Electrode for aluminum electrolytic capacitor and method for manufacturing same

A technology of aluminum electrolytic capacitors and manufacturing methods, applied in the direction of electrolytic capacitor manufacturing, electrolytic capacitors, capacitors, etc., can solve the problems of chemical conversion film or porous layer damage, etc., to suppress the reduction of dielectric constant, realize electrostatic capacity, water resistance excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

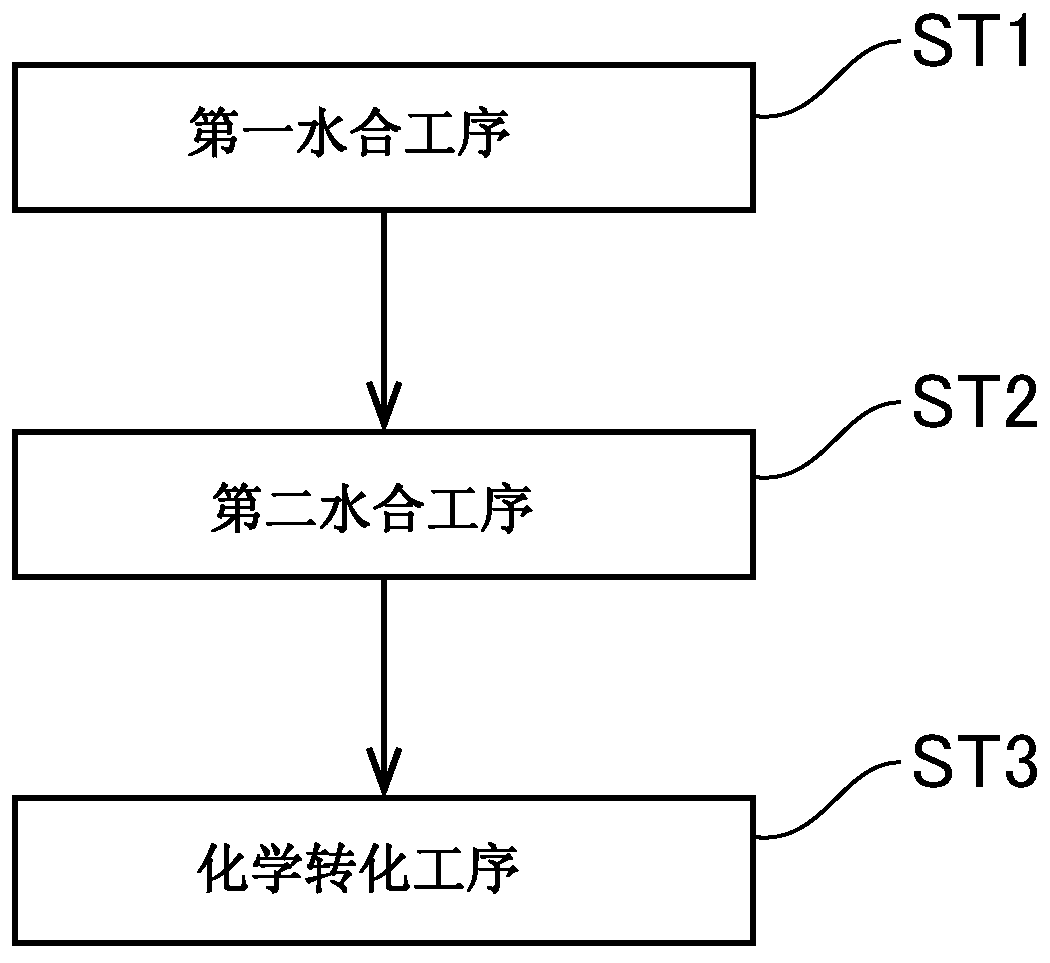

Method used

Image

Examples

