Coal ash heat-preservation heat-insulation fire-proof slab and producion method thereof

A thermal insulation board, thermal insulation technology, applied in the direction of thermal insulation, fire prevention, building thermal insulation materials, etc., can solve the problems of wall falling off and hurting people, loss of thermal insulation effect and decorative effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

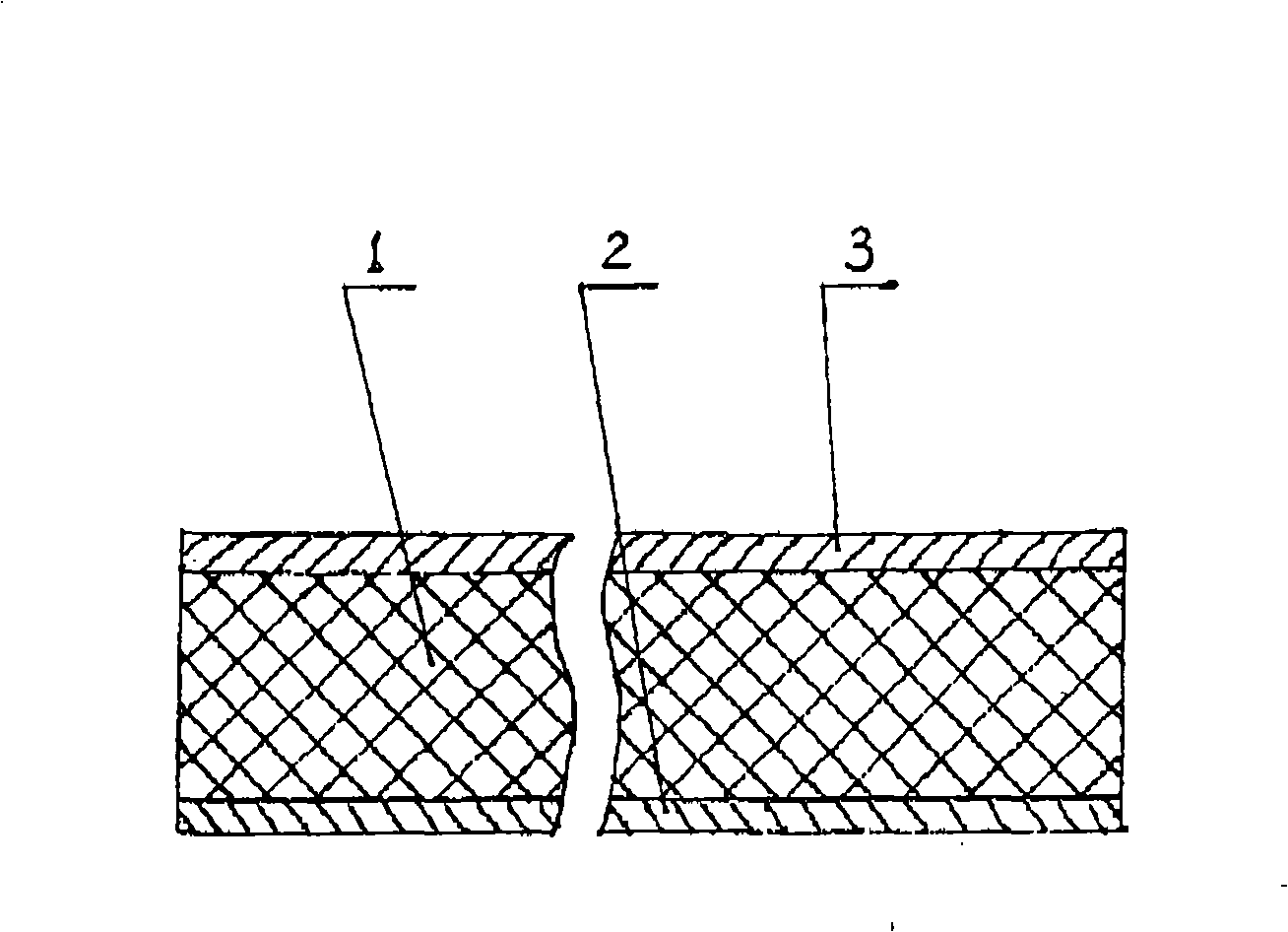

[0019] Embodiment 1, the thermal insulation and fire prevention board of fly ash is composed of phenolic foam board layer 1 and fly ash layer 2, and a fly ash layer mixed with fireproof resin is hot-pressed on one surface of the phenolic foam board. Its production method is as follows: A, prepare raw materials according to the following components by weight: 1000 parts of fly ash, 100 parts of phenolic resin (solid content), 10 parts of curing agent chloromethylenetetramine; B, the above-mentioned components are mixed , pour into the mold, smooth; C, put the phenolic foam board in the mold; D, heat and pressurize on the hot press. The required pressing pressure is 0.001 MPa. The heating temperature was 100°C. The molding time is 1200S.

Embodiment 2

[0020] Embodiment 2, the thermal insulation and fire prevention board of fly ash is composed of phenolic foam board layer 1 and fly ash layer 2, and a fly ash layer mixed with fireproof resin is hot-pressed on one surface of the phenolic foam board. Its production method is as follows: A, prepare raw materials according to the following components by weight: 1000 parts of fly ash, which are mixed with 400 parts of glass foamed hollow microspheres, 150 parts of phenolic resin (solid parts), curing agent chloromethine tetra 20 parts of amine; B. Mix the above components, pour them into the mold and smooth them; C. Put phenolic foam board in the mold; D. Heat and press on the hot press. The required pressing pressure is 0.1 MPa. The heating temperature was 120°C. The molding time is 800S.

Embodiment 3

[0021] Embodiment 3, the fly ash thermal insulation and fire prevention board is made up of phenolic foam board layer 1 and fly ash layer 2, and one surface of the phenolic foam board is hot-pressed a fly ash layer mixed with fireproof resin, the phenolic foam board The other side is provided with a hot-pressed fly ash layer 3 mixed with fireproof resin. Its production method is as follows: A, prepare raw materials according to the following components by weight: 1000 parts of fly ash, 200 parts of melamine resin (solid parts), 15 parts of curing agent chloromethylenetetramine; B, above-mentioned components are mixed , pour into the mold, and smooth it; C, put the phenolic foam board in the mold; D, add the mixed component materials, and smooth it; E, heat and press on the hot press. The required pressing pressure is 0.08 MPa. The heating temperature was 180°C. The molding time is 600S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com