Method for treating VA-family element oxygen-containing negative ion wastewater through resin adsorption/desorption-diffusion dialysis

A technology of diffusion dialysis and resin adsorption, applied in the direction of osmosis/dialysis water/sewage treatment, special treatment targets, chemical instruments and methods, etc., to achieve the effect of saving procedures and costs, reducing costs, and reducing waste liquid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

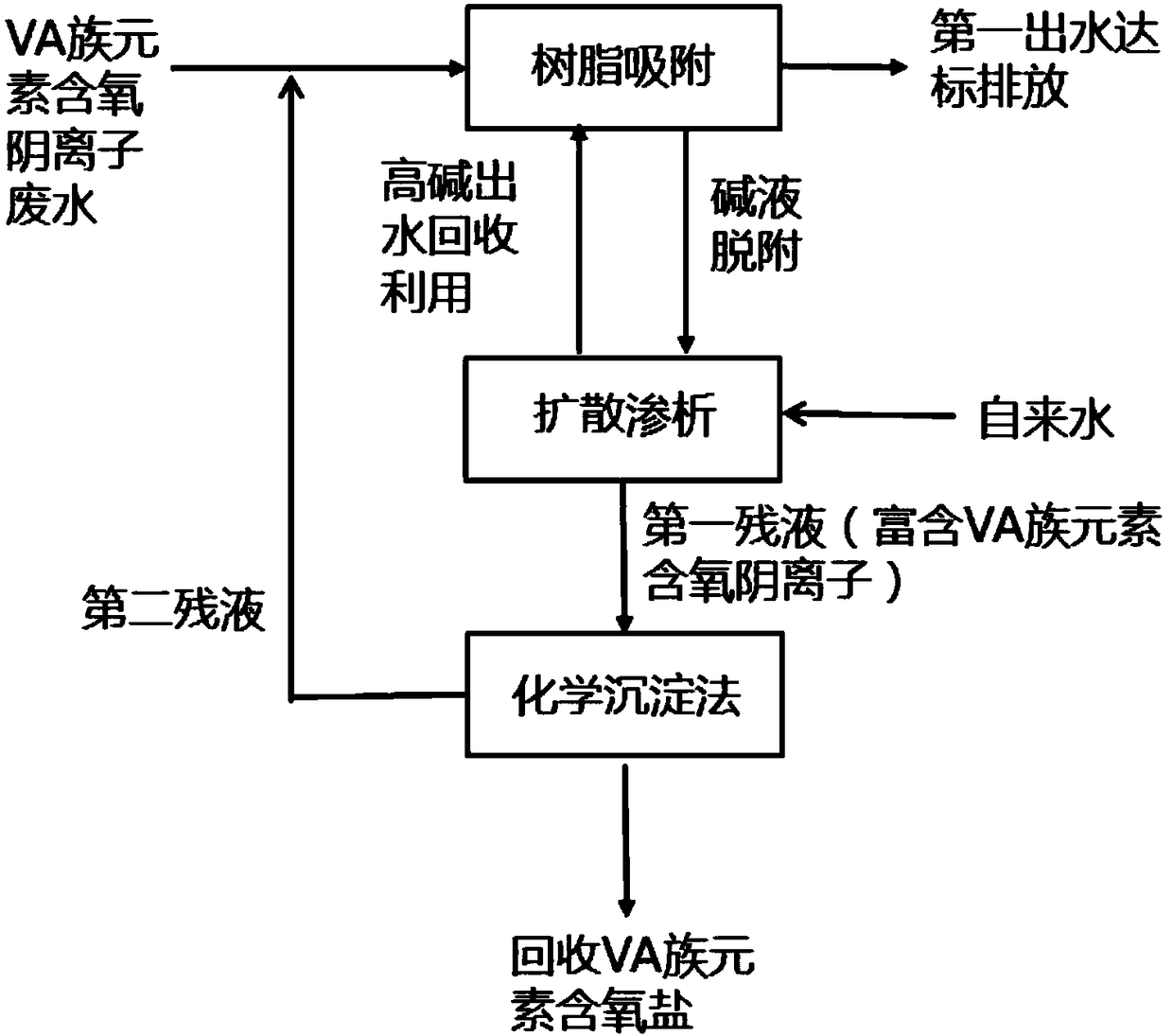

Method used

Image

Examples

Embodiment 1

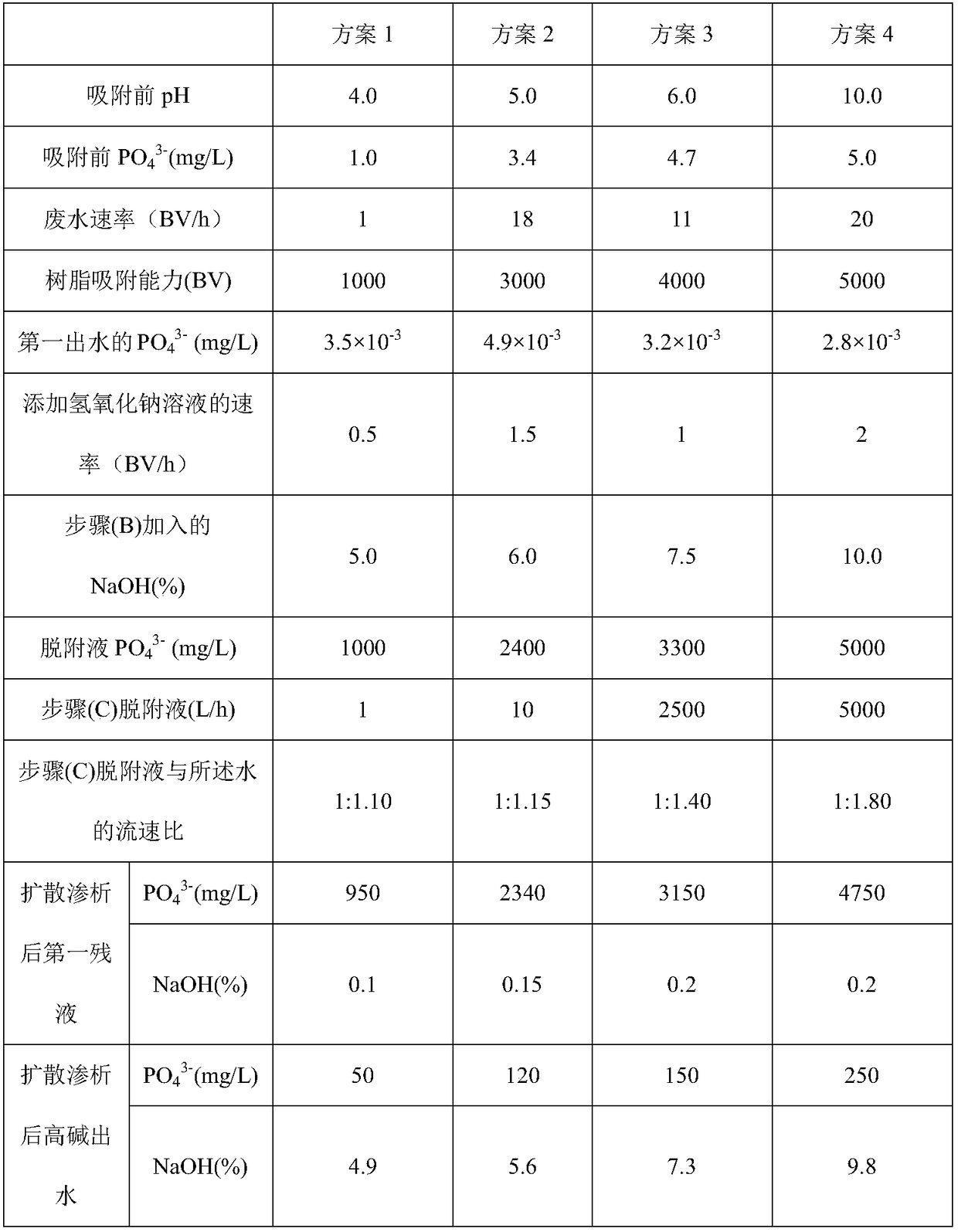

[0039] A method for resin adsorption-desorption-diffusion dialysis treatment of wastewater containing phosphate anions, the steps of which are:

[0040] (A) phosphate ion content, pH value are as shown in table 1 containing phosphate (PO4 3- ) The waste water passes through the NDA-P type resin column at a rate of 1BV / h-20BV / h to saturate the resin adsorption;

[0041] (B) At normal temperature, under the condition of pH 8-10, add 5%-10% sodium hydroxide solution as desorption in the NDA-P type resin of adsorption breakthrough at a rate of 0.5BV / h-2BV / h agent to regenerate the resin and produce a desorption solution;

[0042] (C) The desorption solution and water containing phosphate ion and sodium hydroxide from step (B) are respectively added to the desorption solution injection port and the water injection port of the diffusion dialyzer using NDADFC1 cation exchange membrane, the desorption solution and the water injection port The flow rate ratio of the water is 1:1.10-1...

