Welding slag package suitable for copper slag slow cooling process

A slow cooling and slag ladle technology, applied in manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of production pollution, short service life, high maintenance rate, low maintenance cost, long service life, Weld repair performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

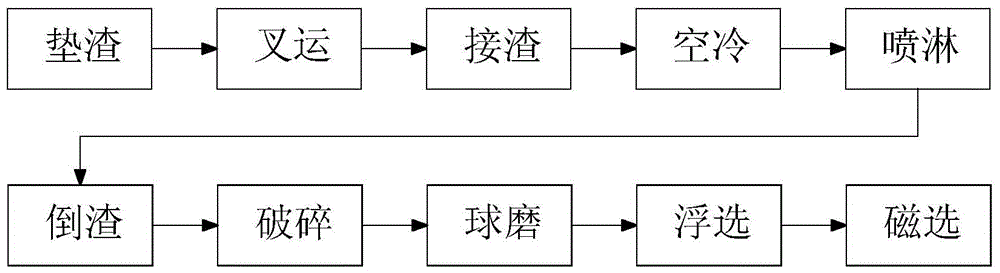

Method used

Image

Examples

Embodiment 2

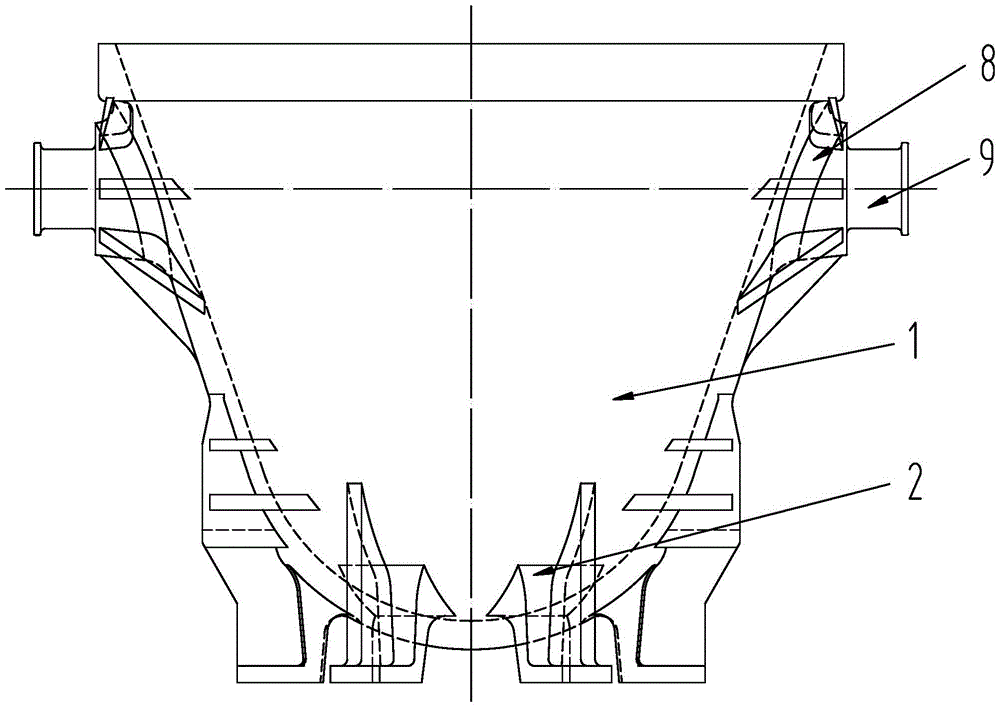

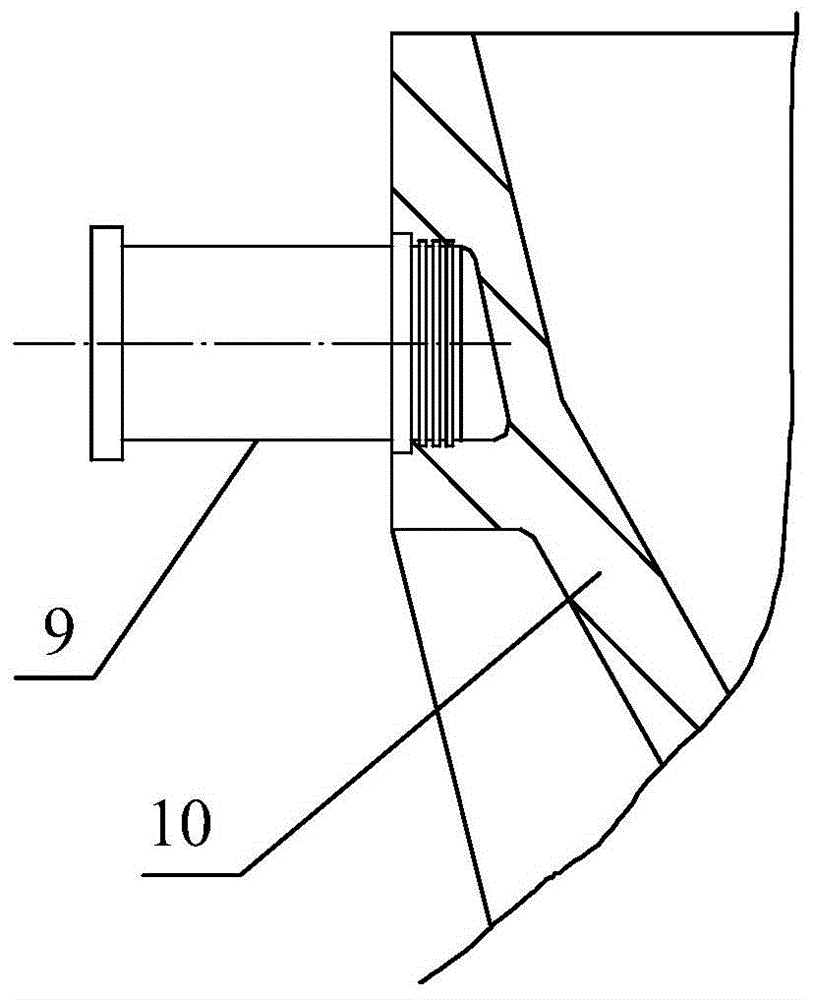

[0090] Embodiment two, see Figure 10 to Figure 12, an upper plate 13, a left plate 14, a lower plate 15, and a right plate 16 are arranged between the trunnion plate 8 and the package body 1, and the upper plate 13, the left plate 14, the lower plate 15, and the right plate 16 are arranged along the ears. The circumferential direction of the shaft 9 is evenly distributed, and the outer peripheries of the upper plate 13 , the left plate 14 , the lower plate 15 and the right plate 16 are all welded with the encasement 1 , the trunnion 9 and the trunnion plate 8 . During installation, four planes perpendicular to each other are milled on the outer peripheral surface of the trunnion 9, the center line is drawn on the trunnion 9, the trunnion 9 and the trunnion plate 8 are assembled together, and then the upper plate 13, The left plate 14, the lower plate 15, and the right plate 16 are respectively stuck on the four planes milled out from the outer peripheral surface of the trunni...

Embodiment 3

[0091] Embodiment three, see Figure 21 to Figure 23 , the inner side of the trunnion plate 8 is provided with a trunnion reinforcing plate 31, the trunnion 9 penetrates into the trunnion plate 8 and the trunnion reinforcing plate 31 in turn, and the trunnion 9 is connected with the trunnion plate 8 and the trunnion reinforcing plate The strong plate 31 is a key connection. In this embodiment, the trunnion 9 and the trunnion plate 8, and the trunnion 9 and the trunnion reinforcing plate 31 are connected by keys 17, and the two sides of the trunnion plate 8 are provided with The side sealing plate 32 connected to the package body 1 is to ensure the strength requirements of the most important parts of the welding slag package. Preferably, a pressure plate 33 is provided on the outer surface of the trunnion plate 8 , the trunnion 9 is penetrated in the pressure plate 33 , and the pressure plate 33 and the trunnion plate 8 are connected by a plurality of fixing bolts 34 . Since t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com