A kind of industrial preparation method of iron oxide resin composite adsorbent

A technology of resin compounding and adsorbent, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of huge disparity in material handling capacity, difficulty in industrial production, and huge differences, and achieve Avoid acid-base loss, save process and cost, and avoid excessive heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The iron oxide resin composite adsorbent of the present embodiment, the industrial preparation method of the strongly basic anion resin adsorbent of immobilized Fe(III), comprises the following specific steps:

[0037] (A) First, add the commercially available NDA900 resin raw material into the filter car, put 2t of resin in each batch, add about 2t of methanol solution, stir intermittently at 20-45°C, let it stand for 1h, and filter out the methanol by gravity filtration Solution, the filtered methanol solution is returned to the distillation system for distillation and reused; then the resin is transferred to a vacuum dryer, heated to 30-60°C with a water bath, while maintaining a vacuum of 0.05-0.2MPa, when the water content is reduced to 15-30% after unloading, get washed NDA900 resin;

[0038] Add 1~2t of anhydrous FeCl to the 6000L reactor 3 (commercially available) and 20% hydrochloric acid, prepared into 3000L FeCl 3 solution, wherein the equivalent iron weigh...

Embodiment 2

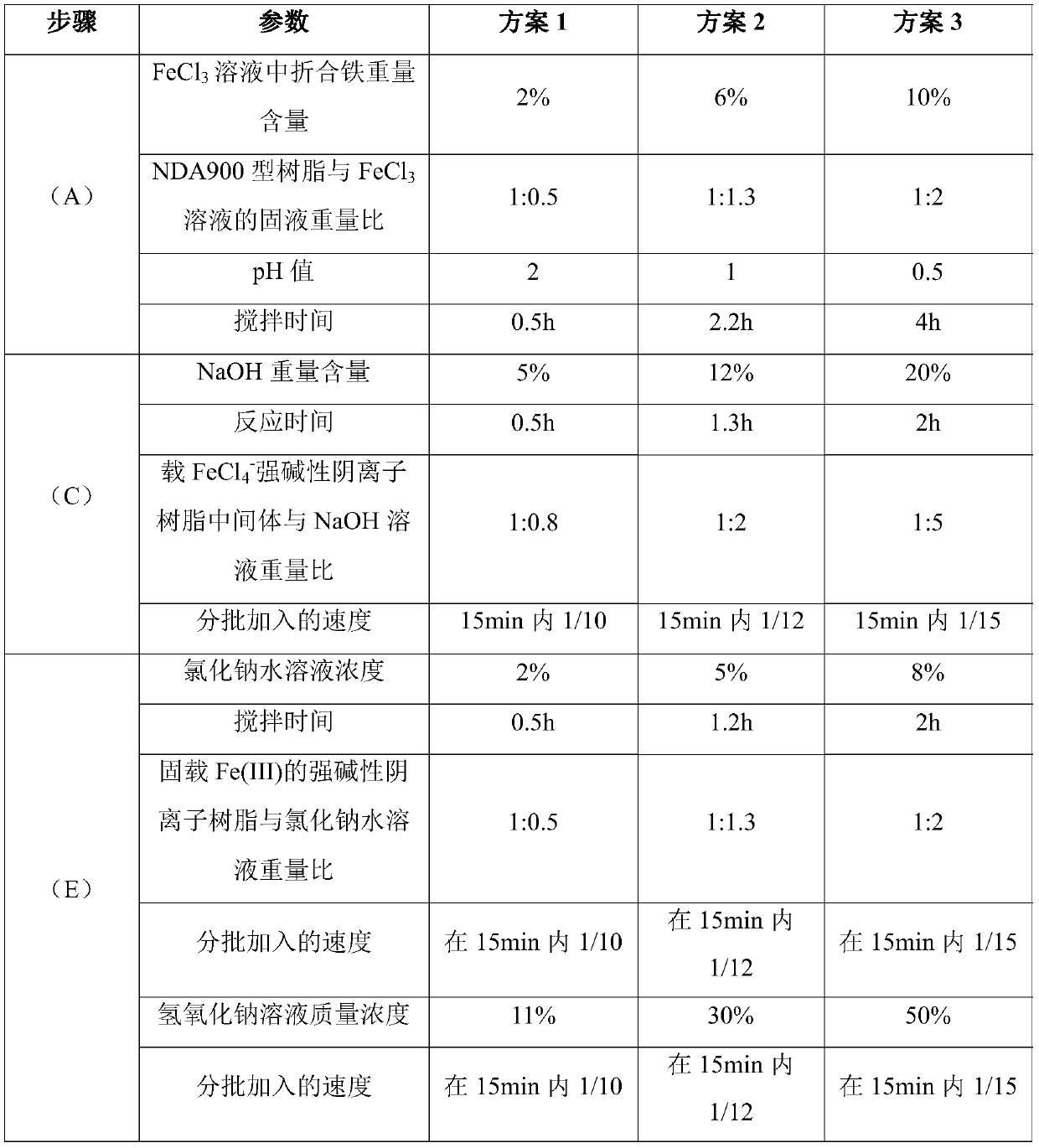

