Patents

Literature

82results about How to "Lower boron content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

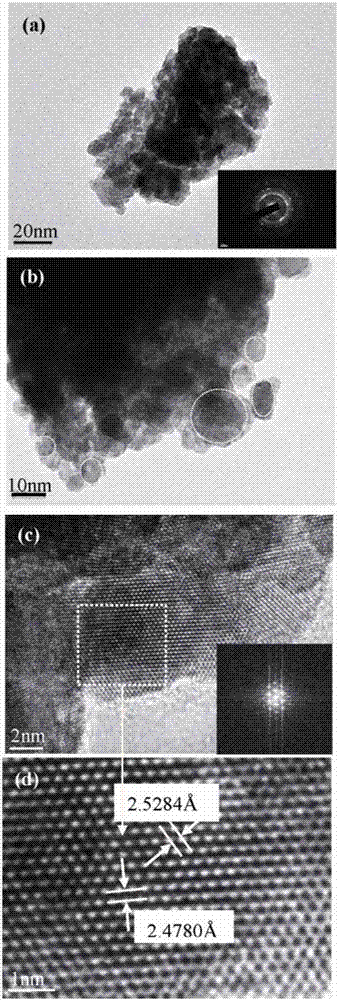

Iron-based nano-crystalline soft magnetic alloy and method for manufacturing same

InactiveCN103489555AHigh saturation magnetic inductionIncrease Fe contentMagnetic materialsElectronic componentCobalt

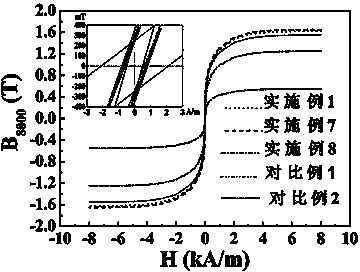

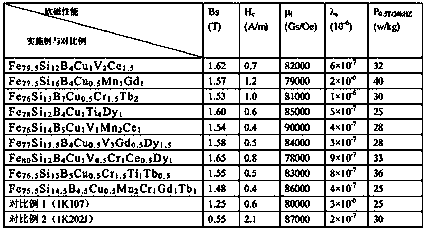

The invention provides iron-based nano-crystalline soft magnetic alloy, and belongs to the technical field of soft magnetic alloy. The iron-based nano-crystalline soft magnetic alloy is characterized in that a chemical formula of the iron-based nano-crystalline soft magnetic alloy is FeSiB<c>Cu<d>T<e>RE<f>, and the T represents at least one of Ti, V, Mn, Cr, Mo, Nb, Zr and W, and the RE represents one or two of La, Y, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho and Er; the a, the b, the c, the d, the e and the f represent atomic percentages of corresponding components, the b ranges from 12 to 16, the c ranges from 4 to 7, the d ranges from 0.5 to 1, the e ranges from 1 to 4, the f ranges from 0.5 to 2, and the a meets an equation of (100-b-c-d-e-f-g). The iron-based nano-crystalline soft magnetic alloy has the advantages that a saturated magnetostriction coefficient of the iron-based nano-crystalline soft magnetic alloy is close to zero, and the iron-based nano-crystalline soft magnetic alloy is high in magnetic permeability and saturated magnetic induction intensity, and can replace cobalt-based amorphous alloy to be applied to the field of manufacture for magnetic cores of precision electronic components.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Boron-iron and iron-titanium composite cored wire and application thereof

The invention relates to a boron-iron and iron-titanium composite cored wire and the application thereof. The powdery raw materials of the boron-iron and iron-titanium composite cored wire include boron iron and iron titanium, wherein the boron content of boron iron is not less than 9wt%, the titanium content of iron titanium is not less than 25wt%, and the mixing ratio of boron iron to iron titanium depends on the actual needs. The boron-iron and iron-titanium composite cored wire is manufactured by adding boron iron and iron titanium to molten steel at the same time, thereby simplifying the alloying operation in boron steel smelting and stabilizing the control of boron content in steel. Compared with the prior boron iron cored wire, the boron-iron and iron-titanium composite cored wire has the advantages of low proportion of boron iron, small fluctuation of deviation of the addition amount of boron iron, less loss, adequate protection of each boron iron fine particle by titanium element, and stable boron recovery rate (over 93%). The boron-iron and iron-titanium composite cored wire achieves the effect that the deviation of boron content in smelting components between furnaces for manufacturing the same boron-containing steel grades is less than 2ppm.

Owner:SHANDONG IRON & STEEL CO LTD +1

Boron removing method for multicrystal silicon

A method for removing boron from polysilicon relates to a polysilicon, in particular to a simple, low cost and small pollution method for removing boron from polysilicon. The present invention provides a method for removing boron from polysilicon with simple process, lower cost, safe technology, and small pollution. The polysilicon block is subjected to pulverization, ball milling and sieving to obtain silicon powder which is deoiling treated by using organic solvent, and the iron power contained in the silicon powder is removed too; the obtained silicon powder is put into a container which is put into a high-temperature furnace, wherein the silicon powder is subjected to wet-oxygen oxidation and recooling; the silicon powder after recooling is put into hydrofluoric acid solution to be corrupted so as to remove the surface oxidation layer; and then the silicon powder is scrubbed repeatedly by water until the washing liquid is neutral; finally, the silicon powder is dried to obtain the object product. The spectral analysis of the silicon powder shows that the boron content can be reduced by 1~3 times once, the present invention is totally compatible with the acid cleaning purification technology, and aluminium can be effectively removed.

Owner:XIAMEN UNIV

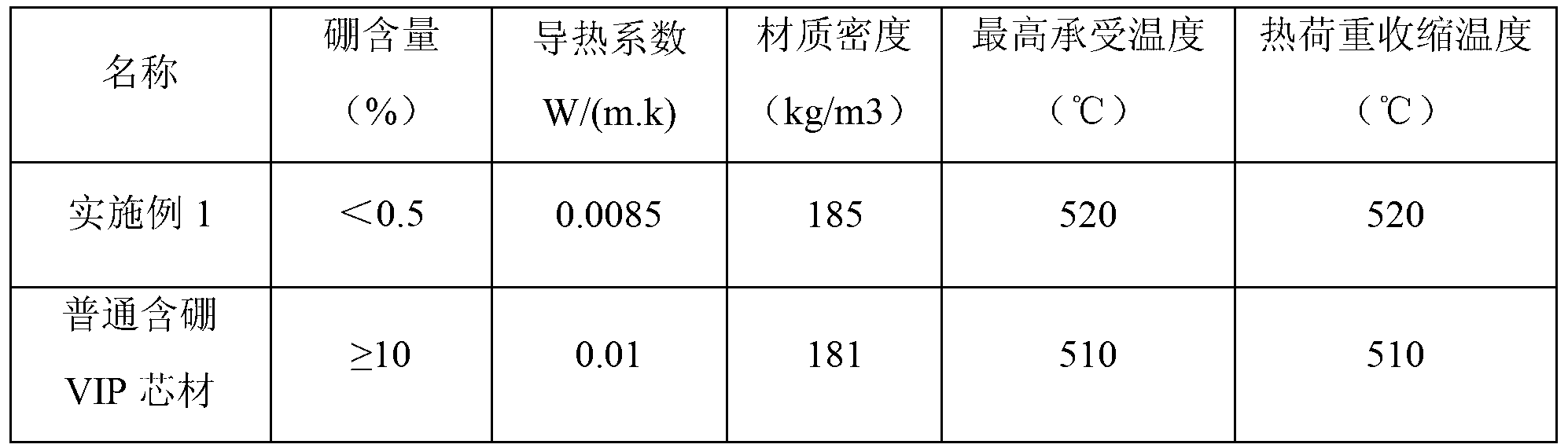

Novel glass fiber vacuum insulation panel core and preparation method

ActiveCN103244793ALower boron contentImprove insulation effectFibreboardThermal insulationAir filtrationGlass fiber

The invention discloses a novel glass fiber vacuum insulation panel core. The vacuum insulation panel core is made of low-boron glass cellucotton which has the boric mass percentage of less than 0.5% and the diameter of 0.5-1.0 micrometer. The invention further discloses a preparation method of the vacuum insulation panel core, which comprises the following steps of: (1) selecting the low-boron glass cellucotton, (2) beating and dispersing the selected low-boron glass cellucotton to obtain slurry, (3) diluting the slurry, (4) deslagging the slurry of Step (3) and preparing wet paper in a wet forming manner, (5) dehydrating the wet paper of Step (4); and (6) drying the wet paper of Step (5). The glass fiber air filtration paper has outstanding comprehensive performances; the preparation process is pollution-free; and the service life is long.

Owner:宣汉正原微玻纤有限公司

Process method for extracting low-concentration boracic acid in magnesium-containing brine

InactiveCN101544378AQuality improvementReduce manufacturing costBoron-oxygen compoundsSolventMagnesium

The invention relates to a process method for extracting low-concentration boracic acid in magnesium-containing brine, which comprises the following steps that: at room temperature, a mixed solvent mixed by monacid alcohol and a nonpolar organic solvent is used as a complexing extractant to extract acidified brine to obtain an extraction phase; then water is used for carrying out back extraction on the extraction phase; the boracic acid is back-extracted to a water phase; a mixed extraction solvent is regenerated; and the water phase containing the boracic acid is condensed and evaporated to directly obtain a boracic acid product. The process method can remove the low-content boron to substantially improve the quality of a produced magnesium product, can obtain the boracic acid as a byproduct, fully realizes the comprehensive development and utilization of magnesium-containing saline brine and has remarkable economic benefits.

Owner:HEBEI UNIV OF TECH

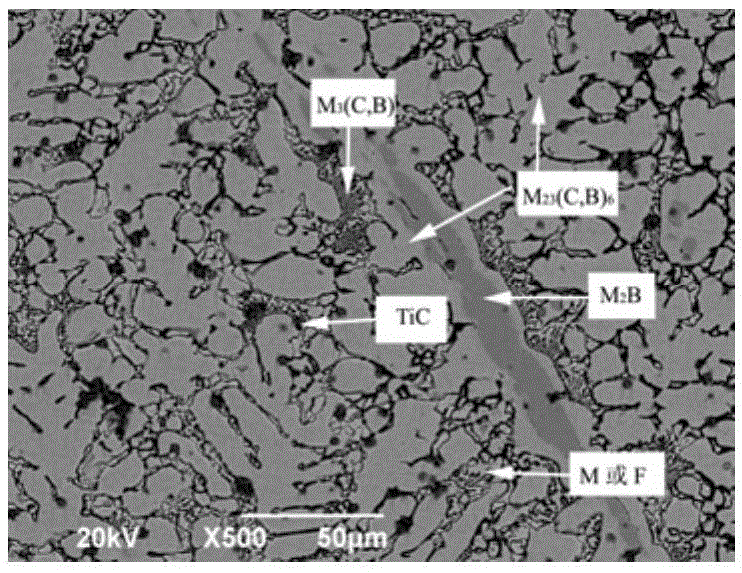

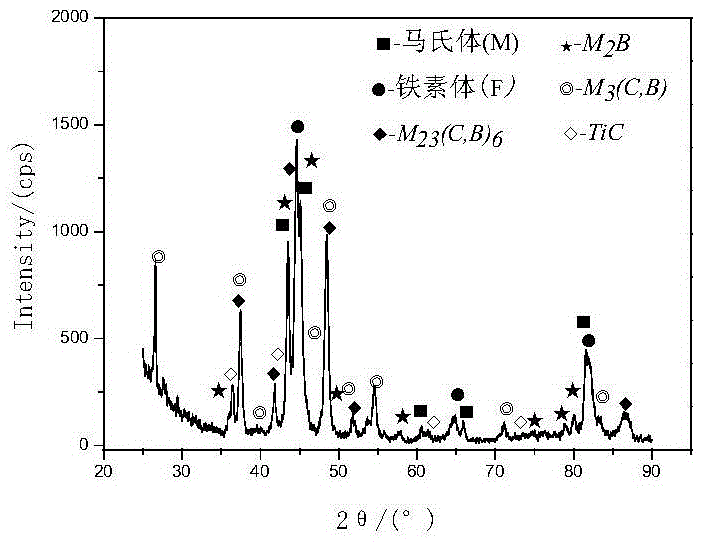

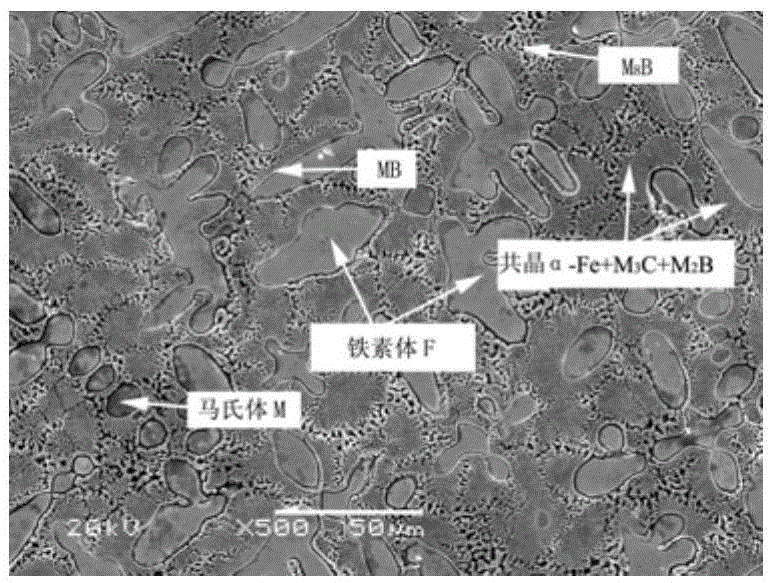

Carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire

InactiveCN105537797ARealize carbon control and tougheningReduce carbon contentWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire. According to the technical scheme, a low-carbon-steel H08A cold-rolled thin steel strip is adopted as an outer sheath, and an alloy, graphite and other metal powder are mixed in the sheath to form a powder core, wherein the surfacing alloy is alloy powder obtained by adding high-content ferro-boron, high-carbon ferrochrome and ferrotitanium with different melting properties into the flux-cored wire; by virtue of open-arc surfacing current control, a high-boron surfacing melt with the alloy component in an incompletely-molten and unevenly-mixed state is formed, so that an alloy element phase structure is selectively optimized and configured; the powder core mainly consists of the following components: ferro-boron, high-carbon ferrochrome, ferrotitanium, graphite, medium-carbon ferromanganese, ferrosilicon and reduced iron powder. The carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire overcomes the defect that a current high-boron surfacing alloy is great in brittleness due to microstructure characteristics of the high-boron surfacing alloy, can be widely applied to surfacing manufacturing or repairing of parts with abrasive wear resistance, for example, a concrete cement conveying tube, and is especially suitable for surfacing manufacturing or paring of the parts with low-stress abrasive wear resistance.

