Industrial preparation method of anionic resin loaded nano zirconia composite material

A technology of nano-zirconia and anion resin, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of reducing the utilization efficiency of nano-particle sites, high energy consumption of evaporation and concentration, and carrier pores Problems such as clogging can be avoided, and the effects of reducing cost and energy consumption, less environmental pollution, and less pore clogging can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

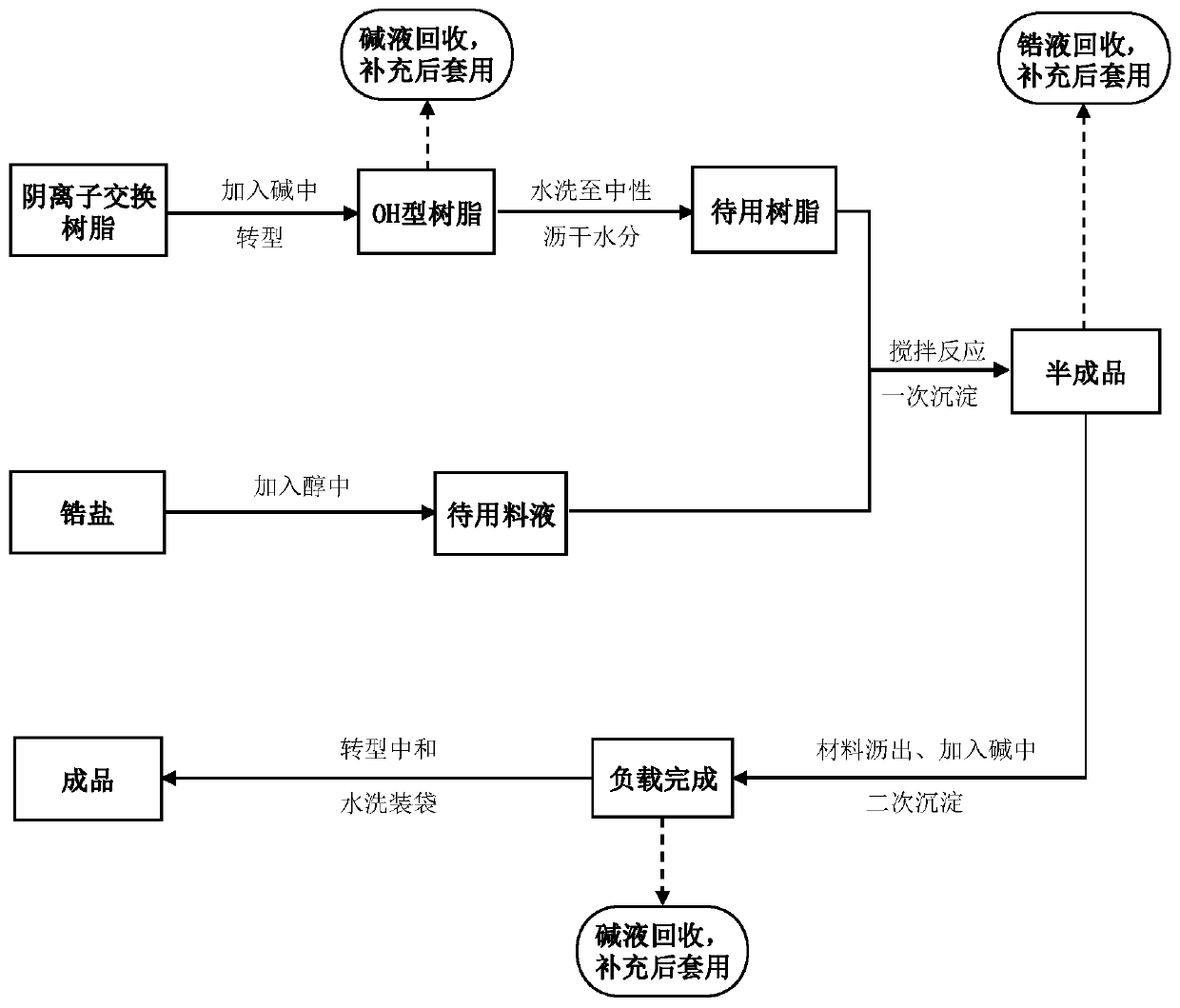

[0029] The preparation method of the present embodiment comprises the following steps:

[0030] (1) Resin transformation: wash and dry 20kg of commercially available D201 resin, add it to 40L of 10% (w / w) NaOH solution, stir at 300rpm for 2 hours, then leach out and recover the lye;

[0031] (2) Preparation of zirconium alcohol feed solution: 24kg zirconium oxychloride octahydrate (commercially available) was dissolved in 40L methanol, stirred at a speed of 300rpm for 1h, and the alcohol solution of zirconium was prepared as feed solution for later use, wherein the concentration of zirconium was about 170g / L (zirconium / alcohol);

[0032] (3) Primary precipitation: Add the transformed resin in step (1) into the zirconium alcohol material liquid prepared in step (2), stir at a speed of 300 rpm, and react for 3 hours to complete the primary precipitation of zirconia in the resin, and the zirconium liquid Recycle;

[0033] (4) Secondary precipitation: Leach out the material afte...

