Patents

Literature

41results about How to "Comply with the industrial policy of energy conservation and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

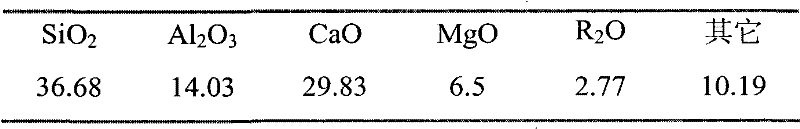

The invention discloses a method for preparing jade type microcrystalline glass with high-temperature furnace slag, which comprises the steps of: taking molten furnace slag as main materials; adding auxiliary materials such as fluxing clarifying agent and additive, and the like; further melting and clarifying in a high-temperature furnace to form glass liquid; pouring or calendaring the glass liquid to form basic glass; heat processing the basic glass by means of crystallization to obtain the rough product of the jade type microcrystalline glass; and finish machining to obtain the finished product of the jade type microcrystalline glass. The method not only effectively utilizes the molten high-temperature furnace slag, but also sufficiently utilizes heat energy stored in the high-temperature furnace slag, and prevents the high-temperature furnace slag from generating huge amounts of corrosive hot steam in the process of discharging. The jade type microcrystalline glass prepared by the method is in the status of semitransparent wax, exactly looks like natural jade, has good cutting performance, high intensity and good tenacity, can be used for replacing natural stones in construction industry, and can be used for replacing natural rare jades in machining artware.

Owner:TSINGHUA UNIV

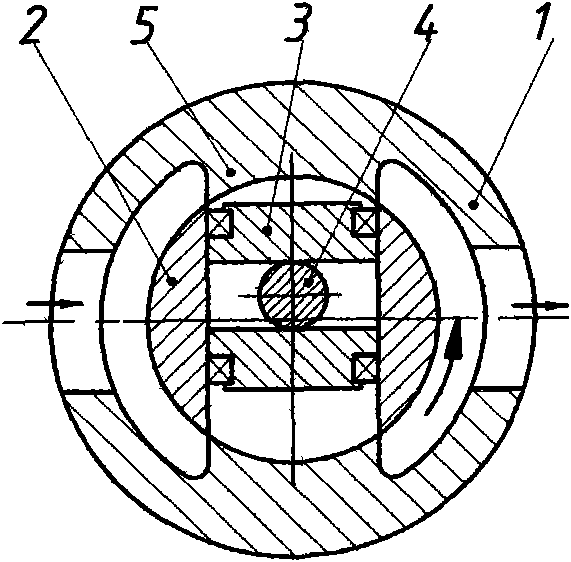

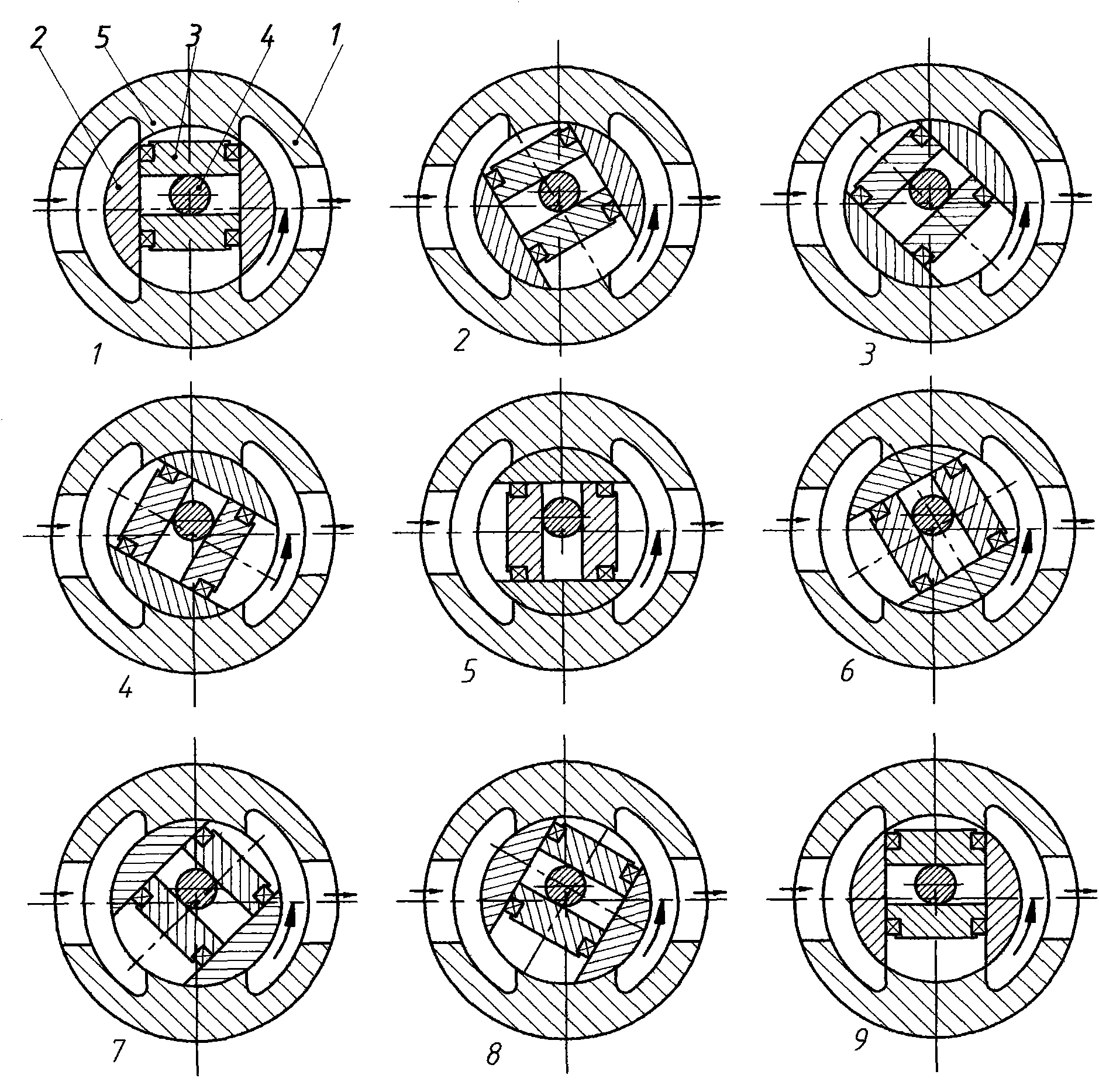

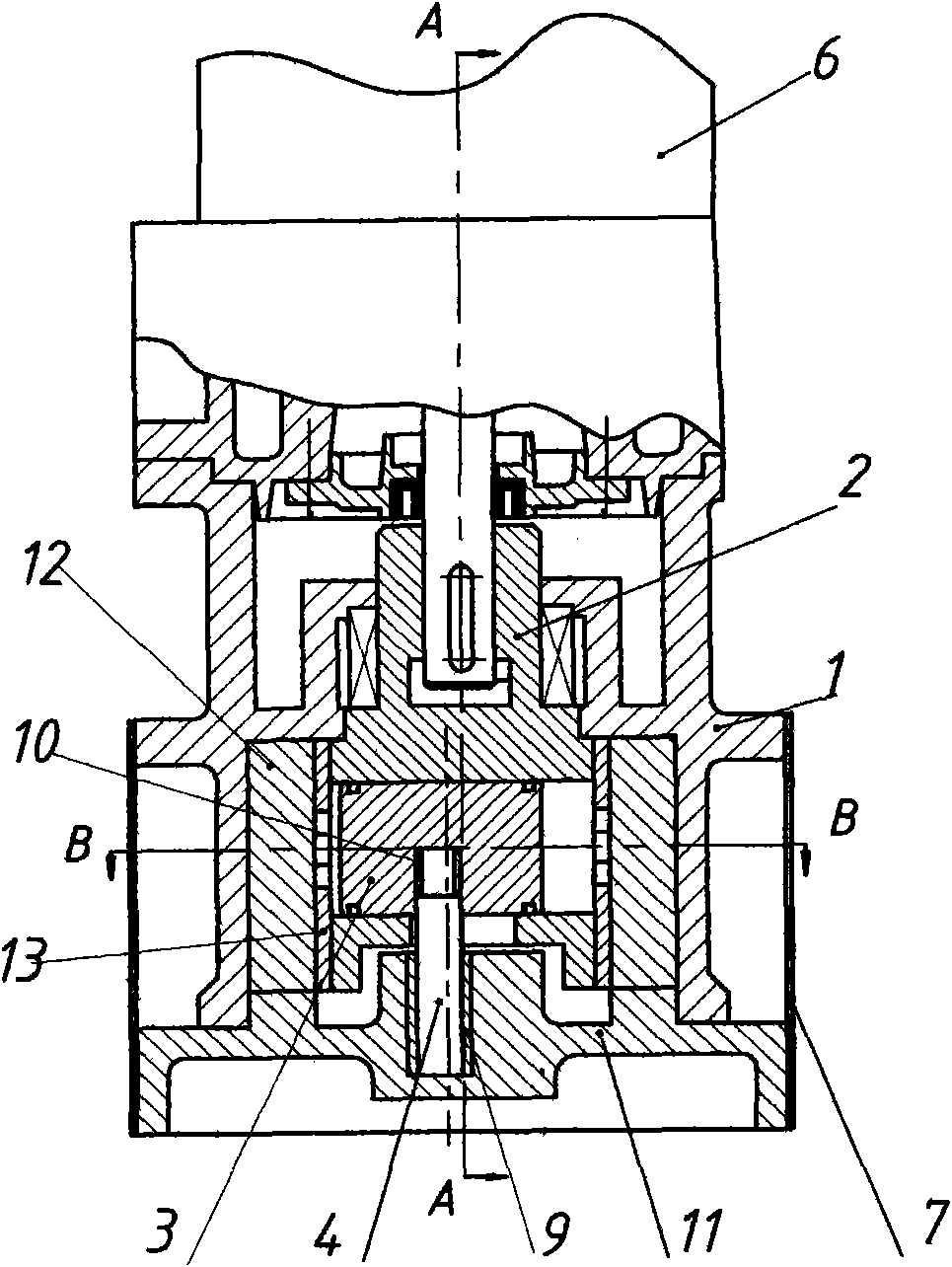

Small rotor-type submersible pump

InactiveCN101871449AGood self-primingWide runnerRotary piston pumpsRotary piston liquid enginesViscous liquidMotor drive

The invention relates to a small rotor-type submersible pump suitable for operation under liquid, which is formed by a pump body, a volute tongue bush, a rotor, a rotor bush, a piston, an eccentric shaft, a pump base, a filter screen and a submersible motor. The invention uses the principle of an eccentric mechanism to realize the reciprocating motion of the piston. When the submersible motor drives the rotor to rotate, the piston rotates around the eccentric shaft while the piston makes reciprocating motion and thereby liquid is drawn in and drained. Under the high-speed rotation, the piston drains liquid two times per turn and thereby the liquid flow output is stable, no pulse is caused, the vibration is low and the noise is low; and moreover, the volume is small, the number of parts is small, the cost is low, the hydraulic loss and the volumetric loss are small, the efficiency is above 70 percent and the pump is a high-efficiency energy-saving product for replacing a centrifugal submersible pump. Moreover, the pump has the good self-absorption performance and the wide runner of a displacement pump and can be used for delivering water liquid and pumping viscous liquid such as petroleum and liquid containing fibrous impurities and particle impurities, and thereby the application scope of the pump is widened.

Owner:余文凌

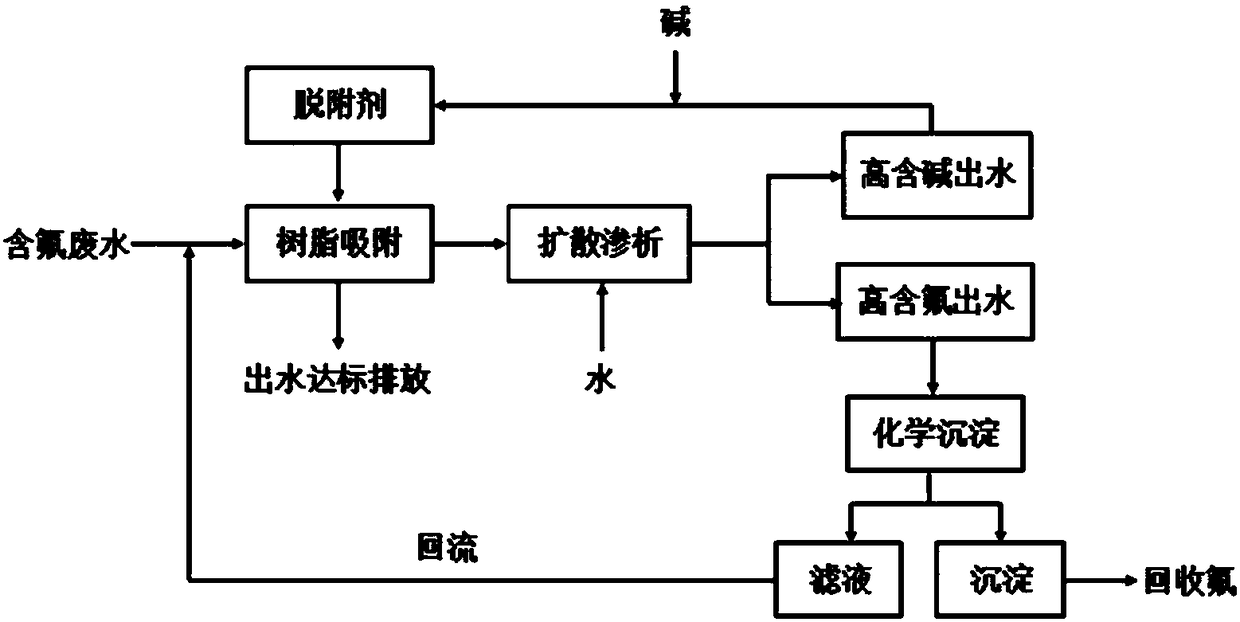

Method for recovering fluoride ions from wastewater

InactiveCN108191118AImprove use valueGuaranteed emission standardsSpecific water treatment objectivesWater contaminantsDesorptionResource recovery

The invention discloses a method for recovering fluoride ions from wastewater and belongs to the fields of wastewater treatment and resource recovery. The method specifically comprises the following steps: the fluoride ions in the fluorine-containing wastewater are discharged up to standard by resin adsorption; a resin desorption solution is treated with combination of a diffusion dialysis technique and a chemical precipitation method, wherein high-alkali effluent of diffusion dialysis effluent can serve as a resin desorption agent to be recycled to a resin desorption section; for high-fluorine effluent of the diffusion dialysis effluent, the fluoride ions are precipitated and recovered in a form of precipitates with the chemical precipitation method, a filtrate and the fluorine-containingwastewater are mixed in a certain ratio, resin is introduced for defluorination, and the fluoride ions in the wastewater are recovered in the form of high-purity calcium fluoride precipitates after being subjected to resin adsorption separation. In the method, alkali in the resin desorption solution is recovered with the diffusion dialysis technique, so that alkali amount needed by resin desorption is reduced substantially, sewage treatment cost is reduced, and effluent quality is guaranteed.