Embodiment 2

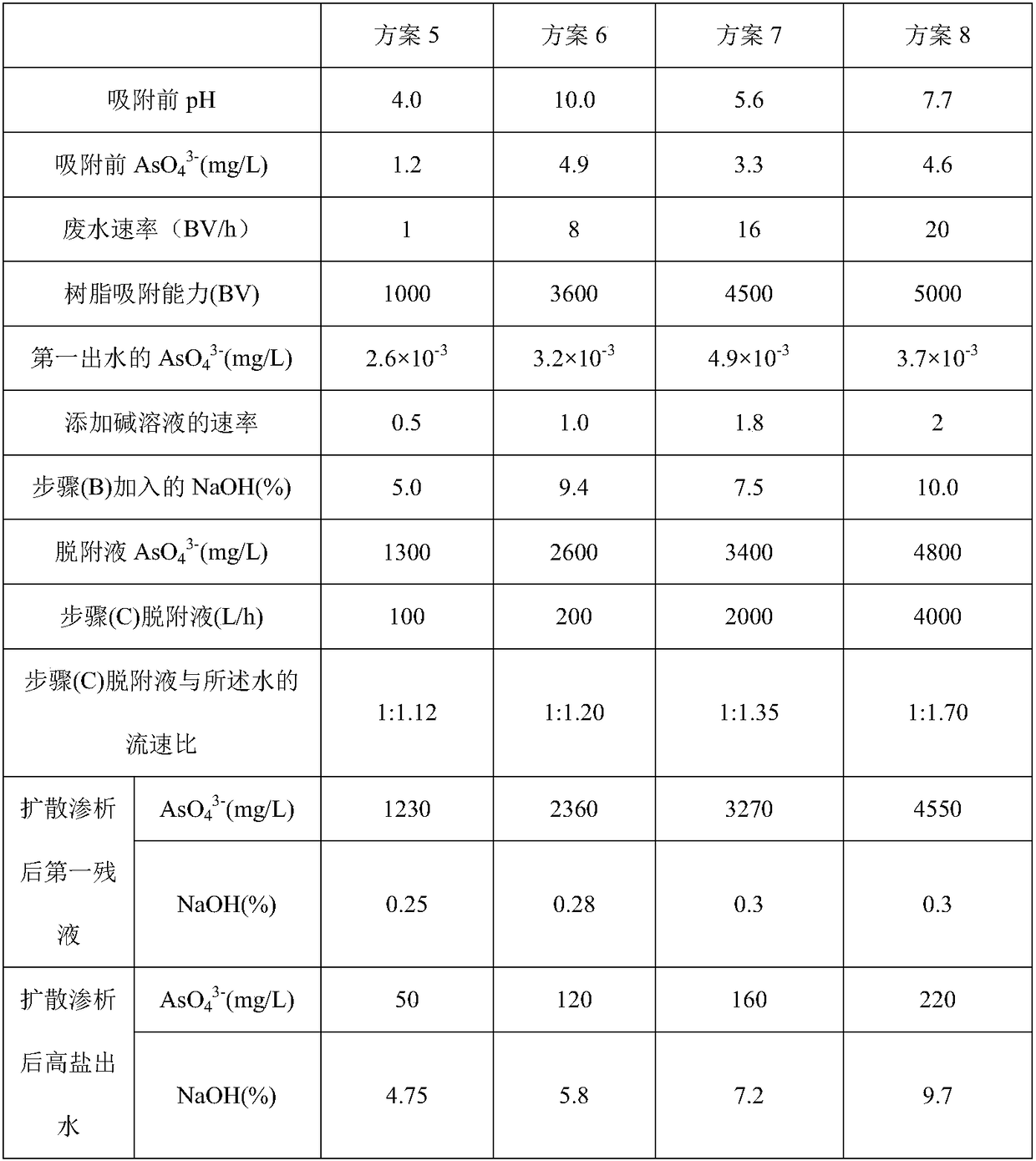

[0049] A method for resin adsorption-desorption-diffusion dialysis treatment of arsenate-containing wastewater, the steps of which are:

[0050] (A) Pass the arsenate-containing wastewater with arsenate ion content and pH value as shown in Table 2 at a rate of 1BV / h-20BV / h for 2h through the NDA-As type resin column to saturate the resin adsorption;

[0051] (B) At normal temperature and pH 4-10, add 5%-10% sodium hydroxide solution at a rate of 0.5BV / h-2BV / h in the NDA-As resin that has penetrated through adsorption as desorption agent to regenerate the resin;

[0052] (C) The desorption solution and water containing arsenate ion and sodium hydroxide from step (B) are respectively added to the desorption solution injection port and the water injection port of the diffusion dialyzer using NDADFC2 cation exchange membrane, the desorption solution and the water injection port The flow rate ratio of the water is

[0053] 1:1.12-1:1.70, wherein the desorption solution is 100L / h-...

Embodiment 3

[0058] A method for resin adsorption-desorption-diffusion dialysis treatment of oxygen-anion wastewater containing VA group elements, the steps are:

[0059] (A) Pass the wastewater containing oxyanions of VA group elements through the resin to saturate the resin; that is, the concentration of oxyanions of VA group elements is 0.5mg / L-5mg / L. In specific implementation, 0.5mg / L, 1mg can be selected / L, 1.2mg / L, 2.5mg / L, 4.2mg / L or 5mg / L and other values; pH is 4-10 (in specific implementation, you can choose 4, 5, 6, 7, 8, 9 or 10, etc. Numerical value) waste water with 1BV / h-20BV / h (during specific implementation, can select 1,20,12,6 or 2 etc. numerical value) rate to pass through resin, total 1000BV-5000BV (during specific implementation, can select 1000,1200, 3600, 4800 or 5000 etc.), to saturate the resin adsorption;

[0060] Wherein, the oxyanions of group VA elements in this embodiment can be one or more of phosphate, phosphite, arsenate, arsenite or antimonate;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com