Owner:XIANGTAN UNIV

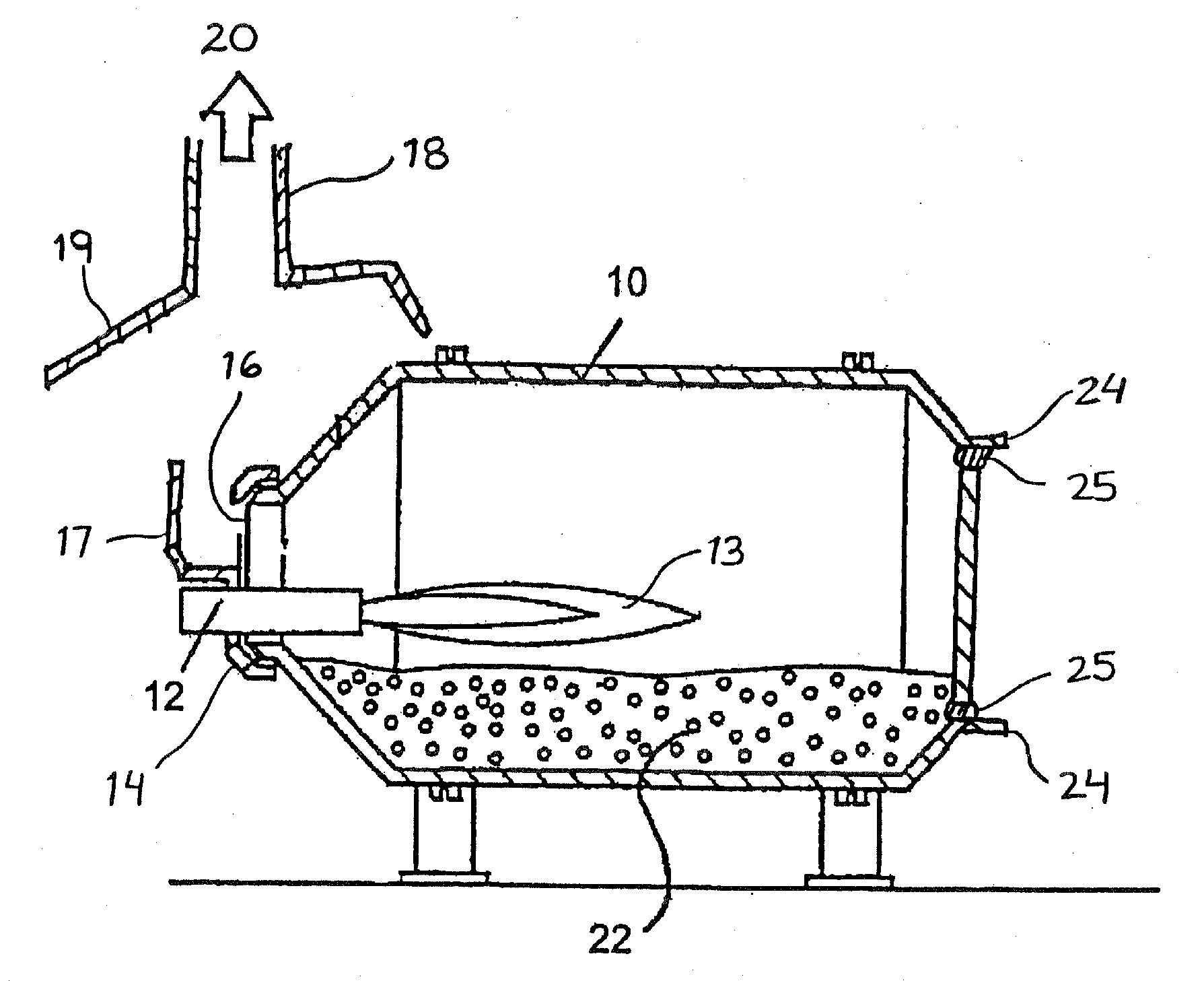

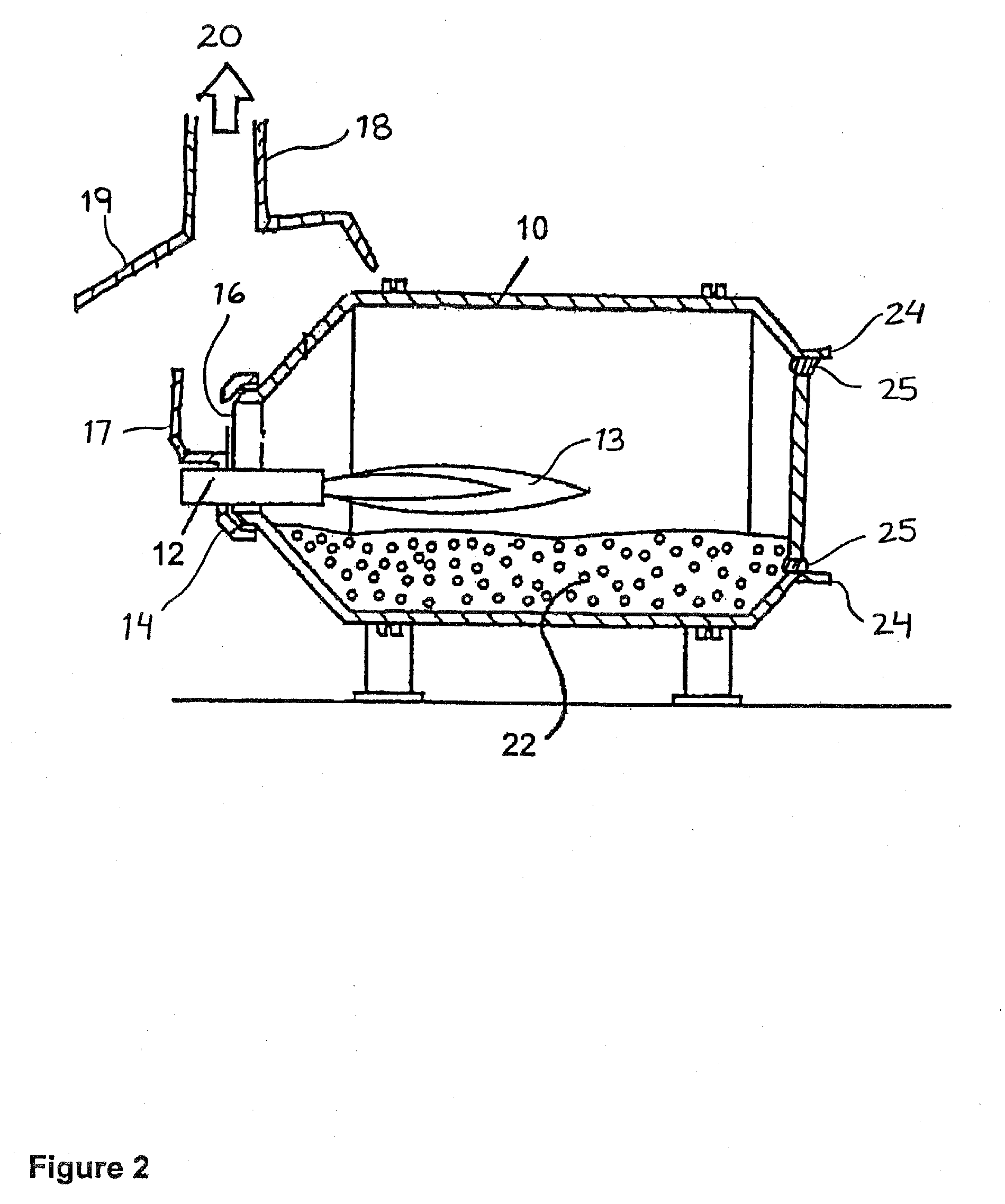

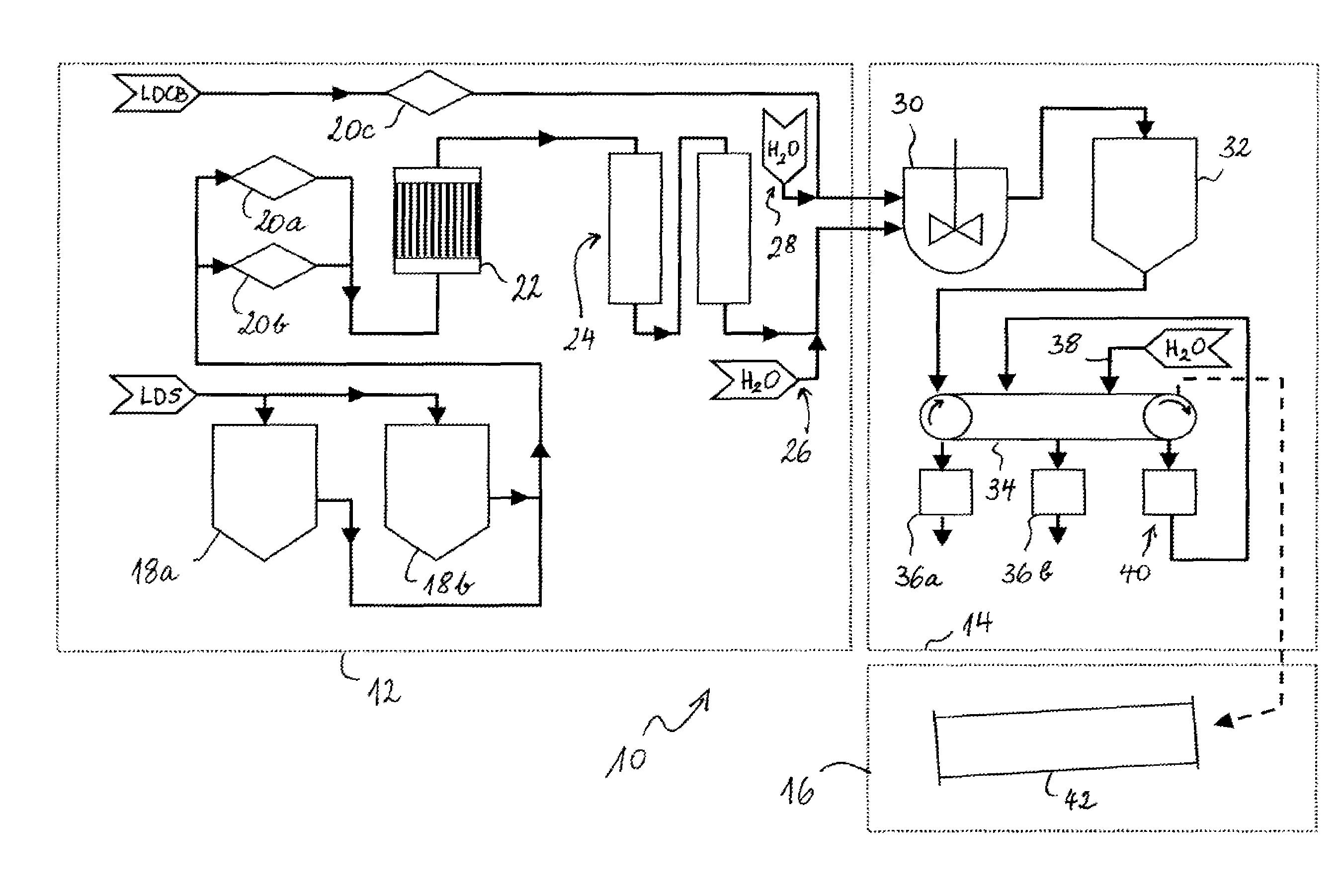

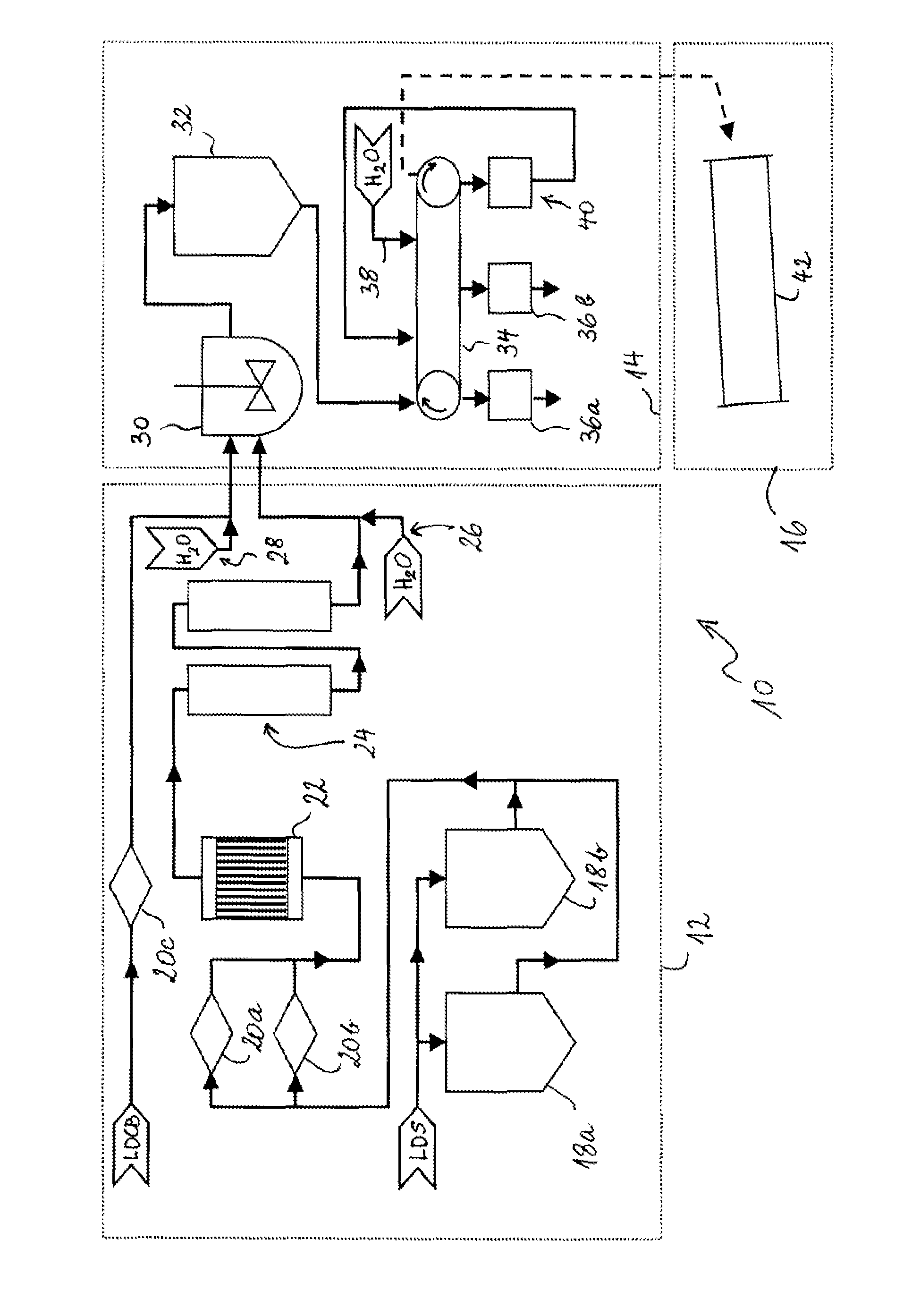

Process and apparatus for purifying low-grand silicon material

InactiveUS20080253955A1Improve purification effectSafe and controlled and mannerPolycrystalline material growthSilicaSlagReducing atmosphere

A process and apparatus for purifying low-purity silicon material and obtaining a higher-purity silicon material is provided. The process includes providing a melting apparatus equipped with an oxy-fuel burner, and melting the low-purity silicon material in the melting apparatus to obtain a melt of higher-purity silicon material. The melting apparatus may include a rotary drum furnace and the melting of the low-purity silicon material may be carried out at a temperature in the range from 1410° C. to 1700° C. under an oxidizing or reducing atmosphere. A synthetic slag may be added to the molten material during melting. The melt of higher-purity silicon material may be separated from a slag by outpouring into a mould having an open top and insulated bottom and side walls. Once in the mould, the melt of higher-purity silicon material can undergo controlled unidirectional solidification to obtain a solid polycrystalline silicon of an even higher purity.

