Smelting technology of ultralow boron steel

An ultra-low boron, process technology, applied in the direction of improving process efficiency, manufacturing converters, etc., can solve the problems affecting the low-temperature impact performance of steel, affecting the surface quality of steel, etc., and achieve the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

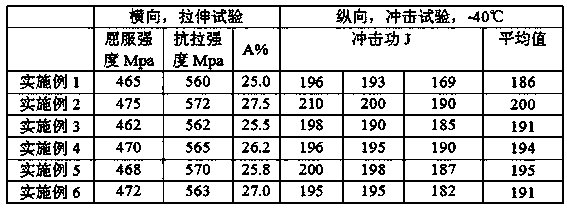

Examples

Embodiment 1

[0038] A smelting process for ultra-low boron steel, comprising the following steps:

[0039] (1) Pretreatment of KR molten iron: the molten iron entering the furnace is pretreated by desulfurization and cleaned of slag, and the sulfur content of the molten iron after desulfurization is controlled to be ≤0.003%;

[0040] The mass percentage of the chemical composition of the desulfurizer is: SiO 2 7.04%, CaO 79.68%, CaF 2 8.05%, S0.050%, desulfurizer particle size (0.3-2mm) ≥ 85%;

[0041](2) Converter smelting: add 100 tons of molten iron and 20 tons of steel scrap to the top-bottom combined blowing converter, add lime 41Kg / ton steel and light-burned dolomite 18Kg / ton steel during the converter smelting process, add low-carbon manganese when tapping Iron alloy 17Kg / ton steel, lime 1.8Kg / ton steel and aluminum grain 0.25Kg / ton steel, control the end temperature of converter smelting above 1650°C, control the carbon content of converter tapping to 0.035%, phosphorus ≤ 0.025...

Embodiment 2

[0055] A smelting process for ultra-low boron steel, comprising the following steps:

[0056] (1) Pretreatment of KR molten iron: the molten iron entering the furnace is pretreated by desulfurization and cleaned of slag, and the sulfur content of the molten iron after desulfurization is controlled to be ≤0.003%;

[0057] The mass percentage of the chemical composition of the desulfurizer is: SiO 2 7.04%, CaO 79.68%, CaF 2 8.05%, S0.050%, desulfurizer particle size (0.3-2mm) ≥ 85%;

[0058] (2) Converter smelting: add 100 tons of molten iron and 20 tons of steel scrap to the top-bottom combined blowing converter, add lime 42Kg / ton steel and light-burned dolomite 20Kg / ton steel during the converter smelting process, add low-carbon manganese when tapping Iron alloy 18Kg / ton steel, lime 2Kg / ton steel and aluminum grain 0.3Kg / ton steel, control the end temperature of converter smelting above 1650°C, control the carbon content of converter tapping to 0.04%, phosphorus ≤ 0.025%, ...

Embodiment 3

[0072] A smelting process for ultra-low boron steel, comprising the following steps:

[0073] (1) Pretreatment of KR molten iron: the molten iron entering the furnace is pretreated by desulfurization and cleaned of slag, and the sulfur content of the molten iron after desulfurization is controlled to be ≤0.003%;

[0074] The mass percentage of the chemical composition of the desulfurizer is: SiO 2 7.04%, CaO 79.68%, CaF 2 8.05%, S0.050%, desulfurizer particle size (0.3-2mm) ≥ 85%;

[0075] (2) Converter smelting: add 100 tons of molten iron and 20 tons of steel scrap to the top-bottom combined blowing converter, add lime 43Kg / ton steel and light-burned dolomite 19Kg / ton steel during the converter smelting process, add low-carbon manganese when tapping Iron alloy 19Kg / ton steel, lime 1.9Kg / ton steel and aluminum grain 0.35Kg / ton steel, control the end temperature of converter smelting above 1650°C, control the carbon content of converter tapping to 0.05%, phosphorus ≤ 0.025...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com