Knitting technology for high-elastic silk stocking

A technology of stockings and elastic, which is applied in the field of knitting technology of high elastic stockings, can solve the problems of low cotton content, poor comfort of socks, easy to produce peculiar smell, etc., and achieve high cotton content, comfortable wearing and good shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

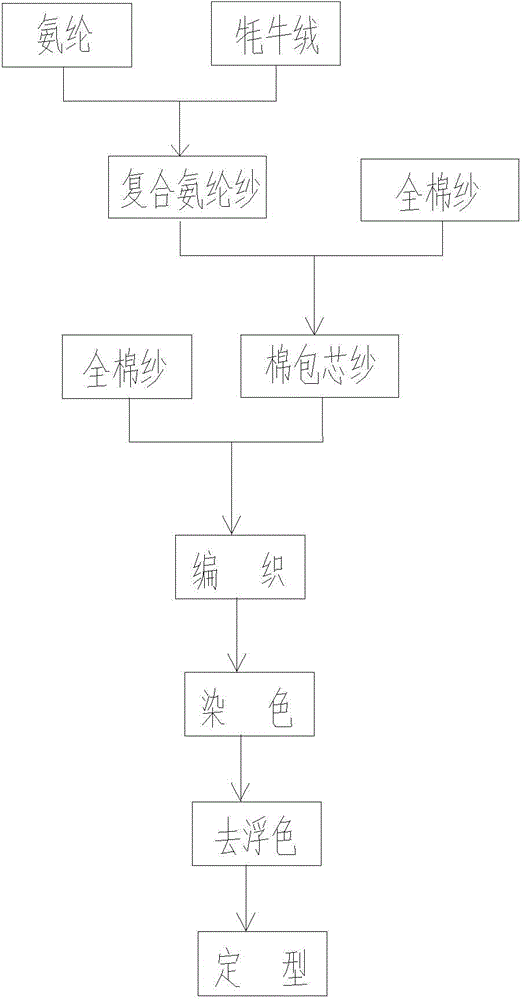

[0022] The weaving process includes the following steps:

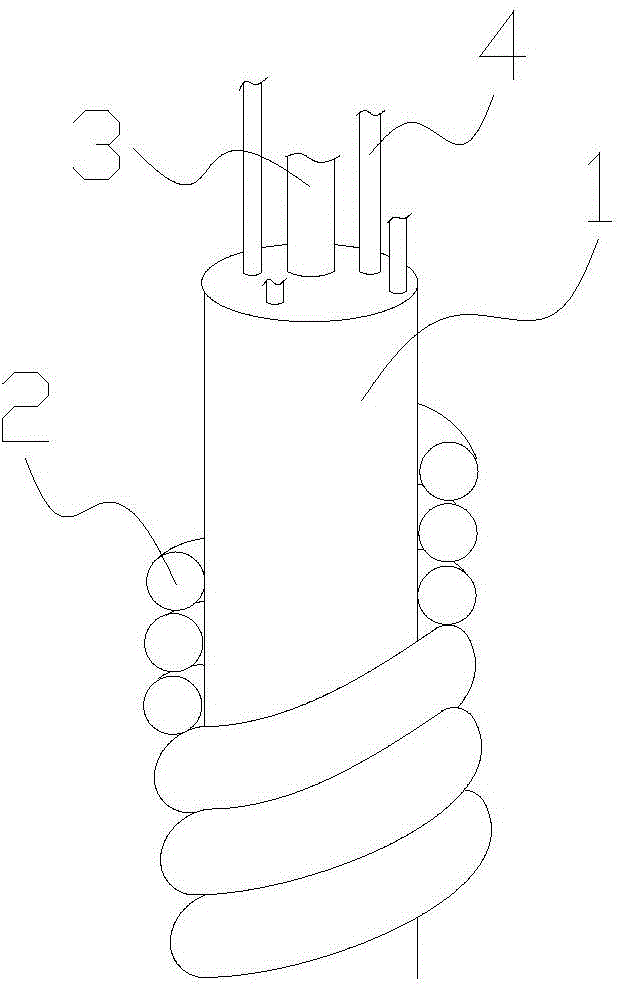

[0023] 1) Composite spandex yarn production, using spandex as the inner yarn, and then wrapping yak velvet on the surface of spandex through the nozzle on the air-jet spinning machine to produce a high-elastic composite spandex yarn with a twist of 1800T / M and a draft ratio of 3.0 , spandex is 15D / 1F spandex.

[0024] 2), the production of cotton core-spun yarn, the composite spandex yarn produced in step 1) is used as the inner yarn, and then the cotton yarn is wrapped on the composite spandex yarn on a high-speed wrapping machine to produce a twist of 2000 with the cotton yarn as the outsourcing yarn. / M, cotton core-spun yarn with a draft ratio of 3.5;

[0025] 3), weaving, the composite spandex yarn and cotton core-spun yarn produced in step 1) and step 2) are fed into the knitting machine simultaneously according to two or more strands to carry out plain weave weaving.

[0026] 4) Dyeing: under the condition of ...

Embodiment 2

[0031] The weaving process includes the following steps:

[0032] 1) Composite spandex yarn production, using spandex as the inner yarn, and then wrapping yak velvet on the surface of spandex through the nozzle on the air-jet spinning machine to produce a high-elastic composite spandex yarn with a twist of 2200T / M and a draft ratio of 2.4 , spandex is 15D / 1F spandex.

[0033] 2), the production of cotton core-spun yarn, the composite spandex yarn produced in step 1) is used as the inner yarn, and then the cotton yarn is used as the outer covering yarn on the high-speed wrapping machine to wrap the cotton yarn on the composite spandex yarn to produce a twist of 2400T / M, cotton core-spun yarn with a draft ratio of 3.0;

[0034] 3), weaving, the composite spandex yarn and cotton core-spun yarn produced in step 1) and step 2) are fed into the knitting machine simultaneously according to two or more strands to carry out plain weave weaving.

[0035] 4) Dyeing: under the conditio...

Embodiment 3

[0040] The weaving process includes the following steps:

[0041] 1) Composite spandex yarn production, using spandex as the inner yarn, and then wrapping yak velvet on the surface of spandex through the nozzle on the air-jet spinning machine to produce a high-elastic composite spandex yarn with a twist of 2000T / M and a draft ratio of 2.7 , spandex is 15D / 1F spandex.

[0042] 2), cotton core-spun yarn is made, and the composite spandex yarn produced in step 1) is used as lining yarn, and then cotton yarn is wrapped on the composite spandex yarn on a high-speed wrapping machine as outsourcing yarn to produce a twist of 2200 / M, cotton core-spun yarn with a draft ratio of 3.25;

[0043] 3), weaving, the composite spandex yarn and cotton core-spun yarn produced in step 1) and step 2) are fed into the knitting machine simultaneously according to two or more strands to carry out plain weave weaving.

[0044] 4) Dyeing: under the condition of 65°C, add dyestuff and color fixing ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

| Twist | aaaaa | aaaaa |

| Twist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com