Preparation of m from feedwater sludge 2+ -al 3+ -fe 3+ Methods and applications of hydrotalcite-like materials

A technology for water supply sludge and hydrotalcite, which is applied in the field of waste recycling, can solve the problems of less research on recycling and utilization, and achieve the effects of less reaction steps, low energy consumption and small equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

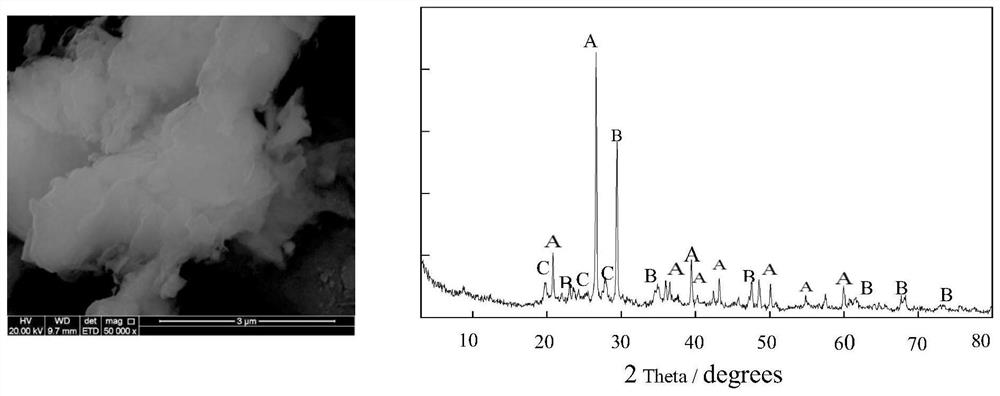

[0032] Example 1: Zn 2+ -Al 3+ -Fe 3+ Preparation of hydrotalcite-like

[0033] Step 1. Acidification of Feedwater Sludge

[0034] Grind and sieve the feedwater sludge sample, weigh 0.5008g feedwater sludge and place it in a 100mL beaker, add 5-10mL deionized water to it, adjust the pH of the sample to 1 with 14% dilute hydrochloric acid, and wrap the beaker with plastic wrap The mouth is sealed, and it is placed on a magnetic stirrer and stirred for 4 hours, so that the amorphous ferric hydroxide and aluminum hydroxide in the sample are dissolved and converted into Fe 3+ and Al 3+ .

[0035] Step 2, adding divalent metal ions and precipitating agent

[0036] Dilute the slurry obtained in step 1 to 100mL and transfer it to a 120mL reactor, add zinc nitrate hexahydrate 2.8645g, urea 1.7331g, control positive divalent cations (Zn 2+ ): Positive trivalent cation (Al 3+ and Fe 3+ ): Urea (H 2 NCONH 2 ) in a molar ratio of 3:1:9. The reaction kettle was placed in a homo...

