Preparation method of high-uniformity boron-containing titanium alloy cast ingot

A titanium alloy and ingot casting technology, which is applied in the field of preparation of highly uniform boron-containing titanium alloy ingots, can solve problems affecting titanium alloy processing and product performance, poor processability, and unqualified product performance, so as to avoid the formation of refractory materials and inclusion defects, reduce the risk of local segregation and enrichment, and increase the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

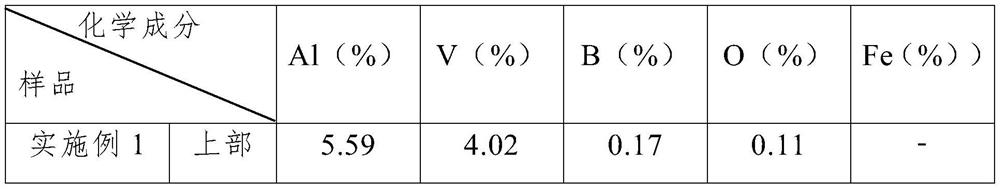

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] Step 1, raw material selection: according to the composition of the target product boron-containing TC4 ingot Ti-6Al-4V-0.2B, select AlTiB ternary alloy, sponge titanium, aluminum vanadium master alloy and aluminum beans as raw materials;

[0034] The mass content of boron element in the AlTiB ternary alloy is 5.0%, the mass content of Ti element is 15.0%, and the balance is Al element;

[0035] The AlTiB ternary alloy is block-shaped, and the size, length, height and width of the block-shaped AlTiB ternary alloy are all 1 mm to 6 mm;

[0036] The particle size of the titanium sponge is 3.0 mm to 12.7 mm;

[0037] Step 2, electrode block pressing: use a mixer to mix the raw materials selected in step 1 for 5 minutes, and then press to obtain an electrode block;

[0038] Step 3. Electrode block assembly welding: The electrode block obtained in step 2 is assembled and welded, and the solder joints are cleaned to sil...

Embodiment 2

[0051] This embodiment includes the following steps:

[0052] Step 1, raw material selection: according to the composition of the target product boron-containing TC4 ingot Ti-6Al-4V-0.2B, select AlTiB ternary alloy, sponge titanium, aluminum vanadium master alloy and aluminum beans as raw materials;

[0053] The mass content of boron element in the AlTiB ternary alloy is 0.2%, the mass content of Ti element is 5.0%, and the balance is Al element;

[0054] The AlTiB ternary alloy is chip-shaped, and the thickness of the chip-shaped AlTiB ternary alloy is not more than 2mm, and the width and length are both 15mm;

[0055] The particle size of the titanium sponge is 3.0 mm to 12.7 mm;

[0056] Step 2, electrode block pressing: use a mixer to mix the raw materials selected in step 1 for 10 minutes, and then press to obtain an electrode block;

[0057] Step 3. Electrode block assembly welding: The electrode block obtained in step 2 is assembled and welded, and the solder joints a...

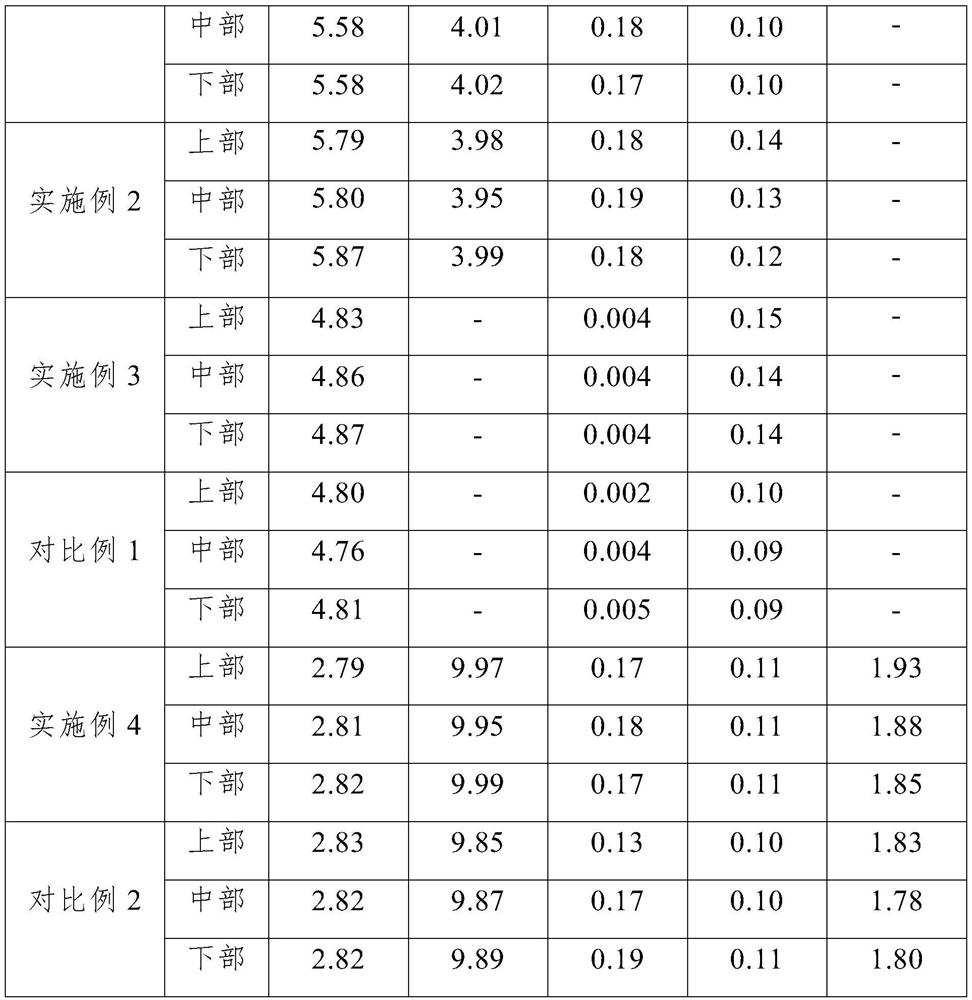

Embodiment 3

[0070] This embodiment includes the following steps:

[0071] Step 1. Raw material selection: according to the composition of the target product boron-containing TA5 ingot Ti-4Al-0.005B, select AlTiB ternary alloy, sponge titanium, and aluminum beans as raw materials;

[0072] The mass content of boron element in the AlTiB ternary alloy is 1.0%, the mass content of Ti element is 8.0%, and the balance is Al element;

[0073] The AlTiB ternary alloy is block-shaped, and the size, length, height and width of the block-shaped AlTiB ternary alloy are all 1 mm to 6 mm;

[0074] The particle size of the titanium sponge is 3.0 mm to 12.7 mm;

[0075] Step 2, electrode block pressing: use a mixer to mix the raw materials selected in step 1 for 5 minutes, and then press to obtain an electrode block;

[0076] Step 3. Electrode block assembly welding: The electrode block obtained in step 2 is assembled and welded, and the solder joints are cleaned to silvery white to obtain an electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com