Owner:NANJING UNIV +1

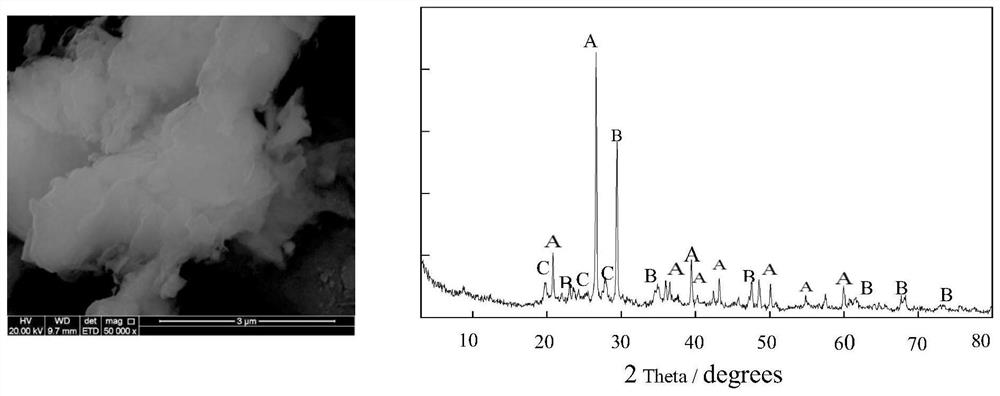

Method for recycling iron-containing zinc-containing sludge to prepare zinc hydroxide and dye-grade iron oxide red

InactiveCN106745193AEliminate secondary pollutionProtect the environmentZinc oxides/hydroxidesFerric oxidesChemistryScrap

The invention relates to a method for recycling iron-containing zinc-containing sludge to prepare zinc hydroxide and dye-grade iron oxide red and belongs to the field of waste resourceful treatment. The method comprises the steps of adding hydrochloric acid into iron-containing zinc-containing sludge to adjusting a pH value, then adding steel scrap, stirring, extracting in an extraction agent, classifying and deoiling; performing back extraction on zinc-containing load organic phase to prepare zinc hydroxide; adding alkaline substance into ferrous chloride solution with the zinc content smaller than or equal to 1g / L to adjust a pH value to be 8.5 to 13.0, introducing oxidizing gas, oxidizing for 60 to 1500min, warming to 50 to 90 DEG C, adding alkaline substance to adjust a pH value as 2.3 to 3.5, introducing oxidizing gas, oxidizing for 30 to 120h, guaranteeing the pH value of liquid is 2.3 to 3.5 in an oxidizing process, finishing oxidization, filtering and drying to obtain the dye-grade iron oxide red. The method is a recycling technology of iron-containing zinc-containing sludge in a hot galvanizing factory and has the advantages of small equipment invest, low energy consumption and high purity of a prepared product.

Owner:NORTHEASTERN UNIV

Method for refining konjak fine powder into konjak micro-powder

The invention discloses a method for refining konjak fine powder into konjak micro-powder. The method mainly comprises the following steps of: swelling and softening 40-mesh to 80-mesh konjak fine powder grains with water in an amount which is 0.5 to 2.5 times the weight of the konjak fine powder grains; and grinding the powder grains with a grinding machine for 3 to 5 minutes to obtain the konjak micro-powder with particle size of less than 120 meshes. The method has the advantages of greatly reducing using amount of ethanol and reducing cost of raw materials, recovery cost and the like, along with high refining degree, high product quality, high production efficiency, low energy consumption, no substances harmful to human body such as sulfur and the like.

Owner:孙光谷

Environmental-friendly clean diesel oil and preparing method thereof

InactiveCN104789280AComply with the basic requirements of dispatchSimple production processLiquid carbonaceous fuelsFuel additivesSocial benefitsCyclohexylamines

The invention provides environmental-friendly clean diesel oil and a preparing method thereof, and belongs to the technical field of the energy industry. An emulsifying agent in the clean diesel oil comprises following raw materials: 15-75 parts of oleic acid, 10-45 parts of methanol, 5-52 parts of cyclohexylamine, 5-45 parts of monoethanolamine, 3-35 parts of octanol, 0.1-5 parts of a lubricant, 0.1-5 parts of ferrocene and 0.1-6 parts of an antioxidant 264. The ratio of the emulsifying agent to water in the diesel oil is 0.5-1.2:1. The diesel oil meets practical application requirements of various vehicles and engineering machines, overcomes defects of other technical schemes at present, and meets basic requirements on vehicle exhaust discharge in China. The diesel oil is simple in production process, low in investment and good in economic benefit and social benefit.

Owner:ZIBO KUNYUAN ENERGY TECH CO LTD

Industrial preparation method of cationic resin based zirconium-loaded nano-composite adsorbent

Belonging to the industrial production filed of nano-composite resin adsorbent for wastewater treatment, the invention discloses an industrial preparation method of a cationic resin based zirconium-loaded nano-composite adsorbent, and specifically relates to a reaction material recyclable industrial preparation method of a cationic resin based zirconium-loaded nano-composite adsorbent. The preparation steps include: preparing a zirconium salt solution; adding acidic cationic resin into the zirconium salt solution in batches, conducting stirring and filtering, and recycling the zirconium salt solution; performing drying; adding a NaOH solution for alkalization to obtain a cationic resin based zirconium-loaded nano-composite, and recycling the alkali liquid; adding a hydrochloric acid solution for neutralization; and performing washing. According to the industrial preparation method of the cationic resin based zirconium-loaded nano-composite adsorbent, the cleaning liquid, the zirconiumsalt solution, the alkali liquid, the acidic liquid and other materials can all be recycled, thus greatly lowering the production cost and environmental pollution. Therefore, the method is in line with the current national energy-saving and emission reduction industrial policies, and is suitable for industrial promotion.

Owner:NANJING UNIV +1

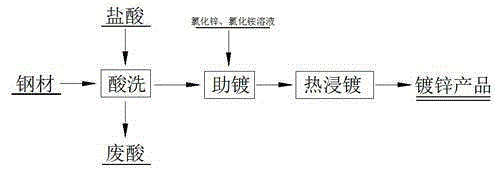

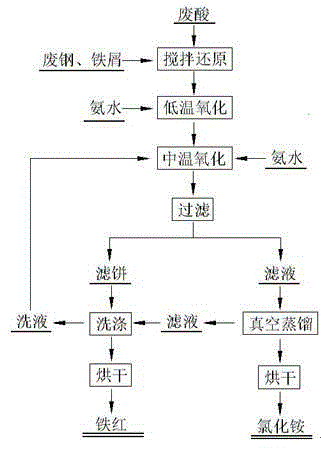

Preparation method of iron oxide red and ammonium chloride

InactiveCN105217694AImprove dynamic conditionsLess investmentFerric oxidesAmmonium halidesOxygenFerric

The invention relates to a preparation method of iron oxide red and ammonium chloride, and belongs to the technical field of waste resourceful treatment. The method is as below: mixing and evenly stirring waste acid and steel scrap or steel scrap leftover to obtain a solution with all iron in the form of Fe<2+> (reducing all Fe<3+> in the waste acid to Fe<2+>); adjusting the pH value of the obtained solution with ammonia, and at the same time introducing air or oxygen for oxidation at low temperature; heating the solution subjected to low temperature oxidation to 70-95 DEG C, adjusting the pH value of the solution by hydrochloric acid, introducing air or oxygen for middle temperature oxidation; filtering the turbid liquid to obtain a filter cake and a filtrate, washing the filter cake, drying at a temperature of 80-130 DEG C for 30-180 min to obtain iron oxide red with uniform color bright and purity greater than 99.5wt%; conducting vacuum distillation on the obtained filtrate and washing water to obtain a crystal, and drying the crystal at the temperature of 80-130 DEG C for 30-180 min to obtain NH4Cl with purity greater than 99.5 wt%. The method can produce high purity ammonium chloride and high tinting strength iron oxide red.

Owner:KUNMING UNIV OF SCI & TECH

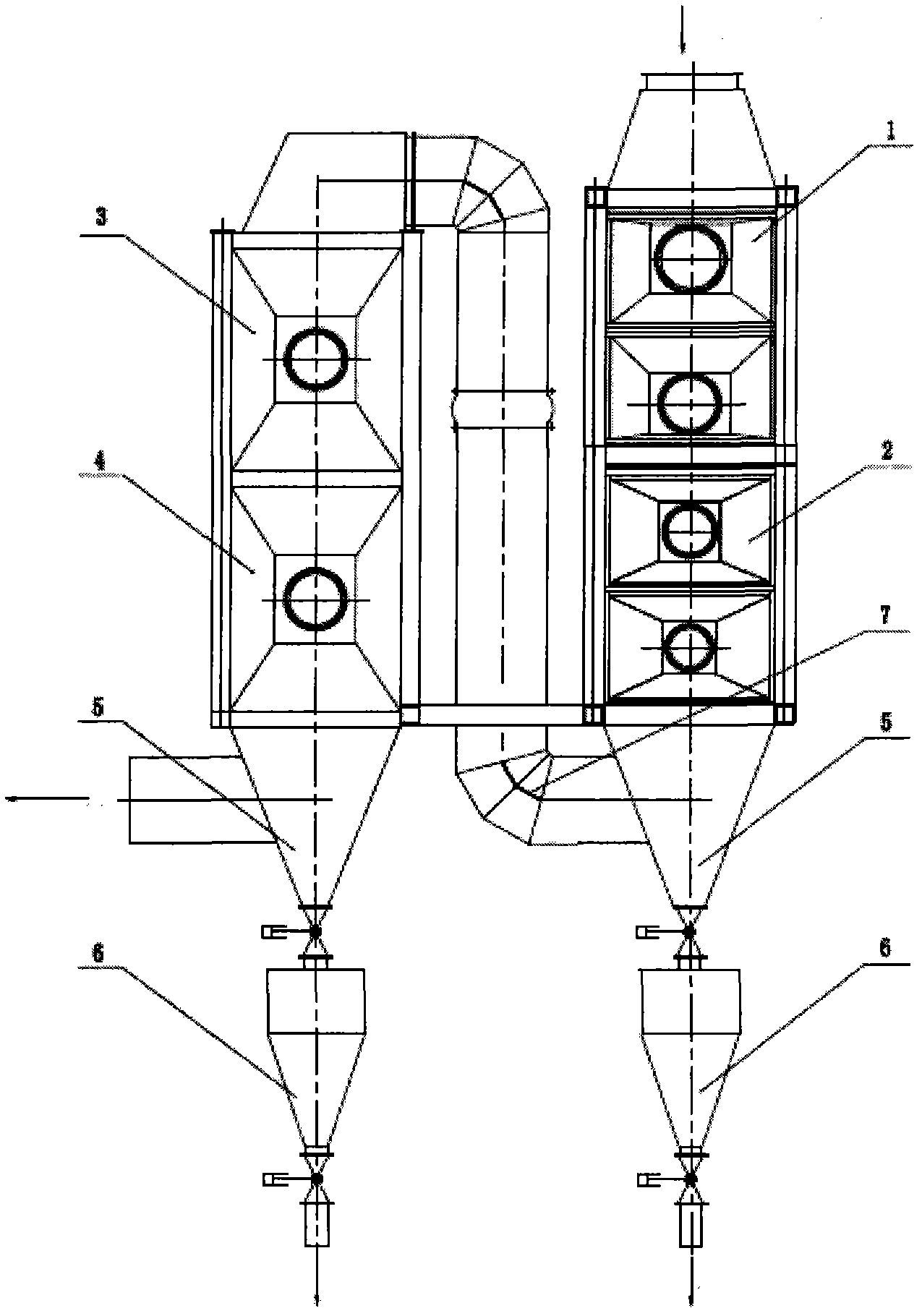

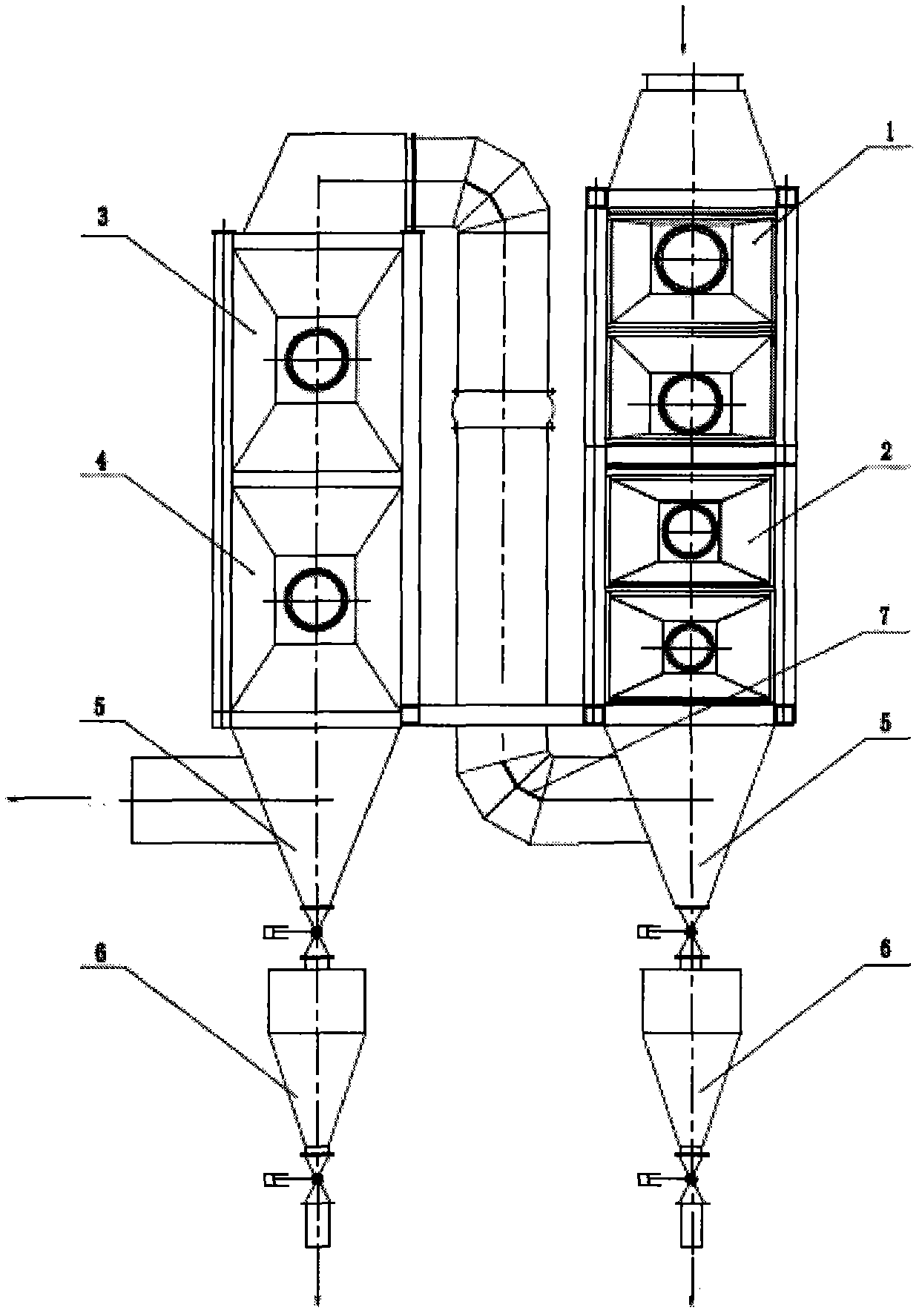

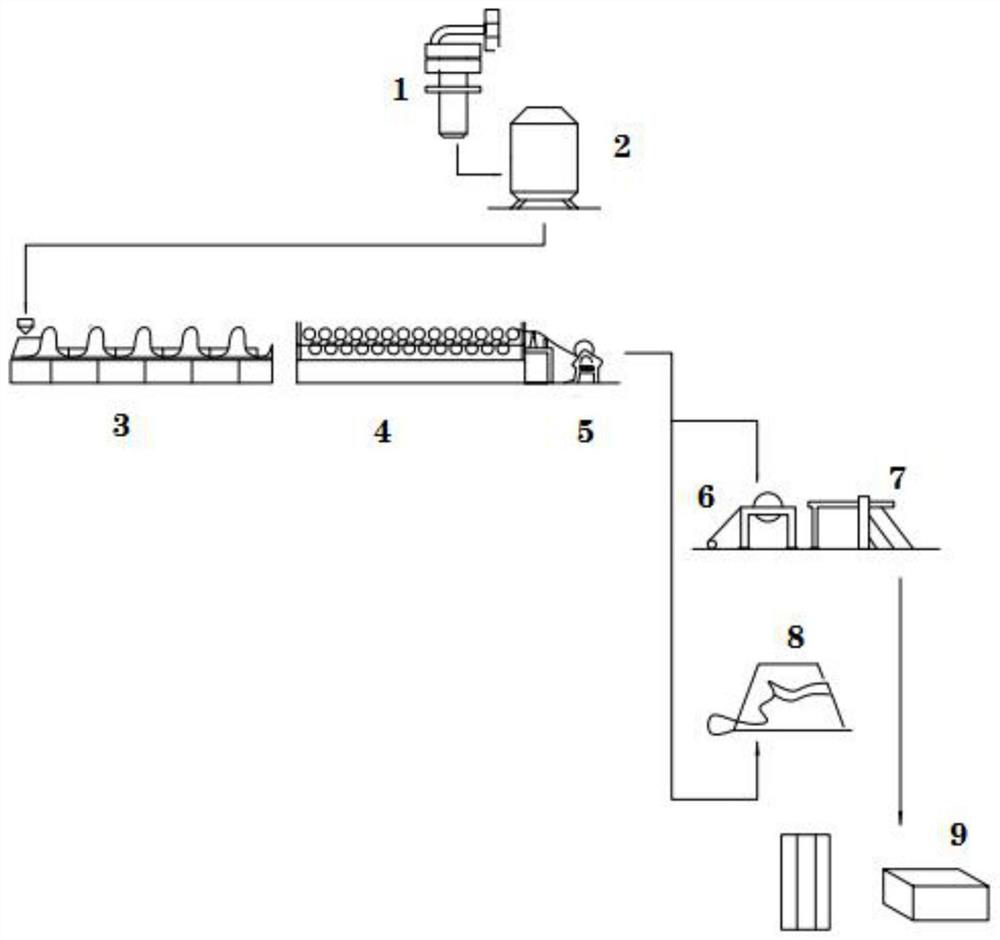

Gas drying type dust removal system of converter

ActiveCN102424887AComply with the industrial policy of energy conservation and emission reductionReduce moisture contentManufacturing convertersIncreasing energy efficiencyThermal energyBaghouse

