Device and method for preparing combined continuous electro-spinning nano fibrous membrane

A technology for electrospinning nanofibers and manufacturing devices, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of decreased production efficiency of electrospun nanofibers, avoid electrostatic repulsion, and achieve good uniformity. , the effect of not easily dissipated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

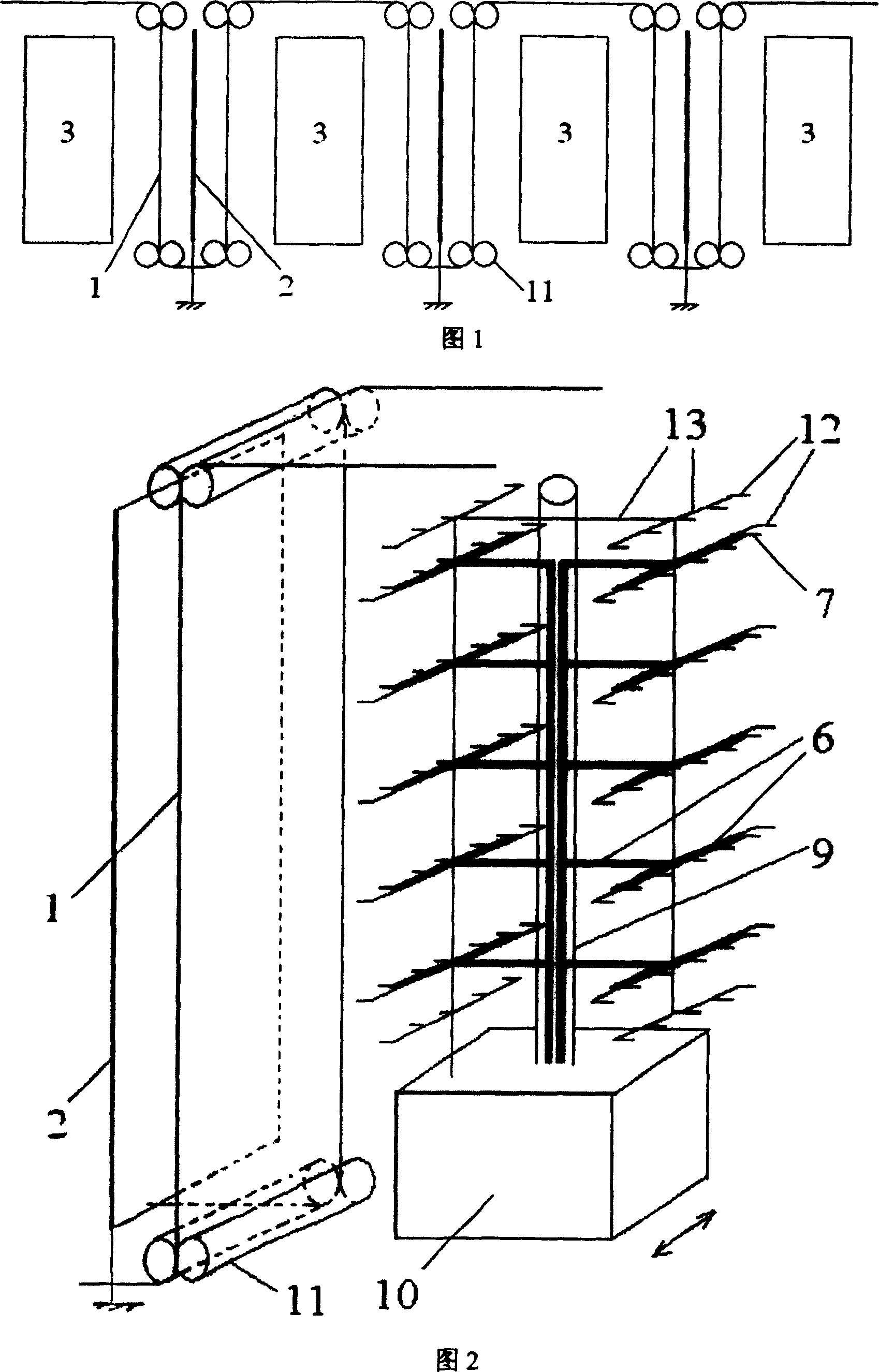

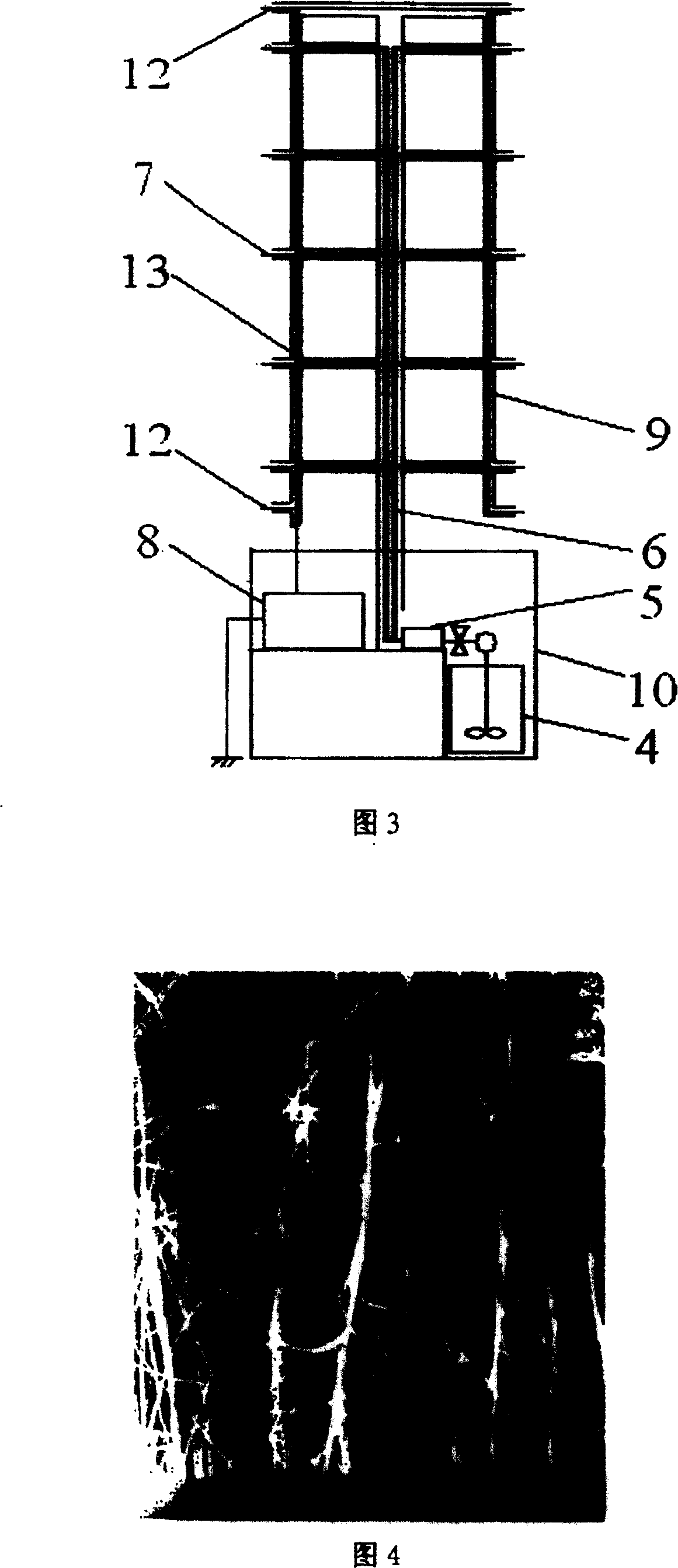

[0027] A method for preparing an electrospun nanofiber membrane suitable for a combined continuous electrospinning nanofiber membrane manufacturing device of the present invention comprises the following steps: (1) dispensing the high polymer solution in the liquid storage tank 4 by a metering infusion pump 5 Pumped out, and delivered to row-type electrospinning nozzle 7 through infusion tube 6; The nozzle 7 applies a DC high voltage of 10KV-100KV with the same or opposite polarity, and the polymer solution at the top of the nozzle is sprayed under the action of an electric field to form nanofibers; 1 The vertical part is parallel and reciprocates at a constant speed, the speed is 2cm / s-20cm / s, and the amplitude is 5-30cm. The continuous receiving web 1 moves upward or downward at a constant speed at a speed of 1-100 cm / s, and the continuous electrospun nanofiber membrane is received on the continuous receiving web 1 .

[0028]The polymer solution is a solution of a polymer d...

Embodiment 1