Owner:BANK OF AMERICA N A +1

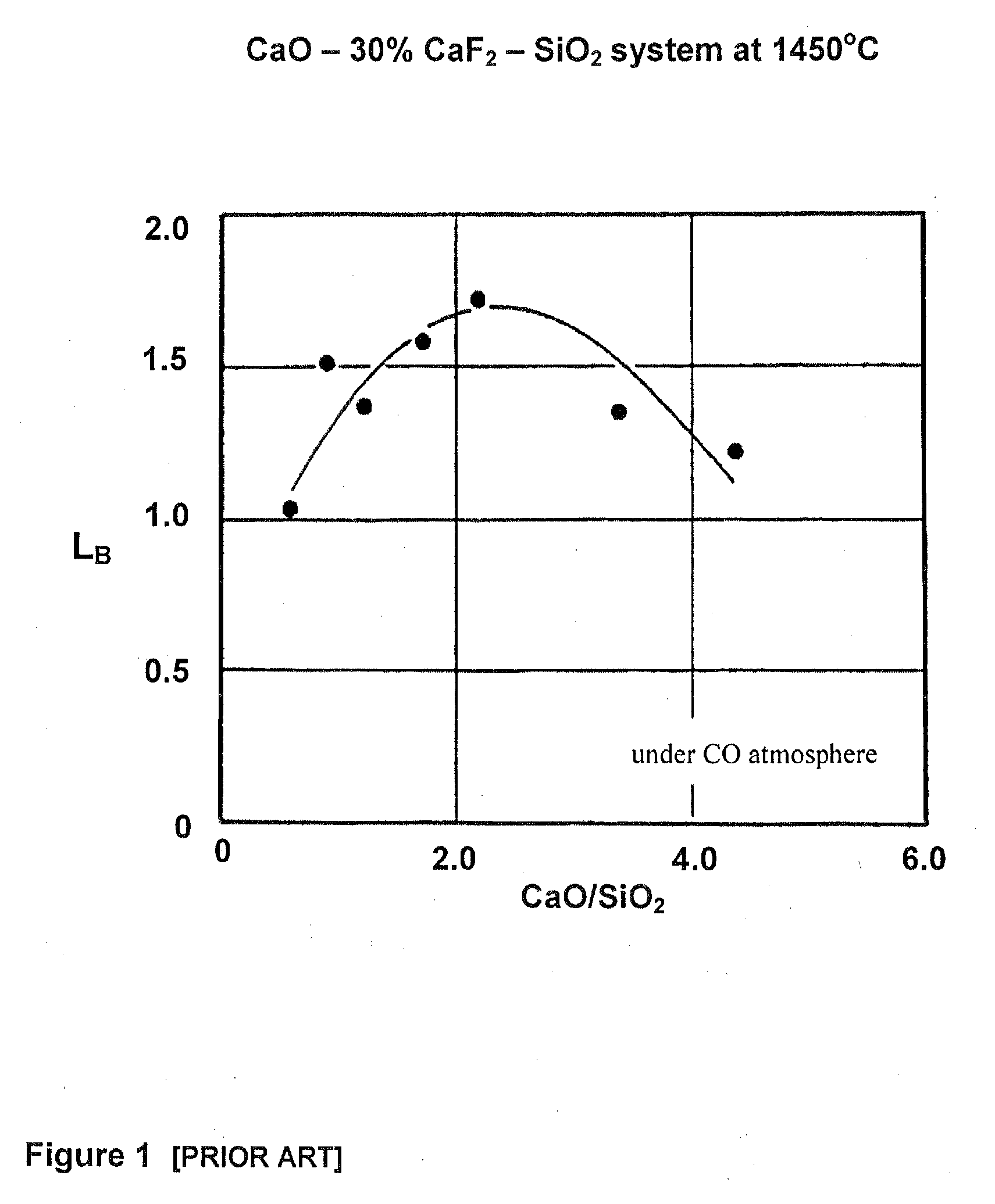

Method for carrying out slagging, pickling and boron removal on metal silicon

The invention discloses a method for carrying out slagging, pickling and boron removal on metal silicon, relates to a method for purifying polysilicon and provides the method for carrying out slagging, pickling and boron removal on the metal silicon. The method comprises the following steps of: premelting a slag forming constituent and placing the slag forming constituent into a charging bin; filling a metal silicon material into a smelting crucible; filling argon into the smelting crucible after vacuumizing; heating to melt the metal silicon material; adding the pre-molten slag forming constituent into the molten liquid metal silicon material; after a reaction is completed, pouring the liquid metal silicon material into a die and cooling the die to obtain a silicon ingot; crushing and grinding the obtained silicon ingot; sieving the obtained powder to obtain silicon powder; soaking the silicon powder in ethanol to remove oil; washing the silicon powder with water; soaking and washing the obtained powder at least once by solution of hydrochloric acid, mixed solution of sulphuric acid and nitric acid, mixed solution of hydrofluoric acid and solution of hydrochloric acid sequentially; and flushing the pickled silicon powder with clear water to obtain the metal silicon subjected to boron removal. The efficiency of removing boron is high and can reach over 96 percent. The boron content in the metal silicon is reduced to below 0.3ppmw from 8ppmw. The requirement of solar polysilicon is met.

Owner:XIAMEN UNIV

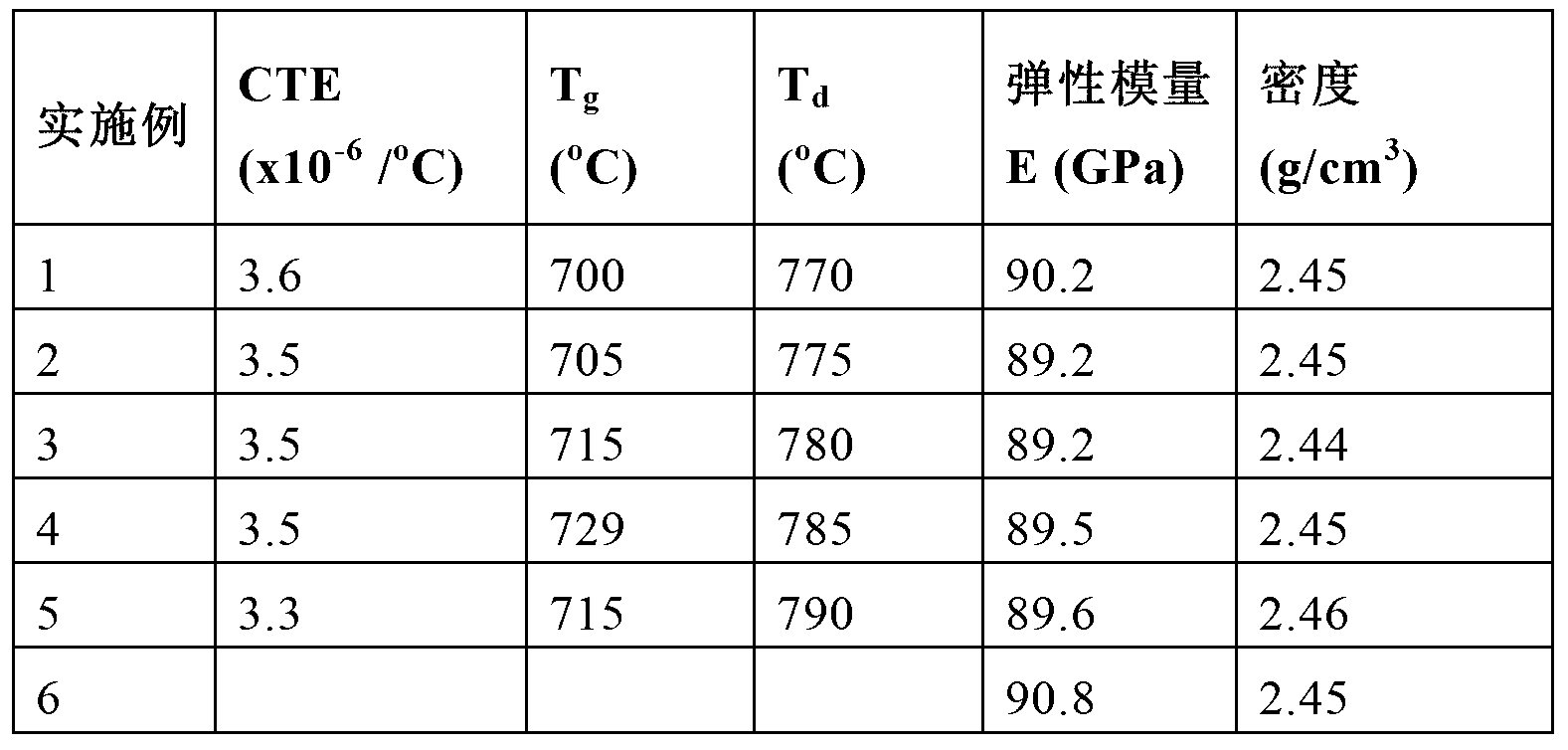

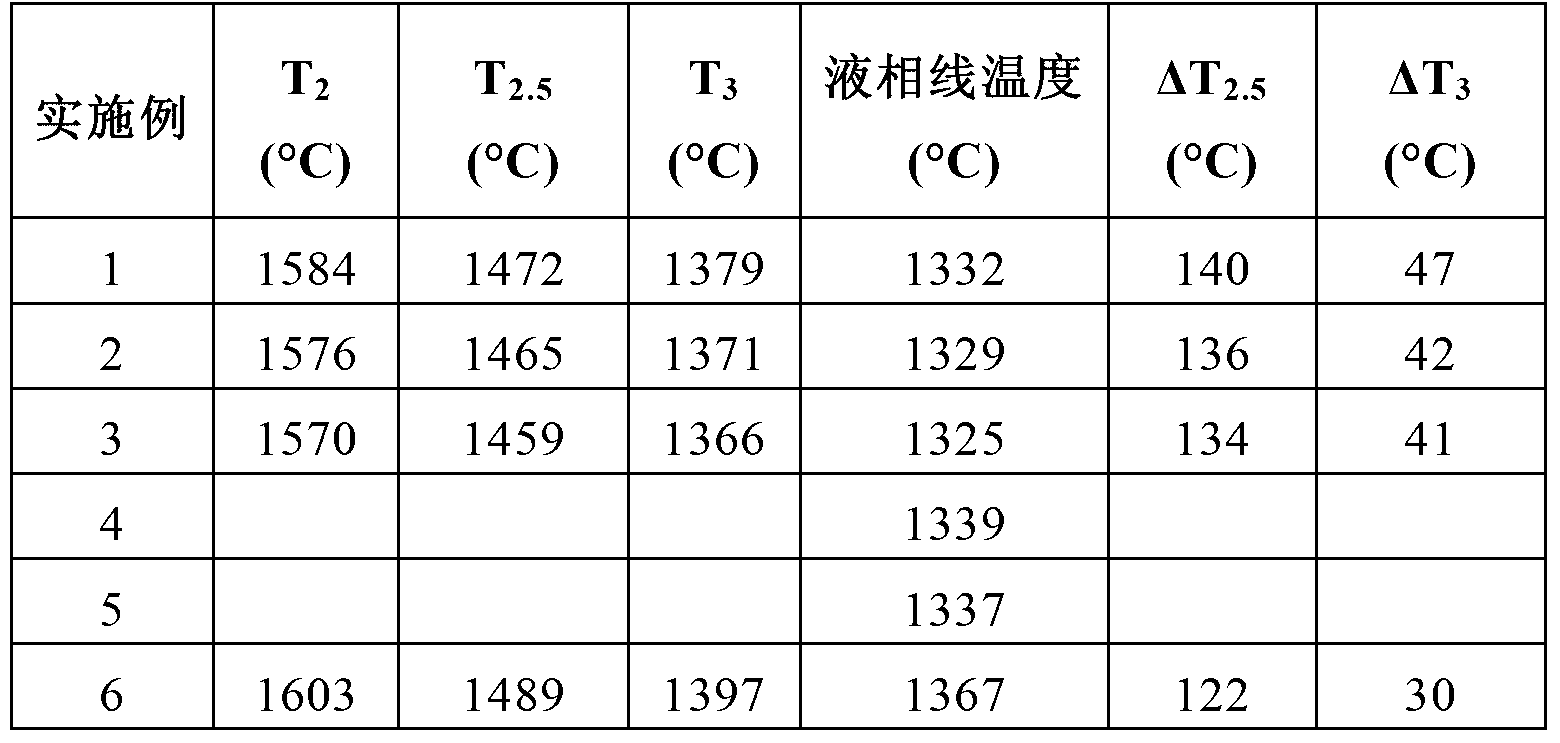

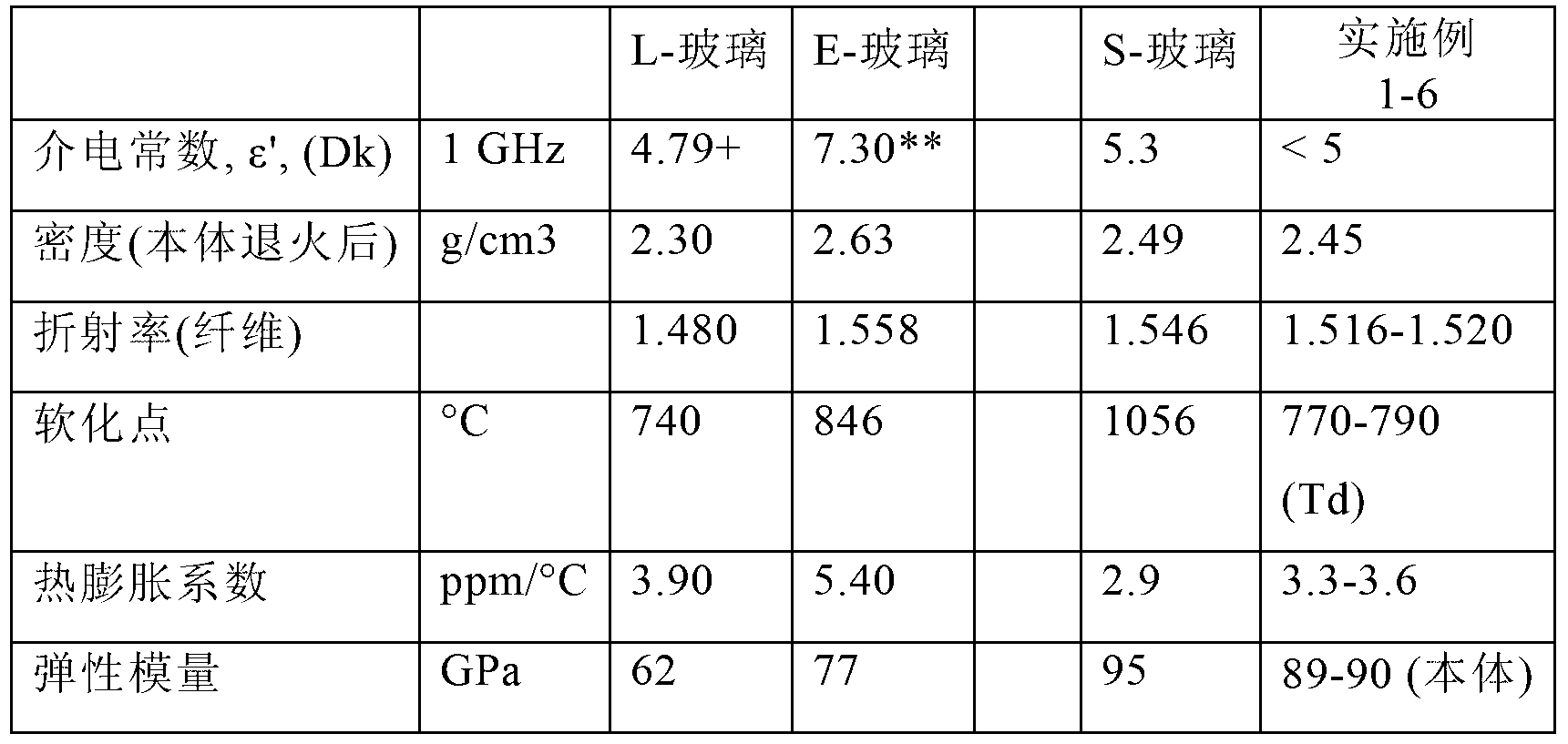

Glass composition with low coefficient of thermal expansion, and glass fiber produced from same

ActiveCN103347831ALower boron contentGlass making apparatusPrinted circuitsGlass fiberAlkali metal oxide

The present disclosure relates to a glass composition having a low thermal expansion coefficient, specifically, a glass composition comprising about 55 to less than 64 weight percent of silicon oxide, about 15 to about 30 weight percent of aluminum oxide, about 5 to about 15 weight percent of magnesium oxide, about 3 to about 10 weight percent boron oxide, about 0 to about 11 weight percent calcium oxide, and about 0 to about 2 weight percent of alkali oxide, the remainder being trace compounds of less than about 1 weight percent, is provided. Glass fibers and composite articles formed therefrom are also provided.

