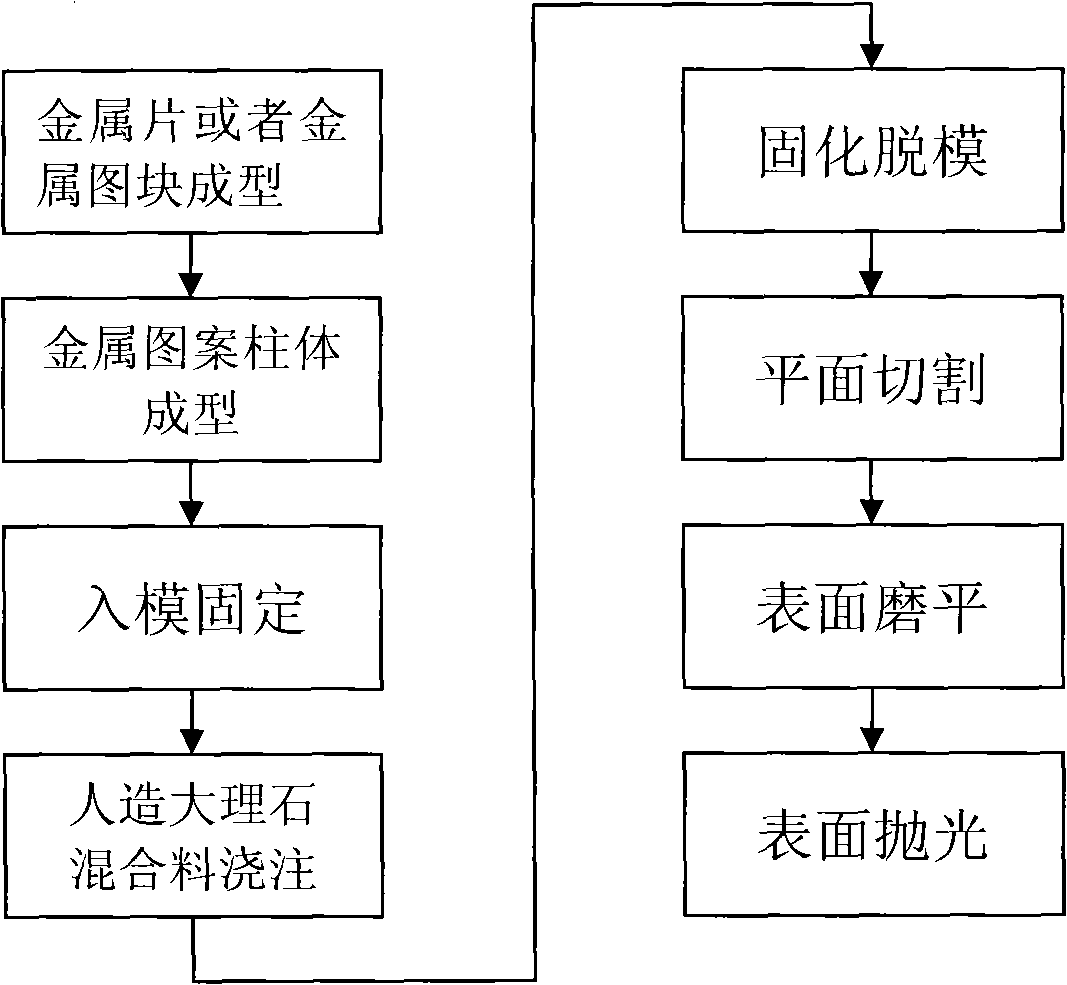

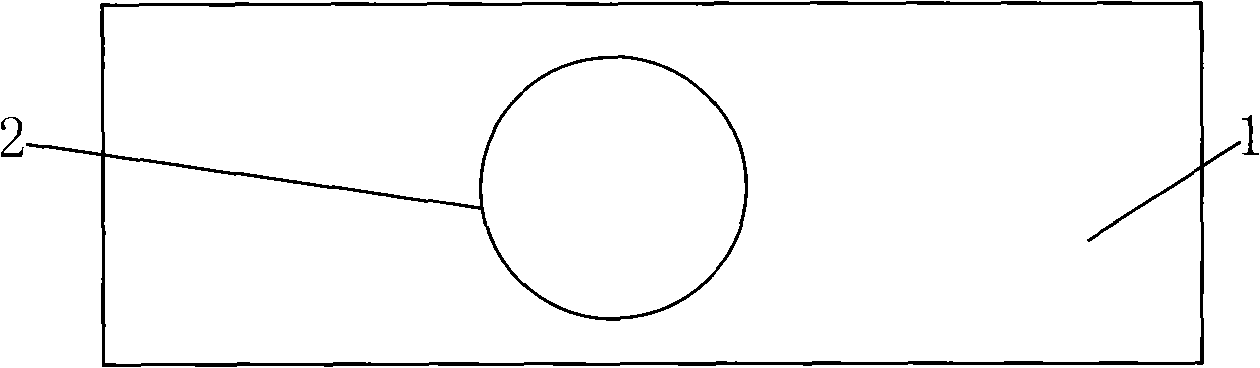

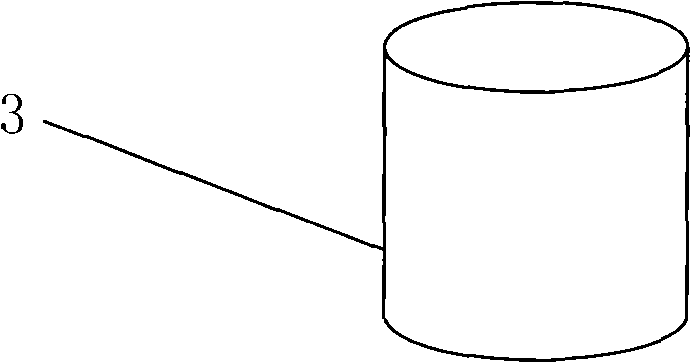

[0024] Such as Figure 1 to Figure 5 As shown in the figure: 1 is an artificial marble slab, 2 is a metal pattern, and 3 is a metal pattern column.

[0025] Make a cylindrical metal pattern column from a metal sheet or a metal block, place it in a mold for making artificial marble and fix it, then pour the artificial marble mixture, compound and solidify, and form an artificial marble material after demoulding, and then cut the marble material And surface polishing, made of artificial marble slabs with inlaid metal patterns.

Embodiment 2

[0027] Such as Figure 4 , Figure 5 As shown, the metal pattern post is an embodiment of a four-pointed star-shaped metal pattern post.

[0028] Such as Figure 1 to Figure 5 As shown, the artificial marble slab inlaid with metal patterns produced by the present invention is made by composite casting of embedded metal pattern columns and artificial marble mixture, and the thickness can be cut to an ultra-thin plate of 5-20mm. The metal can be gold, silver, copper, iron, tin, aluminum, zinc, nickel, chromium or stainless steel or a mixture of several metals. The artificial marble raw materials are made of wollastonite, resin, methyl ethyl ketone peroxide, color paste, Composition of calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com