The invention relates to a primary dust removal system of a converter, which adopts a complete drying method for dust removal. A tower / venturi system and a sewage treatment system are eliminated, the system is changed into a multi-stage gas heat exchange type dust removal device, and environmental protection requirements can be finally achieved via introduction of high-temperature flue gas into the multi-stage gas heat exchange type dust removal system through a vaporizing and cooling flue, prevention of mixing between cooling air and the high-temperature gas, primary dust removal during cooling of the flue gas, and flow of the cooled flue gas into a gas bag type dust removal device for secondary dust removal. The gas drying type dust removal system has a simple structure, can be operatedconveniently, occupies a small space, needs low investment and no water, and is power-saving. Heat of the air can be further recycled after heat exchange, and a large amount of energy can be saved for steel mills.

Owner:许广春

Refining agent for boron removal of slagging and refining industrial silicon melt

The invention provides a refining agent for the boron removal of a slagging and refining industrial silicon melt. The refining agent comprises the following ingredients in mass percent: 1-99% of Li2O, 1-99% of SiO2 and 0-98% of basic oxides. A using method of the refining agent comprises the following steps: industrial silicon with the boron content of 1-500 ppmw is taken as a raw material and is mixed with the refining agent for the boron removal of the slagging and refining industrial silicon melt according to a mass ratio of 10:1 to 1:10, the slagging and refining is carried out at the temperature of 1450-1850 DEG C, then, the cooling is carried out, and finally, the slag-silicon separation is carried out, so that the impurity, i.e. boron is removed along with slag. The refining agent has a remarkable effect in boron removal, and the using method of the refining agent has the advantages that: the boron content of industrial silicon can be lowered to be less than 1 ppmw, the slag-silicon separation is easy, the process operation is simple, the requirements on equipment are low, the cost is low, the energy consumption is low, the pollution is little, no harmful gases are generated, the waste slag can be recycled and reutilized, and the method is environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing cement by using garbage

InactiveCN102329090ASave natural resourcesComply with the industrial policy of energy conservation and emission reductionCement productionPotassiumCoal

The invention relates to a method for producing cement by using garbage. The method is mainly and mainly characterized in that the garbage is screened and classified; and after the usable part of the garbage is crushed and the contents of calcium element, silicon element, ferrum element, aluminum element, sulfur element, magnesium element, potassium element and sodium element of the garbage are analyzed, a small amount of materials are supplemented for producing the cement. The invention has the benefits that the calcium element, silicon element, ferrum element, aluminum element, sulfur element, magnesium element, potassium element and sodium element of the garbage and effective components with thermal value are used to produce the cement instead of clay (or shale), calcium carbonate and coal in a traditional cement raw material, so that precious natural resources are saved; and more importantly, the garbage is changed into valuables, a large amount of garbage is consumed, the environment is protected and the industrial policy of national energy saving and emission reduction is met. In addition, raw materials are easily obtained, so that the production cost is greatly reduced.

Owner:黄天泽

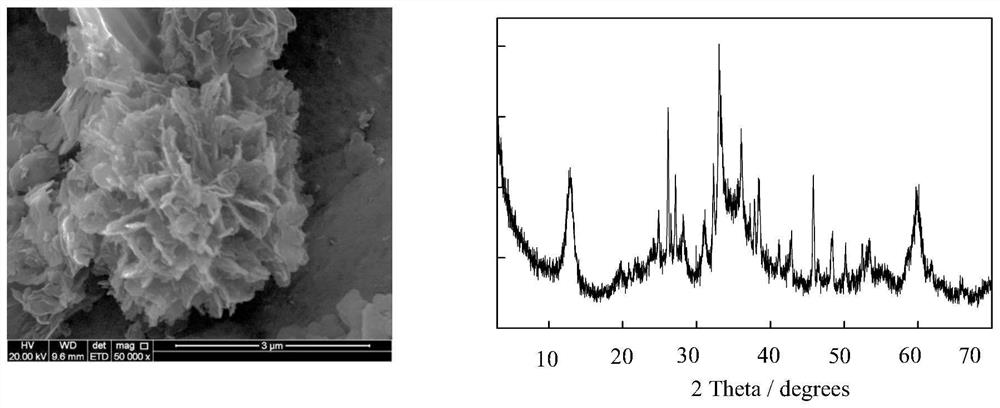

Aramid mica nano composite material and industrial preparation method thereof

InactiveCN112647342APrevent mutual attraction and proximityEvenly distributedPlastic/resin/waxes insulatorsPaper/cardboardThermal conductivityFlame resistance

The invention provides an aramid nanofiber and mica composite material. The composite material comprises aramid nanofibers and mica flakes; and the aramid nanofibers have a three-dimensional network structure, and the mica flakes are distributed in the three-dimensional network structure. The aramid nanofiber and mica composite material has high electrical performance and mechanical performance and excellent thermal conductivity, insulativity and flame retardance, can replace mica tapes, aramid paper and aramid mica paper on the current insulating material market, and has good market prospects.

Owner:通城县云水云母科技有限公司

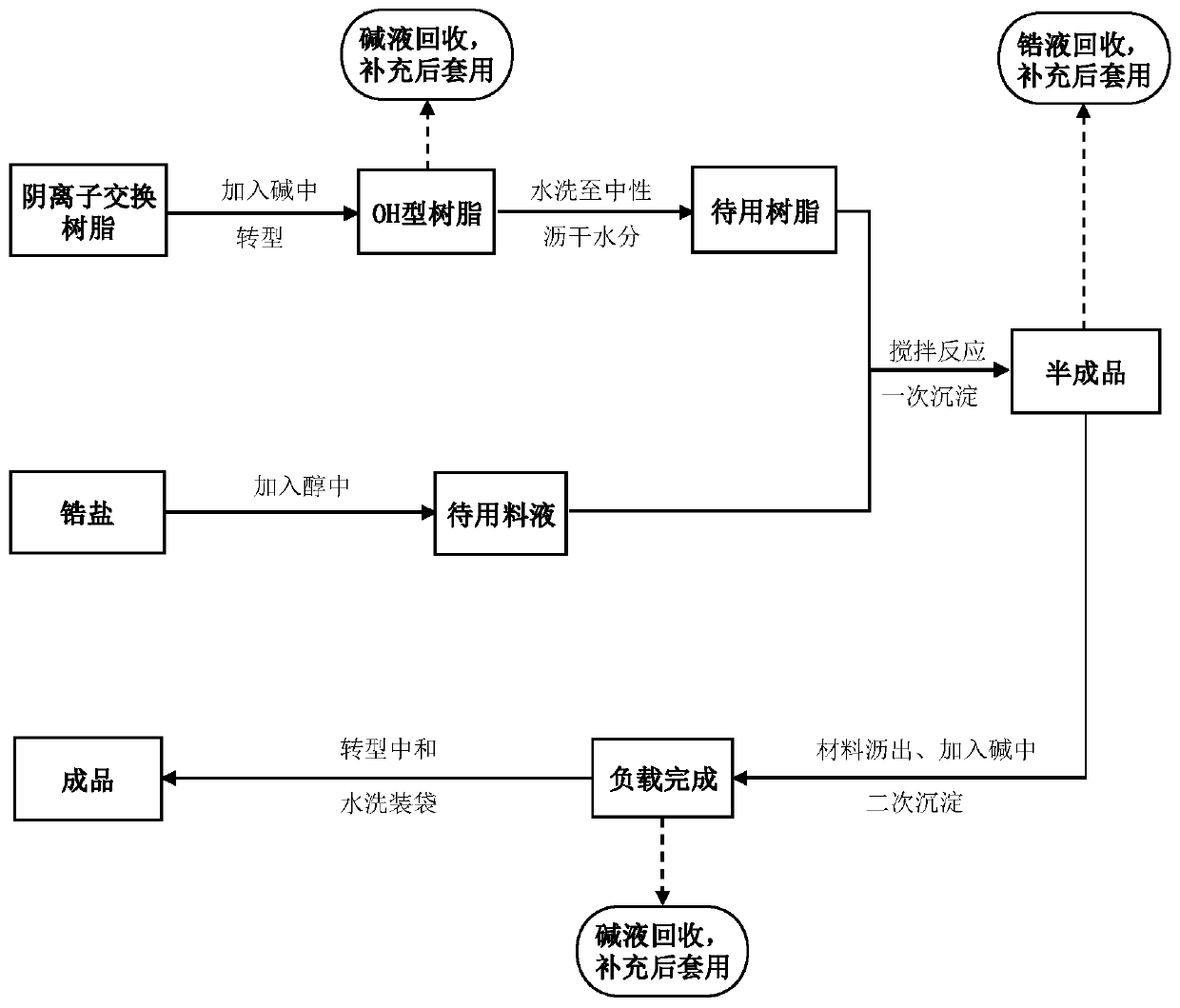

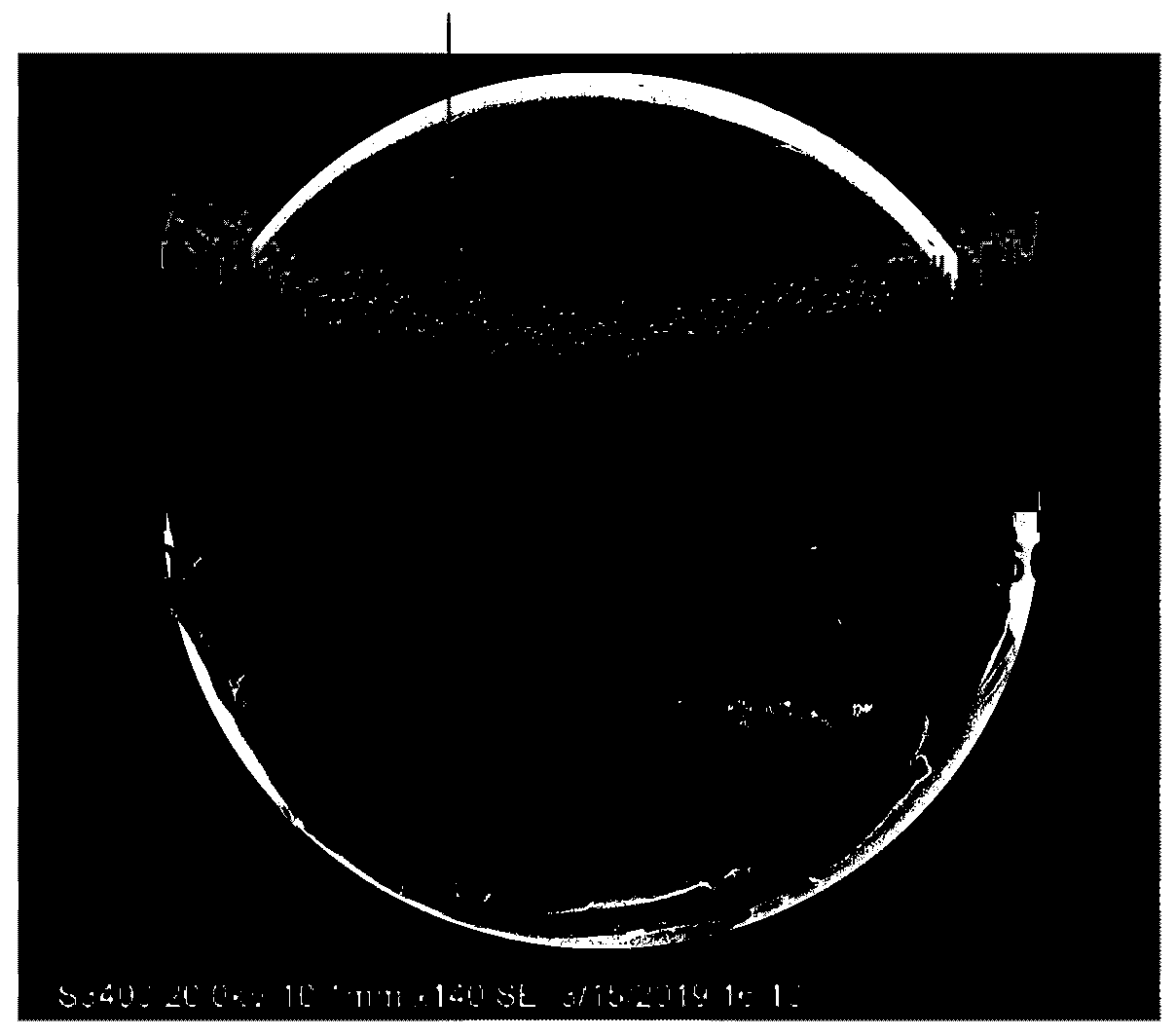

Industrial preparation method of anionic resin loaded nano zirconia composite material

ActiveCN110694584AAvoid electrostatic repulsionSimple processOther chemical processesWater/sewage treatment by sorptionAlcoholZirconium oxide

The invention discloses an industrialized preparation method of an anionic resin-loaded nano zirconia composite material. The main preparation steps include: (1) adding anion exchange resin into alkali liquor, stirring and reacting to convert the resin into OH type, and washing with water to neutrality for later use; (2) dissolving zirconium salt in alcohol to prepare feed liquid for later use; (3) adding the material into the feed liquid, stirring and taking out after fully reacting; (4) adding alkali liquor, stirring, taking out after reaction, soaking with acid liquor, flushing with tap water to neutrality, and bagging; and (5) after the chemicals are added to the feed liquid and lye, directly applying to the next batch of production. The method has the advantages of simple process, noneed of heating and drying, short time consumption and low cost, and can effectively overcome the problem the nano zirconia is not easily loaded in anionic resin; the obtained product has stable zirconium loading amount and excellent decontamination performance, the large-scale production efficiency of the anion resin loaded nano zirconium oxide composite material is greatly improved, and the method has strong economic benefits and environmental protection benefits.