Owner:AGY HOLDIG CORP

Fixed-bed adsorption method for removing boron from salt lake magnesium chloride brine

The invention discloses a fixed-bed adsorption method for removing boron from salt lake magnesium chloride brine. The fixed-bed adsorption method comprises the following steps: (1), adsorbing: removing boron ion in the salt lake magnesium chloride brine containing boron through resin; (2), leaching: removing the residual brine in the resin which is adsorbed with boron by a leaching agent, returning the brine to a drying salt pond; (3), desorbing: removing the born adsorbed on the leached resin by strippant, so that the resin recovers adsorptive property and can be re-used for an adsorption process. The method provided by the invention is adopted, so that the content of the boron in the magnesium chloride brine can be reduced to be lower than 1pp, and the removal rate of the boron reaches more than 99% for providing d a reliable and stable material to electrolyze magnesium chloride to produce magnesium metal.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

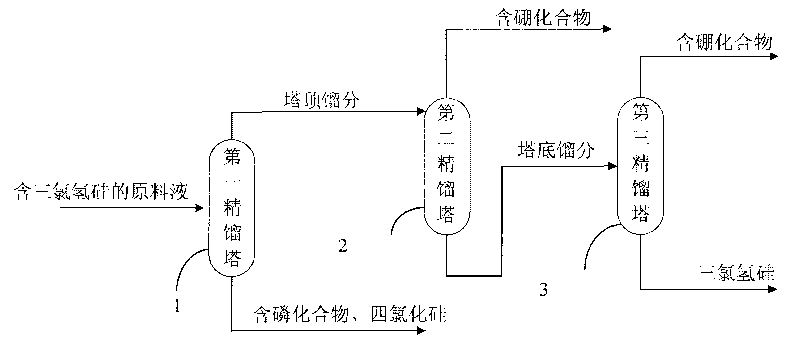

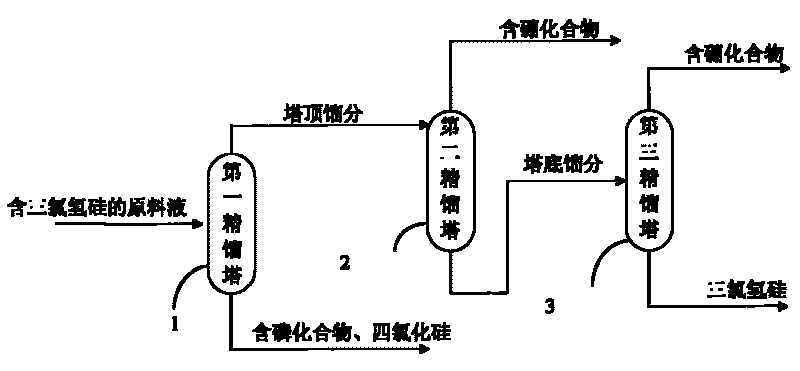

Method and device for purifying trichlorosilane

The invention discloses a method for purifying trichlorosilane, which comprises the following steps: a) sending raw material liquid containing trichlorosilane into a first distillation column for distillation and separating a first part of impurities from the raw material liquid, wherein the relative volatility of trichlorosilane relative to the first part of impurities is 1.6 to 2.5; b) sending overhead fractions of the first distillation column into a second distillation column for distillation and separating a second part of impurities from the overhead fractions, wherein the relative volatility of the second part of impurities relative to trichlorosilane is 1.4 to 1.7; and c) sending column-bottom fractions of the second distillation column into a third distillation column for distillation and separating the second part of impurities from the column-bottom fractions, wherein the reflux ratio of the third distillation column is greater than that of the second distillation column. Experimental results show that the boron content of trichlorosilane can be reduced to 0.01 ppba and the phosphorus content of trichlorosilane can be reduced to 0.1 ppba according to the method provided by the invention.

Owner:GUODIAN NINGXIA SOLAR

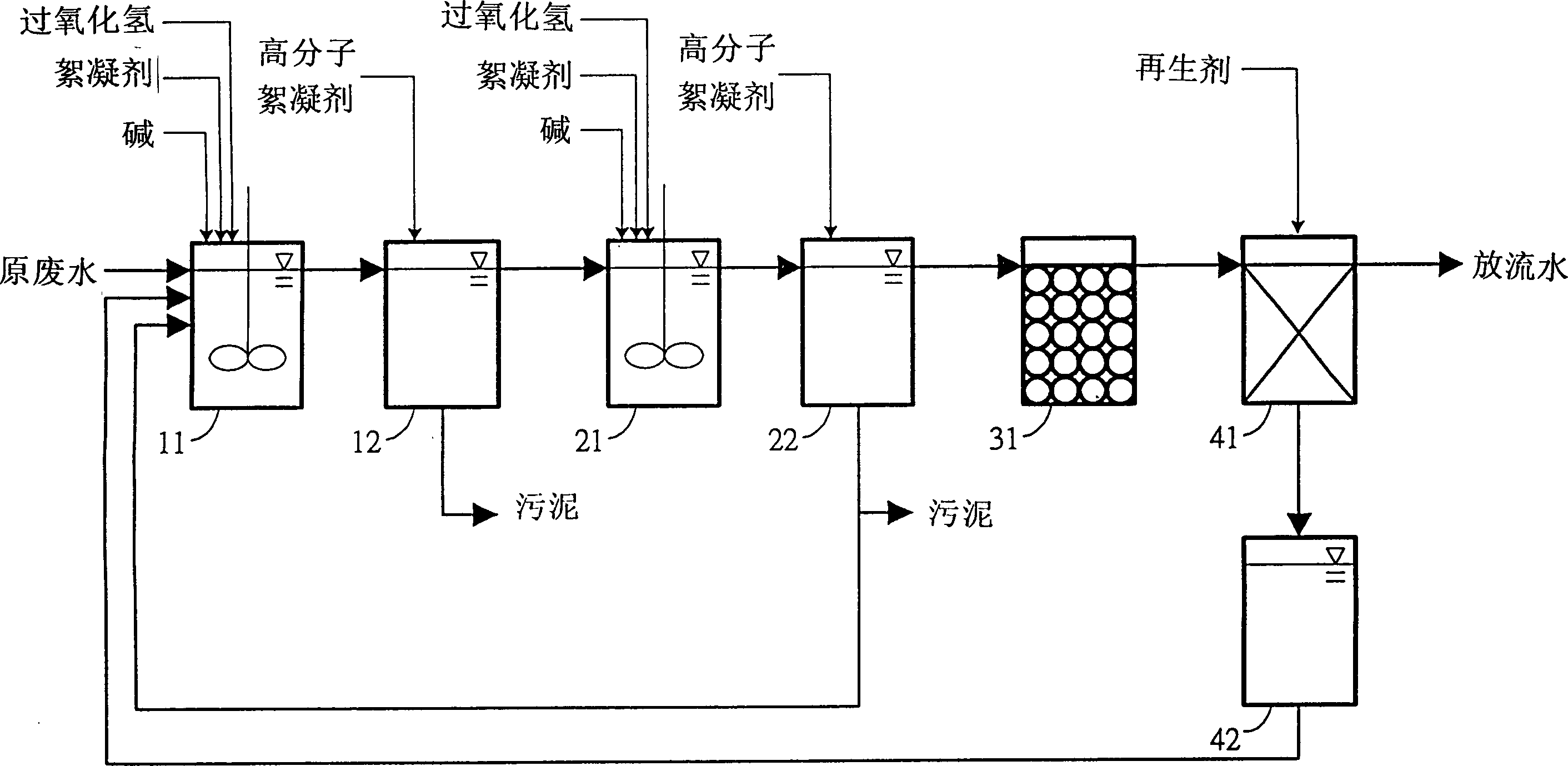

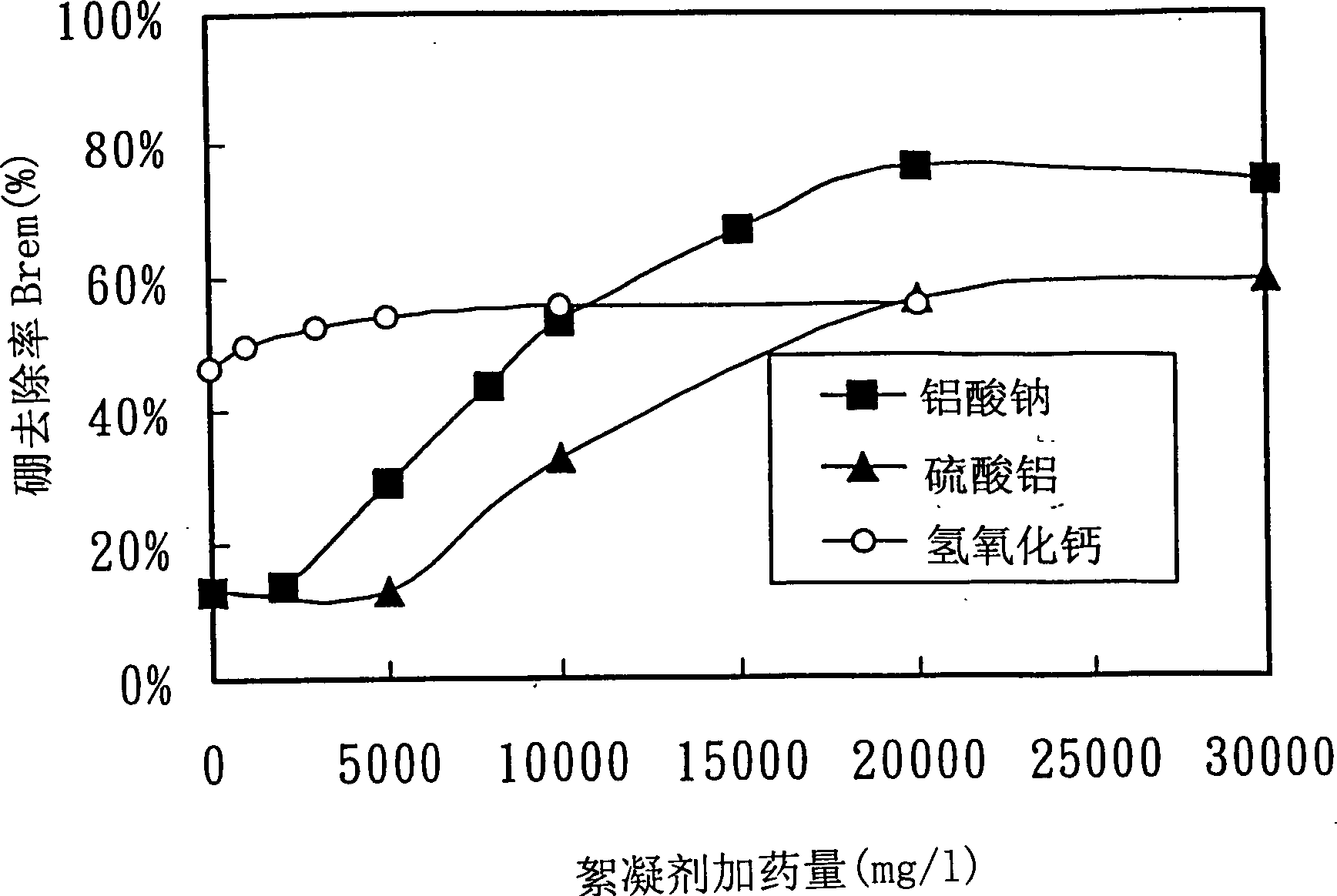

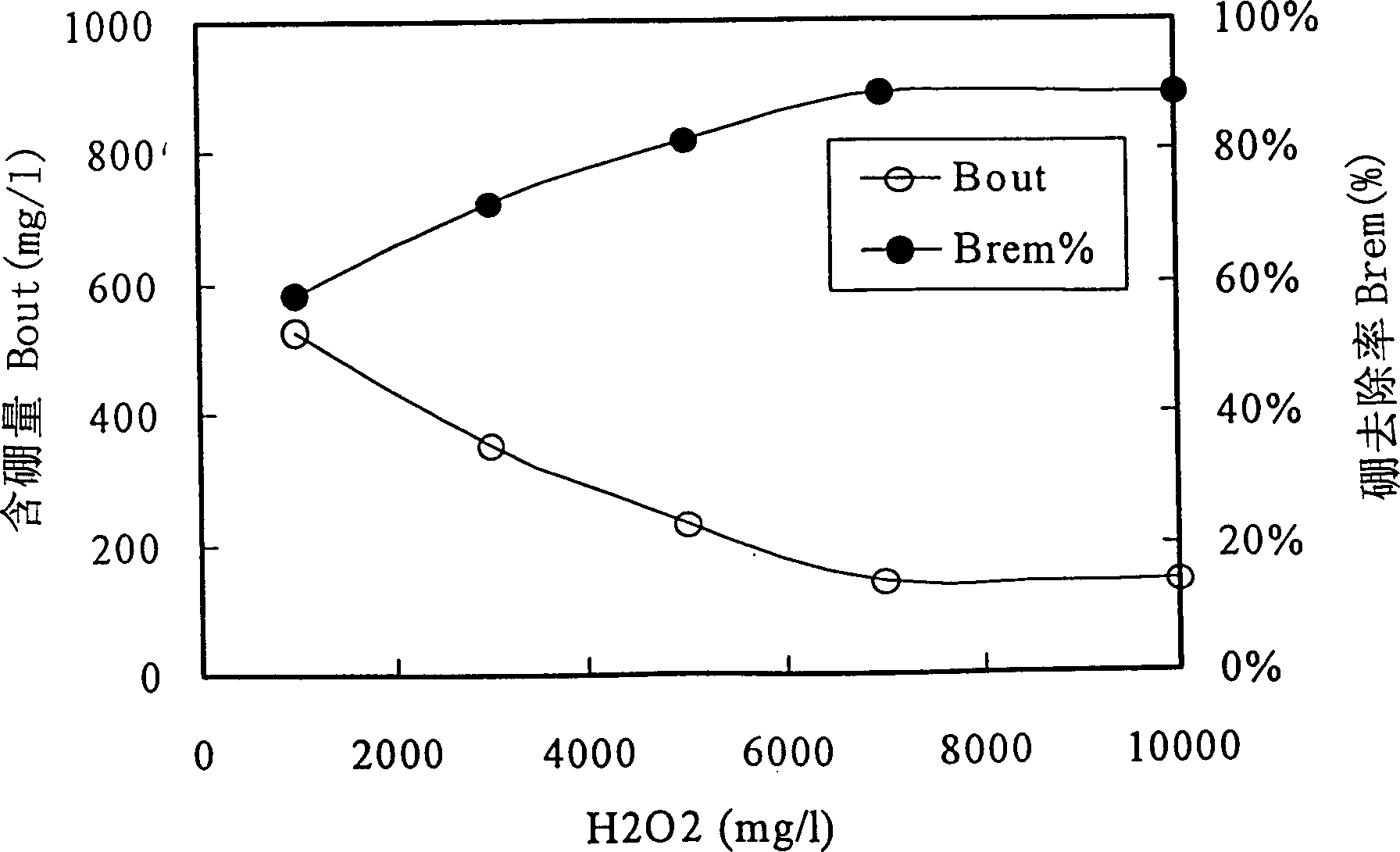

Process for treatment of waste water containing boron

InactiveCN1448344ANo secondary pollutionEfficient removalWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisHigh concentrationFlocculation

The treating process of boron containing waste water includes oxidation / flocculation treatment via adding oxidant and flocculant in two sections to lower boron content greatly, and subsequent ion exchange resin or reverse osmose treatment to eliminate residual boron. The said process can treat high-concentration boron containing waste water, such as waste water from power plant, to reach the exhaust standard.

Owner:IND TECH RES INST +1

Preparation method for silicon powder

InactiveCN103043665AReduce contentMeet the requirements of pickling and impurity removal processSilicon compoundsSlagAtmospheric pressure

The invention discloses a preparation method for silicon powder, relates to a process of removing boron by industrial silicon and a preparation method for high-purity superfine silicon powder. The invention provides the preparation method for the silicon powder capable of remarkably reducing the content of the boron. The silicon powder can be used as an ideal low-boron material for a later process, namely pickling and impurity-removing process of purifying solar polycrystalline silicon by a metallurgy method. The preparation method comprises the following steps of: (1), adopting a metallurgical-grade silicon material as the material, putting the material silicon to a crucible, electromagnetically heating up the silicon material to melt the silicon material by an inductive coil; (2), adding a slag former to control the heating power when the silicon material is molten, so that the temperature of the molten silicon is kept to 1550 DEG C to 1850 DEG C in a reaction process, stewing the molten silicon to remove the slag former on the upper layer of the molten silicon after slagging and refining; and (3), controlling the temperature of the molten silicon to 1500 DEG C to 1700 DEG C, and then opening the valve and starting an atomizer; guiding the molten silicon to the atomizer by a guide tube, adjusting the air pressure of the air outlet of the atomizer so that the molten silicon is sprayed out of the atomizer in the forms of mists to enter an atomizing chamber; and collecting the silicon powder by a supporting rotary plate.