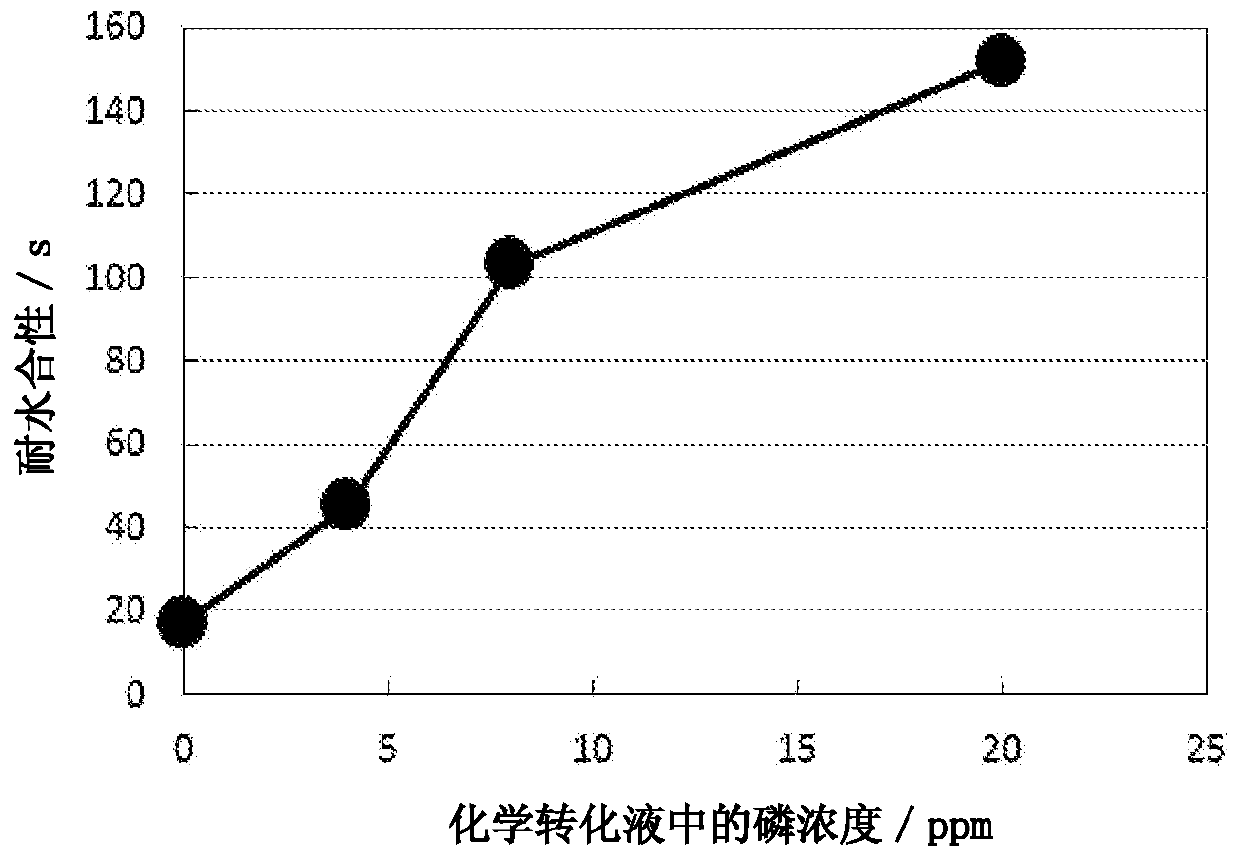

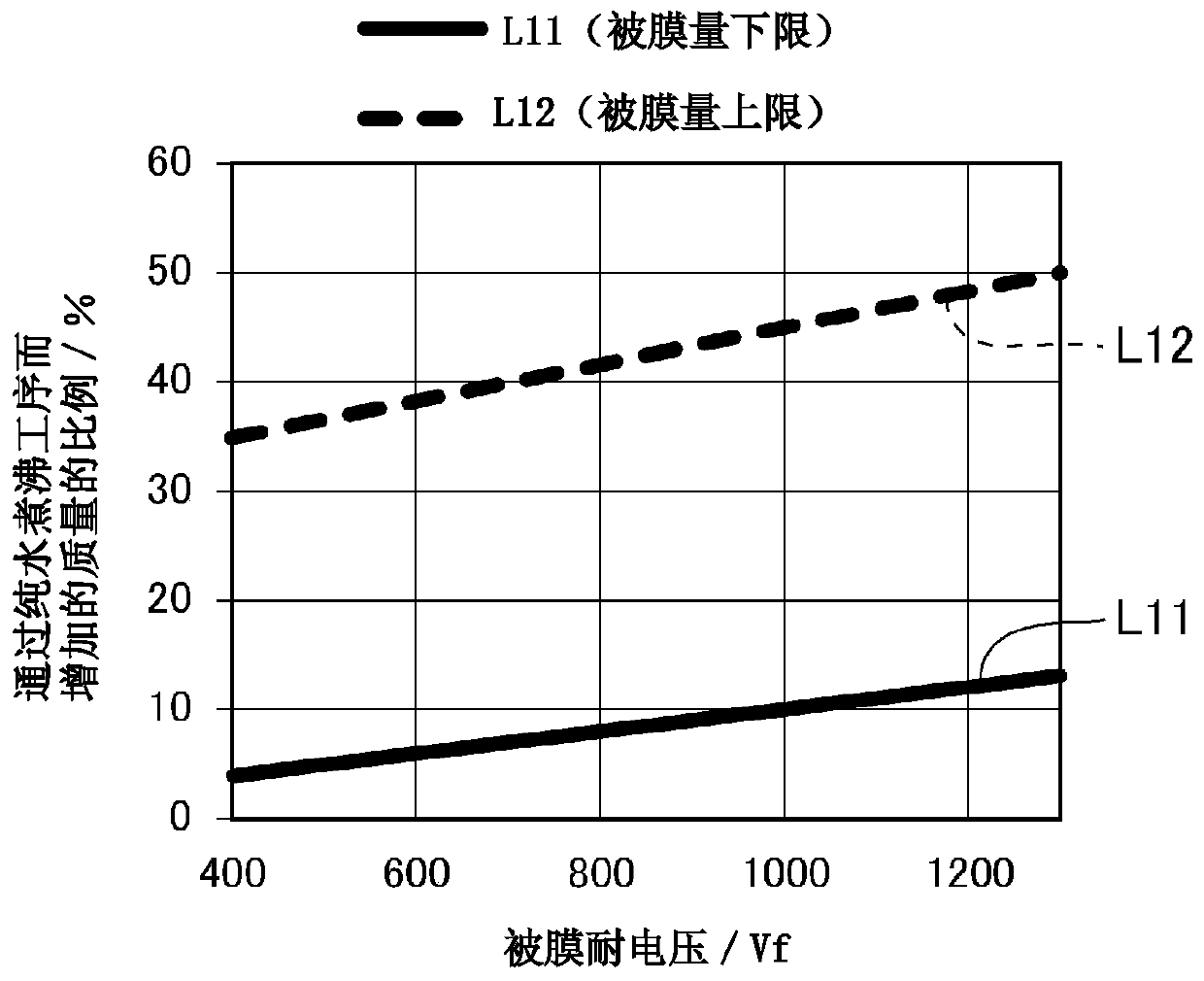

Embodiment Construction

[0039] (Electrodes for Aluminum Electrolytic Capacitors)

[0040] In the present invention, when producing an electrode for an aluminum electrolytic capacitor, the surface of the aluminum electrode is chemically converted to produce an electrode for an aluminum electrolytic capacitor. As the aluminum electrode, an etched aluminum foil, a porous aluminum electrode in which a porous layer obtained by sintering aluminum powder is laminated on both sides of an aluminum core material, or the like can be used. An etched aluminum foil usually has a porous layer in which tunnel-like pits are formed. In the porous aluminum electrode, for example, porous layers each having a thickness of 5 μm to 1000 μm are formed on both surfaces of an aluminum core material having a thickness of 10 μm to 200 μm. Such a porous layer is a layer obtained by sintering aluminum powders having an average particle diameter D50 of 0.5 μm to 100 μm, and the aluminum powders are sintered while maintaining void...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com