Method for recovering fluoride ions from wastewater

A fluoride ion and waste water technology, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve problems such as high fluoride ion concentration, achieve the effects of reducing environmental pollution, improving comprehensive utilization value, and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

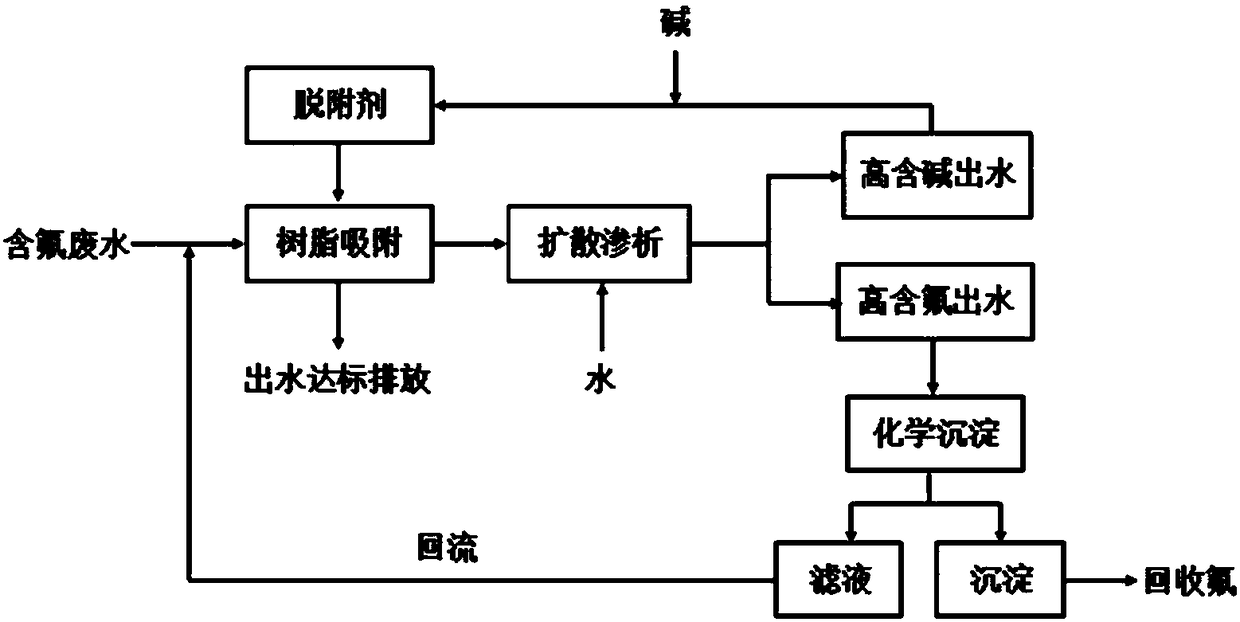

[0038] like figure 1 Shown, the method for recovering fluoride ions in waste water of the present embodiment, its steps are:

[0039] (A) Pass fluorine-containing wastewater with a fluoride ion concentration of 0.5 mg / L through the adsorption tower filled with the resin at a flow rate of 1 times the bed volume of the resin itself per hour, wherein the bed volume of the resin itself refers to the composite resin packed in the adsorption column. The volume of the material matrix and the sum of the pore volume between the matrix; the adsorption tower used is a jacketed glass adsorption column, which is filled with 5mL resin. When the volume of treated fluorine-containing wastewater is 6,000 times the bed volume of the resin itself, the adsorption breakthrough point of the resin is reached at this time. Adopt desorption agent to carry out desorption regeneration to described resin, described desorption agent is sodium hydroxide solution, and the mass concentration of sodium hydro...

Embodiment 2

[0045] The method for recovering fluoride ions in waste water of the present embodiment, its steps are:

[0046] (A) The fluorine-containing wastewater with a fluoride ion concentration of 4 mg / L passes through the adsorption tower filled with the resin at a flow rate of 5 times the bed volume of the resin itself per hour. When the volume of treated fluorine-containing wastewater is 800 times the volume of the bed itself, the adsorption breakthrough point of the resin is reached. Adopt desorption agent to carry out desorption regeneration to described resin, described resin desorption agent is sodium hydroxide solution, and the mass concentration of sodium hydroxide is 7.5%, and this desorption agent is at the flow rate of 2 times of resin self-bed volume per hour For desorption and regeneration, a total of 6 times the volume of the resin's own bed volume of sodium hydroxide solution was used. The fluoride ion concentration in the desorption solution is 500mg / L, and the alkal...

Embodiment 3

[0052] The method for recovering fluoride ions in waste water of the present embodiment, its steps are:

[0053] (A) The fluorine-containing wastewater with a fluoride ion concentration of 8 mg / L passes through the adsorption tower packed with the material at a flow rate of 10 times the bed volume of the resin itself. When the volume of treated fluorine-containing wastewater is 400 times the bed volume of the value itself, the adsorption breakthrough point of the resin is reached at this time. Adopt desorption agent to carry out desorption regeneration to described resin, described resin desorption agent is sodium hydroxide solution, and the mass concentration of sodium hydroxide is 8%, and this desorption agent is with the flow velocity of 3 times resin self-bed volume per hour For desorption regeneration, a total of 4 times the volume of the resin's own bed volume of sodium hydroxide solution is used. The fluoride ion concentration in the desorption solution is 800mg / L, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com