Furnace gas dust remover for sealed electric furnace

A technology for dust collectors and furnace gas, which is applied in membrane filters, chemical instruments and methods, and separation of dispersed particles. Effects of tar precipitation and reduction in the number of facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the purpose, structure and function of the present invention, a kind of airtight electric furnace gas dust collector of the present invention will be further described in detail below in conjunction with the accompanying drawings.

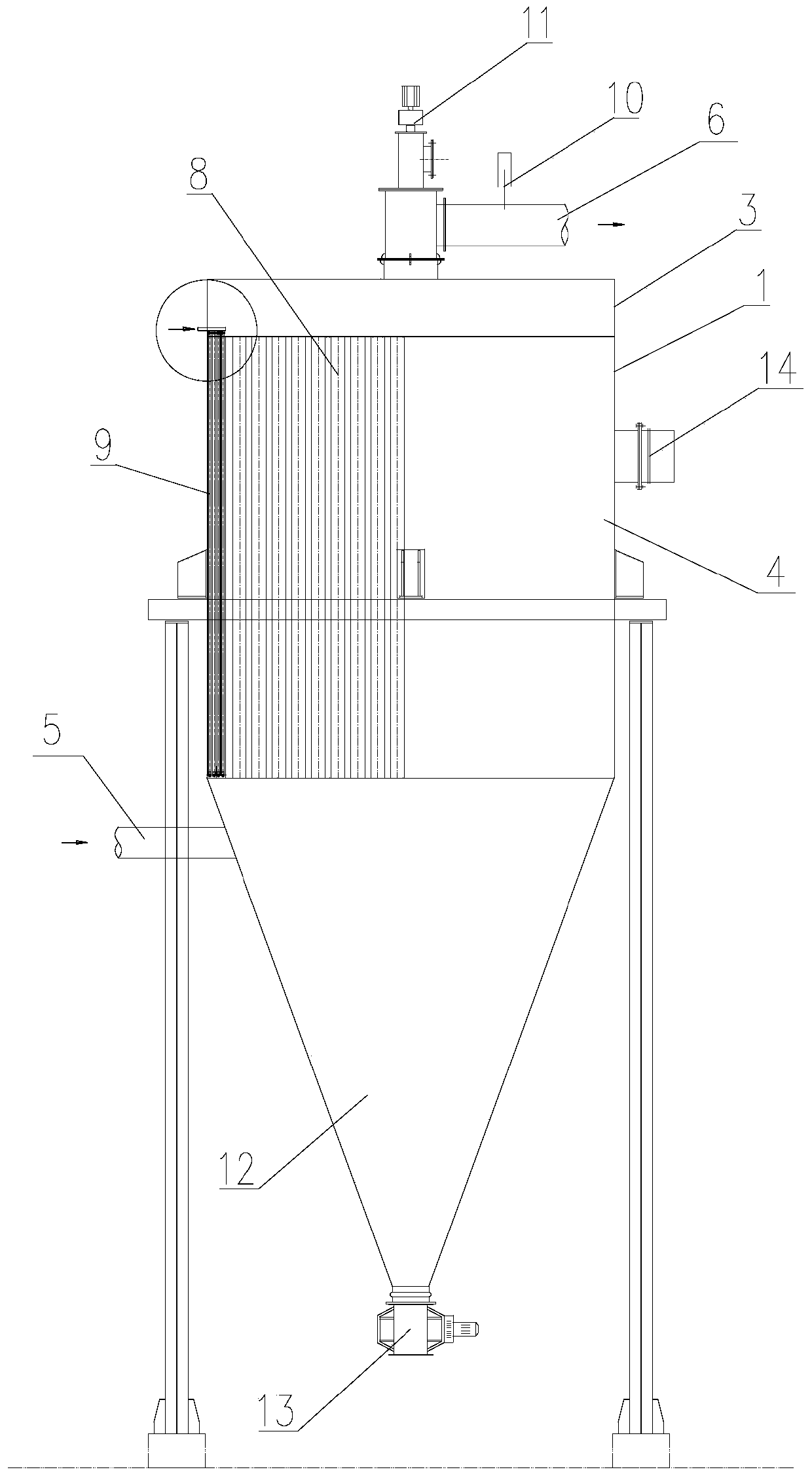

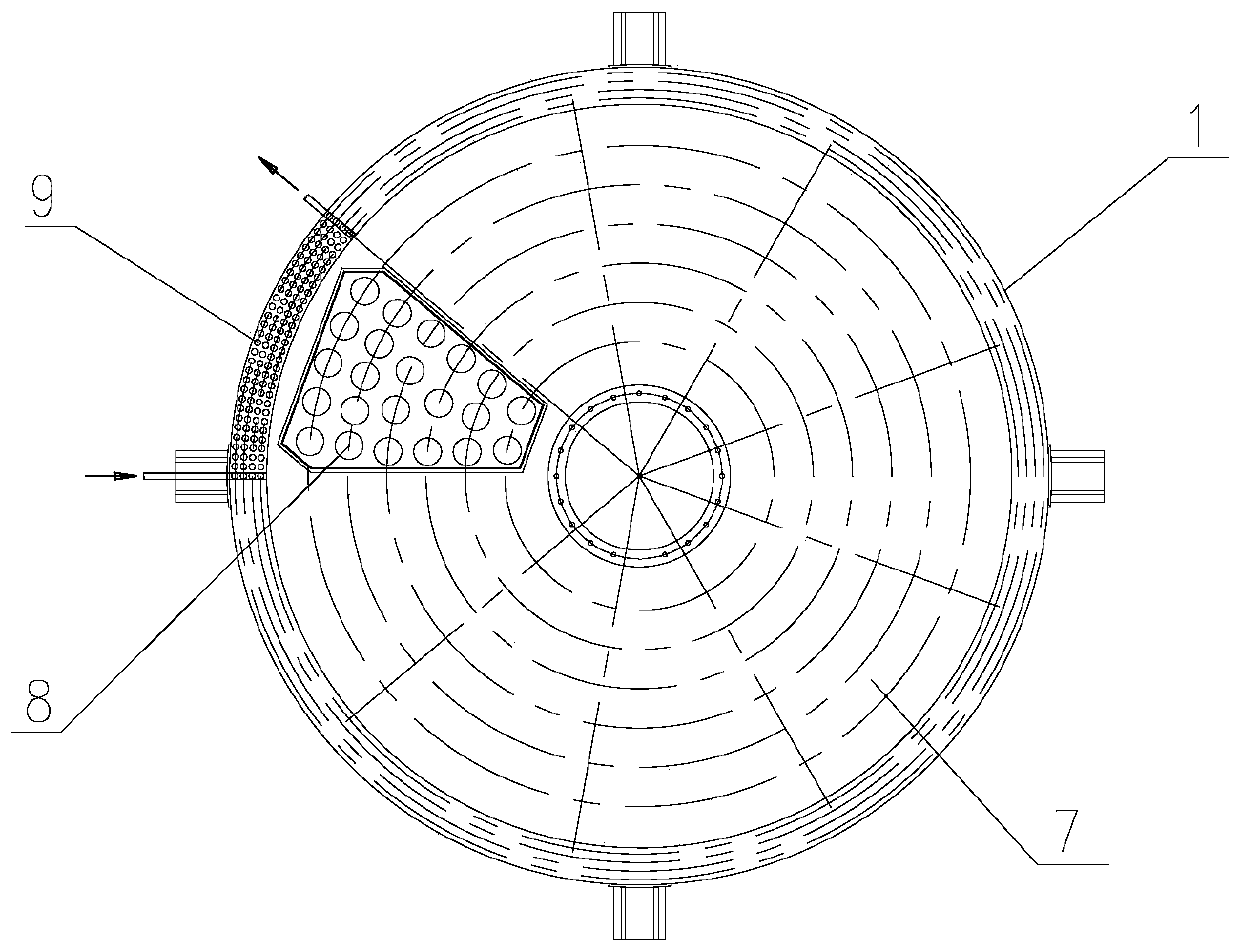

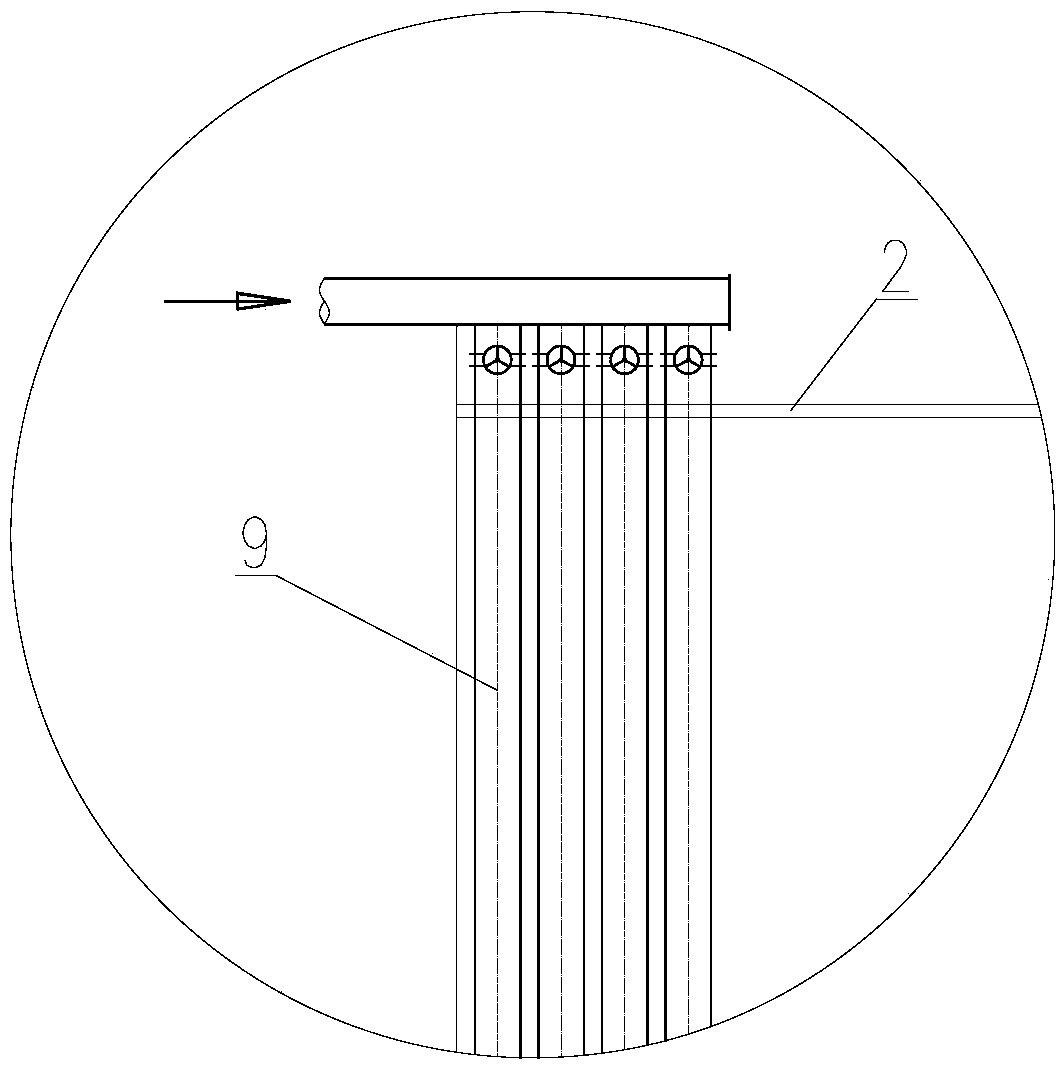

[0015] like Figure 1 to Figure 3 As shown, the airtight electric furnace gas dust collector of the present invention includes a housing 1 , and a dust collector flower plate 2 is arranged laterally inside the housing 1 . Among them, the upper part of the dust collector flower plate 2 is the clean air chamber 3, and the lower part is the dust removal chamber 4. The furnace gas inlet 5 of the airtight electric furnace gas dust collector is connected with the dust removal chamber 4, and the furnace gas outlet 6 is connected with the clean air chamber. Room 3 is connected.

[0016] Further, a plurality of filter chambers 7 arranged vertically are formed in the dust removal chamber 4 . Wherein, the filter chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com