Method for decreasing content of boron impurity in silicon metal through metallurgical process

A technology of metal silicon and boron impurities, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of high equipment requirements, complex operation steps, and high production costs, and achieves low equipment requirements, simple operation steps, and high production costs. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The metal silicon powder used in the whole purification process has a boron content of <30 ppm and a particle size of 1 mesh to 200 mesh.

[0025] Mix 2 kg of calcium carbonate powder with a boron content of 2 o 2 Mix evenly, cool and dry naturally to obtain the mixed material.

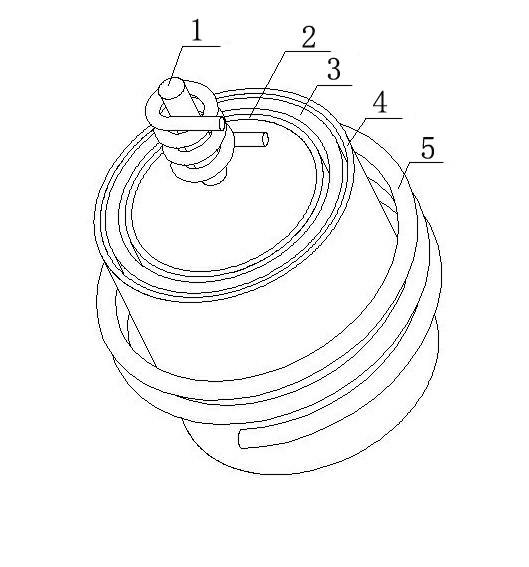

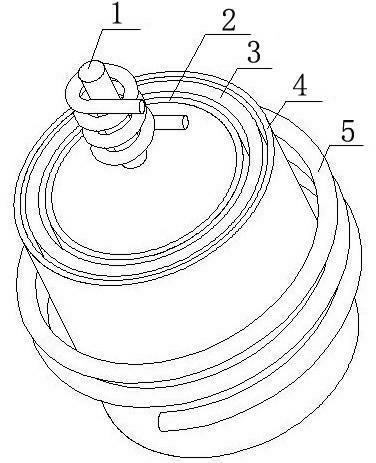

[0026] Such as figure 1 As shown, a heating device consisting of an intermediate frequency plasma heater 1 and an intermediate frequency induction coil 5 is adopted, the ceramic crucible 2 is placed in the intermediate frequency induction coil 5, and an insulating material layer 3 and asbestos cloth 4 are arranged therebetween from the inside to the outside. The intermediate frequency plasma heater 1 is arranged above the ceramic crucible 2 .

[0027] Add the mixed material to 1 / 3 of the volume of the ceramic crucible 2 with a capacity of 30 kg, and the added mixed material is 9 kg, start the intermediate frequency plasma heater 1 and the intermediate frequency induction coil 5, and control t...

Embodiment 2

[0031] The metal silicon powder used in the whole purification process has a boron content of <30 ppm and a particle size of 1 mesh to 200 mesh.

[0032] Mix 1 kg of calcium carbonate powder with a boron content of 2 o 2 Mix evenly, cool and dry naturally to obtain the mixed material.

[0033] Such as figure 1 As shown, a heating device consisting of an intermediate frequency plasma heater 1 and an intermediate frequency induction coil 5 is adopted, the ceramic crucible 2 is placed in the intermediate frequency induction coil 5, and an insulating material layer 3 and asbestos cloth 4 are arranged therebetween from the inside to the outside. The intermediate frequency plasma heater 1 is arranged above the ceramic crucible 2 .

[0034] Add the mixed material to 1 / 3 of the volume of the ceramic crucible 2 with a capacity of 30kg, and the added mixed material is 7kg, start the intermediate frequency plasma heater 1 and the intermediate frequency induction coil 5, and control the...

Embodiment 3

[0038] The metal silicon powder used in the whole purification process has a boron content of <30 ppm and a particle size of 1 mesh to 200 mesh.

[0039] Mix 0.6 kg of calcium carbonate powder with a boron content of 2 o 2 Mix evenly, cool and dry naturally to obtain the mixed material.

[0040] Such as figure 1 As shown, a heating device consisting of an intermediate frequency plasma heater 1 and an intermediate frequency induction coil 5 is adopted, the ceramic crucible 2 is placed in the intermediate frequency induction coil 5, and an insulating material layer 3 and asbestos cloth 4 are arranged therebetween from the inside to the outside. The intermediate frequency plasma heater 1 is arranged above the ceramic crucible 2 .

[0041] Add the mixed material to 1 / 3 of the volume of the ceramic crucible 2 (made of alumina, zirconia, silicon oxide) with a capacity of 30kg, the added mixed material is 8kg, start the intermediate frequency plasma heater 1 and the intermediate fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com