Owner:NANJING UNIV

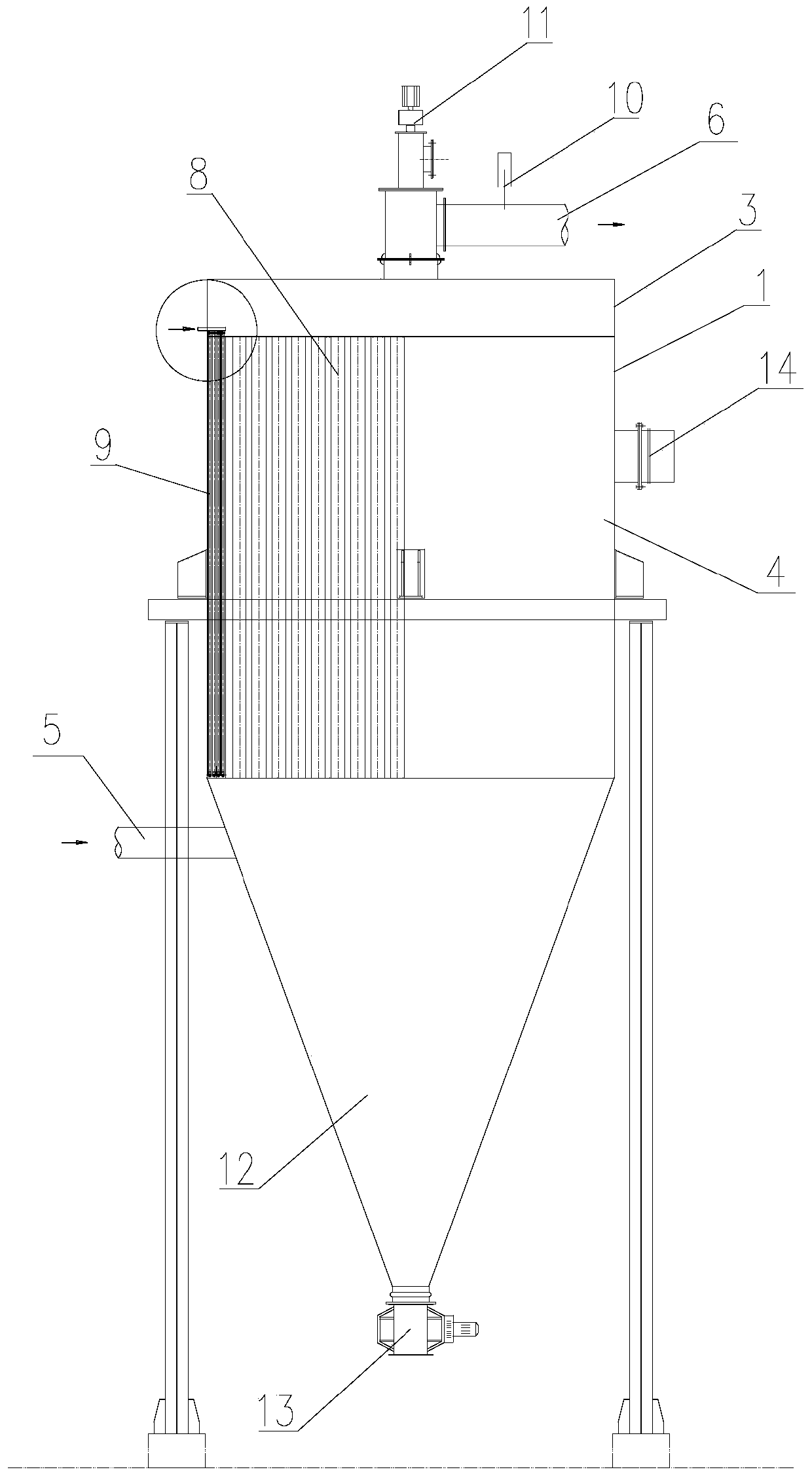

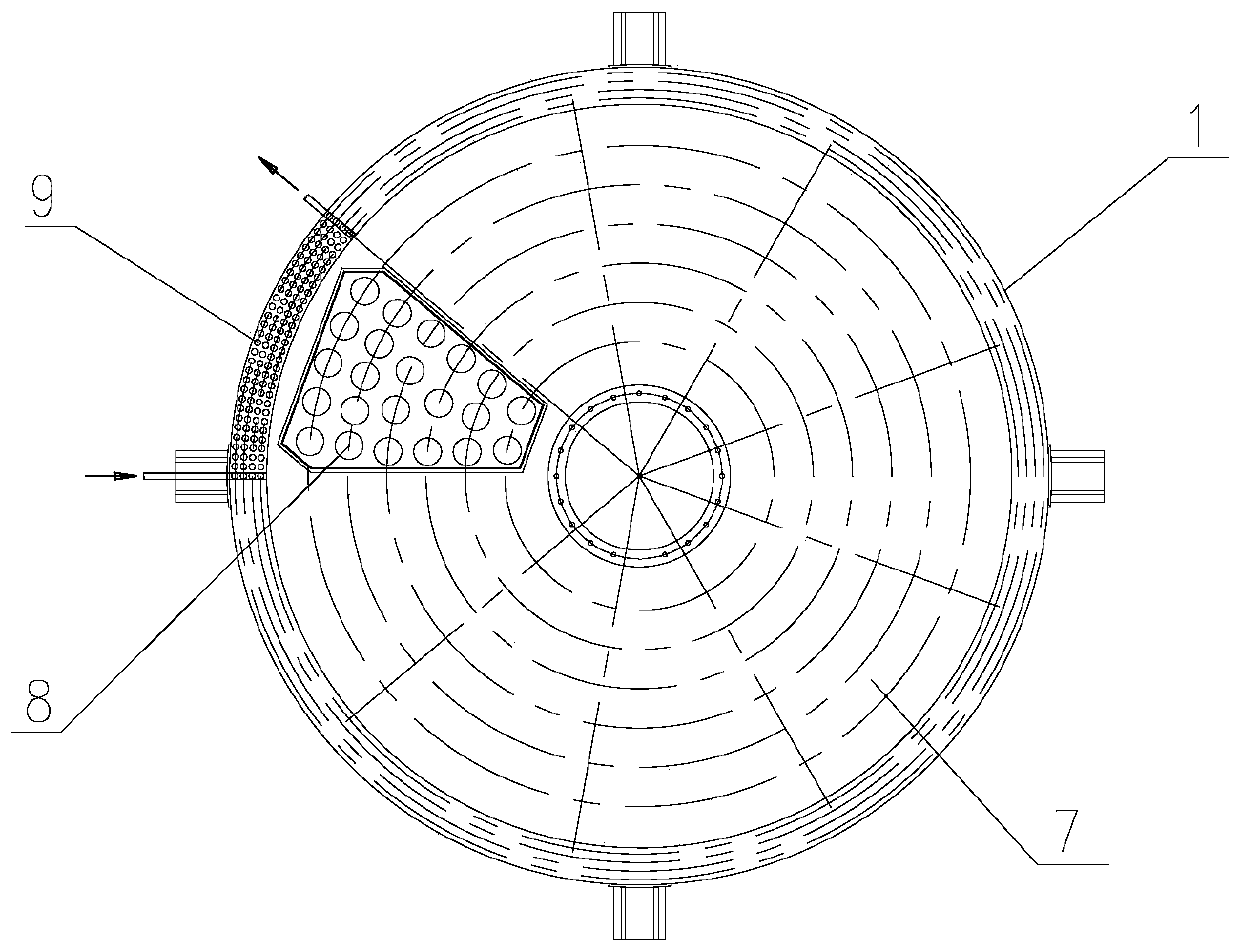

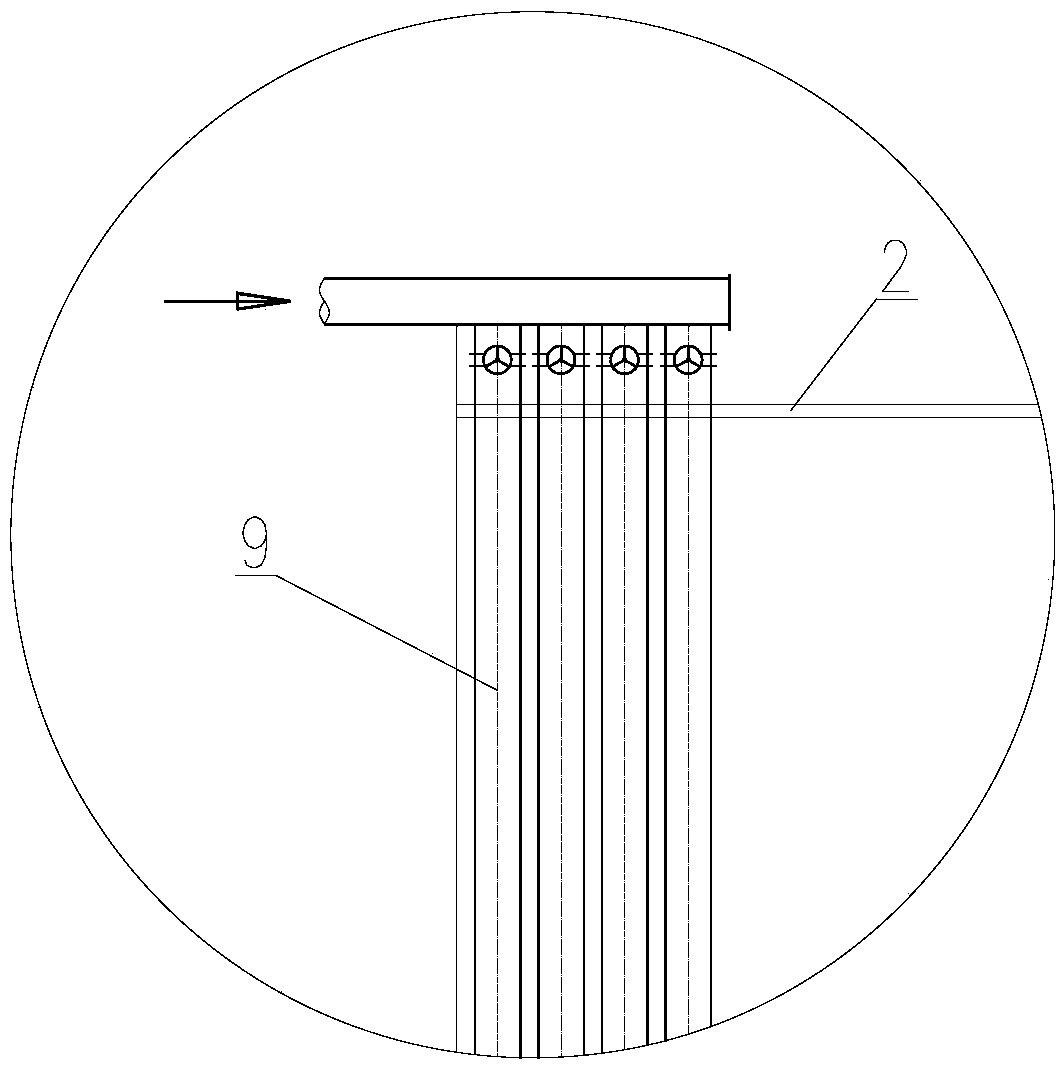

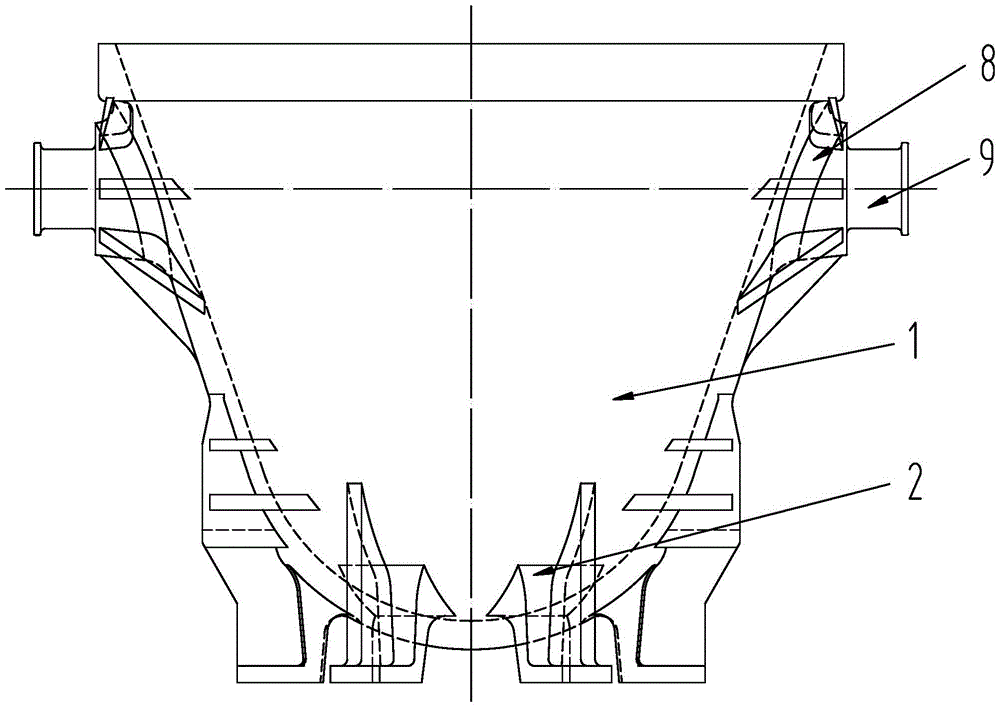

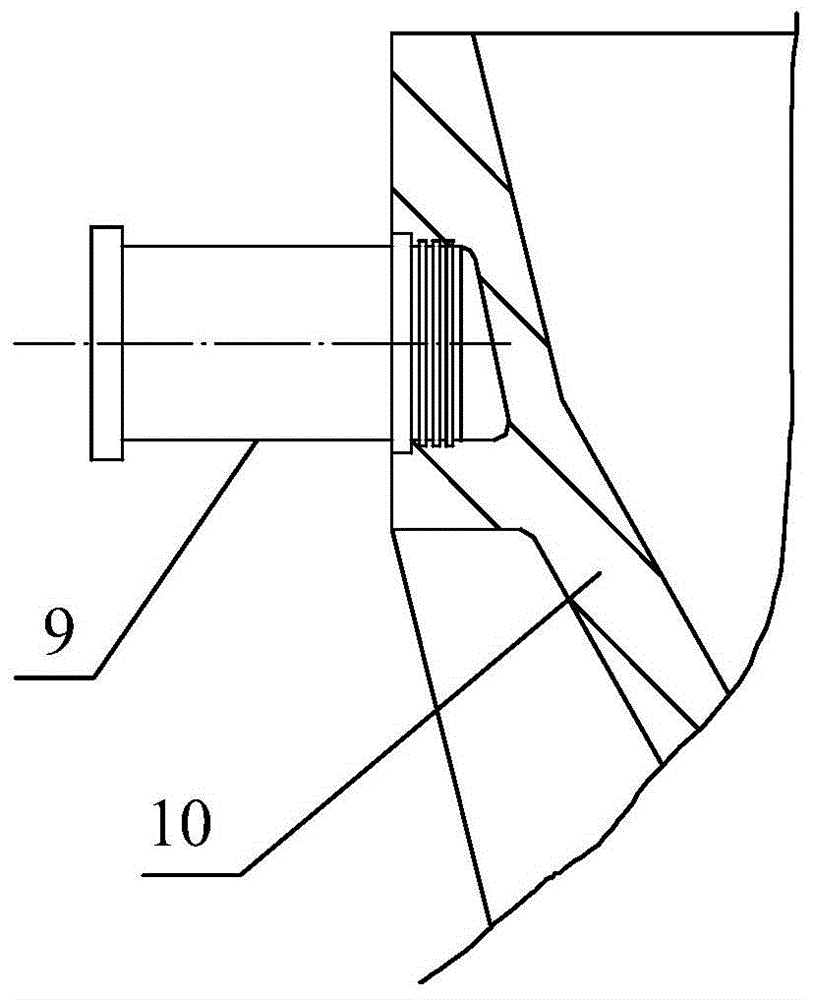

Furnace gas dust remover for sealed electric furnace

InactiveCN105498385AReduce wastageTo achieve the purpose of energy savingDispersed particle filtrationMembrane filtersElectric arc furnaceFiltration

The invention discloses a furnace gas dust remover for a sealed electric furnace. The furnace gas dust remover is used for cooling and purifying furnace gas of the sealed electric furnace and comprises a casing (1), wherein a plurality of filtration chambers (7) in longitudinal arrangement are formed in the casing (1), and a high temperature resistant filtration device (8) and a heat reclaiming device (9) are arranged in each of the filtration chambers (7); the furnace gas flows through the filtration chambers (7) in the casing (1), the high temperature resistant filtration devices (8) in the filtration chambers (7) are used for filtering the furnace gas, and the heat reclaiming devices (9) are used for reclaiming heat of the furnace gas. The furnace gas dust remover for the sealed electric furnace disclosed by the invention is safe to use, compact in arrangement, and small in occupied space, and can effectively reclaim the heat of the furnace gas.

