Preparation method for silicon powder

A technology of silicon powder and silicon material, which is applied in the preparation of solar cell silicon material, industrial silicon boron removal process and the preparation of high-purity ultra-fine silicon powder, can solve the problems of secondary metal pollution, increase processing cost, etc., and achieve broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

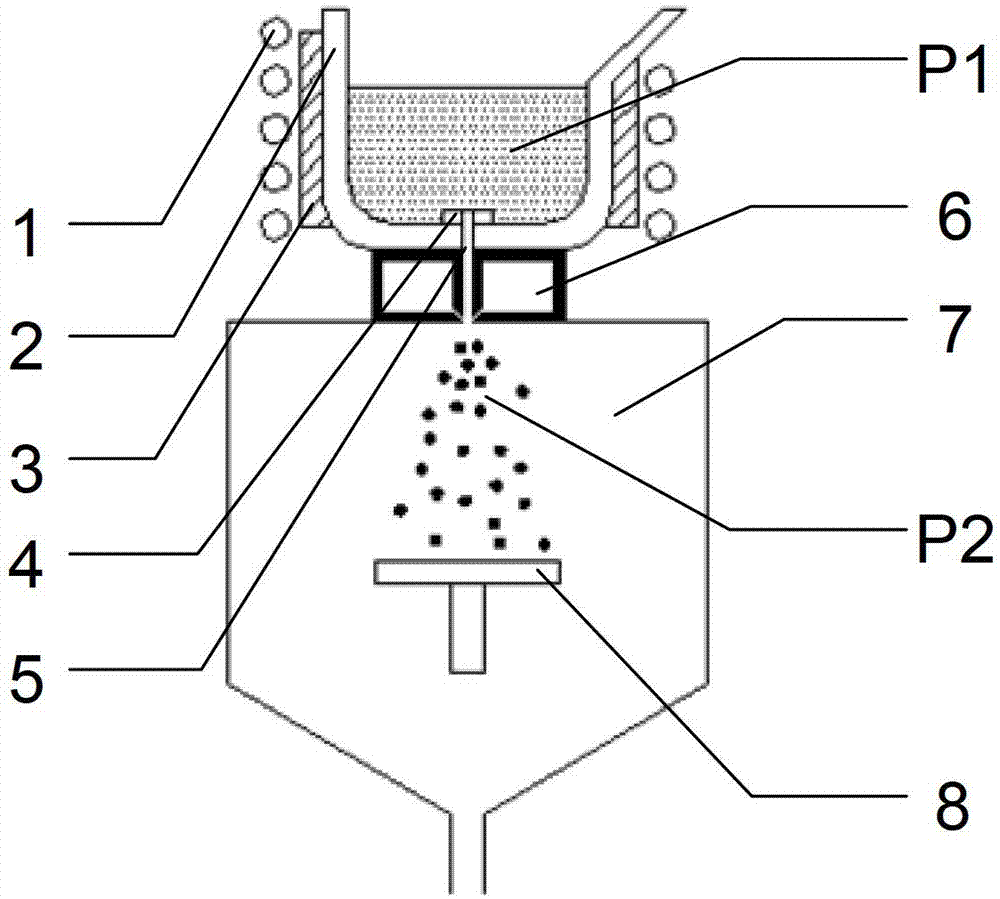

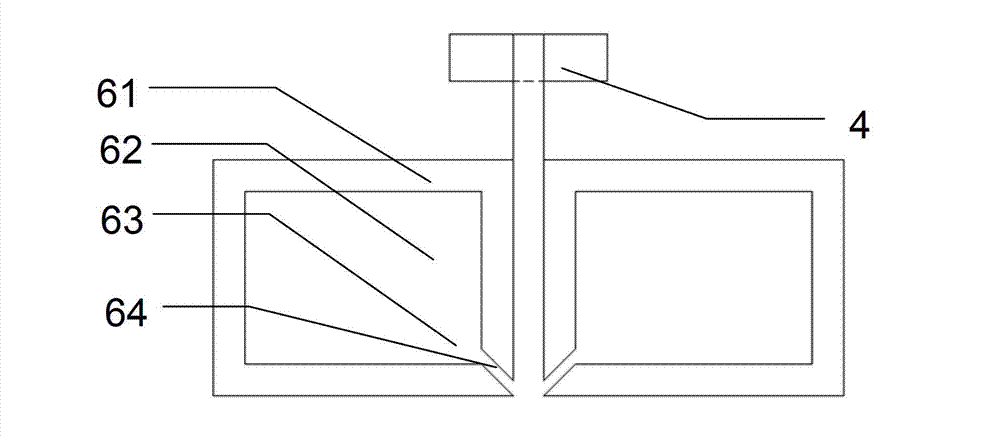

[0028]A metallurgical grade silicon material with a B content of 5.1 ppmw was taken and melted in a graphite crucible. Add slagging agent (sodium bicarbonate 50%, silicon dioxide 30%, sodium fluoride 20%) when the silicon material is melted, slagging and refining boron removal time is 0.5h, control the temperature in the graphite crucible at 1600 ° C ~ 1650 ° C, static Leave it on for 10-20 minutes. Remove the slagging agent floating on the upper layer of the silicon liquid; open the valve, the silicon liquid flows into the atomizer from the diversion tube, the diameter of the diversion tube is 5mm, control the air pressure of the atomizer outlet to 0.5MPa, the liquid outlet of the atomizer is connected to the acceptor The distance of the turntable is 0.3m. The boron content in the obtained silicon powder was 0.24ppmw. The average particle size of silicon powder is 55 μm.

[0029] Through comparative tests, the B content in silicon prepared by ordinary technology (same slag...

Embodiment 2

[0031] The process is the same as in Example 1, the difference is that the slagging agent formula is 40% sodium bicarbonate, 40% silicon dioxide, and 20% sodium fluoride. When slagging and refining boron removal, the temperature in the graphite crucible is controlled at 1650°C to 1700°C. ℃, slagging and refining time 1h, the diameter of the guide tube is 4mm, the air pressure at the gas outlet of the atomizer is controlled at 1MPa, and the distance between the liquid outlet of the atomizer and the receiving turntable is 0.5m. The boron content in the obtained silicon powder was measured to be 0.21 ppmw. The average particle size of silicon powder is 48 μm.

[0032] According to comparative tests, the boron content in silicon prepared by ordinary technology (same slagging refining temperature, time and formula) is 0.51ppmw. It can be seen that the boron content in the silicon powder obtained in this embodiment is significantly reduced.

Embodiment 3

[0034] The process is the same as in Example 1, the difference is that the slagging agent formula is 60% sodium carbonate, 32% silicon dioxide, and 8% sodium fluoride. During slagging, refining and boron removal, the temperature in the graphite crucible is controlled at 1650°C to 1700°C , slagging and refining time is 0.5h, the diameter of the guide tube is 6mm, the air pressure at the gas outlet of the atomizer is controlled at 1.5MPa, and the distance between the liquid outlet of the atomizer and the receiving turntable is 0.75m. The boron content in the obtained silicon powder was measured to be 0.19 ppmw. The average particle size of silicon powder is 41 μm.

[0035] According to comparative tests, the boron content in silicon prepared by ordinary technology (same slagging refining temperature, time and formula) is 0.49ppmw. It can be seen that the boron content in the silicon powder obtained in this embodiment is significantly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com