Process for treatment of waste water containing boron

A treatment method and waste water technology, applied in the direction of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

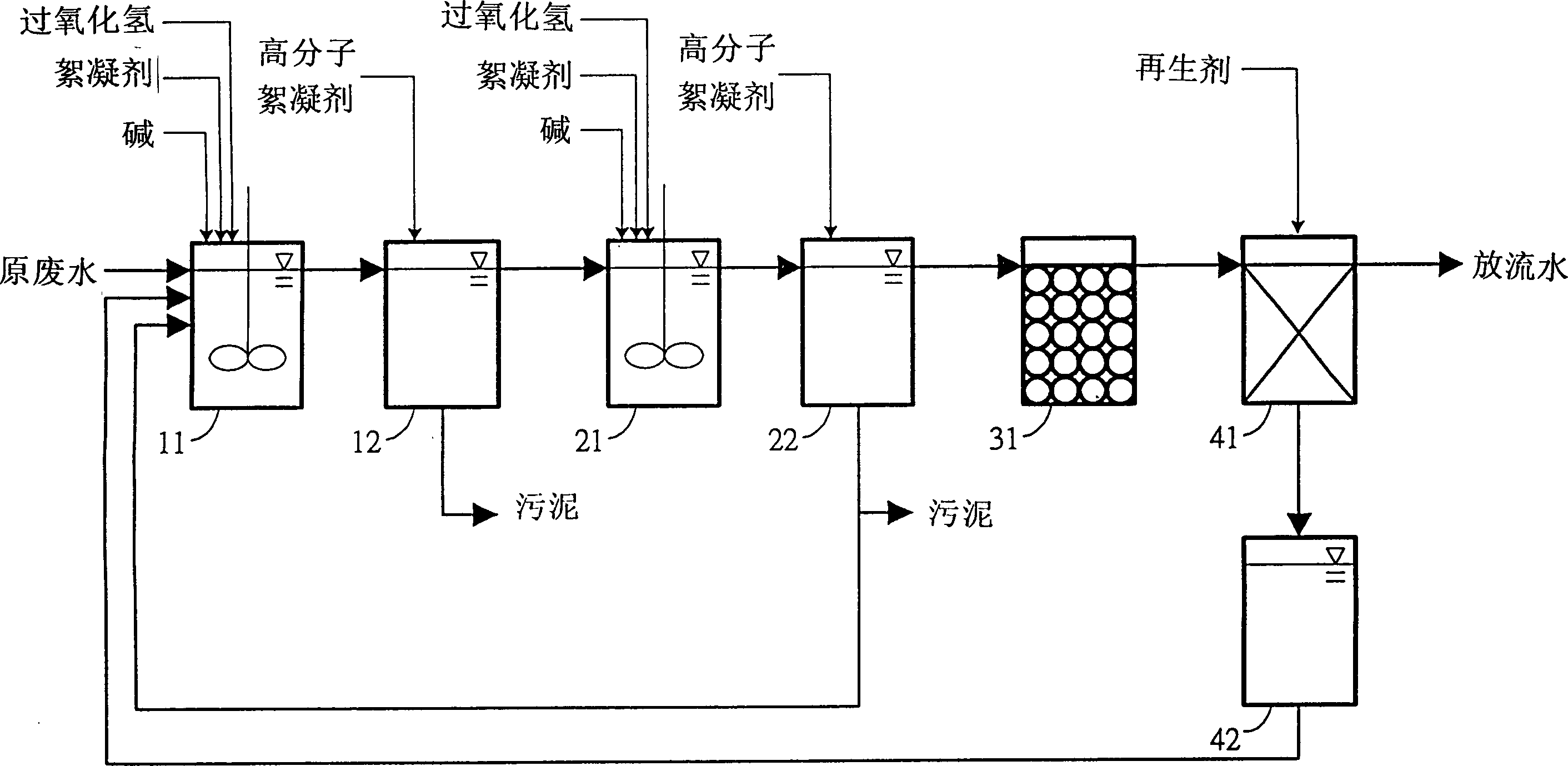

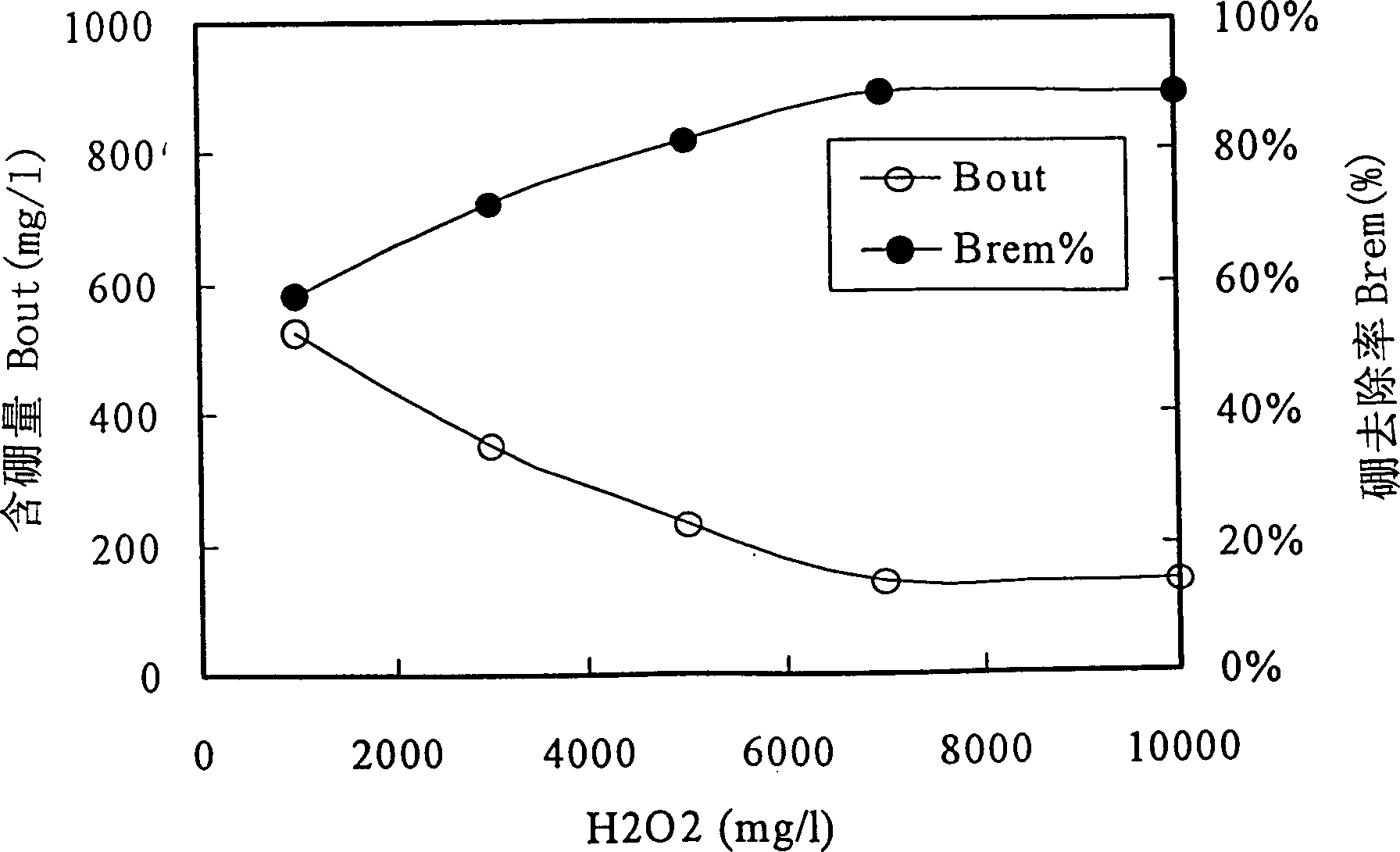

[0055] This embodiment takes the boron content of flowing water (B in ) 1262mg / l power plant waste water is tested, utilizes the inventive method as shown in Figure 1 to add H 2 o 2 and Ca(OH) 2 The oxidation / flocculation mode of the flocculant was tested, and the pH value was controlled at about pH=10. The experimental results are shown in Table 1. H in the first oxidation / flocculation tank in Table 1 2 o 2 and Ca(OH) 2 Dosing amount is 5g / l and 14.2g / l respectively, to the removal rate of B (B rem ) up to 87.9%, compared with Comparative Example 1, confirms that the present invention adds H 2 o 2 The step of the method overcomes the bottleneck of the boron removal rate of the traditional flocculation method, so that the boron content of the treated water (B out ) down to 153mg / l.

[0056] Send the effluent water of the first oxidation / flocculation tank to a first solid / liquid separation tank and add anionic polymer flocculant (purchased from British Ciba (Allied Col...

Embodiment 3

[0061] In this example, the treated water of the oxidation / flocculation tank was used as the inflow water, and the test of ion exchange resin treatment B was carried out. The ion exchange resin was purchased from the Amberlite series of ion exchange resins from Rohm&Haas in the United States, code-named IRA-743. The boron content in the influent water of the resin was 12.7 mg / l, and the operating influent flow rate of the ion exchange resin was controlled at 10 resin volume / hour (BV / h), the hydraulic retention time is about 6 minutes, and the pH value is controlled at about pH=10-11. Experimental results such as Figure 4 as shown, Figure 4 It shows that when the volume of the influent water is below 200BV, the concentration of boron B in the effluent water is very low, almost undetectable. As the operating volume continues to increase, the boron B concentration in the treated water increases gradually, but it is still below the standard of B=1mg / l. When it reaches more tha...

Embodiment 4

[0063]In this embodiment, the waste water from a power plant with different influent boron content is used for testing, and the first oxidation / flocculation tank, the first solid / liquid separation tank, the second oxidation / flocculation tank, and the second solid / liquid After being treated in a separation tank, it is treated with an ion exchange resin similar to Example 3, and the treated effluent reaches below the boron discharge standard of 1 mg / l, as shown in Table 2 below.

[0064] waste water

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com