Owner:XIAMEN UNIV

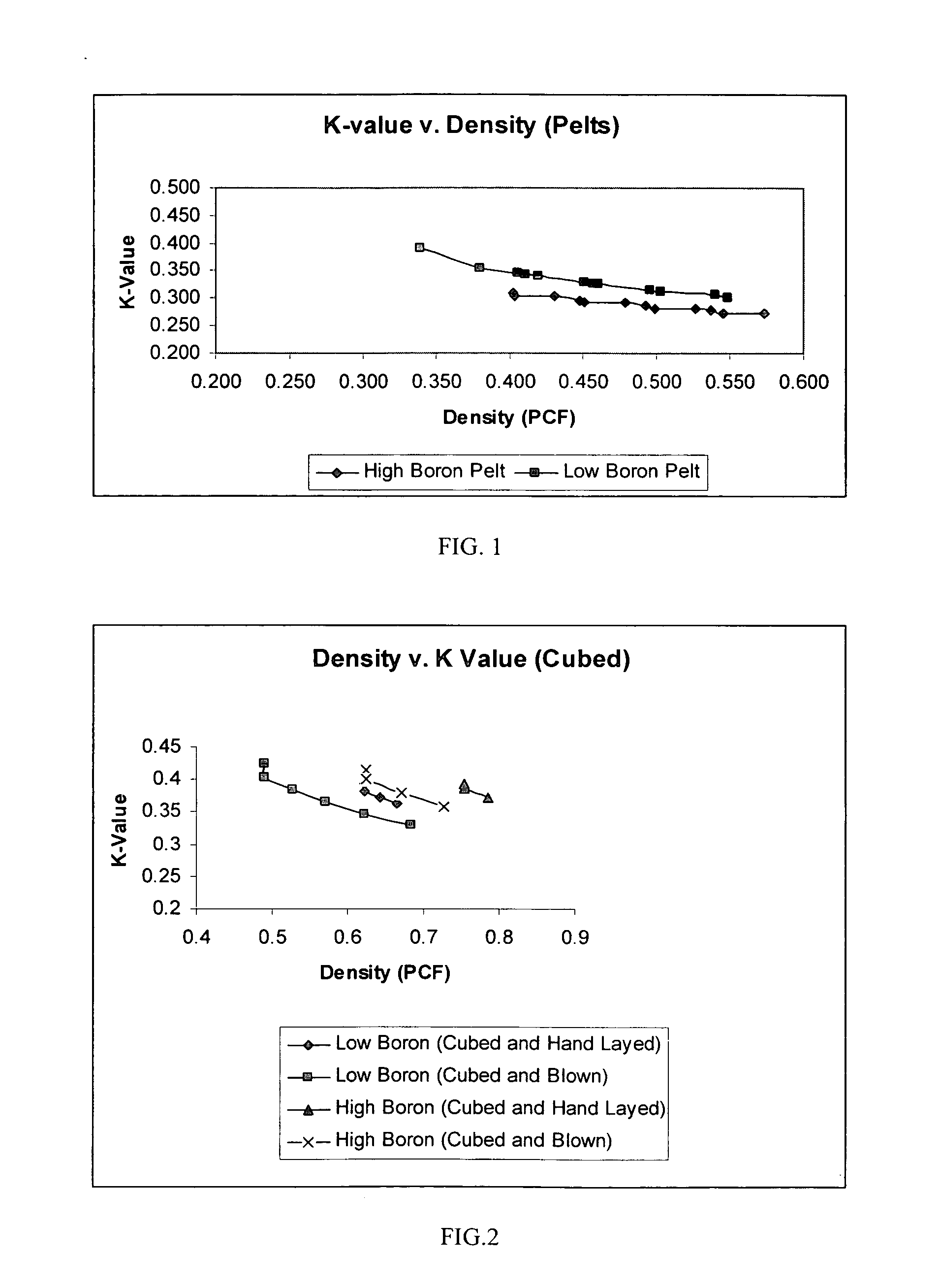

Low boron glass composition for loose-fill fiberglass insulation

ActiveUS20060148634A1Improve furnace lifeReduce the amount of solutionLayered productsThin material handlingGlass fiberVolumetric Mass Density

The present invention relates to fiberglass loose-fill insulation that is insensitive to the content of boron in the composition of the glass. It has been discovered that the level of boron in the glass used for the manufacture of loose-fill glass wool can be substantially reduced without degrading thermal performance. The lowered amount of boron provides for a lower cost batch composition and increased furnace life. The glass composition of the present invention includes a substantially reduced content of boron and preferably an increased amount of sodium dioxide. The primary phase of these glass compositions is typically devitrite (Na2Ca3Si6O16). The glass of the present invention provides a glass fiber blowing wool that does not require an increase in pack density to compensate for the reduced boron content while achieving the similar thermal conductivity. The glass of the present invention is also suitable for use in acoustic insulation.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for reducing content of boron in 20CrMnTiH gear steel

InactiveCN108950125ALower boron contentReduce the amount addedManufacturing convertersProcess efficiency improvementSlagEconomic benefits

The invention provides a method for reducing the content of boron in 20CrMnTiH gear steel. The method comprises the steps that in the converter smelting stage, low-carbon ferromanganese and mid-carbonferromanganese alloy can be used as a manganese additive, and in the LF stage, refining slag with the Al2O3 mass percent being 20 to 25% is used for refining. On the basis of not increasing production cost, through material formula control and refining slag series component adjusting, the step of adding a slagging ball is omitted, the content of B is reduced, the B is controlled to be smaller than or equal to 2ppm, and hardenability of the 20CrMnTiH gear steel is stabilized. The method is adopted, meanwhile, added value of the steel is increased, the technical reference is provided for an enterprise capable of smelting 20CrMnTiH gear steel, the problem that after heat treatment by a customer, gear deformation is not regular is effectively solved, and the good economic benefits and application prospects are achieved.

Owner:CHENGDE JIANLONG SPECIAL STEEL

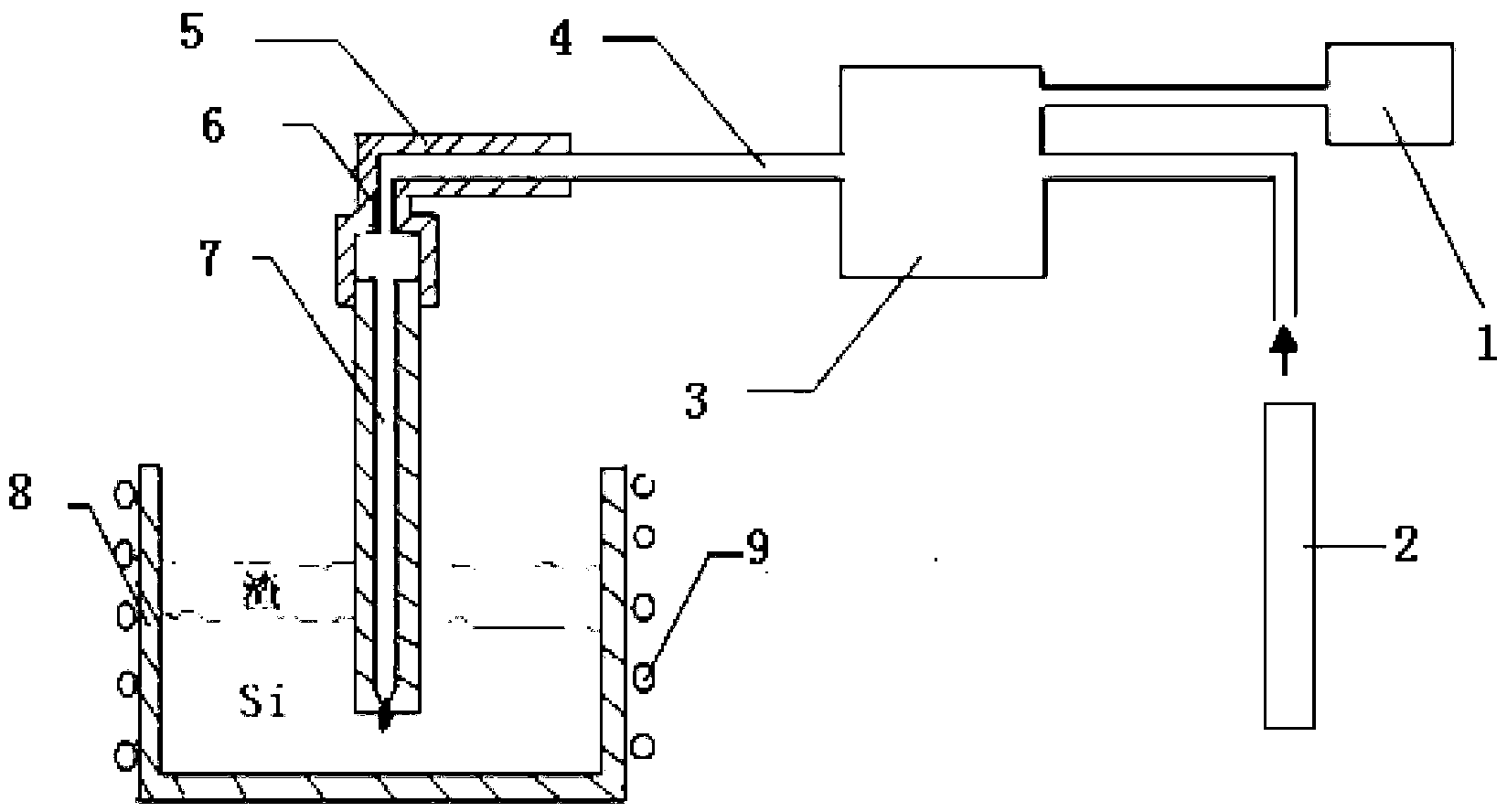

Method for removing boron in polycrystalline silicon

The invention relates to a novel method for removing boron in polycrystalline silicon. The method comprises the steps of: filling a silicon briquette into a graphite crucible of a medium-frequency induction furnace to heat, and melting to a silicon liquid; casting a slag former to the silicon liquid, continuously heating to completely melt the slag former, and maintaining temperature of the silicon liquid, wherein the slag former consists of NaCl, KCl and SiO2; preheating a graphite rod with a ventilating channel, and inserting the ventilating rod to the silicon liquid after adequate preheating and starting to introduce oxygen; meanwhile, starting a high pressure plasma generator, ionizing oxygen in an oxygen channel at room temperature to oxygen ions and injecting the oxygen ions to the silicon liquid through the graphite rod; and solidifying the silicon liquid obtained in an insulating furnace, and after a silicon ingot is cooled, removing slag blocks on the surface of the silicon ingot. According to the method, the slag amount can be effectively reduced, the silicon loss caused by silicon wrapped in slag is reduced, the cost of purifying polycrystalline silicon is lowered, the content of boron in the refined low boron polycrystalline silicon purified is lower, and the boron removing effect is good.

Owner:福建兴朝阳硅材料股份有限公司

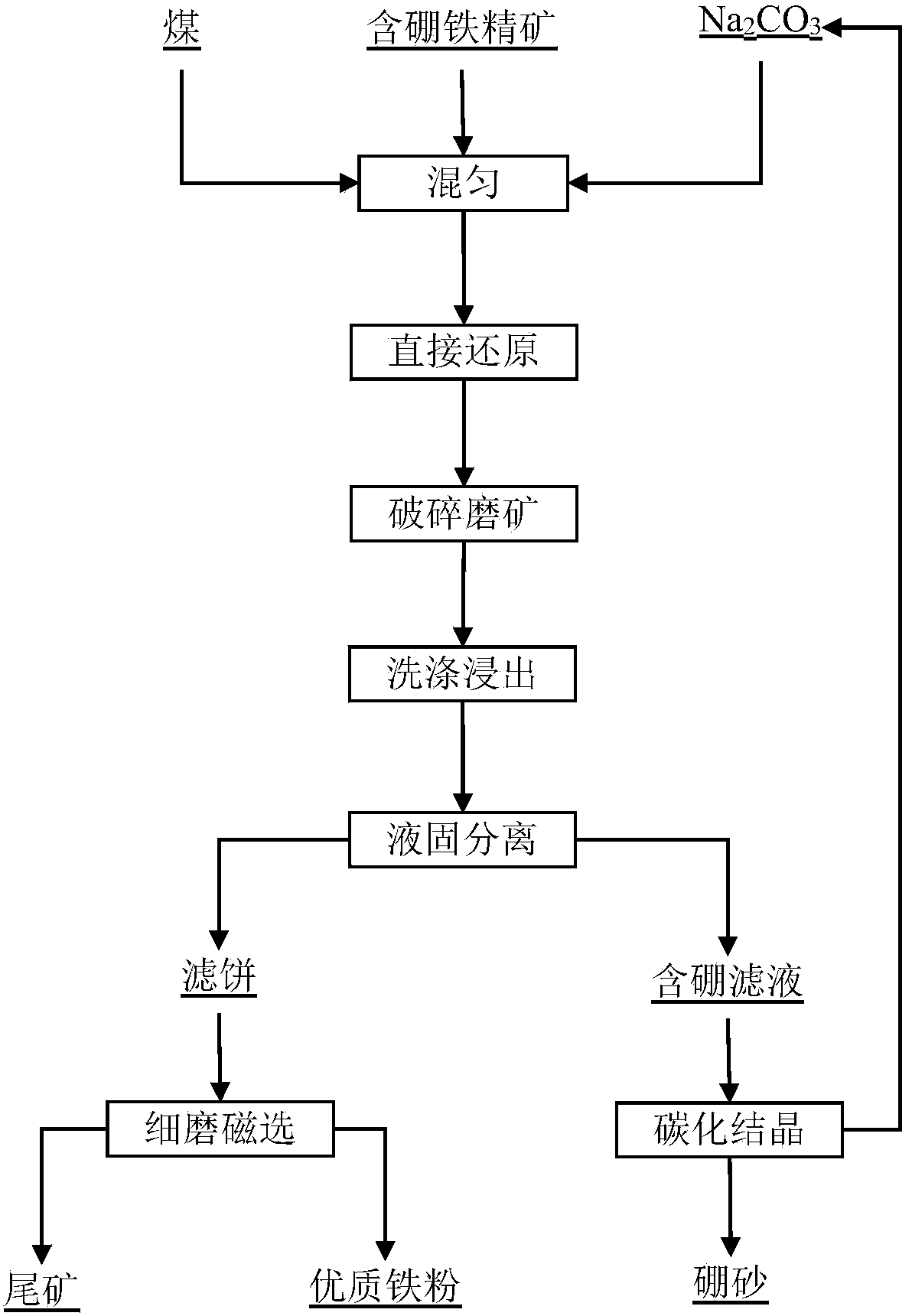

Method for extracting high-quality iron powder and borax from paigeite

ActiveCN103952537AShort processReduce energy consumptionMagnetic separationBoratesPowder metallurgyIron reduction

The invention belongs to the field of metallurgy of steel and iron and processing of mineral resources and specifically relates to a method for extracting high-quality iron powder and borax from paigeite. The method provided by the invention comprises the following steps: (1) mixing boron-containing iron concentrate, solid Na2CO3 and coal together to obtain a mixture; (2) roasting the mixture under a reducing atmosphere at the temperature of 950-1150 DEG C to obtain a roasted product; (3) crushing and grinding the roasted product and then, leaching, washing and filtering ore slurry to obtain an alkaline filtrate and an iron-containing filter cake; (4) performing desilication, CO2 carbonization, filtration and crystallization on the alkaline filtrate to obtain qualified borax and simultaneously realize recycling of reaction medium Na2CO3; (5) performing magnetic separation, grinding and secondary magnetic separation on the obtained filter cake to obtain high-quality reducing iron powder (TFe is more than 98.5%) which can be used as an iron-based raw material for powder metallurgy. According to the method provided by the invention, by adding a large amount of Na2CO3, the leaching of boron minerals is simultaneously realized during iron reduction, the process flow is shortened and the energy consumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-purity calcium compounds

InactiveUS20100129282A1Promote formationInhibit co-precipitationCalcium/strontium/barium carbonatesSiliconCalcium hydroxideSulfate

A calcium product contains, in dry state, at least 97% by weight of a calcium compound selected from the group consisting of calcium oxide, calcium hydroxide, calcium sulfate (up to 3% by weight, preferably less) and calcium carbonate, and less than or equal to 4.2 ppm by weight of phosphorus with respect to calcium content and less than or equal to 1.4 ppm by weight of boron with respect to calcium content.