[0030] Dissolve 100g of polyacrylonitrile PAN in 1000ml of N,N-dimethylformamide, pump the solution in the liquid storage tank from the metering infusion pump, and send it to the row-type electrospinning nozzle through the infusion tube, and the fixing bracket is fixed from top to bottom 5 row-type electrospinning nozzles, the distance between each row is 20cm, and there is a row of limiting electrodes connected by wires at the positions 20cm away from the uppermost and lowermost row-type electrospinning nozzles. Each row-type electrospinning nozzle has 5 nozzles, the distance between the nozzles is 20 cm, and there are two limiting electrodes connected to the nozzles through wires at a distance of 20 cm from the nozzles at both ends, and the inner diameter of the nozzles is 1.0 mm. A positive DC high voltage of 20KV is applied to the row-type electrospinning nozzles of the adjacent electrospinning units, and the polymer solution at the top of the nozzles is spun under the acti...

Embodiment 2

[0032] Dissolve 100g of poly-L-lactic acid PLLA (viscosity average molecular weight: 100,000) in a mixed solvent of 500ml acetone and 500ml N,N-dimethylformamide, pump the solution in the storage tank from the metering infusion pump, and pass it through the infusion tube Delivered to the row-type electrospinning nozzles, the fixed bracket fixed 10 row-type electrospinning nozzles from top to bottom, and the distance between each row was 15cm. Each row-type electrospinning nozzle has 10 nozzles, the distance between the nozzles is 15 cm, and there are two limiting electrodes connected to the nozzles through wires at a distance of 15 cm from the nozzles at both ends, and the inner diameter of the nozzles is 0.5 mm. A positive DC high voltage of 10KV is applied to the row-type electrospinning nozzles of the adjacent electrospinning units, and the polymer solution at the top of the nozzles is spun under the action of an electric field to form nanofibers. The distance between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com