Foaming ceramic micro-ball heat preservation heat insulation fire-proof slab and producing method thereof

A technology of foaming ceramics, heat preservation and heat insulation, applied in covering/lining, construction, building structure, etc., can solve the problems of loss of heat preservation and heat insulation effect and decorative effect, wall falling off and hurting people, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

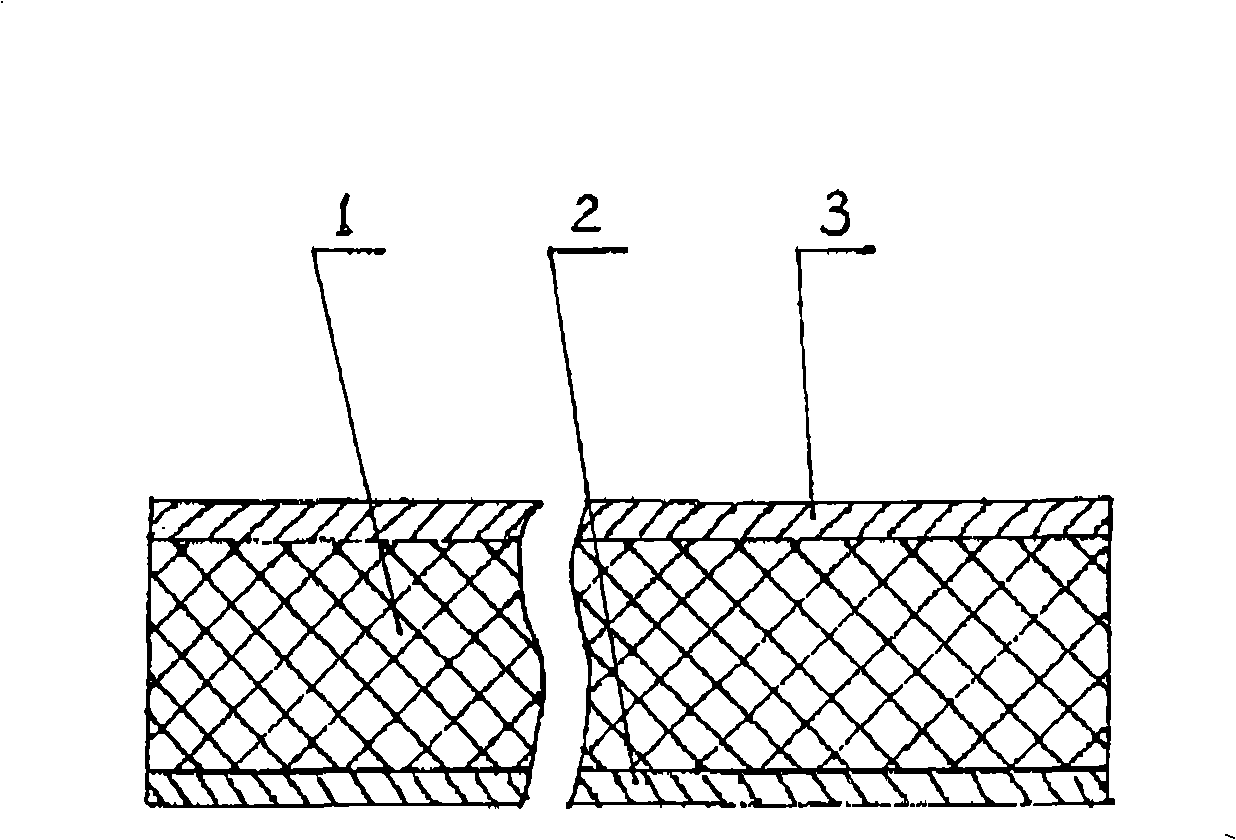

[0018] Embodiment 1, the foamed ceramic microbead thermal insulation and fireproof board is composed of a phenolic foam board layer 1 and a foamed ceramic microbead layer 2, and one surface of the phenolic foam board is hot-pressed with a foamed ceramic microbead mixed with a fireproof resin layer. Its production method is as follows: A, prepare raw materials according to the following components by weight: 1000 parts of powdery ceramic hollow microspheres, 100 parts of phenolic resin (solid parts), 10 parts of curing agent chloromethylenetetramine; B, the above-mentioned composition Mix the parts evenly, pour into the mold, and smooth; C. Put the phenolic foam board in the mold; D. Heat and pressurize on the hot press. The required pressing pressure is 0.001 MPa. The heating temperature was 100°C. The molding time is 1200S.

Embodiment 2

[0019] Embodiment 2, the foamed ceramic microbead thermal insulation and fireproof board is composed of a phenolic foam board layer 1 and a foamed ceramic microbead layer 2, and one surface of the phenolic foam board is hot-pressed with a foamed ceramic microbead mixed with a fireproof resin layer. Its production method is as follows: A, prepare raw materials according to the following components by weight: 1000 parts of powdery ceramic hollow microspheres, 150 parts (solid parts) of phenolic resin, 20 parts of curing agent chloromethylenetetramine; B, above-mentioned composition Mix the parts evenly, pour into the mold, and smooth; C. Put the phenolic foam board in the mold; D. Heat and pressurize on the hot press. The required pressing pressure is 0.1 MPa. The heating temperature was 120°C. The molding time is 800S.

Embodiment 3

[0020] Embodiment 3, the foamed ceramic microbead thermal insulation and fireproof board is composed of a phenolic foam board layer 1 and a foamed ceramic microbead layer 2, and one surface of the phenolic foam board is hot-pressed with a foamed ceramic microbead mixed with a fireproof resin layer, the other side of the phenolic foam board is provided with a hot-pressed foamed ceramic bead layer (3) mixed with fireproof resin. Its production method is as follows: A, prepare raw materials according to the following components by weight: 1000 parts of powdery ceramic hollow microspheres, 200 parts of melamine resin (solid parts), 15 parts of curing agent chloromethylenetetramine; B, the above-mentioned composition Mix evenly, pour into the mold, and smooth; C, put phenolic foam board in the mold; D, add the mixed component materials, smooth; E, heat and press on the hot press. The required pressing pressure is 0.08 MPa. The heating temperature was 180°C. The molding time is 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com