Owner:BERIS ENG & RES CORP

Industrial preparation method of iron oxide-loaded cation resin base composite adsorbent

ActiveCN107537449AStrong loadPromote dissolutionOther chemical processesWater contaminantsSorbentResin-Based Composite

The invention discloses an industrial preparation method of an iron oxide-loaded cation resin base composite adsorbent, and belongs to the industrial production field of composite resin adsorbents forwaste water treatment. The preparation comprises the following steps: (A) acidic cation resin is added into a ferric salt solution in batch with stirring; (B) filtering is carried out, and filtrate is recycled and reused in the step (A); (C) vacuum hot air and drying are carried out for a Fe3+ composite intermediate loaded cation resin base; (D) the material obtained in the step (C) is added intoa sodium hydroxide solution in batch for carrying out a reaction, and filtering is carried out; (E) hydrochloric acid is added into the solid obtained in the step (D) for adjusting the pH value, andfiltering is carried out; (F) filtered solids obtained in the step (E) are washed with water, and water is filtered and dried. In the industrial preparation method of the iron oxide-loaded cation resin base composite adsorbent, ferric salt solution, alkali solution, acid solution and other materials can be recycled and reused, production cost and environment pollution can be greatly reduced, the method accords with national energy saving and emission reduction industrial policy at present, and the method is suitable for industrial promotion.

Owner:NANJING UNIV +1

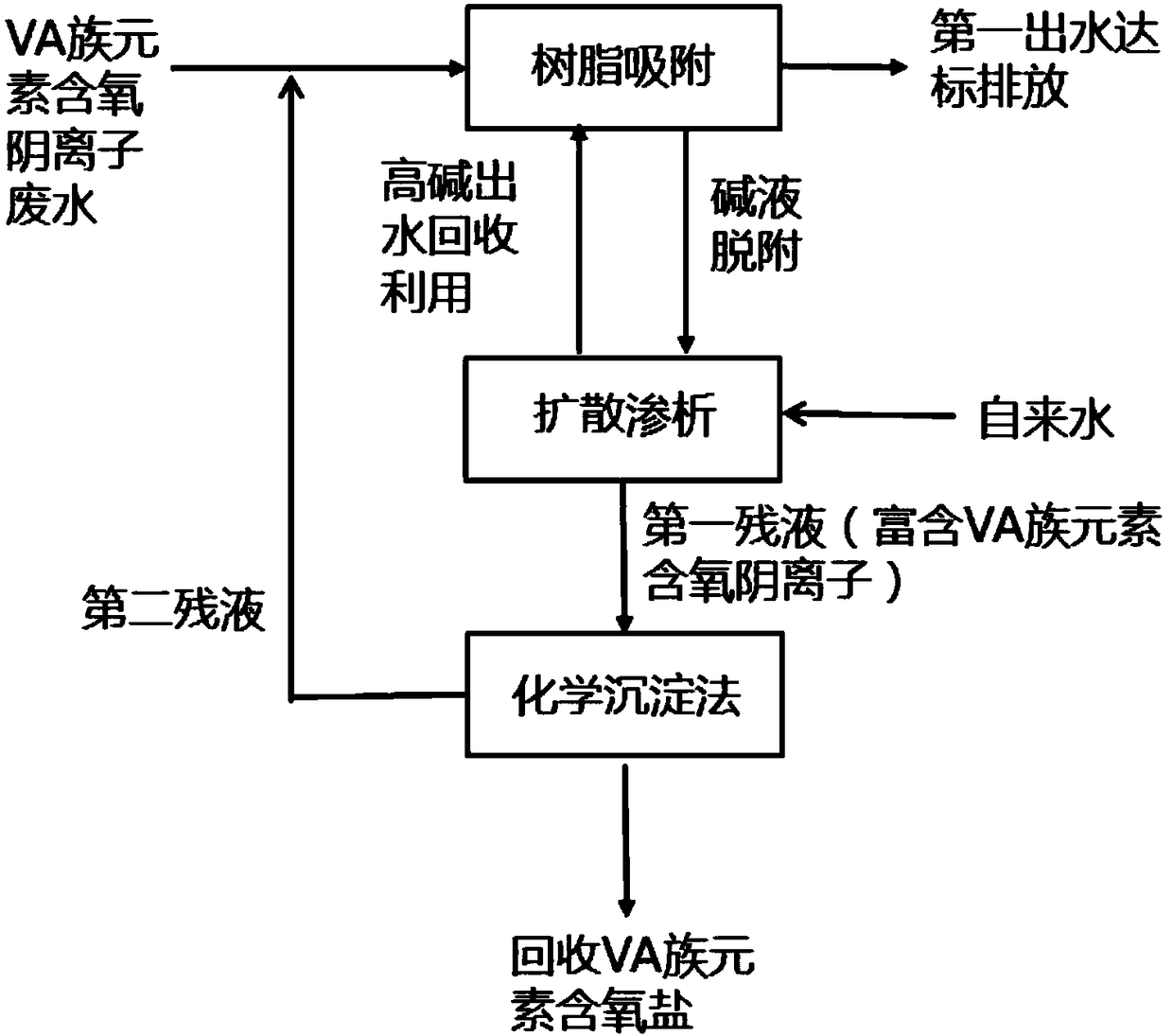

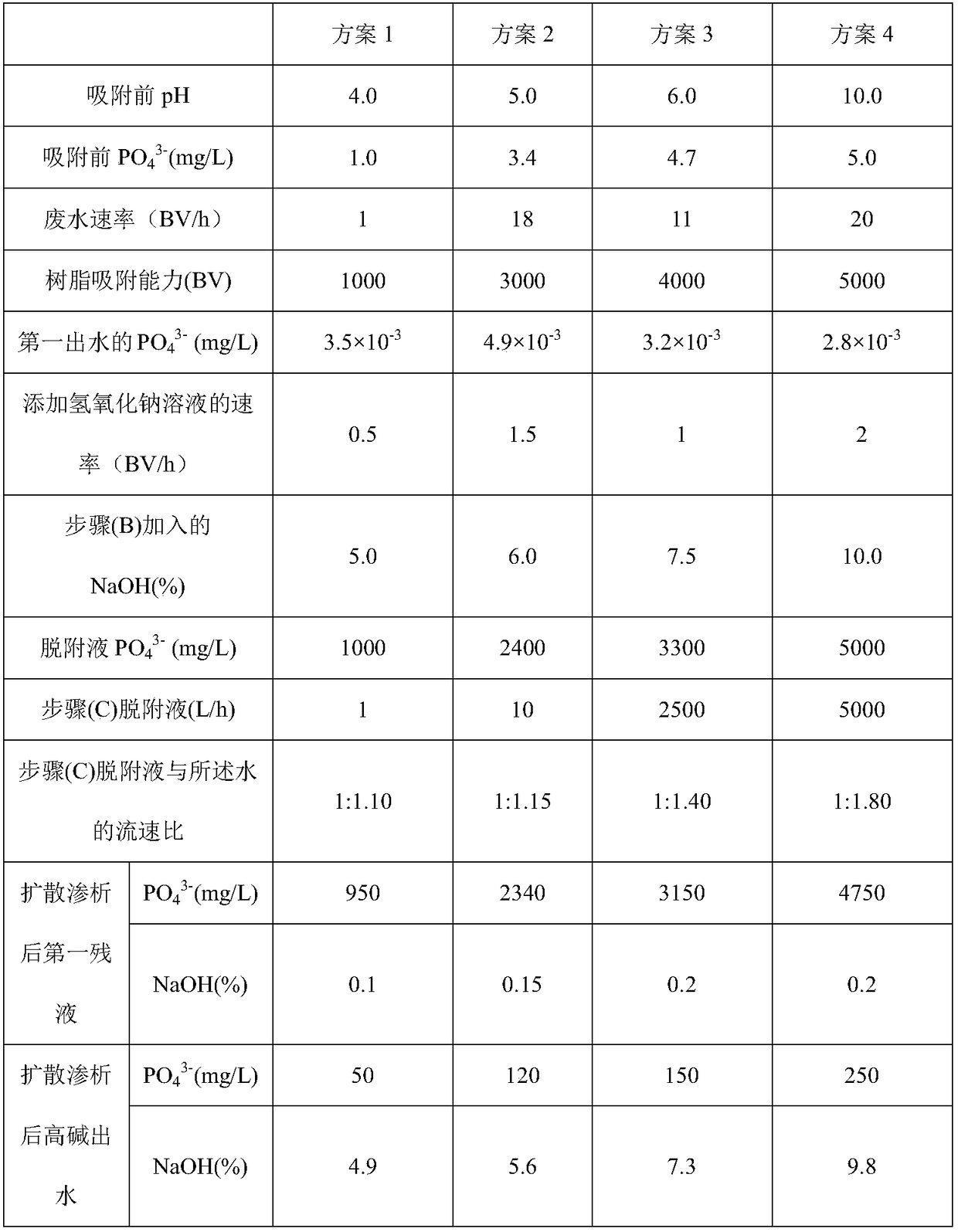

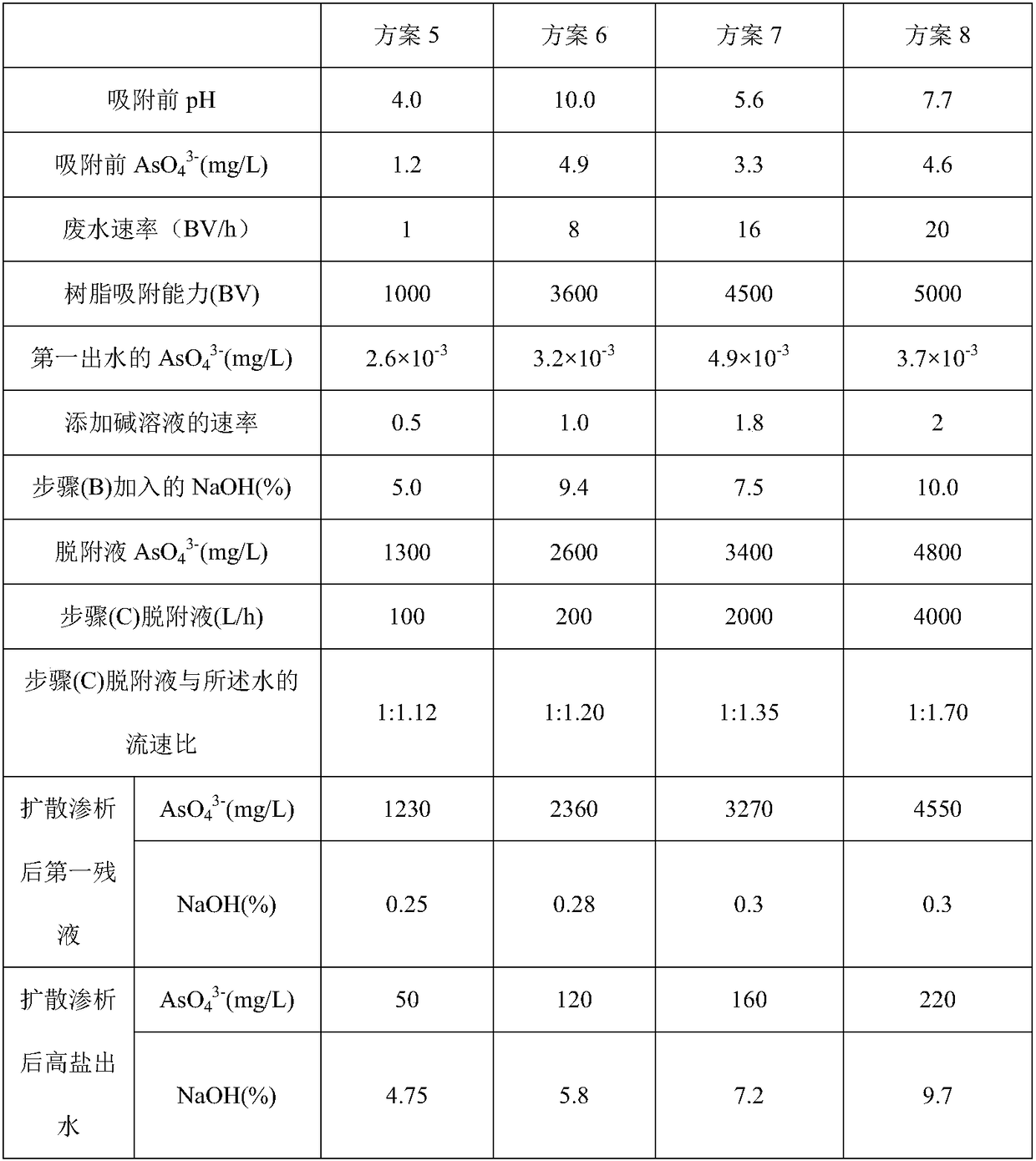

Method for treating VA-family element oxygen-containing negative ion wastewater through resin adsorption/desorption-diffusion dialysis

InactiveCN108218039AReduce pollutionReduce manufacturing costSpecific water treatment objectivesWater/sewage treatment by ion-exchangeDiffusionDesorption

The invention discloses a method for treating VA-family element oxygen-containing negative ion wastewater through resin adsorption / desorption-diffusion dialysis, belongs to the field of wastewater treatment and resource reuse, and particularly relates to a recycling method of wastewater containing phosphate radicals, phosphite radicals, arsenate radicals, arsenite radicals and antimonate radicals.The method comprises the following steps: adsorbing the VA-family element oxygen-containing negative ion wastewater by using resin; subsequently performing desorption regeneration on the resin by using an alkali solution, and then separating VA-family element oxygen-containing negative ions from alkali liquor by using a diffusion dialysis method, wherein the alkali liquor can be recycled and applied in the desorption regeneration step. According to the method disclosed by the invention, besides that VA-family element oxygen-containing negative ions are separated and enriched, the alkali liquor can be recycled and applied again, and finally, the concentration of the VA-family element oxygen-containing negative ions in discharged water is reduced to 0.01mg / L or below, so that production cost and environmental pollution are greatly reduced, a current national energy conservation and emission reduction industrial policy can be met, and the method is suitable for being industrially popularized.