Owner:SOLVAY SA

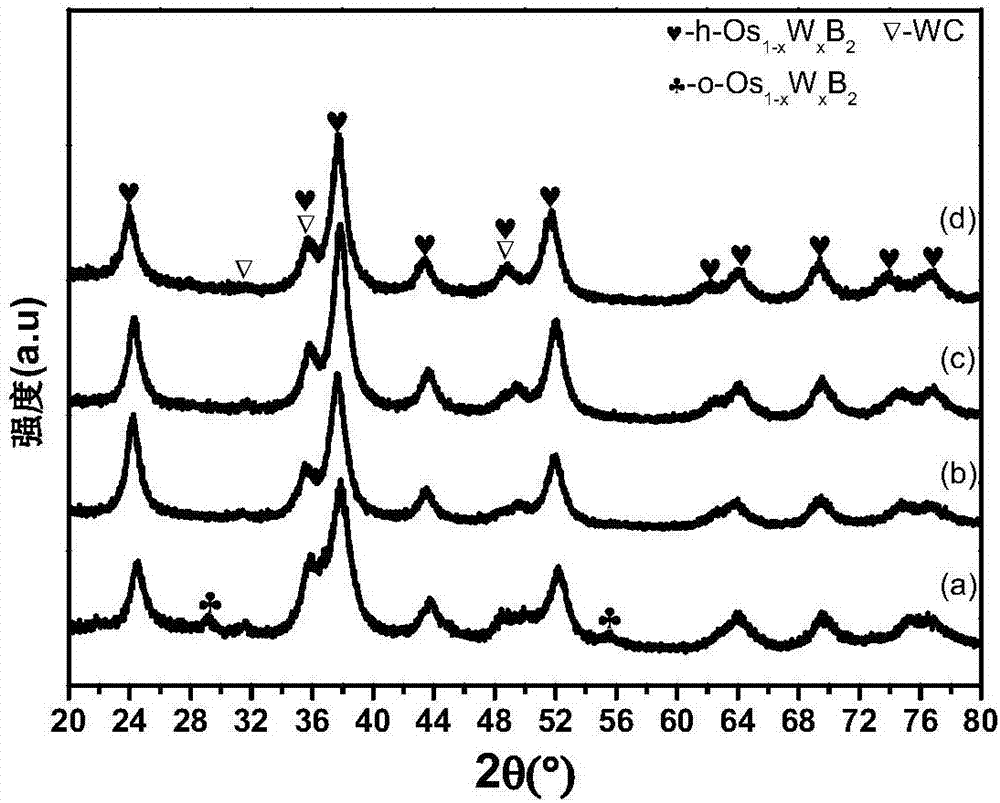

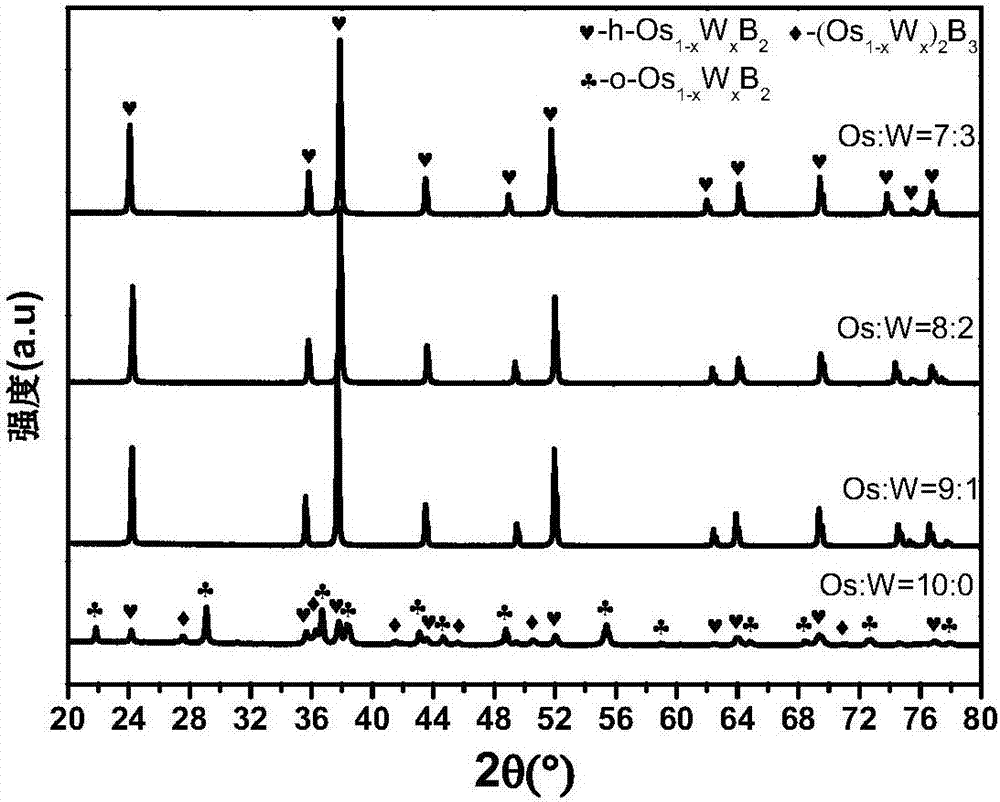

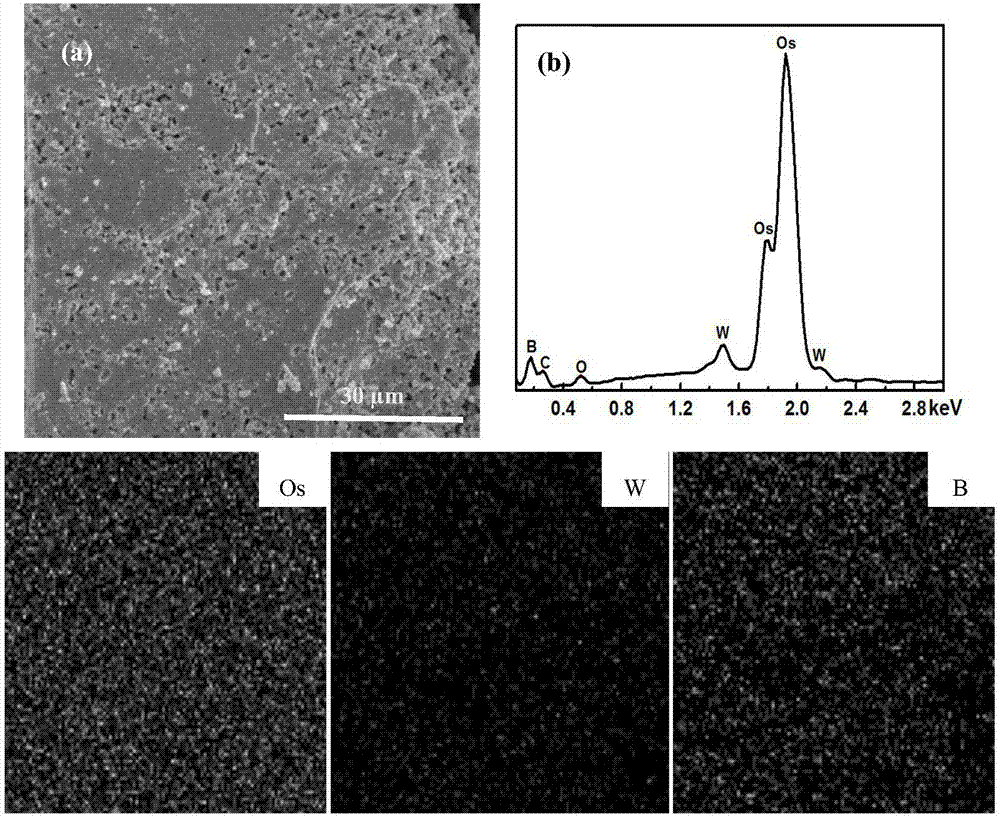

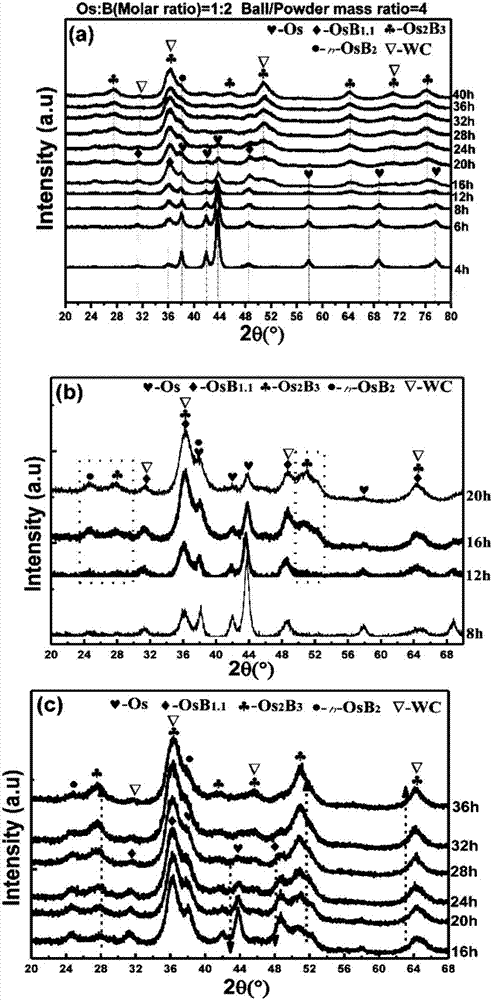

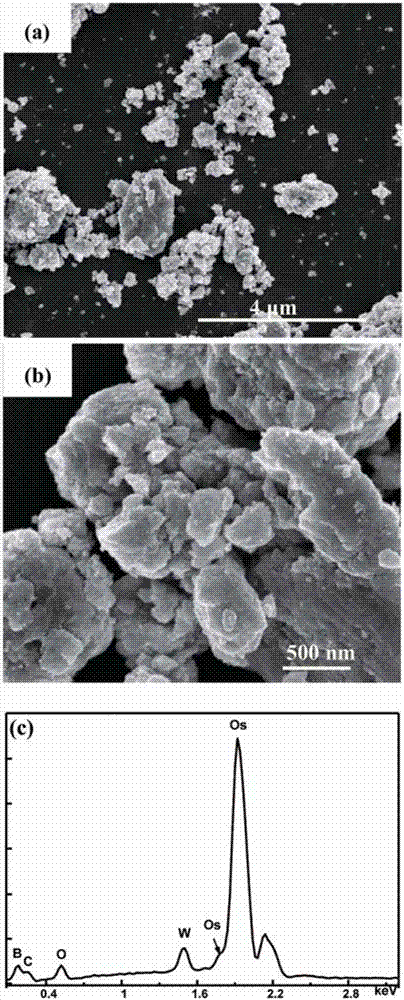

Ternary system osmium-tungsten diboride hard material as well as preparation method and application thereof

The invention belongs to the field of inorganic non-metallic hard materials and discloses a preparation method of a ternary system osmium-tungsten diboride hard material. The preparation method comprises the following steps: adopting a mechanical and chemical method, utilizing high-energy ball milling equipment, taking high-purity osmium (Os), tungsten (W) and boron (B) power as a raw material and synthesizing osmium-tungsten diboride powder at a room temperature; then sintering at a high temperature under an argon gas protection atmosphere and densely sintering the synthesized osmium tungsten diboride powder to obtain the ternary system osmium-tungsten diboride hard material. The ternary system osmium-tungsten diboride hard material (Os1-xWxB2) has high density, high hardness and high temperature stability. The prepared osmium-tungsten diboride hard material is used in industrial applications such as cutting tools and grinding.

Owner:GUANGDONG UNIV OF TECH

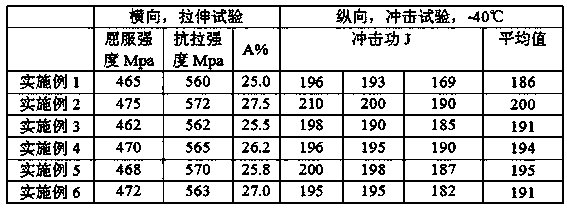

Smelting technology of ultralow boron steel

ActiveCN107841687AMeet the needs of smeltingLower boron contentManufacturing convertersProcess efficiency improvementMolten steelBoron

The invention discloses a smelting technology of ultralow boron steel, and belongs to the technical field of steel smelting. The smelting technology specifically comprises the stages of KR molten ironpretreatment, converter smelting, LF refining, pouring, cast blank stack cooling and cleaning, heating and rolling and steel plate stack cooling. According to the smelting technology, the boron content in molten steel can be controlled to be 0.0005% or below, the smelting requirements of the ultralow boron steel can be completely met, according to a prepared steel plate, the yield strength is higher than or equal to 462 MPa, the tensile strength is higher than or equal to 560 MPa, the ductility is higher than or equal to 25%, the impact strength at the temperature of minus 40 DEG C can reach186 J or above, and the overall performance is excellent.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

E glass fiber with low boron and low softening point, preparation method and application thereof

The invention relates to E glass fiber with low boron and low softening point. The E glass fiber comprises the components in percentage by weight as follows: 54.2-55.3% of SiO2, 14.2-15.2% of Al2O3, 22.8-24.3% of CaO, 2.2-2.8% of MgO, 0.5-0.8% of (Na2O+K2O), 2.0-3.0% of B2O3 and the balance of Fe2O3. According to the E glass fiber with low boron and low softening point, the use level of borocalcite is lowered, so that the boron content in the E glass fiber is reduced, the dependence on imported borocalcite is reduced, and the cost of raw materials is greatly lowered. Compared with ECR (Electron Cyclotron Resonance) components, the softening point of the E glass fiber is reduced, the melting and forming temperature is reduced, and the energy consumption is reduced. The E glass fiber prepared is good in corrosion resistance and insulation performance and long in service life, and can satisfy performance demands of yarns on high pressure petroleum pipelines. According to the preparation method of the E glass fiber with low boron and low softening point provided by the invention, the process step is simplified, the preparation difficulty is reduced, and the energy loss is reduced, so that the work efficiency is improved while the cost is lowered.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

