Method for preparing phenol

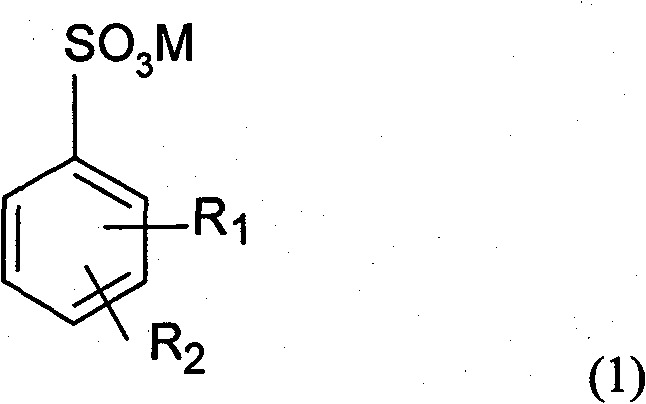

A production method and technology of aryl sulfonate, which is applied in the field of phenol preparation, can solve the problems of decomposition, phenol product loss, and low production efficiency, and achieve the goals of reducing the amount of phenol-containing water vapor, increasing the reaction yield, and reducing the pressure on environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

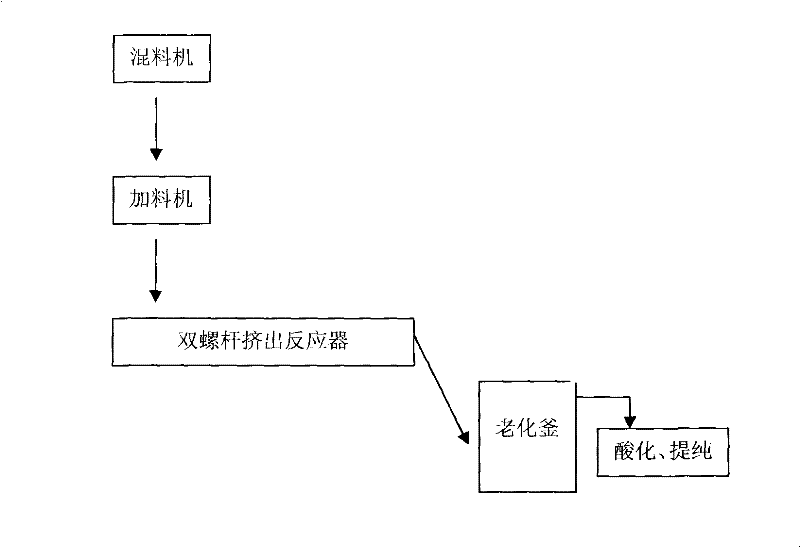

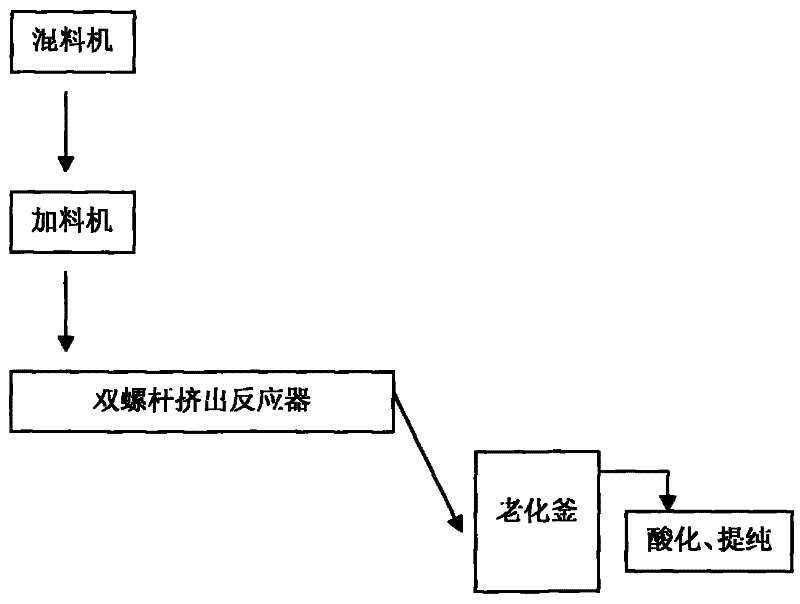

Method used

Image

Examples

Embodiment 1

[0024] 100kg of sodium p-toluenesulfonate solid and 50kg of sodium hydroxide solid are mixed uniformly in a mixer. Turn on the electric heating to control the temperature of the twin-screw extrusion reactor to 350° C., and then feed the mixed material into the twin-screw extrusion reactor at a uniform speed at a rate of 15 kg / h through the feeder. Under the extrusion of the screw, it moves to the other end of the pipeline and simultaneously undergoes an alkali fusion reaction. The rotational speed of the twin-screw extrusion reactor is 85 rpm, and the residence time of the material therein is 16 minutes. The material from the outlet of the twin-screw extrusion reactor enters the aging kettle for aging for 40 minutes, the aging temperature is controlled at 360°C, and the aged material overflows through the outlet at the upper end of the aging kettle. The obtained material was subjected to acid treatment according to a conventional method, and then purified to obtain 43.5 kg of ...

Embodiment 2

[0026] 100kg of sodium p-toluenesulfonate solid and 46kg of sodium hydroxide solid are mixed uniformly in a mixer. Turn on the electric heating to control the temperature of the twin-screw extrusion reactor to 350° C., and then feed the mixed material into the twin-screw extrusion reactor at a uniform speed at a rate of 15 kg / h through the feeder. Under the extrusion of the screw, it moves to the other end of the pipeline and undergoes an alkali fusion reaction at the same time. The rotational speed of the twin-screw extrusion reactor is 280 rpm, and the residence time of the material in it is 5 minutes. The material from the outlet of the twin-screw extrusion reactor enters the aging kettle for aging for 40 minutes, the aging temperature is controlled at 360°C, and the aged material overflows through the outlet at the upper end of the aging kettle. The obtained material was acid-treated and purified according to a conventional method to obtain 41.2 kg of p-cresol crude produc...

Embodiment 3

[0028] 100kg of sodium p-toluenesulfonate solid and 50kg of sodium hydroxide solid are mixed uniformly in a mixer. Turn on the electric heating to control the temperature of the twin-screw extrusion reactor to 340°C, and then feed the mixed materials into the twin-screw extrusion reactor at a uniform speed at a rate of 15kg / h through the feeder. Under the extrusion of the screw, it moves to the other end of the pipeline and undergoes an alkali fusion reaction at the same time. The rotational speed of the twin-screw extrusion reactor is 280 rpm, and the residence time of the material in it is 5 minutes. The material from the outlet of the twin-screw extrusion reactor enters the aging kettle for aging for 40 minutes, the aging temperature is controlled at 360°C, and the aged material overflows through the outlet at the upper end of the aging kettle. The obtained material was acid-treated and purified according to a conventional method to obtain 42.7 kg of p-cresol crude product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com