Embodiment 2

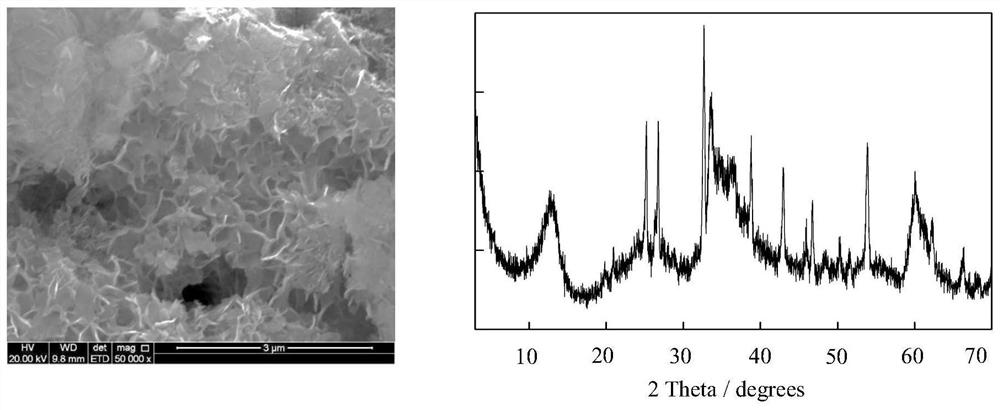

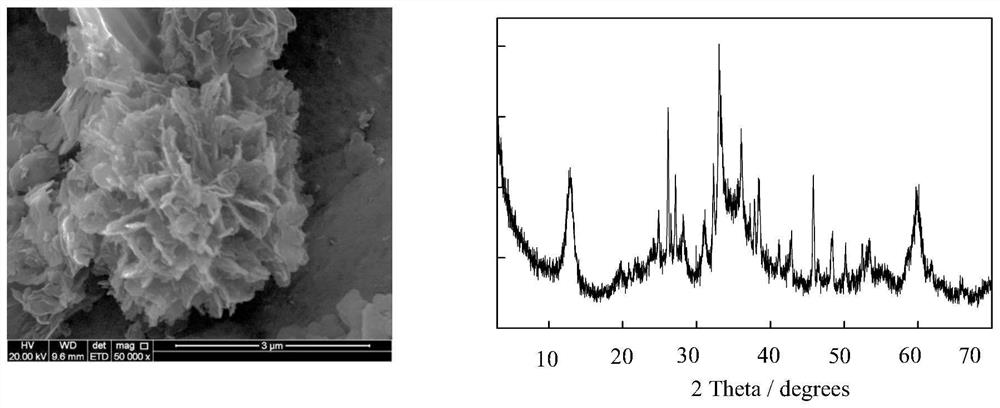

[0041] Example 2: Ni 2+ -Al 3+ -Fe 3+ Preparation of hydrotalcite-like

[0042] Step 1. Acidification of Feedwater Sludge

[0043] Grind and sieve the feedwater sludge sample, weigh 0.4321g feedwater sludge and place it in a 100mL beaker, add 5-10mL deionized water to it, adjust the pH of the sample to 1 with 14% dilute hydrochloric acid, and wrap the beaker with plastic wrap The mouth is sealed, and it is placed on a magnetic stirrer and stirred for 4 hours, so that the amorphous ferric hydroxide and aluminum hydroxide in the sample are dissolved and converted into Fe 3+ and Al 3+ .

[0044] Step 2, adding divalent metal ions and precipitating agent

[0045] Step 1 gained slurry is diluted to 100mL and is transferred in the reactor of 120mL, adds nickel nitrate hexahydrate 2.4158g, urea 1.4954g, controls positive divalent cation (Ni 2+ ): Positive trivalent cation (Al 3+ and Fe 3+ ): Urea (H 2 NCONH 2 ) The ratio of the amount of substance is 3:1:9. The reaction k...

Embodiment 3

[0050] Example 3: Zn 2+ -Al 3+ -Fe 3+ Hydrotalcite-like Phosphorus Removal from Wastewater

[0051] The most common method that adopts the determination of phosphate in water---the phosphomolybdenum blue method, measures the Zn prepared by Example 1 2+ -Al 3 + -Fe 3+ Effect of hydrotalcite-like materials on phosphorus removal from wastewater. At room temperature, measure 20mL of 20mg / L phosphorus-containing sewage water samples in total of 6 parts, add 0.05g of Zn 2+ -Al 3+ -Fe 3+ Multi-component hydrotalcite materials were added to the water samples, and each water sample was stirred with a magnetic stirrer for 0, 5, 10, 15, 20, and 25 minutes, and the filter residue Zn was separated by suction filtration. 2+ -Al 3+ -Fe 3+ For multi-component hydrotalcite materials, add ammonium molybdate solution and tin dichloride glycerin solution to all filtrates, mix well, and quickly measure the absorbance with an ultraviolet spectrometer.

[0052] Depend on Figure 4 Visib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com