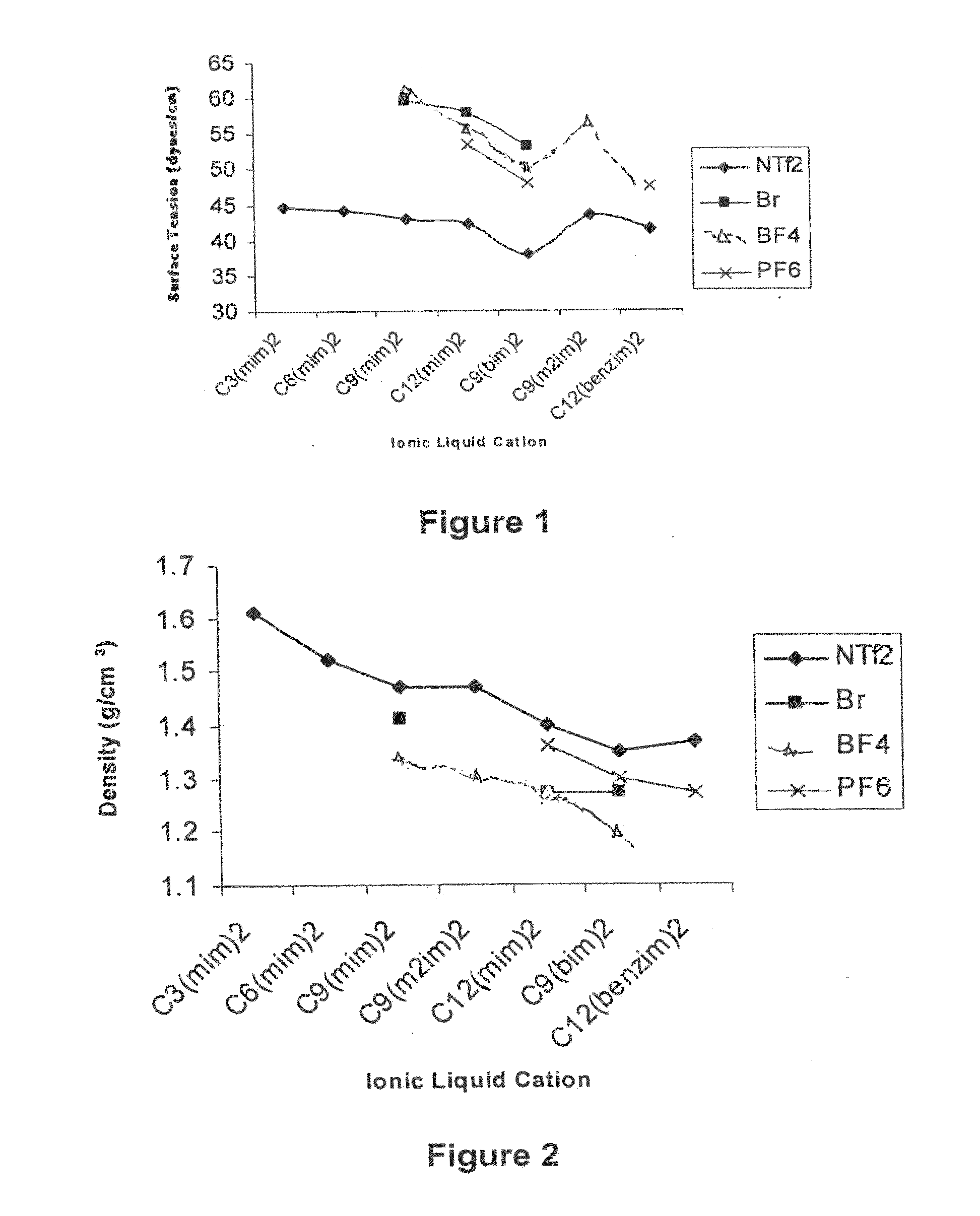

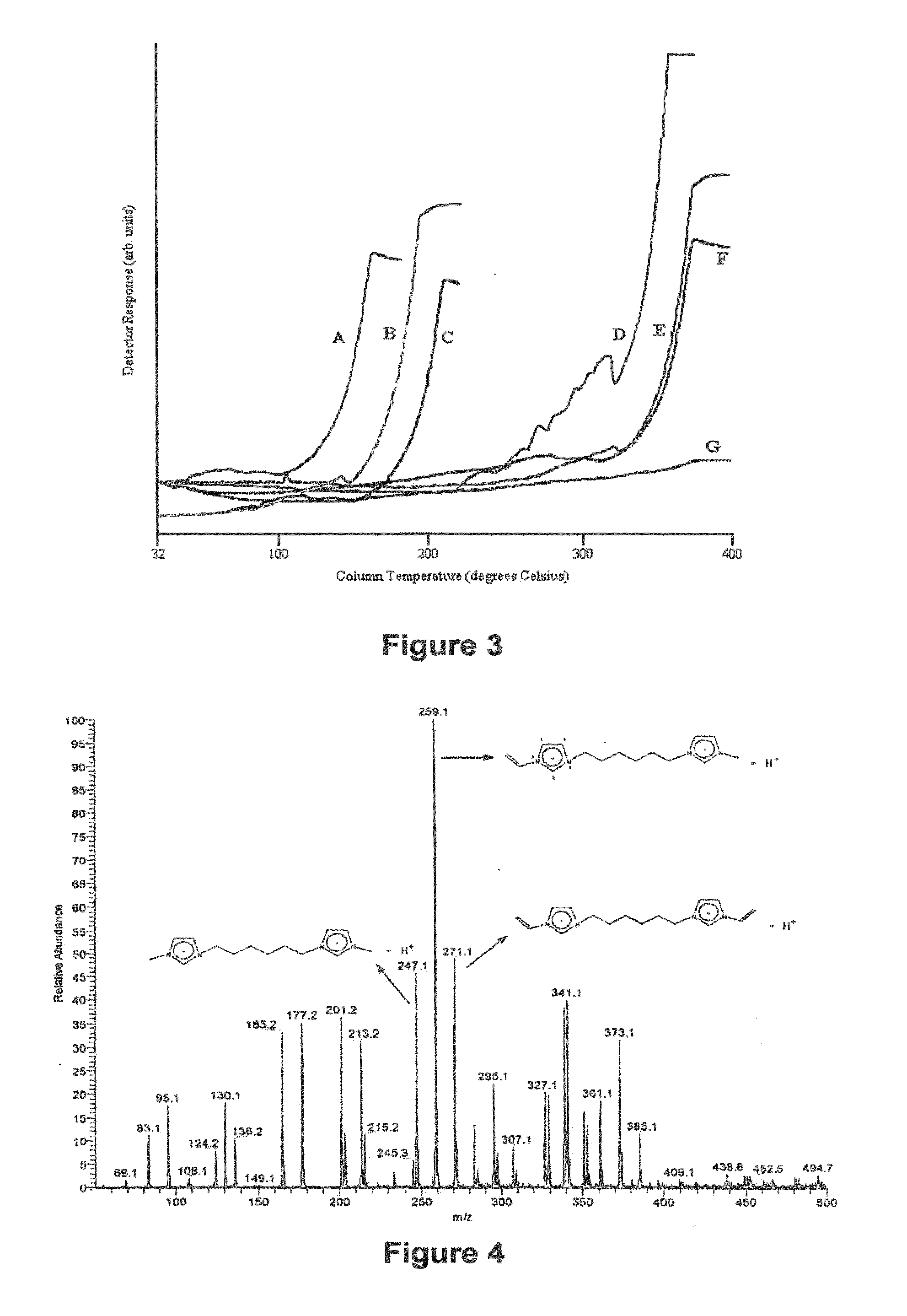

Boron Selective Ionic Liquids and Polymeric Ionic Liquids, Methods of Making and Methods of Use Thereof

InactiveUS20120111796A1Lower boron contentImprove efficiencyCation exchanger materialsCarbon compoundsBoronIonic liquid

Boron selective ionic liquids and polymeric ionic liquids, methods of making and methods of using the same are disclosed.

Owner:UNIVERSITY OF TOLEDO

Os2B3 hard material and preparation and application thereof

The invention belongs to the field of inorganic nonmetallic hard materials, and particularly relates to an Os2B3 hard material and a preparation method and application thereof. The preparation method comprises the following steps: by a mechanochemical method, with high-purity Os powder and B powder as raw materials, synthesizing Os2B3 powder at room temperature by using high-energy ball milling equipment; then, by high-temperature sintering technology, and performing compacted sintering on the synthesized Os2B3 powder under the protection of an argon atmosphere to obtain a high-compactness and high-hardness block material. By the preparation method, the Os2B3 powder is synthesized at room temperature, and the Os2B3 block material adopting a hexagonal structure and having high temperature stability is prepared. The Os2B3 material prepared by the preparation method provided by the invention can be applied to the industrial fields of cutting tools, machine manufacturing, aerospace, automobiles and the like.

Owner:GUANGDONG UNIV OF TECH

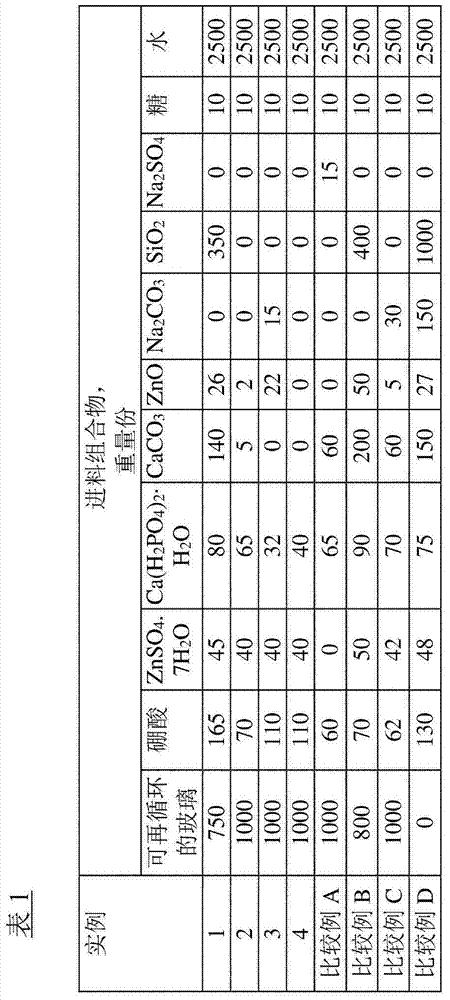

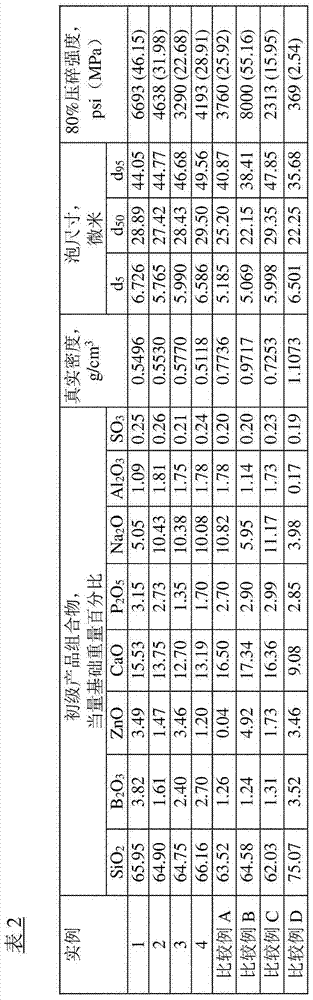

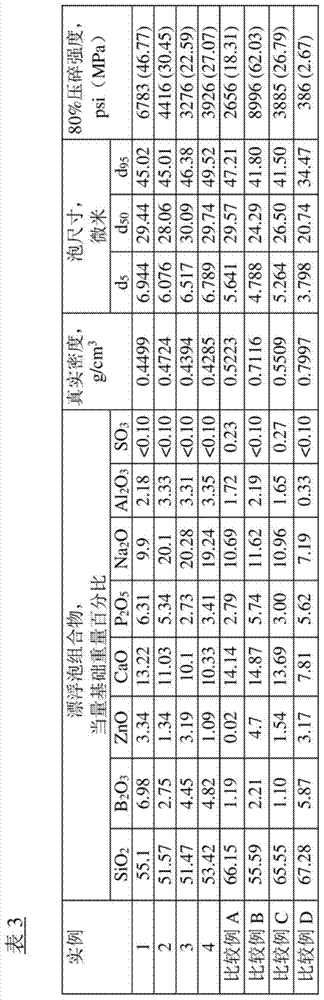

Low density glass particles with low boron content

Glass particles comprise glass microbubbles. The glass particles have a size distribution with a d50 in the range of from 15 to 100 microns, and have a true density of less than 0.7 g / cm3. The glass particles comprise, on an equivalent weight basis: from 50 to 70 weight percent silica; from 2 to 7 weight percent of boria; from 0.5 to 4 weight percent of weight zinc oxide; from 8 to 17 weight percent of calcia; from 0.8 to 7 weight percent of phosphorus pentoxide; and from 2 to 9 weight percent of sodium oxide.

Owner:3M INNOVATIVE PROPERTIES CO

Smelting method of ultra-low boron steel

ActiveCN108148941ALower boron contentReduce converter slag controlManufacturing convertersSmelting processOxide

The invention discloses a smelting method of ultra-low boron steel. The smelting method of the ultra-low boron steel comprises a series of processes that the sulfur content of the melted iron put in afurnace is controlled within 0.01% through the melted iron in the furnace, carbon is controlled at a lower amount during tapping in the converter smelting process, roughing slag control of the converter is reduced, boron reduction amount is reduced in the refining stage, and increment of slag material is reduced, and the ultra-low boron steel with the boron content below 0.0005% is smelted. Compared with the prior art, the smelting method of the ultra-low boron steel not only reduces the boron content in cupric oxide water as much as possible and reduces the reduction amount of the boron, thus reducing the boron content in the whole smelting process; and as far as possible to reduce the boron content brought by foreign materials, and the produced ultra-low boron steel can meet the development direction of the future steel products.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Refining agent for boron removal of slagging and refining industrial silicon melt

The invention provides a refining agent for the boron removal of a slagging and refining industrial silicon melt. The refining agent comprises the following ingredients in mass percent: 1-99% of Li2O, 1-99% of SiO2 and 0-98% of basic oxides. A using method of the refining agent comprises the following steps: industrial silicon with the boron content of 1-500 ppmw is taken as a raw material and is mixed with the refining agent for the boron removal of the slagging and refining industrial silicon melt according to a mass ratio of 10:1 to 1:10, the slagging and refining is carried out at the temperature of 1450-1850 DEG C, then, the cooling is carried out, and finally, the slag-silicon separation is carried out, so that the impurity, i.e. boron is removed along with slag. The refining agent has a remarkable effect in boron removal, and the using method of the refining agent has the advantages that: the boron content of industrial silicon can be lowered to be less than 1 ppmw, the slag-silicon separation is easy, the process operation is simple, the requirements on equipment are low, the cost is low, the energy consumption is low, the pollution is little, no harmful gases are generated, the waste slag can be recycled and reutilized, and the method is environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

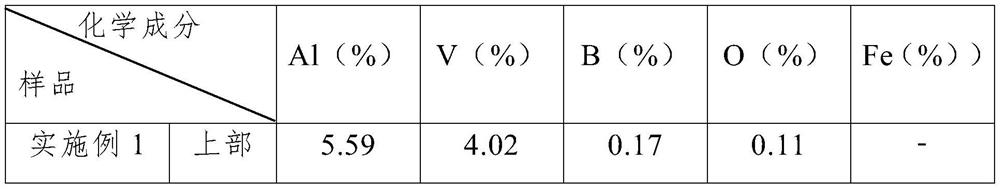

Preparation method of high-uniformity boron-containing titanium alloy cast ingot

The invention discloses a preparation method of a high-uniformity boron-containing titanium alloy cast ingot. The method comprises the steps that firstly, an AlTiB ternary alloy, titanium sponge and an intermediate alloy are selected as raw materials according to components of a target product boron-containing titanium alloy cast ingot; secondly, after the raw materials are mixed, the raw materials are pressed to obtain electrode blocks; thirdly, the electrode blocks are installed and welded and are cleaned to obtain an electrode group; fourthly, vacuum self-consuming electric arc melting is carried out on the electrode group to obtain a boron-containing titanium alloy cast ingot crude product; and fifthly, the boron-containing titanium alloy cast ingot crude product is machined and sawed, and the high-uniformity boron-containing titanium alloy cast ingot is obtained. The AlTiB ternary alloy is adopted as the raw material, the density of the AlTiB ternary alloy is closer to that of a titanium matrix, the melting point is greatly reduced, the boron content is reduced, the material mixing uniformity and the liquid phase mixing uniformity in the smelting process are effectively improved, the homogenization degree of boron-containing titanium alloy cast ingot components is improved, the local segregation and enrichment risk is reduced, generation of refractory materials and inclusion defects is avoided, and the uniformity of each element is improved.