Owner:NANJING UNIV +1

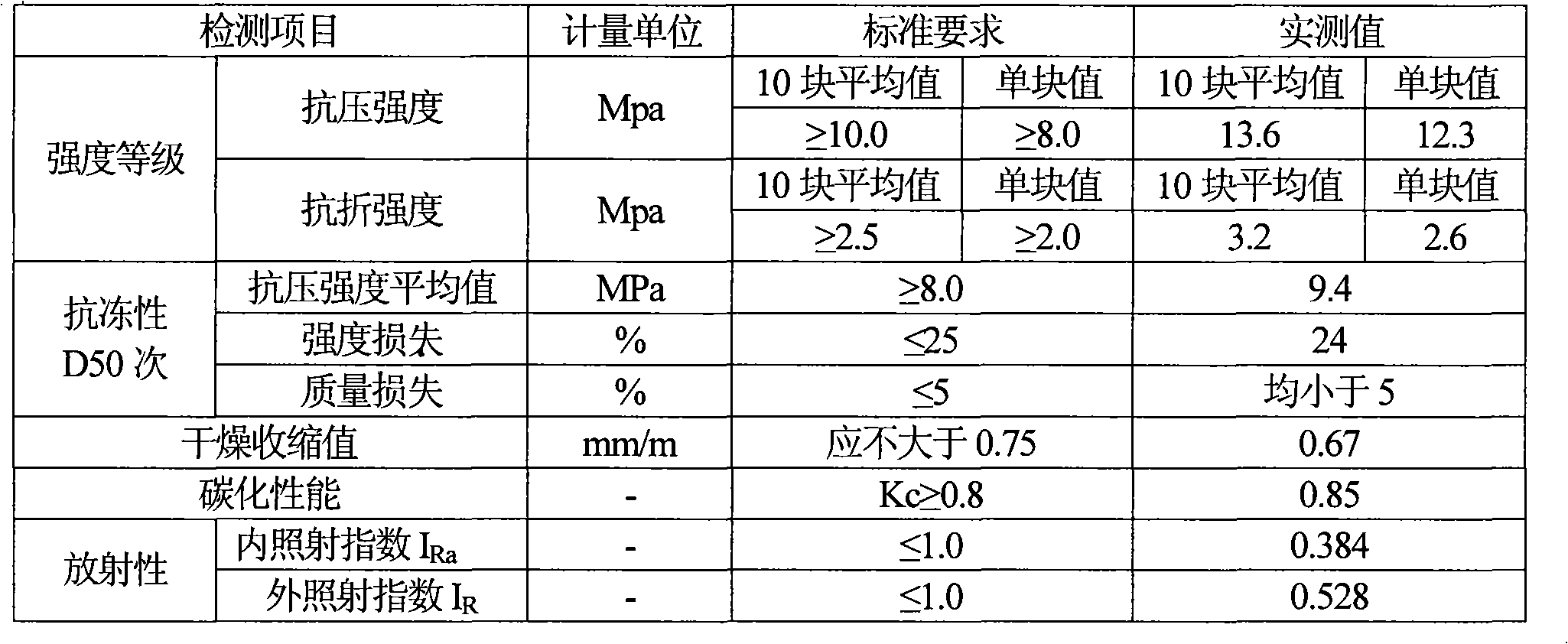

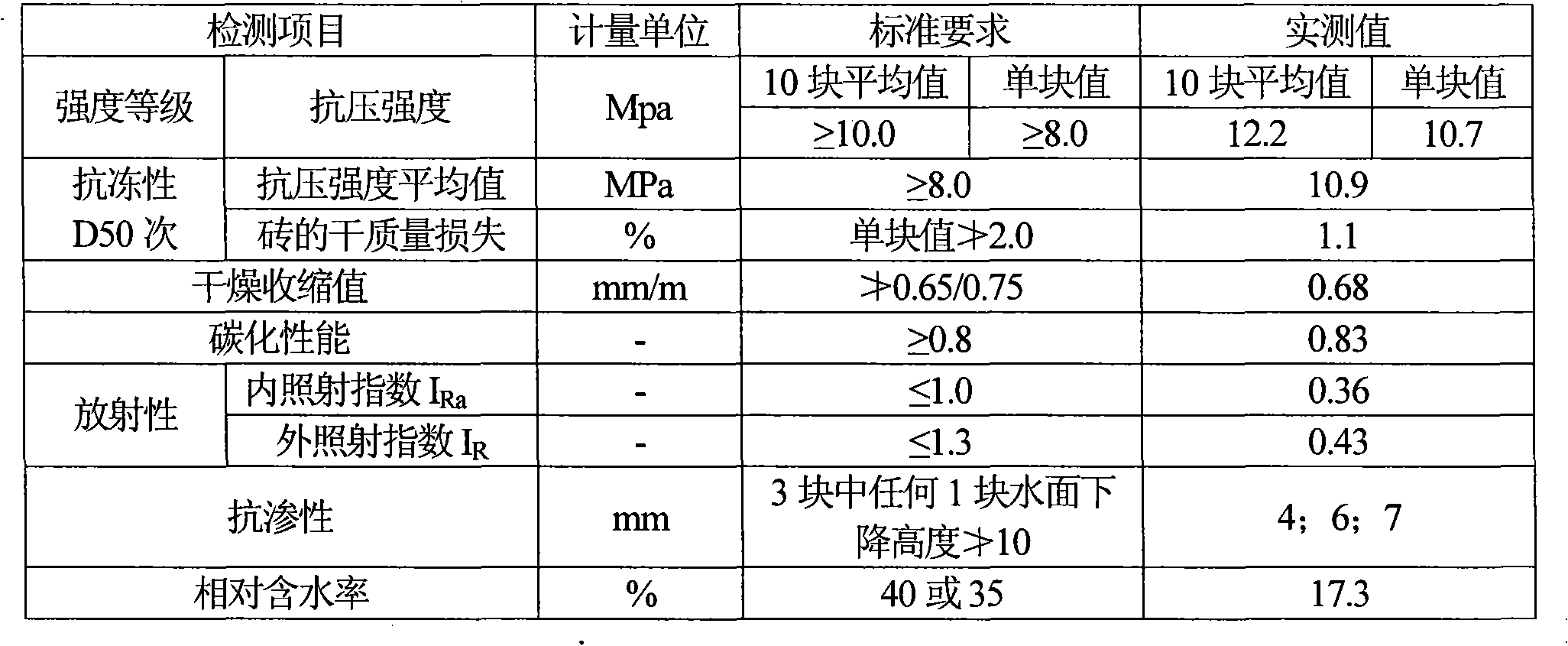

Cold region fly ash brick

InactiveCN101274830AHigh molding pressureReduce land occupationSolid waste managementLand resourcesSlag

The invention relates to a wall body material, in particular to a pulverized fuel ash brick used in cold areas. The brick uses sands, carbide slag, pulverized fuel ashes and cement as raw materials which have weight percentage as follows: 25 to 40 percent of sand, 10 to 20 percent of carbide slag, 35 to 50 percent of pulverized fuel ashes and 8 to 12 percent of cement. The invention utilizes the large amount of pulverized fuel ashes exhausted from power plants as the major raw material used for producing the product, thus protecting environment, saving land which is used for a plant storing the pulverized fuel ashes in a power plant, meeting the industrial policy of energy saving and exhaust reducing of China, providing a novel wall body material for building market, canceling sintering of clay red bricks and making contribution to saving land resources. The pulverized fuel ash brick used in the cold areas of the invention is different from sintering-free bricks and autoclaved bricks, has the advantages of large forming pressure and good anti-freezing ability, is applicable to be used in the cold areas, and is characterized by good anti-freezing capacity (25 times higher than the national standard) and good insulation capacity and thermal conductivity thereof is less than the traditional clay red bricks and other solid bricks.

Owner:MUDANJIANG ZHONGYUAN INDAL GROUP

Fever heat dissipating apparatus

InactiveCN104434387AEffectively control water temperatureGuaranteed cooling effectTherapeutic coolingTherapeutic heatingCooling effectEngineering

The invention discloses a fever heat dissipating apparatus, and relates to a medical apparatus. The fever heat dissipating apparatus comprises a water bag, a water inlet pipe, a water outlet pipe, a water pump and a refrigerating device, wherein one end of the water inlet pipe is connected with a water inlet of the water bag, and the other end of the water inlet pipe is connected with a water outlet of the water pump; one end of the water outlet pipe is connected with a water outlet of the water bag, and the other end of the water outlet pipe is connected with the refrigerating device; the water pump is connected with the refrigerating device; the water pump is connected with a power supply through conductive wires. The fever heat dissipating apparatus has the advantages of low cost, good heat-dissipating and cooling effect, high convenience for use, comfort and the like, and has a high scientific popularization and promotion value.

Owner:李成

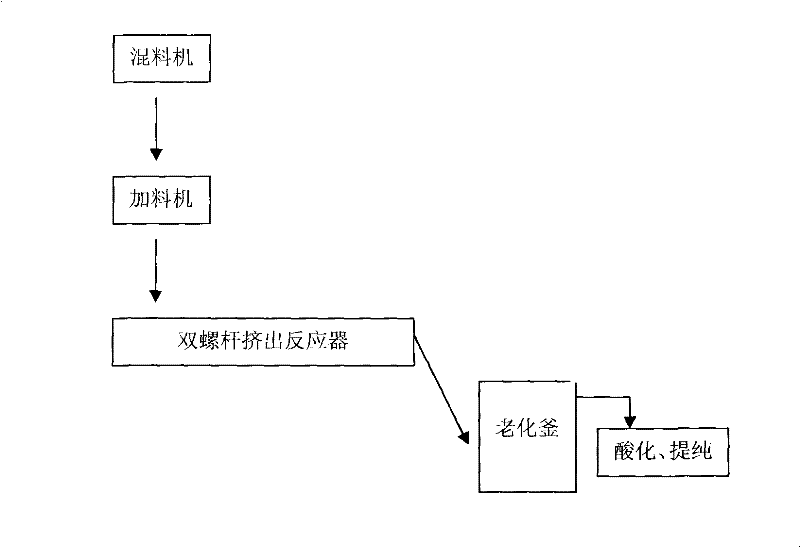

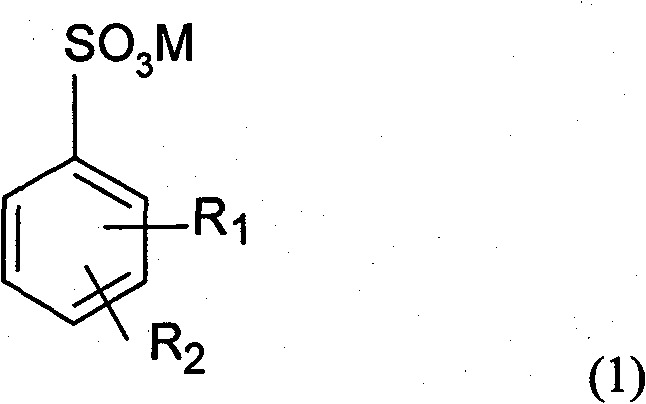

Phenol production technology

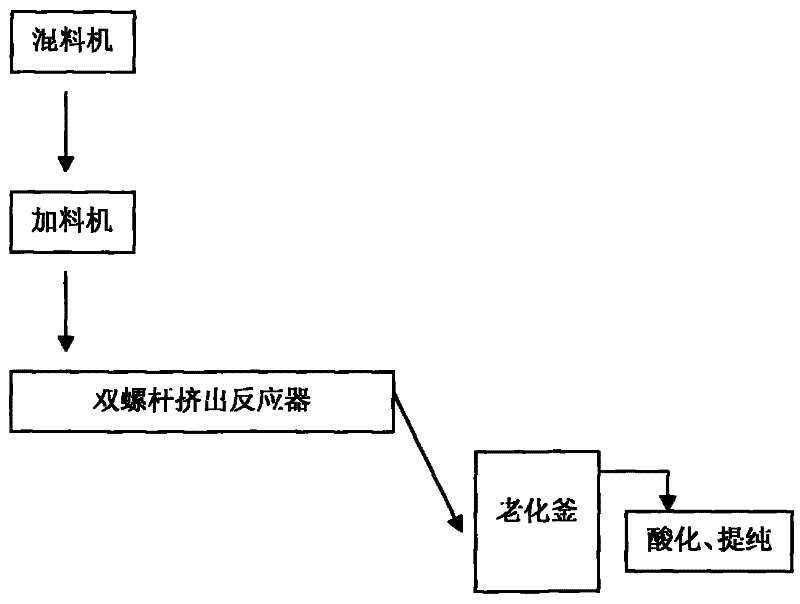

InactiveCN105218321AShort reaction timeReduced breakdownOrganic chemistryOrganic compound preparationChemistryDecomposition

The invention relates to a phenol production technology. The technology realizes continuous production, and improves the production efficiency and the reaction yield. The phenol production technology is characterized in that aryl sulfonate and an alkali undergo an alkali fusion reaction, the alkali fusion reaction is carried out in a screw reactor, and the screw reactor is a twin-screw extrusion reactor. The aryl sulfonate and the alkali are solids. Compared with traditional intermittent kettle type alkali fusion technologies, the technology shortens the reaction time by 2 / 3, obviously reduces material coking and decomposition phenomena, improves the reaction yield by 10% or above and improves the content of crude phenols to 90% or above. The aryl sulfonate solid is used in the reaction, so the content of phenol-containing water steam generated in the alkali fusion process is greatly reduced, treatment is simple, the environmental protection pressure is obviously reduced, and the national present energy saving and emission reduction industry policy is met.

Owner:严兴扬

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

Owner:TSINGHUA UNIV

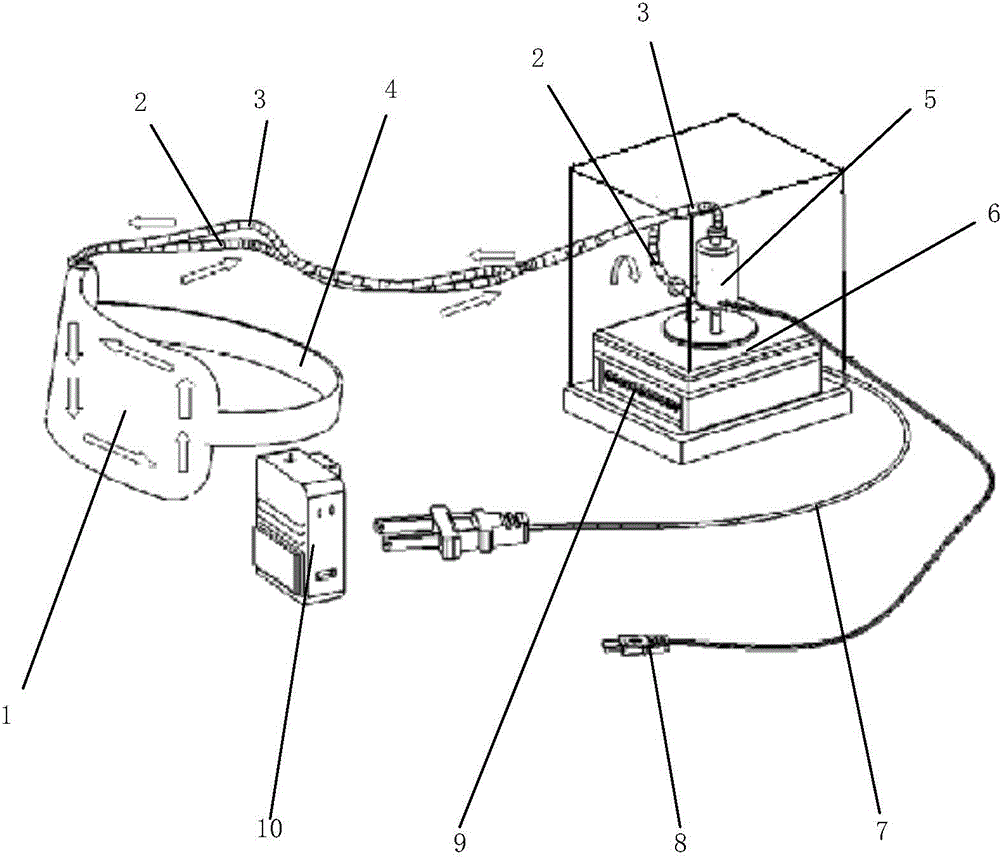

A multi-station power frequency induction furnace based on the Internet of Things platform

ActiveCN110307723BIncrease profitReduce production energy consumptionCrucible furnacesControl devices for furnacesRound barCoating system

The invention discloses a multi-station power frequency induction furnace based on the Internet of Things, which includes a power frequency induction furnace main body and an auxiliary structure, the power frequency induction furnace main body and the auxiliary structure form a multi-station power frequency induction furnace, and the auxiliary structure includes The round ingot horizontal continuous casting system and the round ingot horizontal continuous casting system, the round bar material lifting unit is arranged between the round ingot horizontal continuous casting system and the round ingot horizontal continuous casting system, and the round bar material lifting unit passes through It is connected with the round ingot horizontal continuous casting system and the round ingot horizontal continuous casting system in a cable or wireless way, maximally integrating the advantages of power frequency induction furnace and holding furnace power matching and holding furnace structure, and adding the equipment to various Advanced sensors, data acquisition modules, wireless transmission modules, and docking with the Internet of Things platform can not only realize one machine with multiple functions, but also can actually receive the machine's operating status, production specifications and output, and are widely used in metal and metal alloy smelting and casting industries.

