Aramid mica nano composite material and industrial preparation method thereof

A composite material and aramid fiber technology, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, plastic/resin/wax insulator, etc. The electrical properties of fiber-based insulating paper need to be improved to achieve the effects of preventing mutual attraction and approach, reducing production costs, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

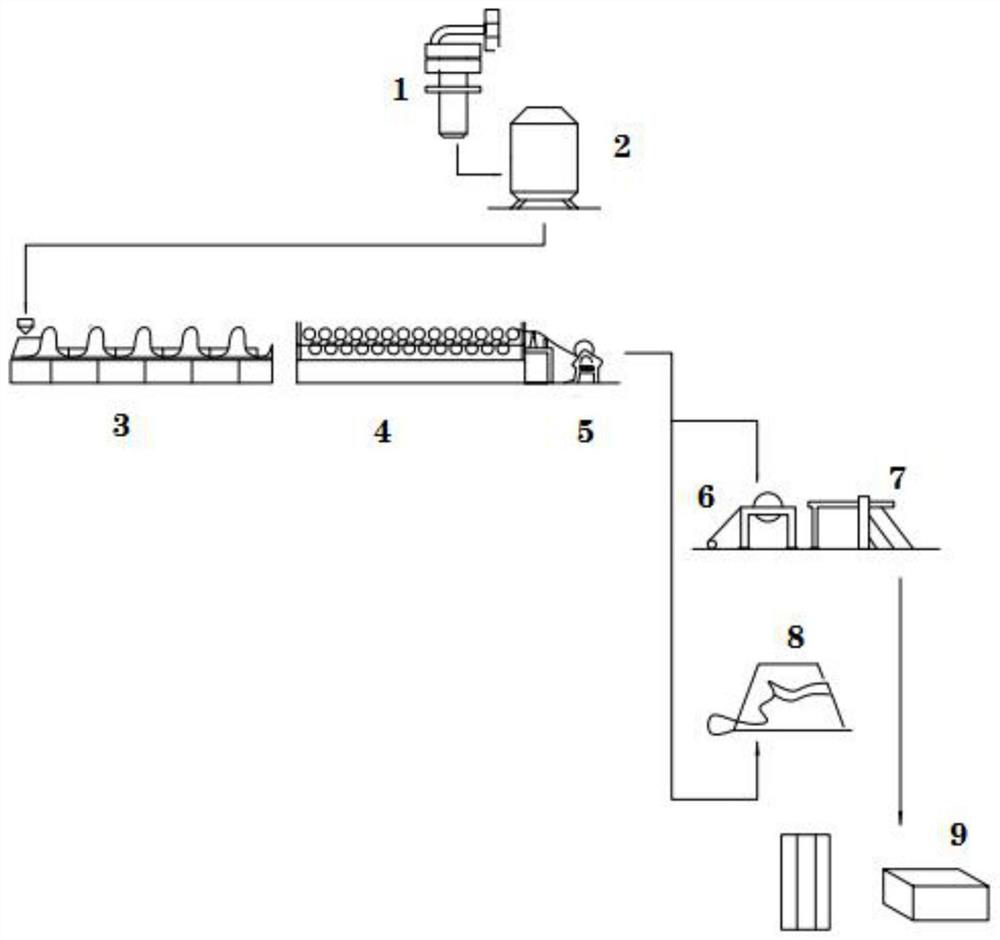

[0048] see figure 1 , the present invention provides a kind of industrial preparation method of aramid nanofiber mica composite material, and its technological process is specifically:

[0049] Mix aramid nanofibers and solvents to obtain an aramid nano-dispersion, add mica flakes to the aramid nano-dispersion to obtain a sol; after the sol is degassed by the instant defoaming machine 1, it is sprayed into the film making machine 2 In the process, the sol is solvent-exchanged with water or a low-concentration solvent aqueous solution to obtain a hydrogel, and then washed in a water washing device 3 and then dried by a dryer 4 to obtain an aramid nanofiber mica composite material.

[0050] Then it is coiled by the coiler 5, slitting by the slitter rewinder 6 or rewinded by the rewinder 8, and finally packaged to obtain the finished product of the aramid mica nanocomposite material.

[0051] In the following specific embodiments of the present invention, as an example, the sol ...

Embodiment 1

[0053] Embodiment 1 para-aramid fiber-muscovite nanocomposite material

[0054] (1) Take by weighing 400kg of poly-p-phenylene terephthalamide fiber, join 4000kg solvent (the mass ratio=1:50 of KOH:DMSO), stir 60h, form uniform aramid fiber nano-dispersion;

[0055] (2) Take muscovite 800kg, join in the aramid fiber nano-dispersion liquid, stir for 12h, obtain uniform p-aramid fiber synthetic mica sol;

[0056] (3) The sol is sprayed out through the nozzle and replaced with water to obtain a hydrogel, and after soaking for 4 hours, the water is changed for a total of 5 cycles to obtain a para-aramid nanofiber / muscovite hydrogel;

[0057] (4) Dry the para-aramid nanofiber / muscovite hydrogel in air at 60° C. for 60 minutes to obtain a para-aramid muscovite nanocomposite material.

[0058] After testing, the para-aramid nanofiber / synthetic mica insulating paper prepared in this example has a thickness of 50 μm, a dielectric strength of 180 kV / mm, and a tensile strength of 61.36 ...

Embodiment 2

[0059] Embodiment 2 p-aramid fiber phlogopite nanocomposite material

[0060] (1) Take by weighing 400kg of poly-p-phenylene terephthalamide fiber, join 20000kg solvent (the mass ratio of LiCl:DMA=1:10), stir 60h, form uniform aramid fiber nano-dispersion;

[0061] (2) Take phlogopite 400kg, join in the aramid fiber nano-dispersion liquid, stir 12h, obtain uniform p-aramid fiber synthetic mica sol;

[0062] (3) The sol is sprayed out through the nozzle and replaced with water to obtain a hydrogel. After soaking for 4 hours, the water is changed, and the water is circulated for 5 times to obtain the para-aramid nanofiber / phlogopite hydrogel;

[0063] (4) The para-aramid nanofiber / phlogopite hydrogel was dried in air at 70° C. for 50 min to obtain a para-aramid phlogopite nanocomposite material.

[0064] After testing, the para-aramid nanofiber / synthetic mica insulating paper prepared in this example has a thickness of 30 μm, a dielectric strength of 160 kV / mm, and a tensile st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com