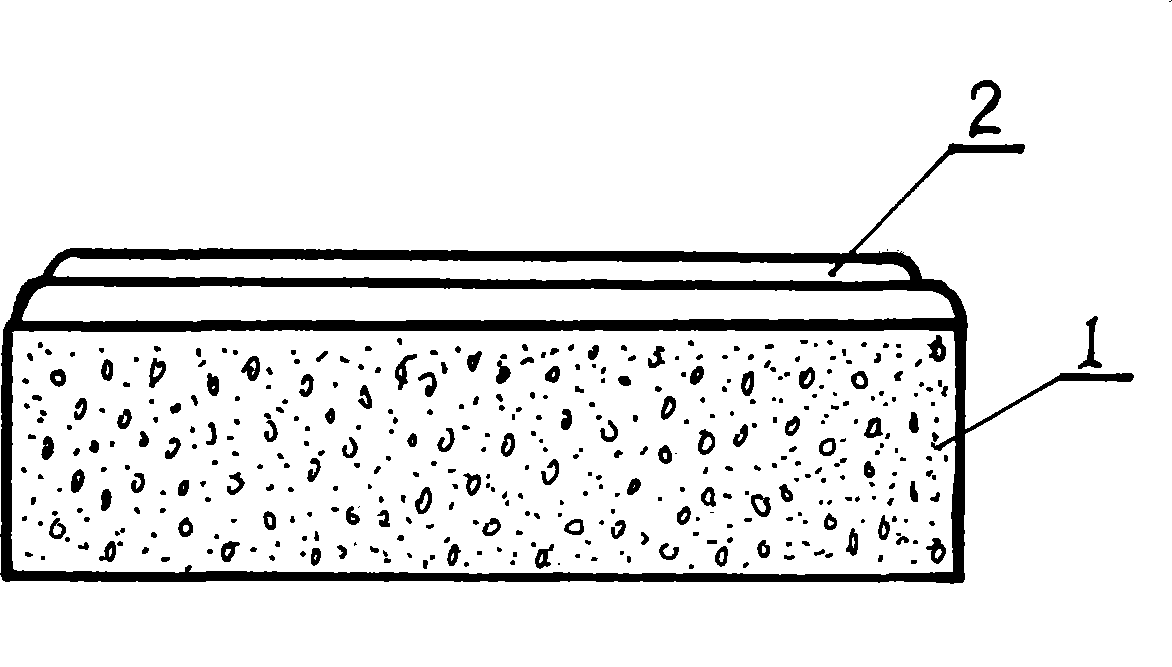

Heat preserving facing integrated inorganic section bar and preparation thereof

An integrated and decorative technology, applied in the field of building wall thermal insulation materials, can solve the problems of unsafe construction, easy cracking, falling off, etc., and achieve the effects of good thermal insulation performance, good water repellency performance, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Inorganic materials with integrated thermal insulation and decorative surface of the present invention can be carried out according to the following steps:

[0031] 1) First sieve from the expanded perlite material to obtain particle core materials with a particle size of ≤3.5mm and ≥1.0mm; then take sodium silicate, potassium dichromate, alum and potassium chromium sulfate from the inorganic salt composite material respectively, and Grind and sieve separately to make powder with a particle size of 180-230 mesh, then take sodium silicate, potassium dichromate, alum and potassium chromium sulfate from the inorganic salt compound, and grind and sieve to make a particle size of 180-230 mesh. Purpose powder, then according to the ratio by weight of 85% of sodium silicate, 5% of potassium dichromate, 5% of alum, and 5% of potassium chromium sulfate, take various powder raw materials and mix them evenly, then add water to prepare slurry, add The amount of water can be tested ...

Embodiment 2

[0037] The production method of the thermal insulation and decorative surface integrated inorganic material in this embodiment is basically the same as that of Example 1, the only difference being: sodium silicate, potassium dichromate, alum and potassium chromium sulfate in the step of preparing the inorganic salt composite slurry shell material The ratio by weight percentage can be: 40% sodium silicate, 20% potassium dichromate, 20% alum, 20% chromium potassium sulfate; The volume ratio of the shell material can be: expanded perlite granular material: inorganic salt composite slurry shell material = 100:70.

[0038] The proportioning by weight of quartz sand, calcium oxide, calcium carbonate, nano-silicon oxide superfine powder and wood fiber superfine powder in the step of preparing the wet material of the facing layer can be: 50 parts of quartz sand, 15 parts of calcium carbonate, 10 parts of calcium oxide part, 15 parts of cement, 5 parts of nano silicon oxide superfine p...

Embodiment 3

[0040] The production method of the thermal insulation and decorative surface integrated inorganic material in this embodiment is basically the same as that of Example 1, the only difference being: sodium silicate, potassium dichromate, alum and potassium chromium sulfate in the step of preparing the inorganic salt composite slurry shell material The ratio by weight percentage can be: sodium silicate 70%, potassium dichromate 10%, alum 10%, chromium potassium sulfate 10%; when preparing the insulation matrix aggregate, expanded perlite granular material and inorganic salt compound slurry The volume ratio of the shell material can be: expanded perlite granular material: inorganic salt composite slurry shell material = 100:60.

[0041] The proportioning by weight of quartz sand, calcium oxide, calcium carbonate, nano silicon oxide superfine powder and wood fiber superfine powder in the step of preparing the wet material of the facing layer can be: 45 parts of quartz sand, 12 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com