Owner:江西凯顺科技有限公司

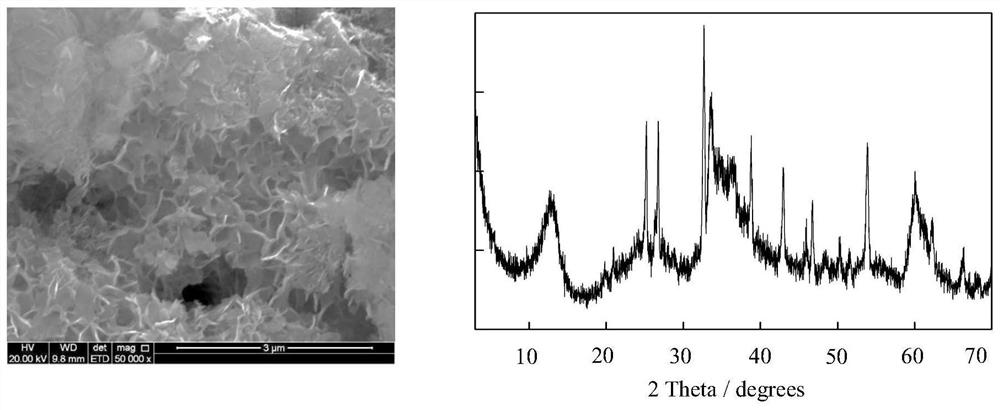

Preparation of m from feedwater sludge 2+ -al 3+ -fe 3+ Methods and applications of hydrotalcite-like materials

ActiveCN110817970BProtect environmentTo achieve the effect of resource recyclingOther chemical processesWater contaminantsFerric hydroxideAluminium hydroxide

The invention provides a method for preparing M 2+ ‑Al 3+ ‑Fe 3+ Methods and applications of hydrotalcite-like materials. The method is: add dilute hydrochloric acid to acidify the feedwater sludge containing amorphous iron and aluminum hydroxide, adjust the pH value, and stir to convert amorphous iron hydroxide and aluminum hydroxide into Fe 3+ and Al 3+ , then add a certain amount of divalent metal salt and urea, react at 120-180°C for 12-48 hours, wash the resulting precipitate, filter, and dry to obtain M 2+ ‑Al 3+ ‑Fe 3+ Multi-component hydrotalcite materials. The method is a new method for resource utilization of water supply sludge from a waterworks, and has the advantages of small equipment investment, low energy consumption, wide application of the obtained product, and high added value.

Owner:BAOJI UNIV OF ARTS & SCI

Waste-utilized environment-friendly fireproof heat-insulating material

The invention relates to building materials and specifically relates to a waste-utilized environment-friendly fireproof heat-insulating material for walls. The waste-utilized environment-friendly fireproof heat-insulating material is prepared from the following raw materials in percentage by weight: 24% to 44% of waste refractory glass fiber composite filter bags, 28% to 20% of leftover materialstrimmed during the production of filter bags from refractory glass fiber composite felt, 28% to 36% of talcum powder, 4% to 6% of flocculant and 4% to 6% of cationic starch. Both the waste refractoryglass fiber composite filter bags and the leftover materials trimmed during the production of the filter bags from the refractory glass fiber composite felt have base fabrics, i.e., glass fiber base fabrics and surface layers, i.e., glass fiber composite surface layers. According to the waste-utilized environment-friendly fireproof heat-insulating material, waste raw materials serve as main raw materials and are recycled, so that the cost is reduced, and land resources are saved; the waste-utilized environment-friendly fireproof heat-insulating material is free of harmful gas emission, has good high-temperature resistance, corrosion resistance and low hygroscopicity, is light in weight, small in coefficient of thermal conductivity, good in suction performance and good in chemical stabilityand is non-combustible.

Owner:遂宁市明川零贰零科技有限公司

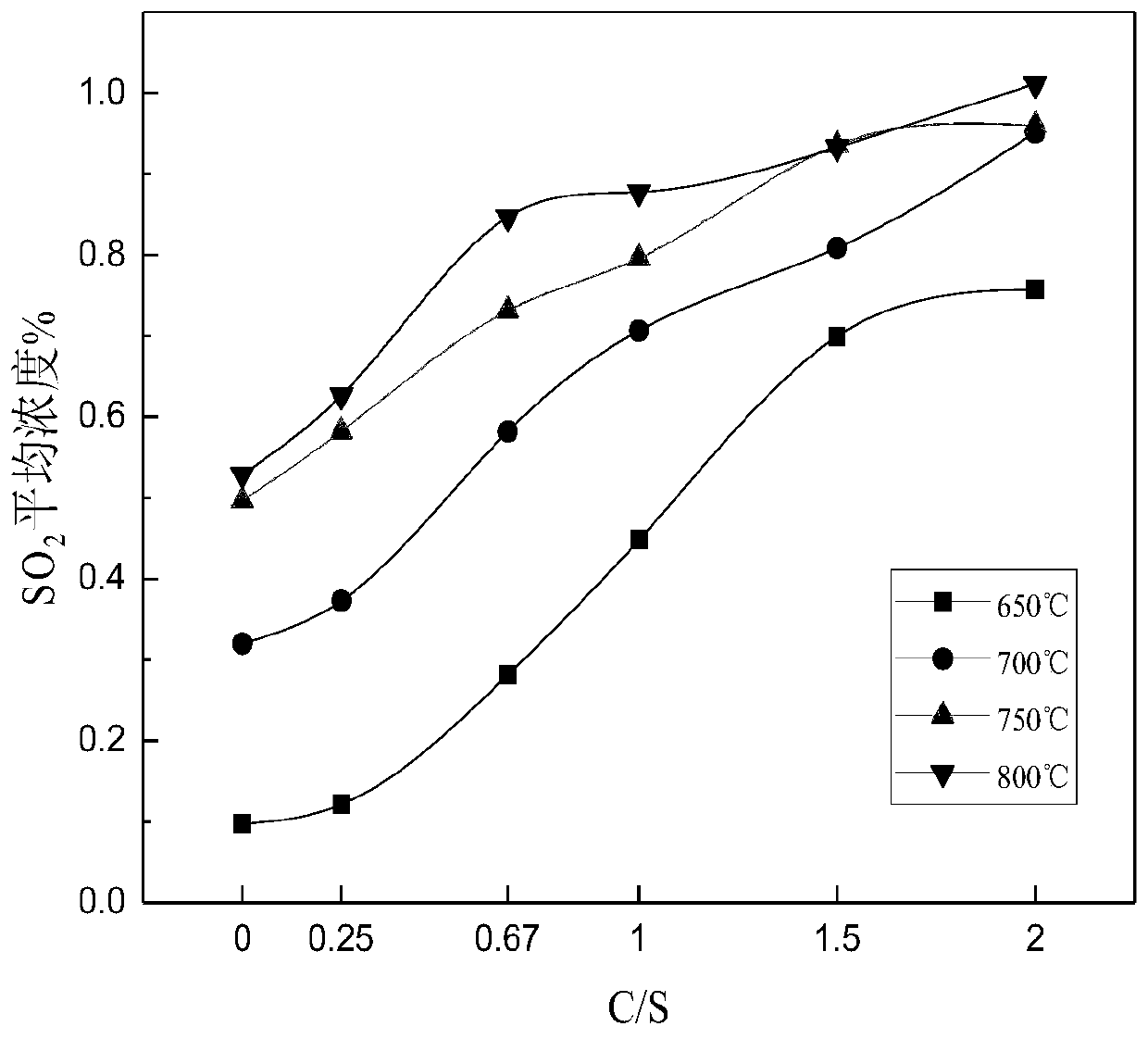

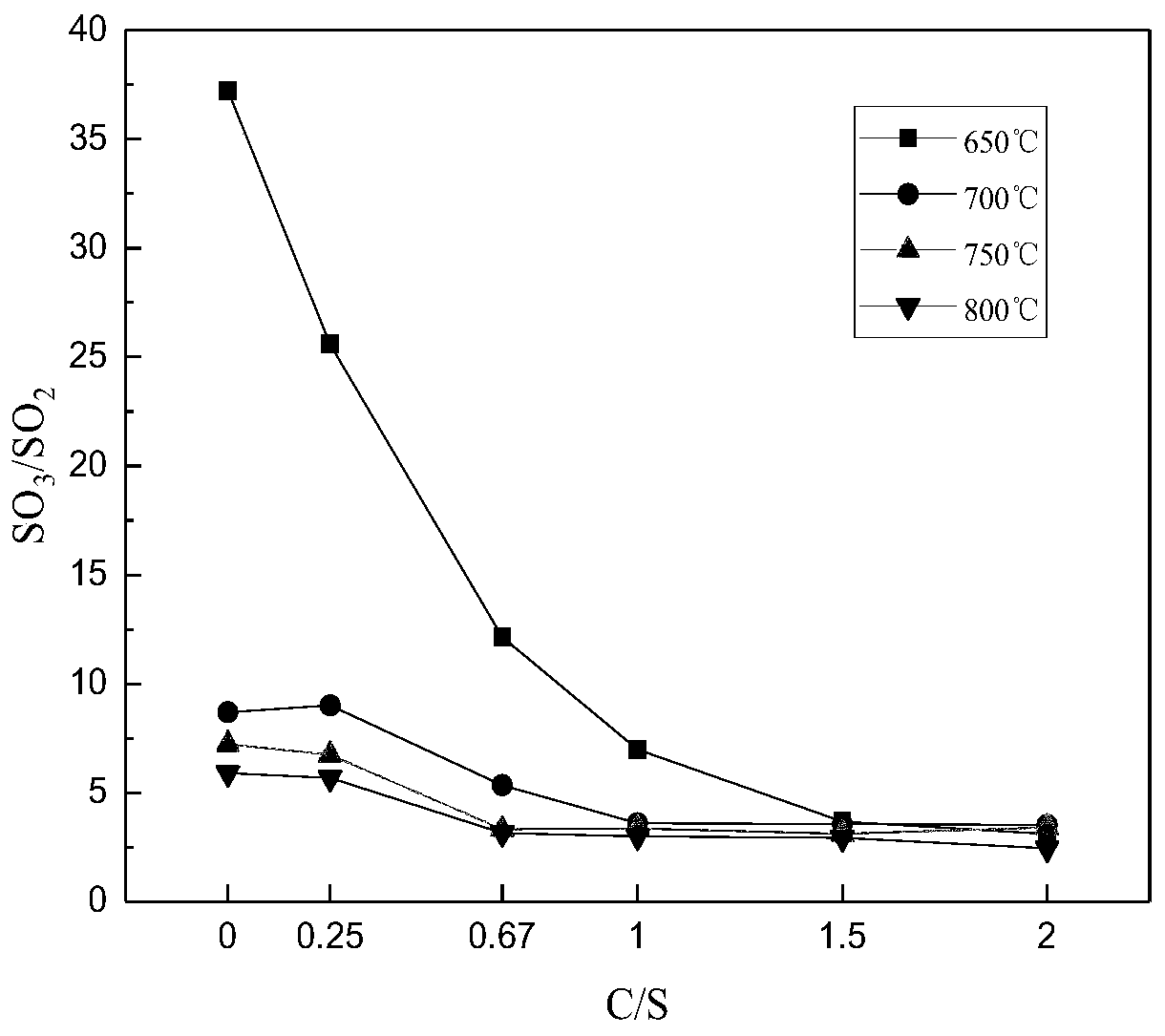

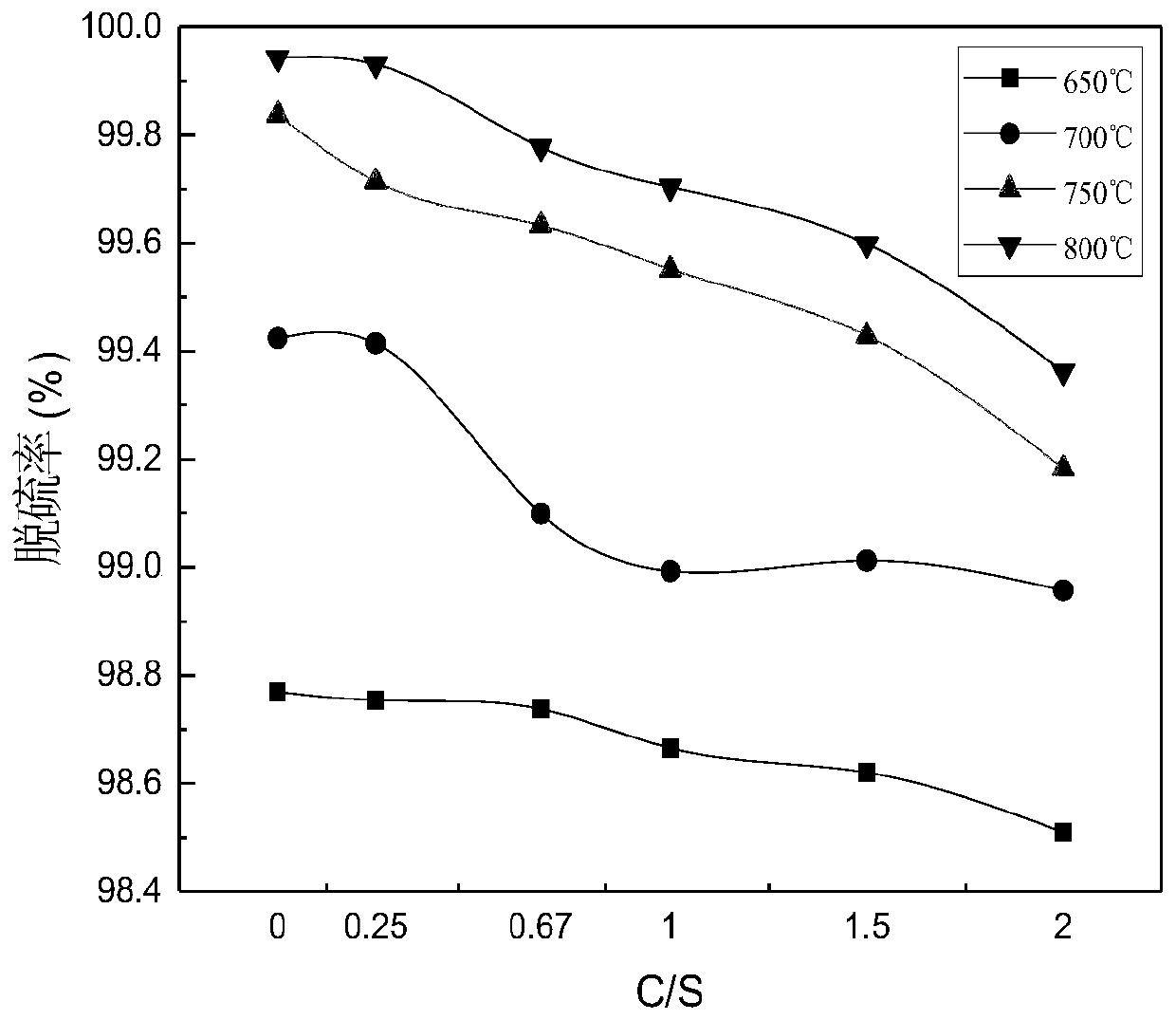

Method for preparing sulfuric acid from ferrous sulfate

The invention relates to a method for preparing sulfuric acid from ferrous sulfate, which belongs to the technical field of solid waste comprehensive utilization. According to the technical scheme, the method comprises the following steps: ferrous sulfate and coal are uniformly mixed and then are fed into a high-temperature decomposition furnace; after roasting, furnace gas containing sulfur dioxide and a solid-phase substance containing Fe2O3 are generated; the furnace gas is catalyzed by a converter to generate sulfur trioxide, the sulfur trioxide is absorbed by concentrated sulfuric acid togenerate sulfuric acid, the aerobic atmosphere means that the volume fraction of oxygen in the gas introduced into the high-temperature decomposition furnace is 5-20%, and the volume fraction of sulfur dioxide in the sulfur dioxide-containing furnace gas is more than or equal to 10%. Compared with the prior art, no waste is generated in the technological process, the desulfurization rate of ferrous sulfate is larger than or equal to 93%, the content of Fe2O3 in the slag is larger than or equal to 86%, and the slag can be directly used as an iron smelting raw material. According to the method,the titanium dioxide production waste ferrous sulfate is recycled, potential sulfur resources are developed, and the current situation of shortage of sulfur resources in China can be relieved, and meanwhile, a circular economy industrial chain of a sulfuric acid method titanium dioxide enterprise is also formed.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for preparing phenol