Owner:WESTERN TITANIUM TECH

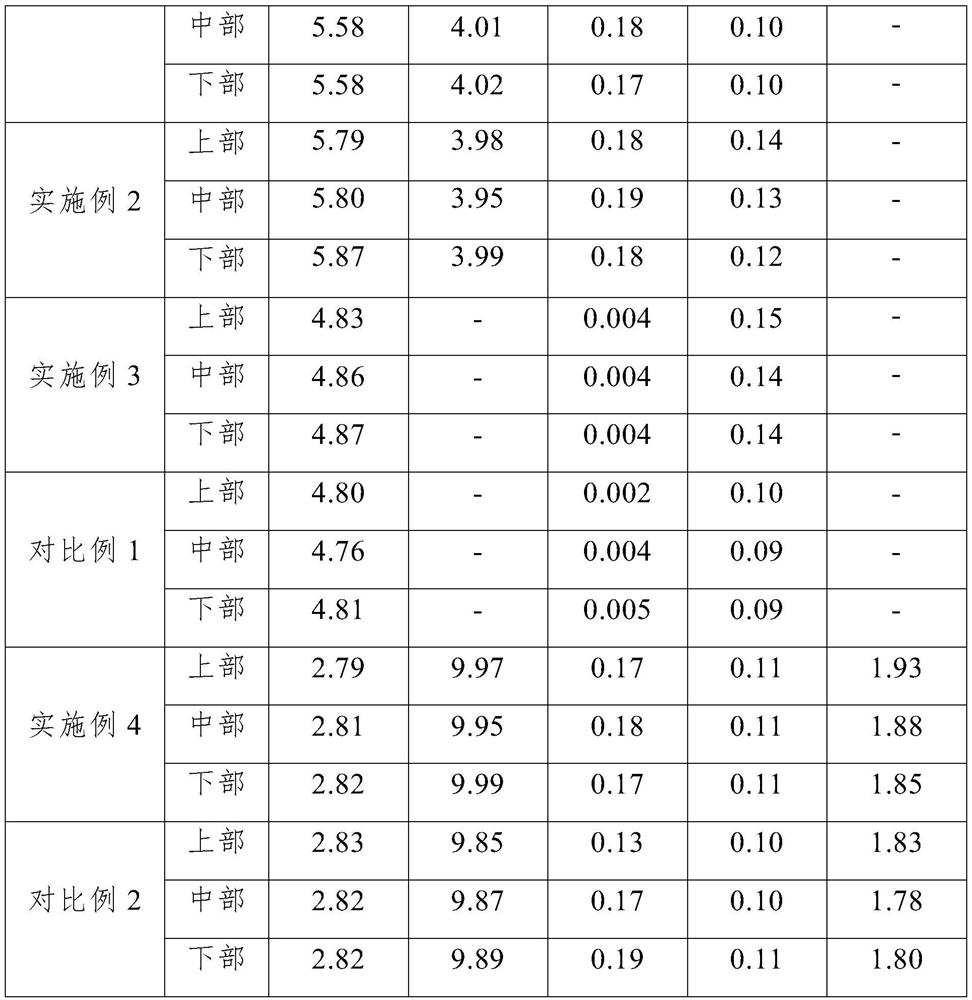

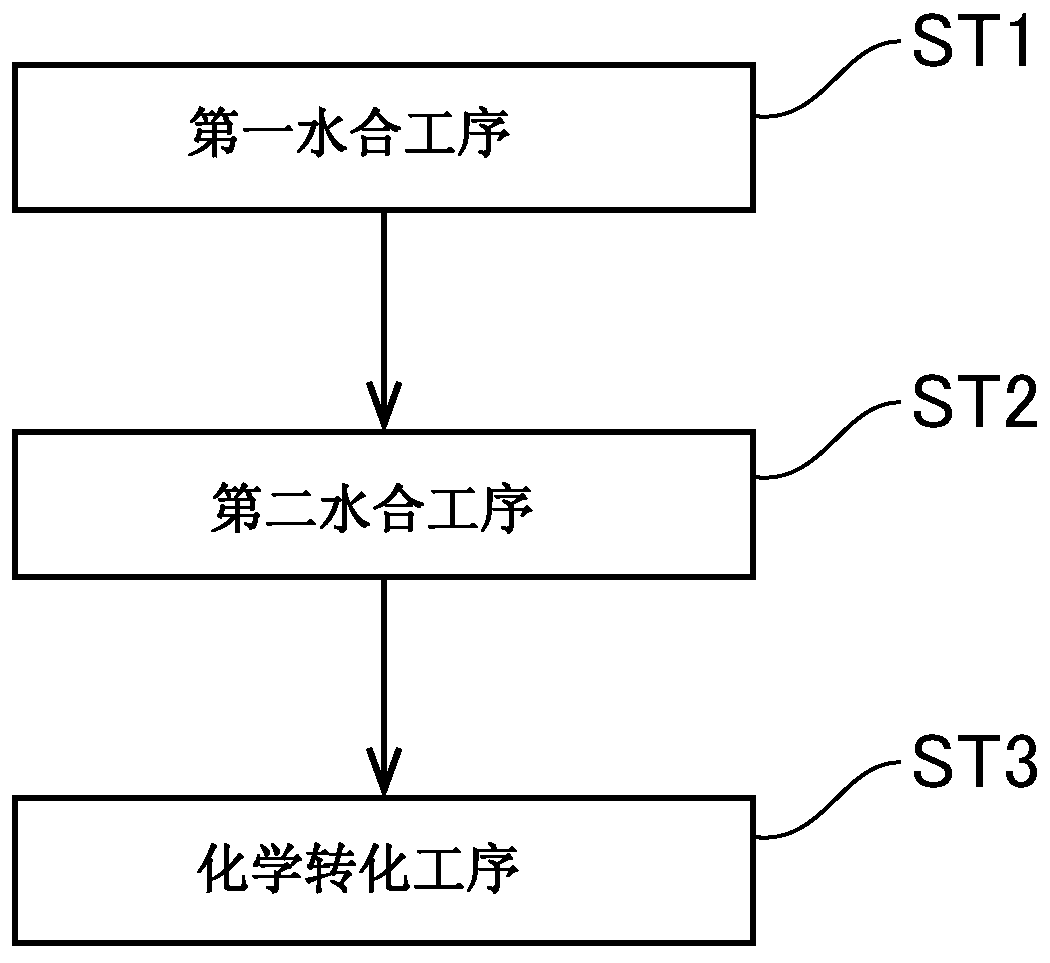

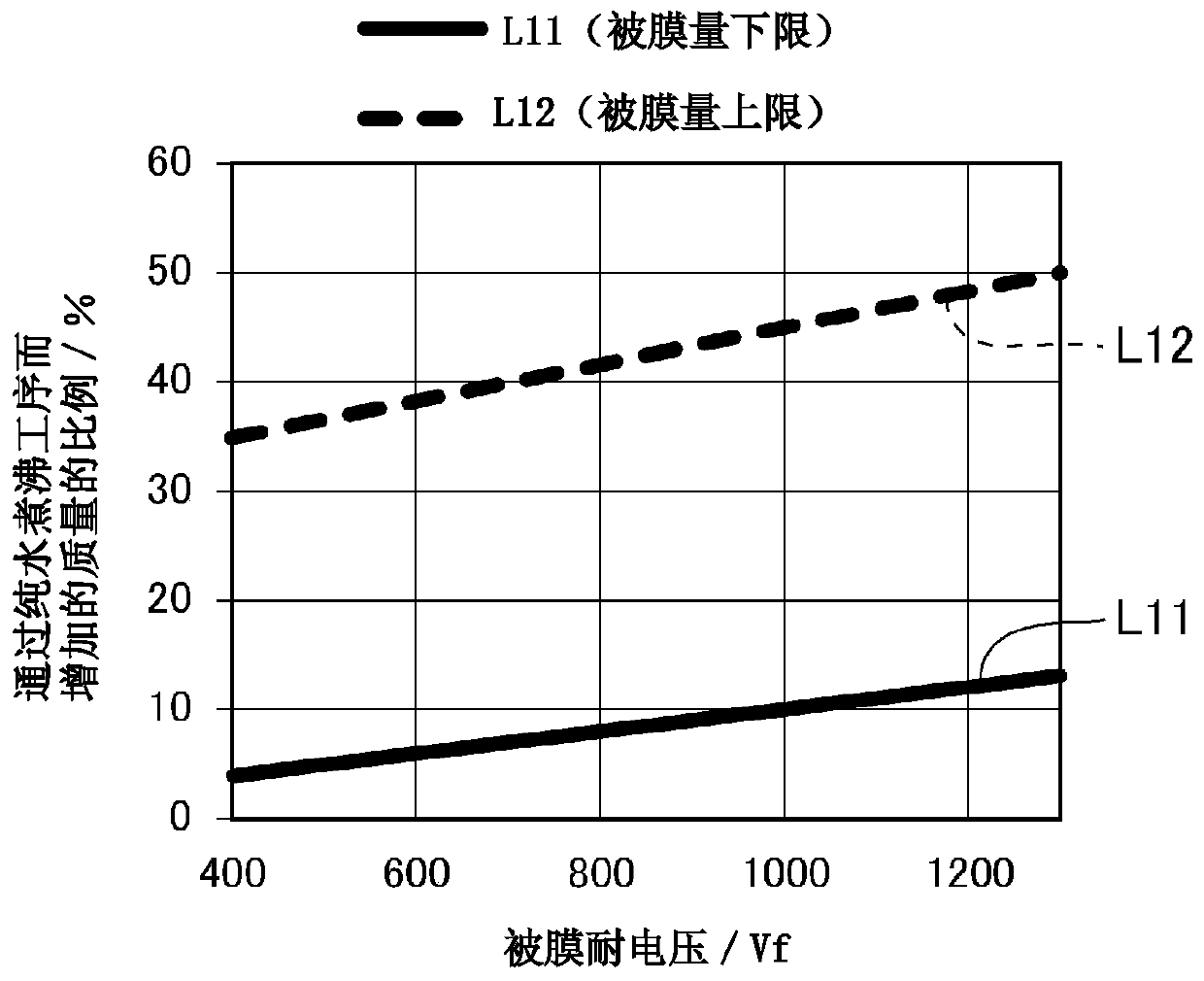

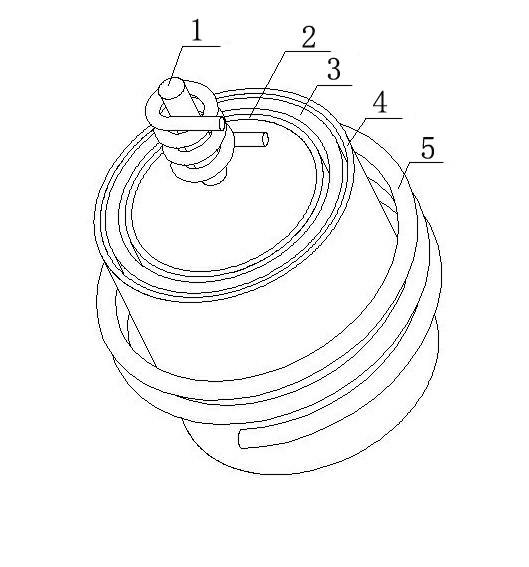

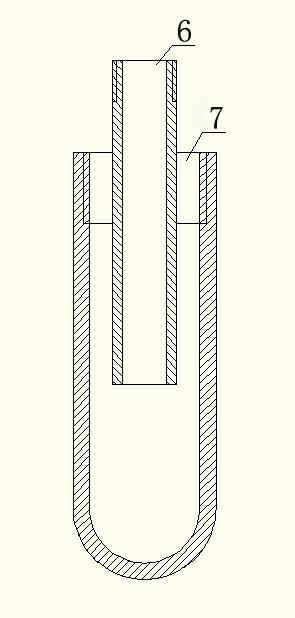

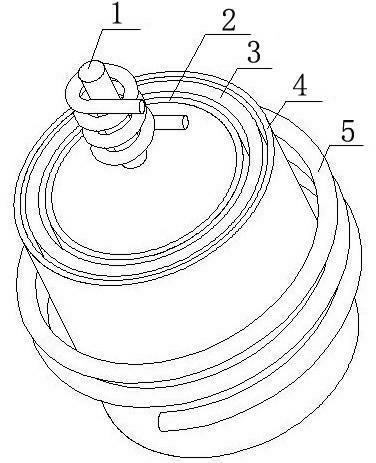

Electrode for aluminum electrolytic capacitor and method for manufacturing same

ActiveCN110959184ALower boron contentSuppresses lowering of dielectric constantElectrolytic capacitor manufactureHydration reactionO-Phosphoric Acid

When manufacturing an electrode for an electrolytic capacitor, in a first hydration step (ST1), an aluminum electrode is immersed in a first hydration processing solution having a temperature of at least 70 DEG C and comprising pure water or an aqueous solution to which phosphoric acid or a phosphate has been added so that the phosphorus concentration is no greater than 4 mass ppm. In a second hydration step (ST2), the aluminum electrode is immersed in a second hydration processing solution to which phosphoric acid or a phosphate has been added so that the phosphorus concentration is 4-5,000 mass ppm, the second hydration processing solution having a pH of 3.0-9.0 and a temperature of at least 70 DEG C. In a chemical conversion step (ST3), at least a boric acid chemical conversion processin which the aluminum electrode is chemically converted in a boric acid-based chemical conversion solution is included, and a chemical conversion coating having a coating withstand voltage of at least200V is formed on the aluminum electrode.

Owner:NIPPON LIGHT METAL CO LTD +1

Preparation method of nuclear grade boron carbide core block for high-temperature gas cooling pile control rod

ActiveCN105913888AImprove production efficiencyReduce manufacturing costNuclear energy generationReactors manufactureBoron carbideHot Temperature

The invention discloses a preparation method of a nuclear grade boron carbide core block for a high-temperature gas cooling pile control rod. Nuclear grade boron carbide powder is used as raw materials; the large-dimension nuclear grade boron carbide core block for the high-temperature gas cooling pile control rod is prepared through nine steps including material mixing, drying, pelletization, steel mold forming, cold isostatic pressing, green blank processing, degreasing, sintering and machining; the large-dimension nuclear grade boron carbide core block can be prepared in a mass and net dimension manner; a pressure-free sintering process is used for replacing a hot pressing process, so that the problems of high production cost and low efficiency of the large-dimension nuclear grade boron carbide core block are solved. The method can be directly used for producing the boron carbide core block for the high-temperature gas cooling pile control rod.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

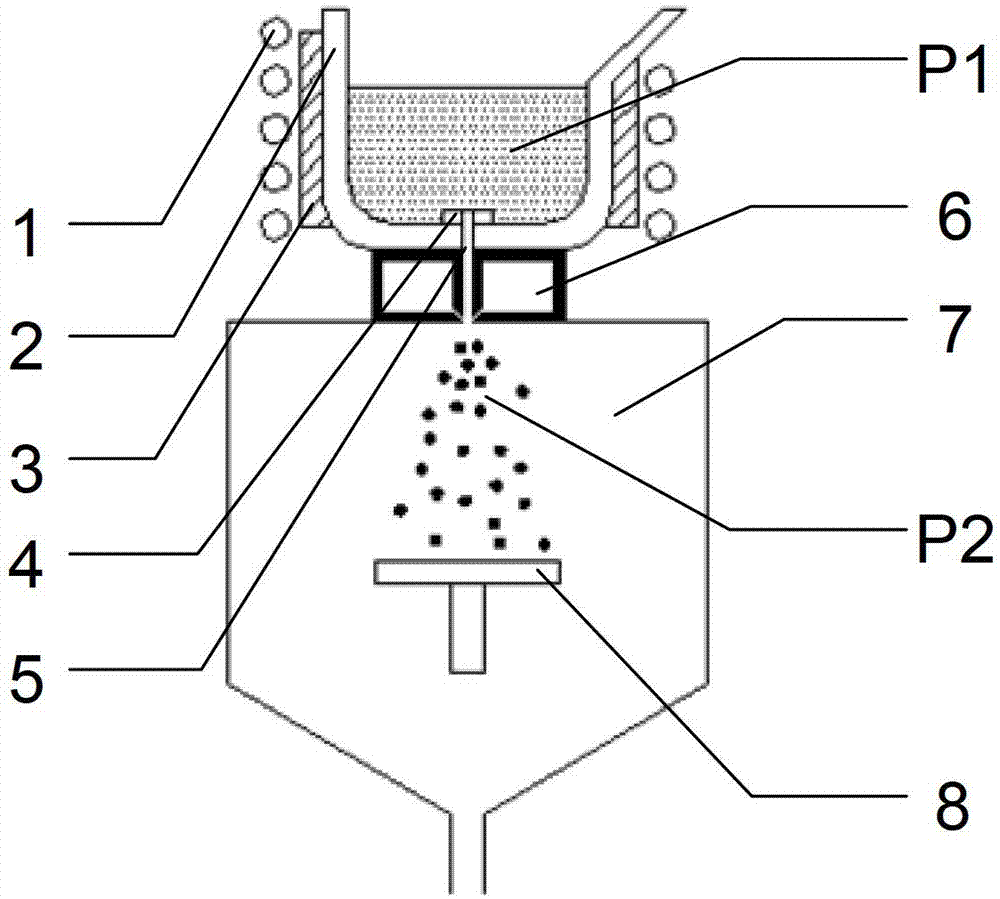

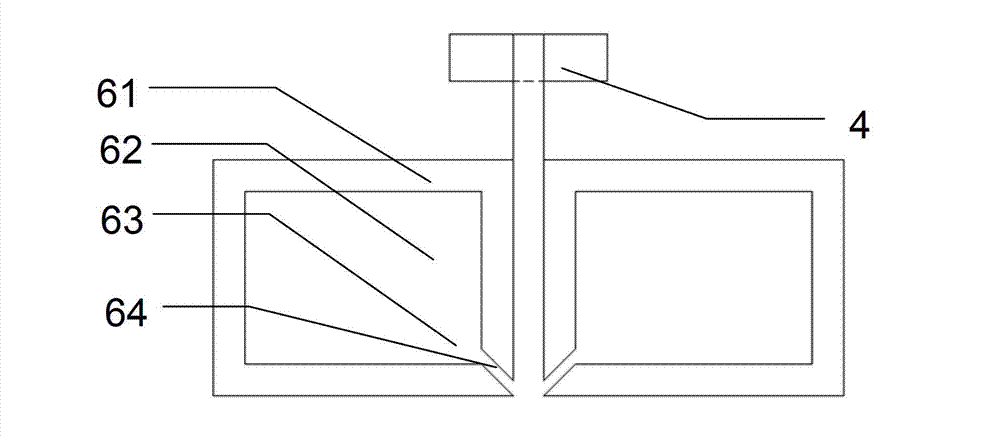

Method for decreasing content of boron impurity in silicon metal through metallurgical process

The invention relates to a method for decreasing content of boron impurities in silicon metal through a metallurgical process. The method comprises the steps of mixing calcium carbonate powder with silicon dioxide powder to obtain a slag forming constituent, mixing the slag forming constituent with silicon metal powder, adding 0.1-10% H2O2, evenly agitating, naturally cooling and drying, adding the mixed materials to one third of the total volume of a ceramic crucible, starting up a heating device consisting of a medium-frequency plasma heater and a medium-frequency induction coil to melt the mixed materials, adding silicon metal powder, shutting down the medium-frequency plasma heater when the silicon metal power is molten, increasing the frequency of the medium-frequency induction coil and continuously heating to fully melt the silicon metal powder into silicon metal liquid; and repetitively dipping quartz rods with a cooling system into the silicon metal liquid and turning the quartz rods to remove a slag phase in the silicon metal liquid. The method has the advantages that the operation steps are simple, the requirement on equipment is not high, the impurities are not apt to be introduced, the wastage of silicon is not caused and the production cost is low; and the content of boron in the purified silicon is below 0.2ppm and the requirement of solar grade polycrystalline silicon is satisfied.

Owner:锦州新世纪多晶硅材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com