[0044] The industrial preparation method of the strongly basic anion resin adsorbent of immobilized Fe (III) of the present embodiment, basic steps are the same as embodiment 1, and carry out quantification in different schemes to each numerical range in embodiment 1, as table 1 Shown:

[0045] Table 1

[0046]

Embodiment 3

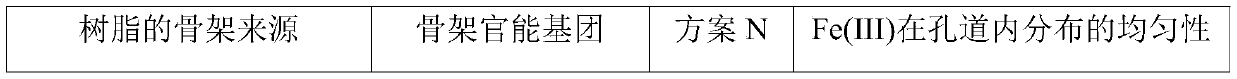

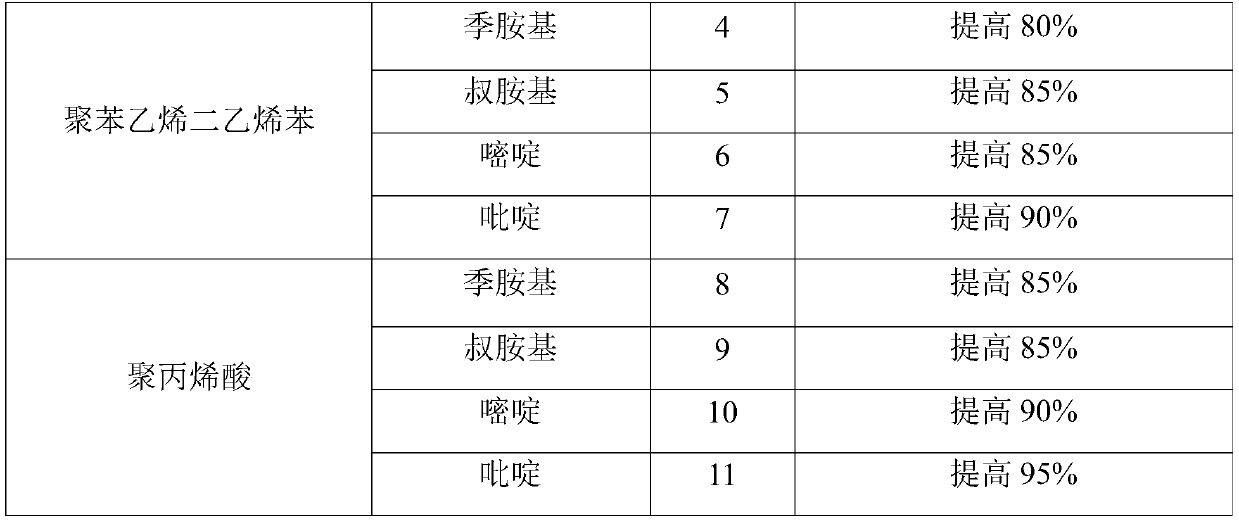

[0048] The industrial preparation method of the strongly basic anion resin adsorbent of immobilized Fe (III) of the present embodiment, basic steps are with embodiment 1, and, the strong basic anion resin described in the step (A) in embodiment 2 The skeletons are respectively selected from polystyrene divinylbenzene and polyacrylic acid, and the functional groups on the skeletons are respectively selected from quaternary amino groups, tertiary amino groups, pyridine and pyrimidine, as shown in Table 2:

[0049] Table 2

[0050]

[0051]

[0052] Since polystyrene divinylbenzene is used as the skeleton, different degrees of cross-linking have different microstructures. Using different porogens and different amounts of porogens can strictly control the particle size of micropores in the resin. Polyacrylic acid is the only Second to the most commonly used resin in polystyrene systems, it has medium polarity and good heat resistance. Moreover, the quaternary ammonium group,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com