Foam glass ceramic and preparation method thereof

A technology of foamed glass-ceramics and foaming agent, which is applied in the field of preparing foamed glass-ceramics by using blast furnace hot slag and its preparation, can solve the problem of few high value-added products, and achieve strong adaptability to high and low temperature changes of flue gas, Low density, high compressive and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

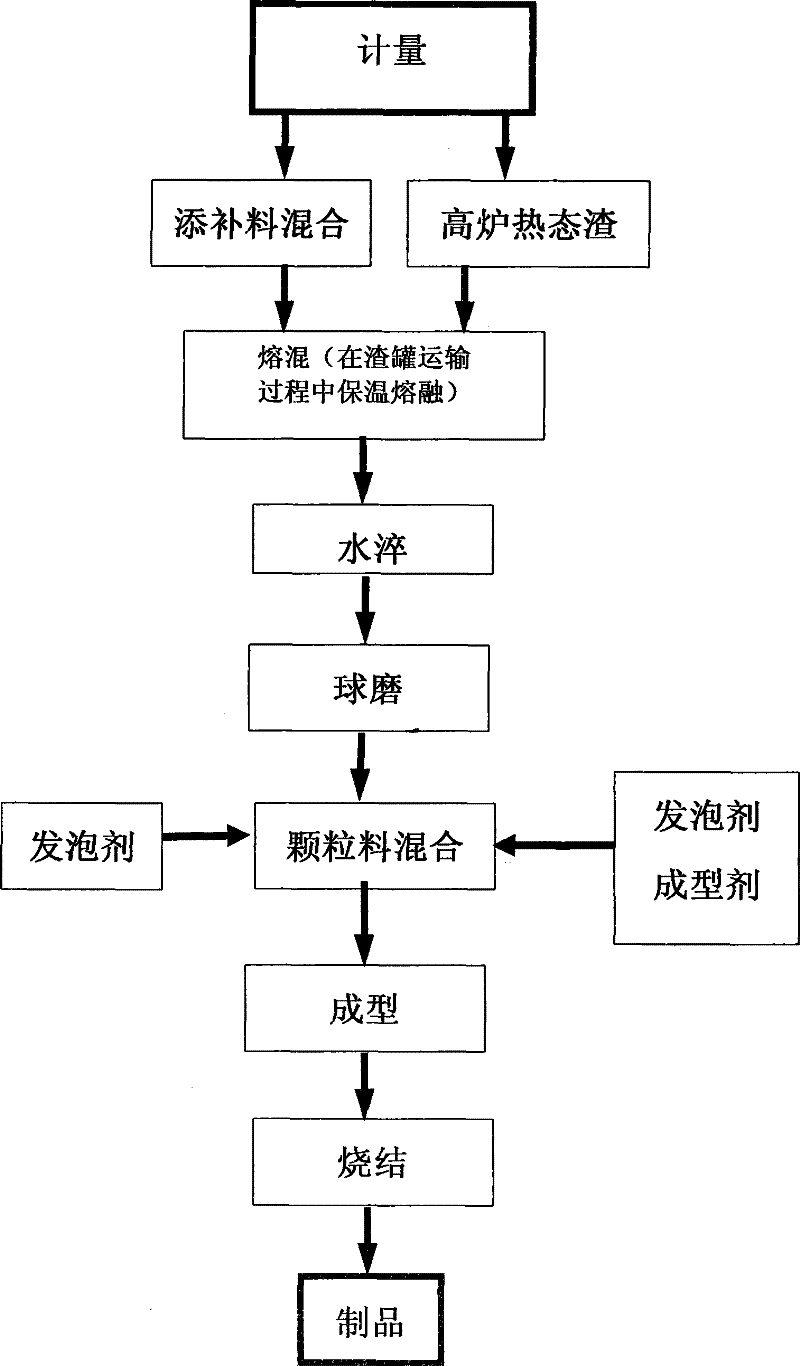

Method used

Image

Examples

Embodiment 1

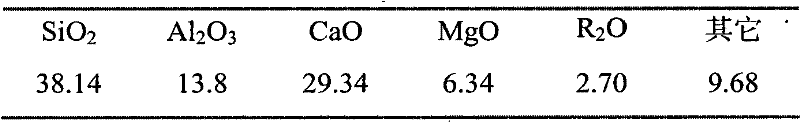

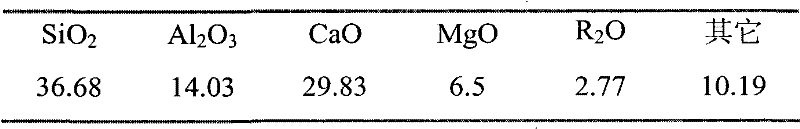

[0030] The blast furnace hot slag used was taken from Baotou Iron Works, and its chemical composition is shown in Table 1. The fly ash was obtained from Hexi Power Plant of Inner Mongolia Huadian Baotou Power Generation Co., Ltd., and the rare-separated tailings were obtained from Baotou Steel Rare Earth Plant. The chemical composition is shown in Table 2 and Table 3, and the particle size is 200 mesh. The chemical composition (wt%) of the base glass is:

[0031]

[0032] (1) Measure 2.01 tons of fly ash, 1.07 tons of borax, 0.1 tons of soda ash, 0.5 tons of rare tailings, and 0.5 tons of quartz sand; then mix fly ash, borax, soda ash, rare tailings, and quartz sand Add to mixer and mix well.

[0033] (2) Put the mixture prepared in step (1) into a grid-shaped mold with cordierite shelving as the substrate, and then sinter it in a shuttle kiln at 650°C for 2 Hours, a porous bulk material is obtained.

[0034] (3) The porous block material prepared in step (2) is placed i...

Embodiment 2

[0040] The blast furnace hot slag used was taken from Baotou Iron Works, and its chemical composition is shown in Table 1. The fly ash was obtained from Hexi Power Plant of Inner Mongolia Huadian Baotou Power Generation Co., Ltd., and the rare-separated tailings were obtained from Baotou Steel Rare Earth Plant. The chemical composition is shown in Table 2 and Table 3, and the particle size is 200 mesh. The chemical composition (wt%) of the base glass is:

[0041]

[0042] (1) Measure 2.12 tons of fly ash, 1.14 tons of borax, 0.11 tons of soda ash, 0.5 tons of rare tailings, and 0.35 tons of quartz sand; then mix fly ash, borax, soda ash, rare tailings, and quartz sand Add to mixer and mix well.

[0043] (2) Put the mixture prepared in step (1) into a grid-shaped mold with cordierite shelving as the substrate, and then sinter it in a shuttle kiln at 700°C for 1.5 Hours, a porous bulk material is obtained.

[0044] (3) Put the porous block material prepared in step (2) in ...

Embodiment 3

[0050] (1) Grind the glass quenching material particles prepared in Example 1 on a ball mill, cross a 200 mesh sieve, weigh 100 parts by weight of glass powder, 60 parts by weight of sodium sulfate with a particle size of 325 objects, mix, and then The material is formed in the type kiln.

[0051] (2) The formed glass frit is subjected to nucleation at 730°C for 1 hour, crystallization at 850°C for 2 hours, and sintering at 1000°C for 10 minutes to prepare foamed glass-ceramics.

[0052] (3) The volume density of the prepared foamed glass-ceramic is 0.87g cm -3 , thermal conductivity 0.19W / k m 2 , compressive strength 9.3MPa., acid resistance 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com