Embodiment 2

[0038] The preparation method of this example is similar to Example 1, but the D201 resin in step (1) is replaced by D301 resin, whose skeleton is polystyrene-divinylbenzene, tertiary amino group.

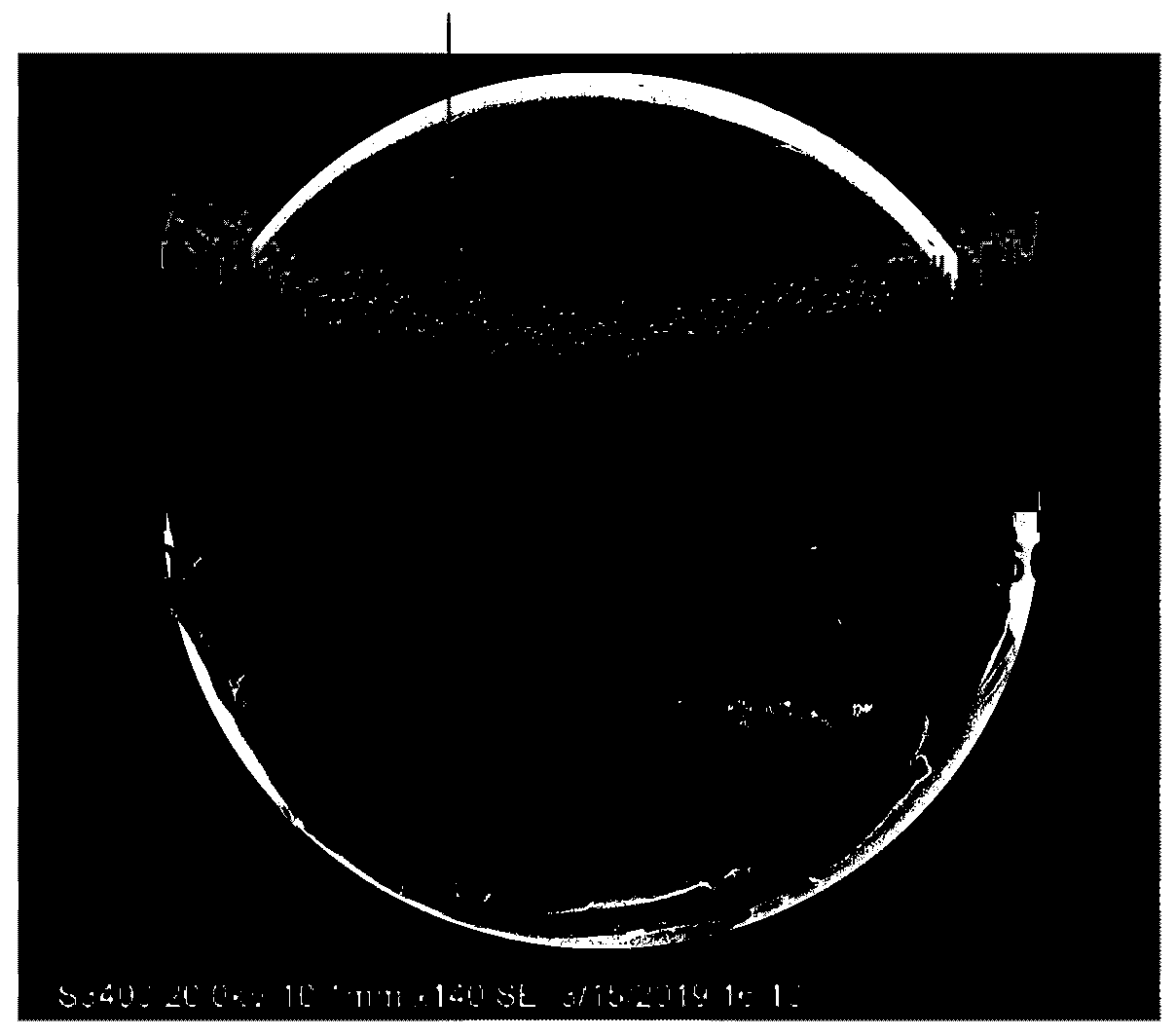

[0039] The nanocomposite material that present embodiment makes is spherical, and diameter is 0.6-0.8mm, and moisture content is 48% (v / v), records zirconium loading amount by inductively coupled plasma optical emission spectrometer (ICP-OES) after drying was 12.1%.

[0040] This example proves that in this invention, different anion exchange resins can be used as carriers, all of which can achieve better loading effects.

Embodiment 3

[0042] The preparation method of this example is similar to Example 1, but the 40L 10% (w / w) NaOH solution in step (1) is replaced by 40L 5% (w / w) NaOH solution.

[0043] The nanocomposite material that present embodiment makes is spherical, and diameter is 0.6-0.8mm, and moisture content is 45% (v / v), records zirconium loading amount by inductively coupled plasma optical emission spectrometer (ICP-OES) after drying was 10.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com