Hypersalinity water-based delayed crosslinking gel fracturing fluid and preparation method thereof

A gel fracturing fluid, high salinity technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low friction, high temperature resistance, etc., achieve strong water solubility, wide application range, The effect of solving the scarcity of fresh water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

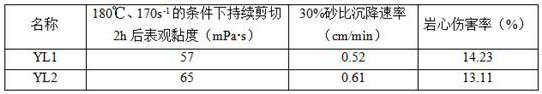

Examples

preparation example Construction

[0029] A preparation method of high-salinity water-based delayed crosslinking jelly fracturing fluid, comprising the following steps:

[0030] Step 1: Add the thickening agent under the stirring condition of high salinity brine to completely dissolve it;

[0031] The preparation method of thickener is as follows:

[0032] Acrylamide, acrylic acid, methacryloyloxyethyltrimethylammonium chloride, 2-acrylamide-2-methylpropanesulfonic acid, N-hexadecylmethacrylamide in a mass ratio of 65:20 :10:4.8:0.2 is added in the solvent to obtain the polymerization reaction solution that the monomer mass concentration is 30 wt.%.

[0033] Sodium dodecylsulfonate is added in the polymerization reaction solution, and the pH value is adjusted to neutrality through sodium hydroxide solution; wherein the mass ratio of sodium dodecylsulfonate and monomer is 10:1;

[0034] Then add the initiator and react for 3-4 hours at 40-50°C to obtain the required thickener. The initiator is a mixture of am...

Embodiment 1

[0041] Follow the steps below to prepare high-salinity water-based delayed cross-linking gel fracturing fluid, including the following steps:

[0042] Step 1: Prepare 1 L of brine system with a salinity of 180,000 mg / L, and then use a high-speed stirrer to stir at a speed of 1000 r / min. Slowly add 3 g thickener SG. Stir for 5 minutes to dissolve completely.

[0043] The preparation method of thickener is as follows:

[0044] Acrylamide, acrylic acid, methacryloxyethyltrimethylammonium chloride, 2-acrylamide-2-methylpropanesulfonic acid and N-hexadecylmethacrylamide are in a mass ratio of 65:20 :10:4.8:0.2 was added to the solvent to prepare a polymerization reaction solution with a monomer mass concentration of 30 wt.%.

[0045] Add 0.1 g sodium dodecylsulfonate to the polymerization reaction solution, add sodium hydroxide solution to adjust the pH value to neutrality, add ammonium persulfate and sodium sulfite to form a redox system initiator with a mass ratio of 2:1, add ...

Embodiment 2

[0050]Follow the steps below to prepare high-salinity water-based delayed cross-linking gel fracturing fluid, including the following steps:

[0051] Follow the steps below to prepare high-salinity water-based delayed cross-linking gel fracturing fluid, including the following steps:

[0052] Step 1: Prepare 1 L of brine system with a salinity of 200,000 mg / L, and then use a high-speed stirrer to stir at a speed of 1000 r / min. Slowly add 3 g thickener SG. Stir for 5 minutes to dissolve completely.

[0053] Thickener preparation method is as follows:

[0054] Acrylamide, acrylic acid, methacryloxyethyltrimethylammonium chloride, 2-acrylamide-2-methylpropanesulfonic acid and N-hexadecylmethacrylamide are in a mass ratio of 65:20 :10:4.8:0.2 was added to the solvent to prepare a polymerization reaction solution with a monomer mass concentration of 30 wt.%.

[0055] Add 0.1 g sodium dodecylsulfonate to the polymerization reaction solution, add sodium hydroxide solution to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com