ActiveCN101555195BShort reaction timeReduce the amount of phenolic water vaporOrganic chemistryOrganic compound preparationWater vaporDecomposition

Owner:LIANYUNGANG KEMING CHEM CO LTD

Method for preparing microcrystalline jade plate by phosphorus slag

The invention provides a method for preparing a microcrystalline jade plate by phosphorus slag, comprising the following steps: blending materials: mixing an addictive with a clarifying agent to form a uniform auxiliary mixed material; melting: adding the auxiliary mixed material to the molten phosphorus slag to obtain molten glass by melting, performing heat preservation, homogenizing and clarifying the molten glass to obtain molten high-temperature glass melt; molding: molding the high-temperature glass melt to obtain a formed base glass plate; crystallizing: transferring the formed glass plate to a crystallizing and annealing kiln for crystallizing and annealing; and finish machining: after the microcrystalline jade plate is delivered from the kiln, machining the glass plate to obtain a finished product of the microcrystalline jade plate. The microcrystalline jade plate obtained by the method has the advantages of wear resistance, corrosion resistance, high temperature resistance, no radiation, high utilization rate of the phosphorus slag, higher social benefit and higher economic benefit.

Owner:TSINGHUA UNIV

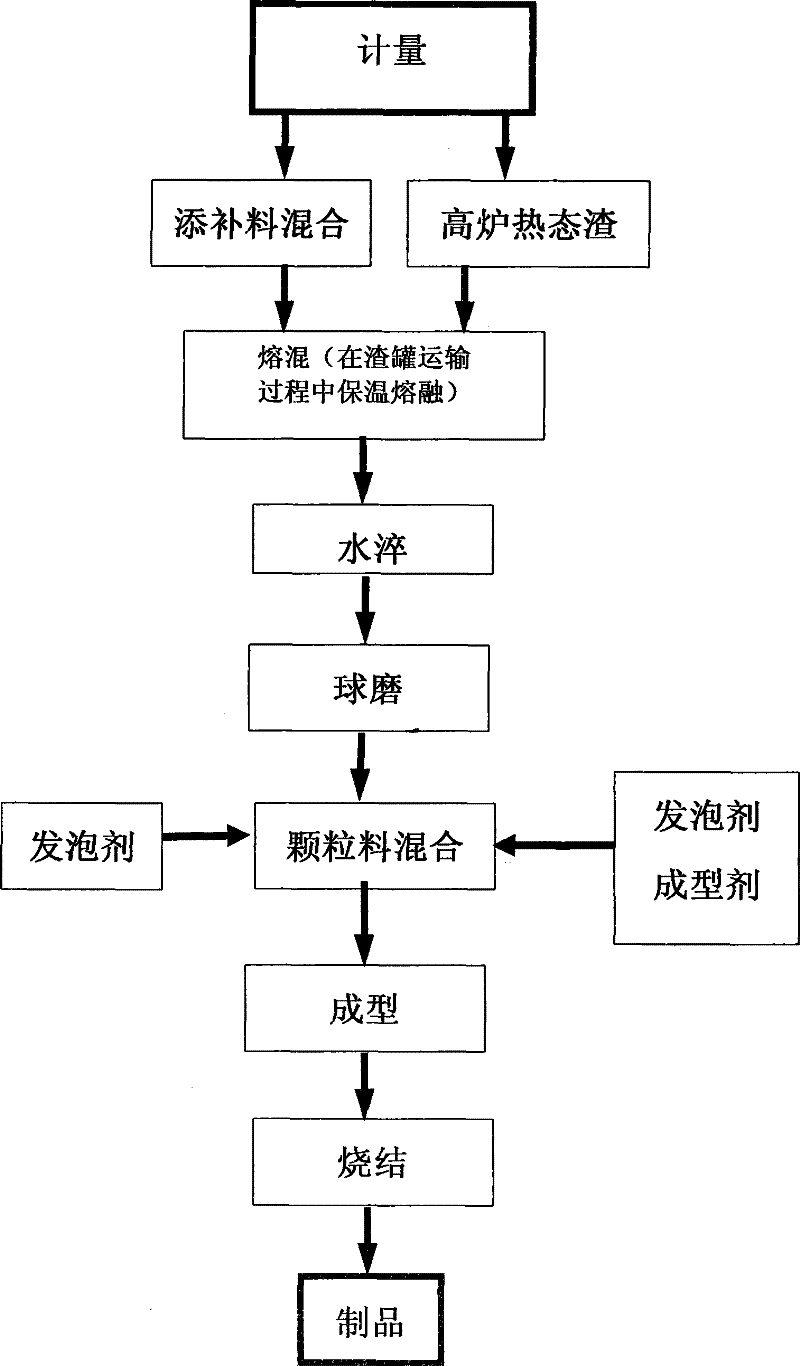

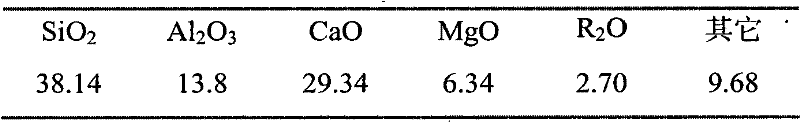

Foam glass ceramic and preparation method thereof

The invention relates to a foam glass ceramic prepared from blast furnace hot melting slag and a preparation method of the foam glass ceramic, belonging to the field of inorganic materials. In the preparation method, steeling blast furnace hot melting slag is used as a main raw material, coal ash, borax, calcined soda, rear sorted tail ore, quartz sand and the like are respectively measured, evenly mixed and then baked into porous blocks, the porous blocks are added in a slag ladle, smelting is carried out by using the blast furnace hot melting slag, a melting material is subject to water quenching to obtain glass water quenching materials with different particle sizes; and the glass water quenching materials are dried and ball-milled, a foaming agent is added to be mixed with the dried and ball-milled glass water quenching materials, press forming or spreading forming is carried out, and then the foam glass ceramic is prepared by nucleating, crystallization and sintering. In the invention, a large amount of heat energy stored in the blast furnace hot melting slag is effectively utilized, and production cost is lowered; and the prepared foam glass ceramic has the characteristics of low thermal conductivity, small density, high temperature resistance, corrosion resistance and high compression resistance and breaking strength, has strong adaptable property on high-low temperature variation of smoke, and can be widely used as a multi-cylinder type and sleeve type lining material for discharging smoke by wet desulphurization in a heat-engine plant, thermal equipment insulation, heat-insulating materials and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

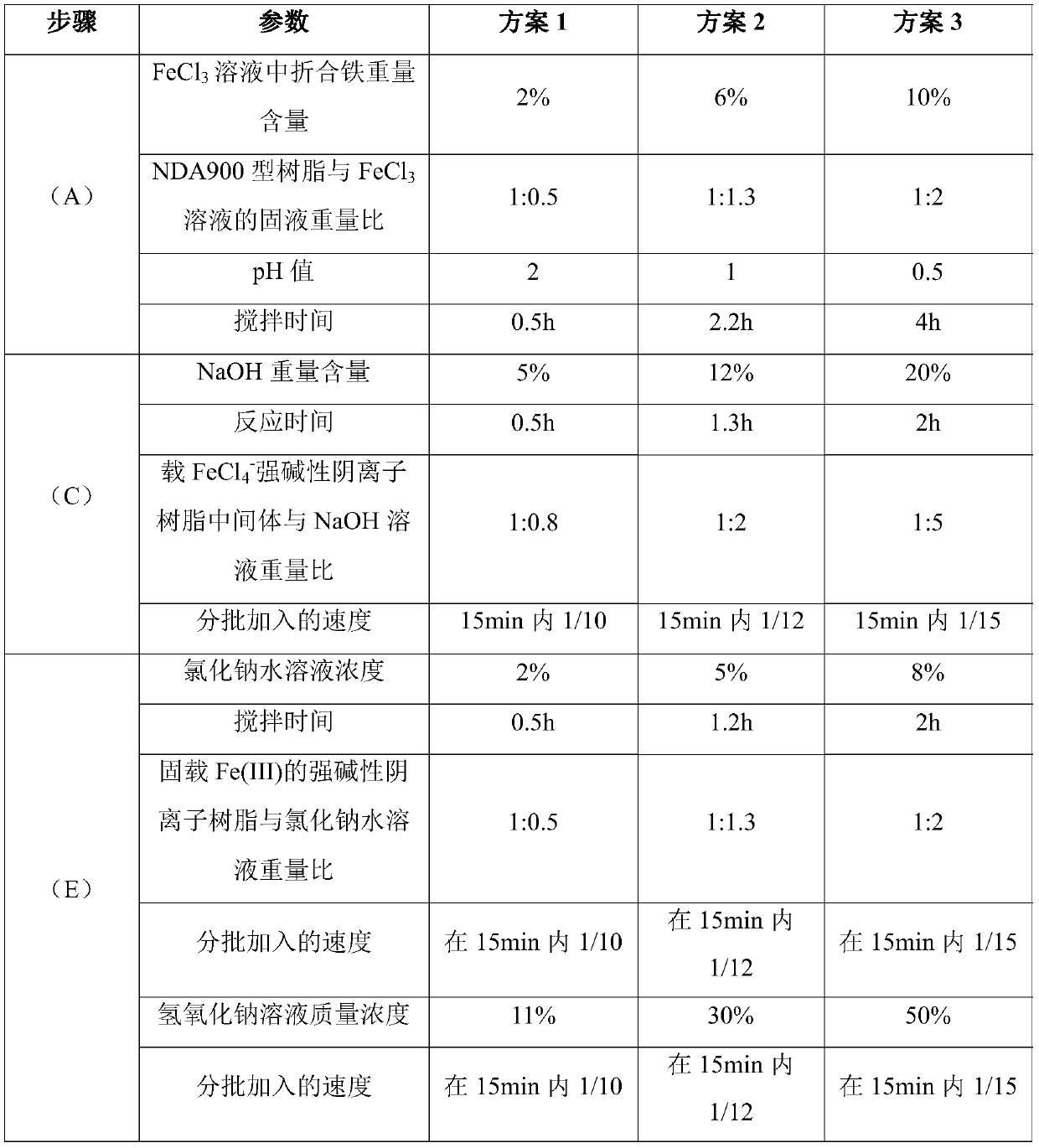

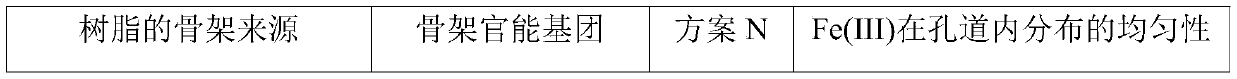

A kind of industrial preparation method of iron oxide resin composite adsorbent

ActiveCN107262071BAvoid lostUniform mass transferOther chemical processesWater/sewage treatment by ion-exchangeSorbentResin-Based Composite

The invention discloses an industrial preparation method of an iron oxide resin composite absorbing agent and belongs to the field of industrial production of composite resin absorbing agents for treating wastewater. The industrial preparation method includes the steps of (A), adding strong-base anion resin into a ferric salt solution in batches, and stirring; (B), filtering, and recycling filtrate to be reused in the step (A); (C), adding the filter residues of the step (B) into a sodium hydroxide solution in batches to perform reaction, and filtering; (D), adding NaOH into the filtrate of the step (C), and reusing the filtrate in the step (C); (E), using a sodium chloride aqueous solution and water to wash the filter residues of the step (C), filtering, and drying. The industrial preparation method of the immobilized Fe (III) strong-base anion resin absorbing agent has the advantages that substances such as the ferric salt solution, alkali liquor and acid liquor can be recycled and reused, production cost and environment pollution are reduced greatly, and the method conforms to the current industrial policy of energy conservation and emission reduction of China and suitable for being industrially popularized.

Owner:NANJING UNIV

Environment-friendly fireproof thermal insulation plate

The invention discloses an environment-friendly fireproof thermal insulation plate, and relates to the technical field of building decoration materials. The environment-friendly fireproof thermal insulation plate is prepared from, by weight, 10% of flame-retardant polystyrene foamed particles, 5% of expanded graphite, 3% of sodium silicate, 20% of a fireproof coating glue, 3% of oxalic acid heat-absorbing graphite, 38% of heat-absorbing thermal insulation stone powder, 8% of ammonium nitrate, and 13% of sodium borate, hydrochloric acid, and sodium citrate. The environment-friendly fireproof thermal insulation plate is made of various thermal-absorbing, thermal-insulating, fireproof and flame-retardant materials, so no dense smoke is discharged when the thermal insulation plate is in contact with high temperature, and the problem that dense smoke and high temperature are easily generated when a polystyrene foam material is in contact with high temperature is solved. The fireproof thermal insulation plate is long in service life and low in thermal conduction coefficient, and has the functions of A-level fire prevention and A-level water prevention. The production cost is low, the national energy conservation and emission reduction policy is met, the living quality of people is improved, and the living environment of people is improved.

Owner:周振美

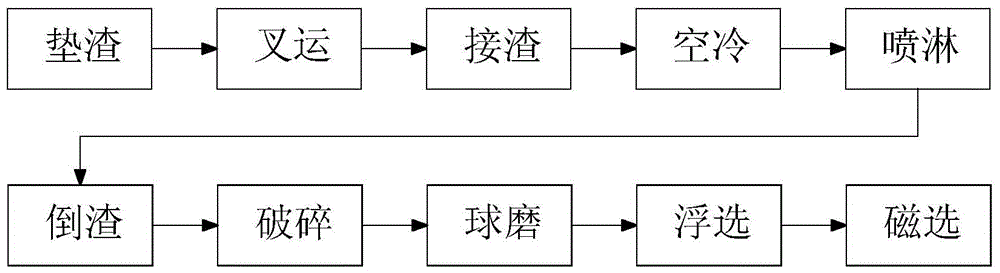

Welding slag package suitable for copper slag slow cooling process

The invention provides a novel welding slag ladle suitable for a slow cooling process of copper slag. The novel welding slag ladle comprises a ladle body, a ladle bottom and a plurality of ladle feet, wherein the ladle body is pressed into a whole; the ladle bottom is welded at the bottom of the ladle body; the ladle feet are welded at the bottom of the ladle bottom; a radiating space is formed between the two adjacent ladle feet; the ladle body, the ladle bottom and the ladle feet are all made of low-alloy high-strength plates. The novel welding slag ladle does not have any structural change during a using process and is particularly suitable for the slow cooling process of the copper slag; the service life of the welding slag ladle is greatly prolonged, so that the recycling cost of the copper slag is reduced.

Owner:MCC BAOSTEEL TECH SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com