Os2B3 hard material and preparation and application thereof

A technology for hard materials and raw materials, which is applied to Os2B3 hard materials and their preparation and application fields, can solve problems such as affecting structure and mechanical properties, and achieve the effects of high hardness, simple and easy process, and high chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

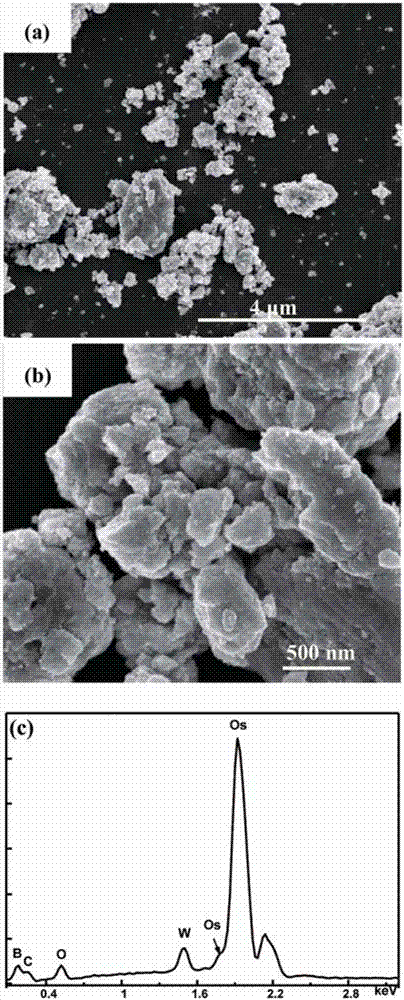

[0037] The powder was synthesized by using a high-energy ball mill model 8000M of the American SPEX company. First, in a glove box filled with argon gas, high-purity osmium powder (Os) and boron powder (B) were mixed in a stoichiometric ratio of 1:2. A total of six tungsten carbide grinding balls are used, with a size of 11.20mm, and the mass ratio of the balls to the mixed powder is 4:1. Fix the tungsten carbide ball mill jar with powder and balls on the high energy ball mill. The total time of ball milling is 40h, every hour of ball milling is shut down for 20min (to prevent the engine from overheating).

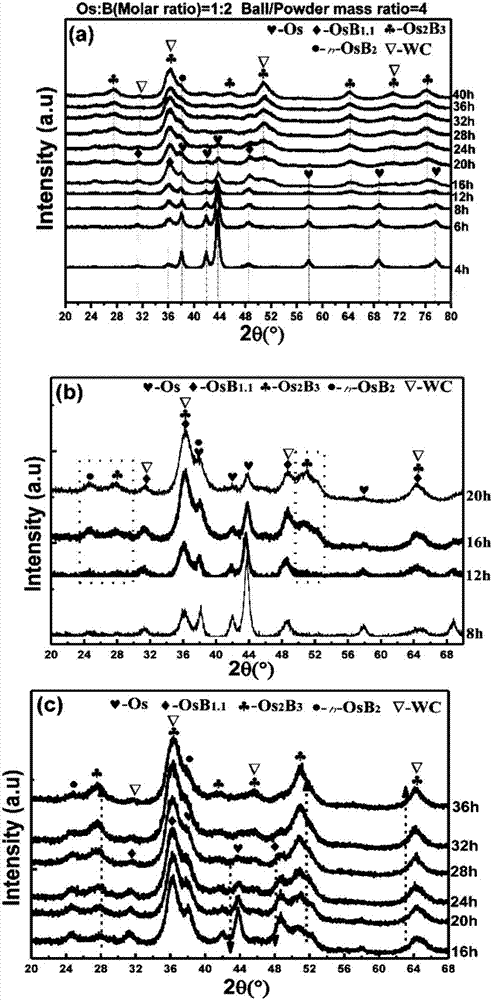

[0038] figure 1 XRD patterns for different milling periods. Depend on figure 1 (a) It can be seen that with the prolongation of ball milling time, the peak of osmium (Os) weakens and the peak shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com