Preparation device and method for ternary aluminum-lithium alloy for hydrogen production

A technology of aluminum-lithium alloy and preparation equipment, which is applied in the field of hydrogen production, can solve the problems of less introduction of aluminum alloy preparation equipment and methods, and achieve the effects of improved hydrolysis kinetics, high activity of the alloy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

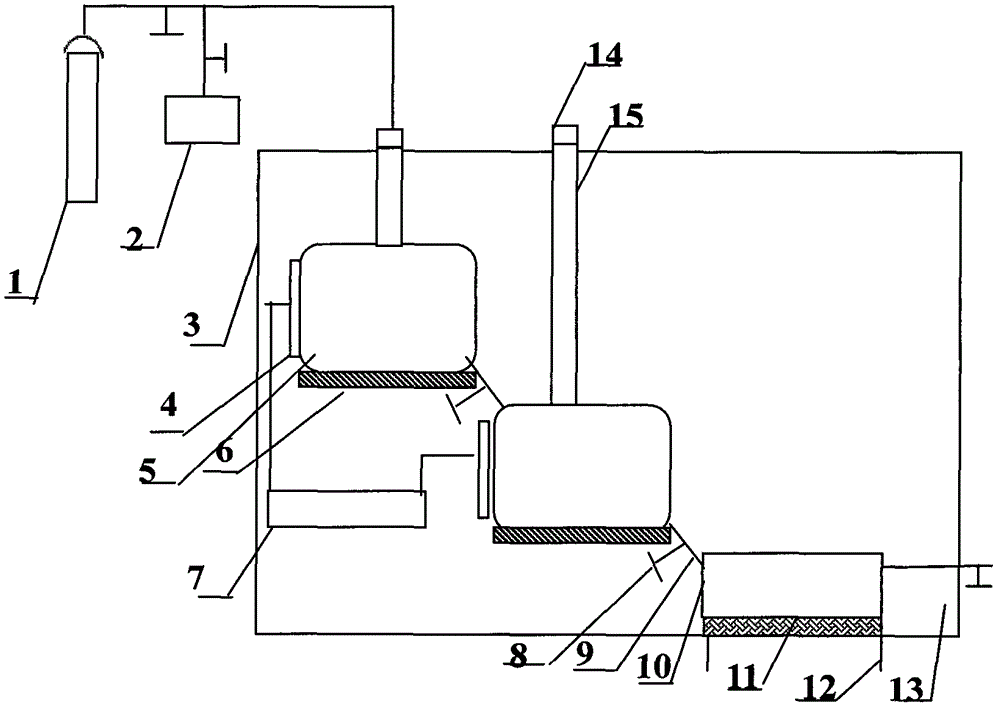

[0027] A ternary aluminum-lithium alloy preparation device for hydrogen production, comprising a housing, 2 alloy preparation containers 1 and 2 of equal volume, and a mold; there are 2 feeding ports on the top of the housing, each feeding port Connected with the alloy preparation container, the top of the shell is equipped with a stainless steel tube; the stainless steel tube is connected to the vacuum pump and the argon gas bottle through a tee and a stainless steel valve; there is an argon gas outlet and a control valve at the bottom of the shell; the bottom of the alloy preparation container is connected to an electric heating wire, a thermocouple and Temperature controller; the alloy preparation container is covered with a heat-resistant insulation layer; the top of the alloy preparation container has a feeding port and a feeding pipe; the bottom of the alloy preparation container is connected to a high temperature resistant pipe and a control valve; between alloy preparati...

Embodiment 2

[0030] The preparation method of the ternary aluminum-lithium alloy is set, and the composition design is as follows:

[0031] System component 1: the content of aluminum is 90wt%, the content of lithium is 5, and the content of iron is 5wt%.

[0032] System component 2: the content of aluminum is 75wt%, the content of lithium is 15wt%, and the content of iron is 10wt%.

[0033] System component 3: the aluminum content is 85wt%, the lithium content is 9, and the iron content is 6wt%.

[0034] System component 4: the aluminum content is 83wt%, the lithium content is 11, and the nickel content is 6wt%.

[0035] System component 7: the content of aluminum is 80wt%, the content of lithium is 10wt%, and the content of cobalt is 10wt%.

[0036] System component 8: the content of aluminum is 79wt%, the content of lithium is 12wt%, and the content of nickel is 9wt%.

[0037] System component 9: the aluminum content is 88wt%, the lithium content is 5, and the cobalt content is 7wt%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com